Using a diamond file for your metalworking projects is a straightforward technique, but first, you need to understand how these tools operate. A Diamond File works by abrading material rather than cutting it like a traditional file. This unique action makes it the perfect tool for shaping extremely hard metals and other tough materials. As industries demand greater precision and efficiency, the need for such advanced tools is rapidly increasing in the professional metalworking field.

| Metric | Value |

|---|---|

| Market Size in 2024 | USD 1.77 Billion |

| Projected Market Size in 2032 | USD 2.84 Billion |

| CAGR (2025-2032) | 6.1% |

Key Takeaways

- Diamond files use tiny diamond particles to grind hard metals. They do not cut like regular files.

- Use light pressure and move the file in many directions. This helps the file work better and last longer.

- Clean your diamond files often with a stiff brush. This stops metal bits from clogging the file.

- Choose the right file grit and shape for your task. Coarse grit removes a lot of material, and fine grit smooths surfaces.

Mastering diamond file techniques

Learning the right technique will help you get the most from your diamond tools. Unlike traditional metal files that cut material away, a diamond file uses abrasion. This difference requires a unique approach to achieve clean, precise results. Mastering these methods ensures your tools last longer and your projects look professional.

Applying light and consistent pressure

You should always use a light touch with a diamond file. Applying too much force is a common mistake that can damage your tools. Heavy pressure does not speed up the work. Instead, it can cause several problems:

- It may break the diamond crystals on the file.

- It can cause diamonds to fall off the tool’s surface.

- It leads to “loading,” where metal particles clog the file.

A gentle, steady motion is the most effective technique. Focus on proper grip and positioning to control the tool. Let the diamond abrasives do the work for you.

Using multi-directional strokes

For the best surface finish, you should use a multi-directional filing technique. Instead of filing in only one direction, work the file in a cross-hatch pattern. This method creates a more uniform surface and prevents deep, uneven grooves. This approach offers significant benefits, including decreased wear on parts and the ability to hold closer tolerances. It helps you create a professional-grade finish that improves the function and lifespan of your metal piece.

Working on hardened metals

Diamond files excel where standard metal files fail. They are designed to shape extremely hard materials. Many high-performance tool steels are too hard for conventional files. A diamond tool makes working on these materials possible.

Tip: Diamond tools are perfect for sharpening carbide cutters or shaping heat-treated steel parts that regular files cannot even scratch.

The table below shows the hardness of some common tool steels.

| Material Type | Hardness (HRC) |

|---|---|

| O1 Tool Steel | 61-63 HRC |

| O2 Tool Steel | 61-63 HRC |

| Shock-Resisting Steel | 58-60 HRC |

Cleaning and maintaining your files

Proper maintenance keeps your files working effectively. Metal particles, or swarf, can build up and clog the abrasive surface. You should clean your files regularly to remove this buildup. A stiff wire brush, such as one with steel or nickel silver bristles, works very well. For stubborn debris, you can use a brush with soap and water. While some professionals use ultrasonic cleaners, a simple manual cleaning is often enough to keep your files in top condition.

Choosing your Aimgrind diamond tools

Choosing the right file is the first step toward a successful project. Aimgrind is a specialized brand with nearly two decades of experience in customized abrasive tools. This expertise makes us a trusted partner in your work. Our range of Diamond Tools offers solutions for any challenge you face.

Matching file grit to your task

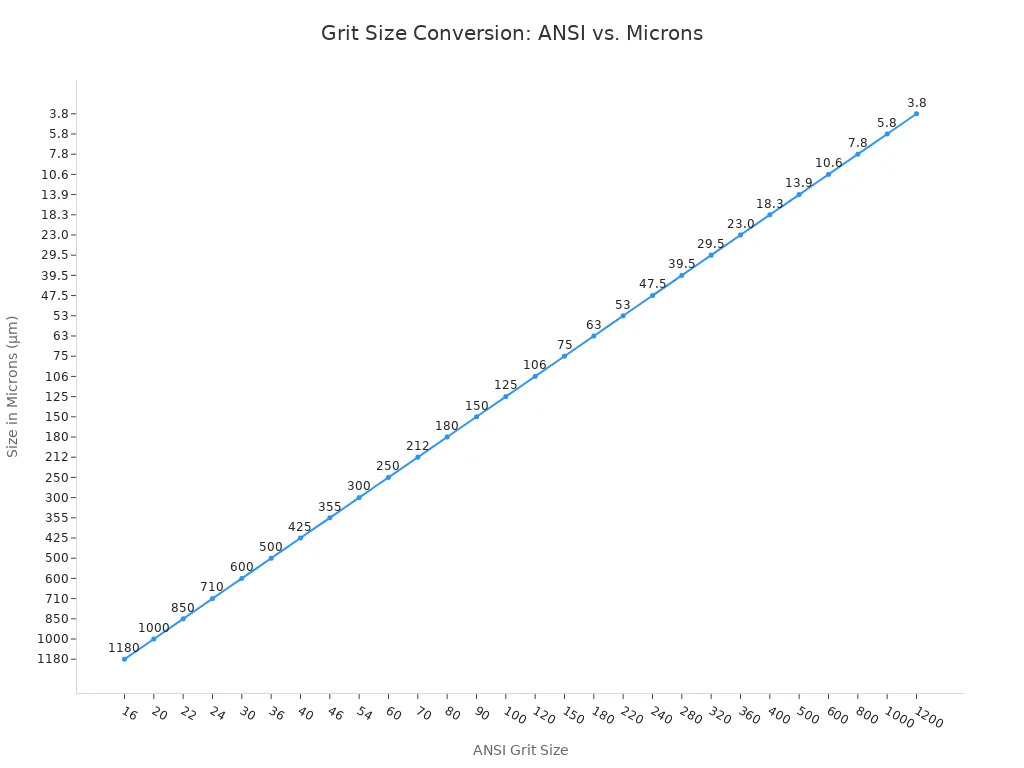

You must match the file’s grit to your job. Grit refers to the size of the diamond particles on the file.

