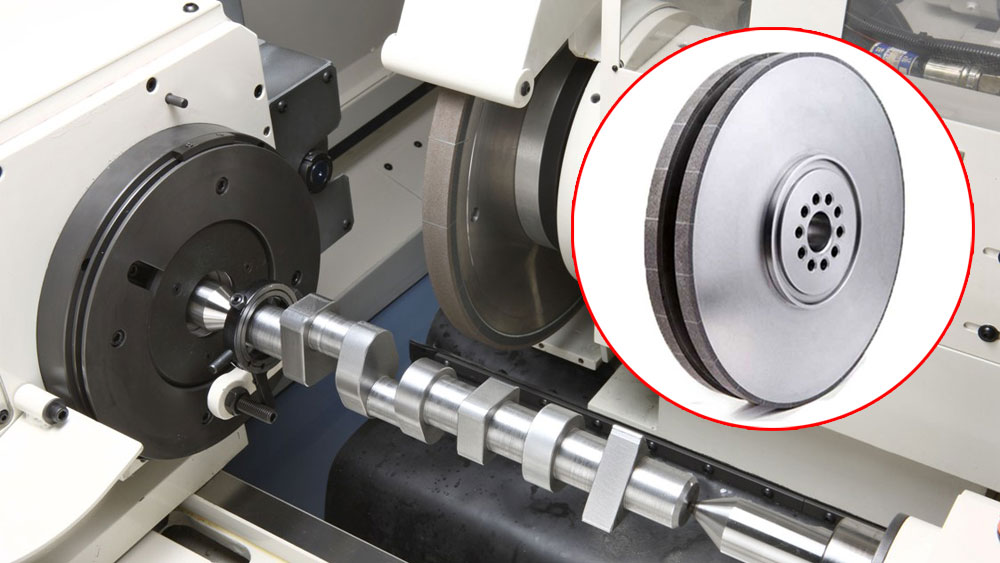

Selecting the perfect vitrified bond grinding wheel comes down to four critical factors. You must evaluate your workpiece material, required finish, machine parameters, and performance goals. Understanding these points leads to a confident choice for your specific grinding application.

💡 Did You Know? These wheels are essential across many industries, including:

- Metalworking and Automotive

- Aerospace and Construction

- Woodworking

This guide provides a clear roadmap to help you make the right decision.

Key Takeaways

- Match the abrasive type to your material. Use aluminum oxide for steel, silicon carbide for non-metals, and superabrasives like CBN or diamond for very hard materials.

- Define your grinding goals. Choose grit size for removal rate or finish, bond grade for wheel hardness, and wheel structure for chip clearance.

- Align with your machine settings. Use the correct wheel speed, enough coolant, and balance infeed and traverse rates for best results.

- Understand the wheel’s code. The letters and numbers on a wheel tell you its abrasive type, grit size, hardness, and bond type.

- Choose a good supplier. Ask about quality control and traceability. A good wheel saves money over time.

Factor 1: Match the Abrasive to Your Material

The first step in choosing a grinding wheel is matching the abrasive grain to your workpiece. Different abrasives have unique properties. You need the right one to cut your material effectively.

Aluminum Oxide for Steels

Aluminum oxide is a versatile and popular abrasive. You should use it for grinding most ferrous metals. This includes steel, iron, and other related alloys. Different types of aluminum oxide work best on specific steels.

| Aluminum Oxide Type | Suitable Steel Alloys |

|---|---|

| Ceramic Alumina | Armored steel, tool steel, stainless steel |

| Zirconia Alumina | Steel, stainless steel |

| White Aluminum Oxide | Stainless steel, harder-grade steel |

| Aluminum Oxide (General) | Steel, iron, and other metals |

Silicon Carbide for Non-Metals

Silicon carbide is harder and sharper than aluminum oxide. This makes it ideal for grinding non-metallic materials. You can use it for:

- Ultra-precision processing of Silicon Carbide (SiC) substrates.

- Achieving a very smooth, sub-nanometer surface finish.

- Avoiding surface and subsurface damage on delicate materials.

- Manufacturing high-performance microelectronic and optoelectronic devices.

Ceramic Alumina for Tough Alloys

You need a tougher abrasive for modern, hard-to-grind alloys. Ceramic alumina grains are engineered for this purpose. They are very effective on materials like:

- Inconel and Titanium

- High Nickel Alloys

- Super Alloys

- Tool Steel

These wheels provide excellent performance when grinding difficult metals.

Superabrasives (CBN & Diamond) for Hardened Materials

Some materials are too hard for conventional abrasives. You will need a superabrasive grinding wheel for these jobs. Cubic Boron Nitride (CBN) and diamond are the two main superabrasives.

CBN is perfect for grinding very hard ferrous materials. It works well on hardened steels with a hardness greater than 45 HRC and up to 70 HRC. CBN does not react with iron at high temperatures. This allows for high material removal rates.

Diamond is the hardest material known. However, you should not use it on steel. The carbon in a vitrified bond diamond wheel reacts with iron at high temperatures, causing it to break down quickly. A vitrified bond diamond wheel is best for non-ferrous materials like tungsten carbide or ceramics. For these applications, a vitrified bond diamond wheel offers unmatched performance.

Factor 2: Define Your Application and Finish Goals

After matching the abrasive to your material, you need to define your goals. Your application determines the right grit size, bond grade, and wheel structure. These factors control the balance between speed and precision.

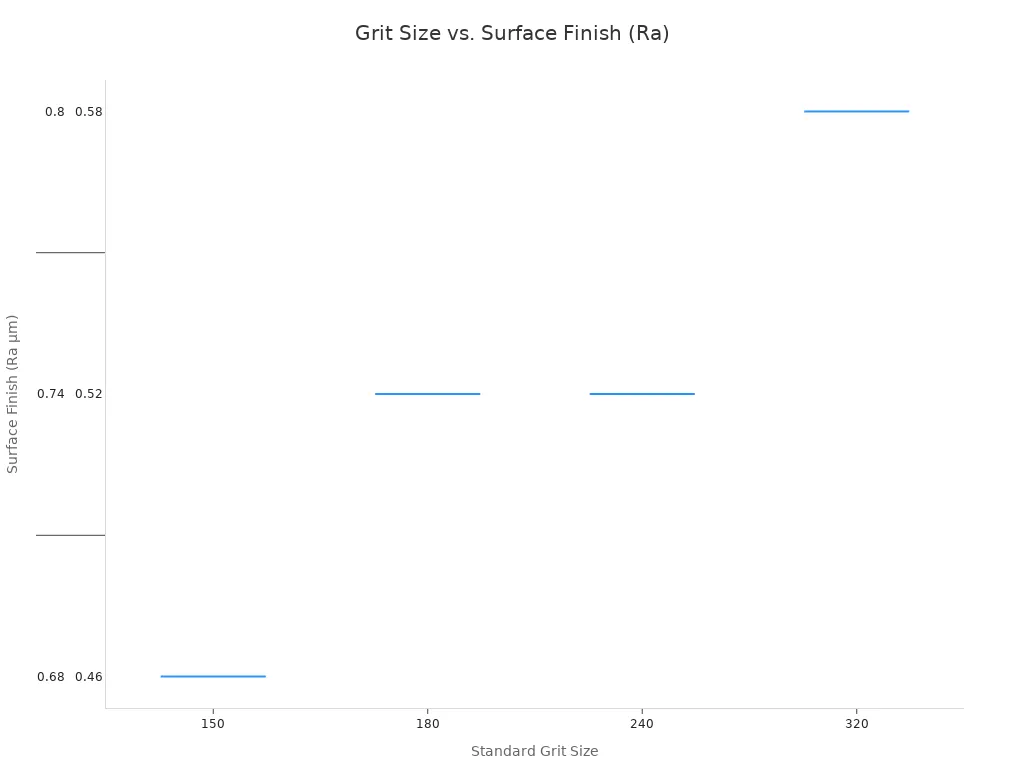

Grit Size: Removal Rate vs. Surface Finish

Grit size directly impacts your material removal rate and the final surface finish. A lower grit number means larger, coarser abrasive particles. These are great for rapid material removal but leave a rougher surface. A higher grit number indicates smaller, finer particles. You should use these for achieving a smooth finish, though the removal rate will be slower.

Choosing the right grit involves balancing speed with your required finish. For example, a coarse 80-grit wheel achieves high stock removal rates, while a fine 400-grit wheel produces a very smooth surface.

The table below shows how grit size relates to surface roughness (Ra).

| Standard Grit | Ra µin Range | Ra µm Range |

|---|---|---|

| 150 | 27 – 32 | 0.68 – 0.80 |

| 180 | 16 – 23 | 0.46 – 0.58 |

| 240 | 14 – 18 | 0.34 – 0.46 |

| 320 | 8 – 10 | 0.21 – 0.25 |

Bond Grade: The Importance of Wheel Hardness

The bond grade measures the wheel’s hardness. This scale runs from A (softest) to Z (hardest). A softer wheel breaks down more easily, exposing new, sharp abrasive grains. This makes it cut more freely but also wear out faster. A harder wheel holds its shape longer, which is ideal for precision work, but it may require more frequent dressing to prevent glazing.

💡 Pro Tip: For hard workpiece materials, you should generally use a softer grade wheel. For soft materials, a harder grade wheel is often better.

Wheel Structure: Managing Chip Clearance

- Open Structure: Has more space between grains. You should choose this for soft materials like aluminum. It provides excellent clearance for chips and coolant, making it ideal for aggressive stock removal.