- Coarse-grit files (lower numbers) remove material quickly. Use them for heavy shaping.

- Fine-grit files (higher numbers) are for finishing and polishing. They create a smooth surface.

Different standards measure grit size. The chart below shows how grit number relates to particle size. A smaller particle size (in microns) means a finer grit.

Selecting the correct file shape

The shape of your diamond file is also important. Common types of files include flat, round, and half-round shapes for general tasks. However, some jobs require special types of metal files. For example:

- Knife File: Use this for filing narrow slots or sharp angles.

- Crossing File: This shape is perfect for interior curved surfaces.

- Barrette File: It lets you file one surface in a tight corner without touching the others.

Aimgrind offers many types of files to ensure you have the right tool for any intricate detail.

The value of quality diamond tools

A quality tool gives you better results and lasts longer. The performance of metal files depends on two things: diamond quality and the bonding method. The bond holds the diamond crystals in place. If the bond is too hard, the tool stops cutting. If it is too soft, the diamonds fall out too soon. Aimgrind’s precision design ensures the bond wears perfectly to expose new, sharp diamonds as you work. This gives our files exceptional wear resistance and a longer service life.

Common metalworking applications

Diamond tools are incredibly versatile. You can use them for many tasks across various industries. Leveraging files for your projects opens up new possibilities, especially when working with tough materials. The table below shows just how many sectors rely on these essential tools.

| Sector | Applications |

|---|---|

| Automotive | Precision shaping of engine components, molds, and dies. |

| Aerospace | Manufacturing and repairing turbine blades and structural parts. |

| Jewelry | Shaping, smoothing, and polishing precious metals and gemstones. |

| Tool & Die Making | Sharpening, shaping, and deburring cutting tools and dies. |

| Glass & Ceramics | Grinding and deburring glass, including optical lenses. |

| General Manufacturing | Deburring and finishing components made from hardened metals. |

Sharpening carbide and steel tools

You can easily restore a sharp edge to your hardened tools. A diamond file is perfect for this job. It works exceptionally well on materials that standard metal files cannot touch. Use these files to refresh the cutting edges on your brazed carbide tools or to sharpen high-speed steel drill bits. This simple maintenance extends the life of your expensive equipment and keeps your workshop running efficiently.

Deburring and shaping edges

You can create clean, smooth edges on your metal parts. After cutting or machining, metal often has sharp, rough burrs. These burrs can affect the part’s fit and function. A few passes with the correct file will remove them quickly. You can also use files for more detailed shaping.

- In jewelry making, you can shape the shank of a ring for a comfortable fit.

- For fabrication, you can create a small groove in a piece of metal to guide a precise bend.

This level of control makes these tools indispensable for detailed work and professional-grade surface finishing.

Enlarging holes in metal

Sometimes you need to make a hole slightly larger. A round or half-round diamond file is the ideal tool for this task. While a reamer can also enlarge holes, it is designed to remove only a very small amount of material. For example, a reamer might only remove 0.15–0.50 mm from the diameter. Attempting to remove 1 mm or more with a hand reamer is often impractical. A diamond tool gives you the power to remove more material with greater control, making it perfect for custom adjustments.

Finishing solder joints

You can achieve a seamless look on your soldered pieces. After joining two pieces of metal, the solder joint may be uneven or lumpy. You can use fine-grit metal files to smooth the joint until it blends perfectly with the surrounding material. This creates a strong and visually appealing connection.

Note: For softer metals, you can use a lubricant to improve the process. While oils like WD-40 can trap metal particles and cause scratches, a simple solution of soapy water works well. It acts as a coolant, prevents the file from clogging, and helps you achieve a smoother finish.

Mastering the diamond file is simple. You must select the correct tool from a quality brand like Aimgrind, use light pressure with multi-directional strokes, and keep it clean. These tools unlock new possibilities for precision work on hard metals. Industries from automotive to electronics demand this level of accuracy. You can elevate your craft and achieve professional results. Explore Aimgrind’s range of Diamond Tools to find the perfect solution for your next project.

FAQ

What is the main difference between a diamond file and a regular file?

A regular file cuts metal with sharp teeth. A diamond file uses tiny diamond particles to grind or abrade the material away. This grinding action allows you to shape extremely hard metals that a regular file cannot scratch.

Can you use a diamond file on soft metals like aluminum?

Yes, you can use a diamond file on soft metals. However, these metals can clog the file quickly. You should use a lubricant like soapy water. This simple step helps prevent clogging and gives you a much smoother finish.

How do you know if you are using too much pressure?

You should always use a light touch. If the file feels like it is catching or skipping, you are likely pressing too hard. Let the diamond abrasives do the work. Too much force can damage the file and your workpiece.

What is the best way to clean a clogged diamond file?

You can easily clean your file with a stiff wire brush. For stubborn buildup, use the brush with soap and water to scrub the surface. Regular cleaning removes metal particles and keeps your tool working effectively for a long time.

See Also

Selecting the Optimal Metal Grinding Wheel for Your Specific Project Needs

Mastering Safe and Effective Dremel Grinding Wheel Operation Techniques

Identifying the Premier Grinding Wheel for Your Carbide Tool Sharpening

Discovering the Ideal Grinding Wheel Dresser for Your Personal Requirements

Selecting the Perfect Grinding Wheel for Your Circular Saw Blade

Contact Us

For More Grinding Solution or Customized Abrasive Tools