- Dense Structure: Has less space between grains. This structure offers better shape retention and produces a smoother finish. However, it generates more heat and has a slower material removal rate.

The Role of a Vitrified Bond Grinding Wheel

A vitrified bond grinding wheel excels in precision applications. Its ceramic-based bond is extremely rigid and thermally stable. This rigidity allows the wheel to hold its shape under pressure, helping you achieve tight dimensional tolerances. Its thermal stability prevents heat from damaging your workpiece during grinding. These features make a vitrified bond grinding wheel the perfect choice for grinding hard metals and ceramics where accuracy is critical.

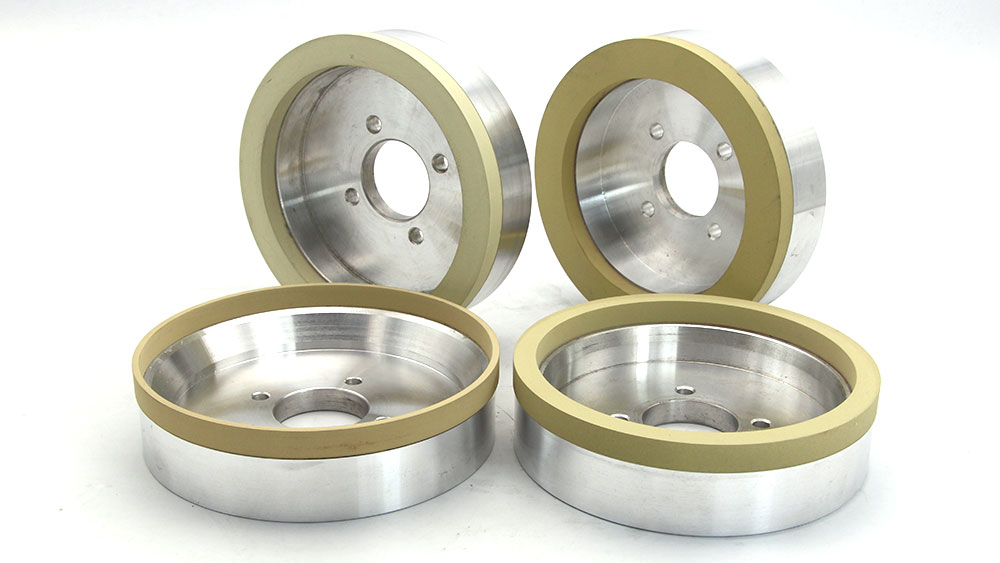

Why Choose an Aimgrind Vitrified Bond Grinding Wheel?

Choosing the right wheel goes beyond just specs; it requires a partner dedicated to your success. Aimgrind is a specialist in customized grinding solutions with nearly two decades of experience. We focus on delivering the perfect tool for your unique needs, ensuring you achieve superior precision.

Our comprehensive service process guarantees a perfect match for your equipment.

Aimgrind’s Proven Process:

- Problem Diagnosis: We start by understanding your specific grinding challenges.

- Parameter Matching: We analyze your machine’s operational settings.

- Formula Design: We create a custom vitrified bond grinding wheel formula just for you.

This tailored approach ensures our vitrified bond grinding wheels deliver optimal performance. Aimgrind wheels offer exceptional hardness and thermal stability. This makes them ideal for the precision grinding of hard metals and ceramics. Their superior wear resistance means fewer replacements and more consistent results for every precision grinding task.

This commitment to quality provides real value across demanding industries. For example, aerospace and tool manufacturing rely on our vitrified bonded grinding wheels for their difficult-to-grind alloys. In the glass industry, our vitrified bond diamond wheels provide clean, precise edges. For tasks requiring extreme hardness, a vitrified bond diamond wheel offers unmatched performance. Aimgrind’s focus on precision grinding helps you enhance productivity and quality. When you need the best results, our vitrified bond diamond tools deliver the precision you demand. Our expertise in precision grinding ensures you get the right wheel every time.

Factor 3: Align with Your Operational Parameters

Your grinding machine’s settings directly affect the wheel’s performance. You must align your choice with your operational parameters to achieve the best results safely. This involves managing wheel speed, coolant, and feed rates to create a balanced and efficient grinding system.

Correct Wheel Speed for Safety and Efficiency

Operating your grinding wheel at the correct speed is crucial for both safety and performance. Every wheel is marked with a maximum safe operating speed (MAX RPM). Running a wheel faster than its rated speed can cause it to break, creating a serious safety hazard.

⚠️ Safety First: Follow ANSI B7.1 Standards

- Always check the MAX RPM marked on the grinding wheel.

- Ensure your machine’s speed does not exceed the wheel’s maximum speed.

- Use the proper wheel guards as required by the ANSI B7.1 safety code.

- Never use a wheel for an application it was not designed for.

Matching the speed correctly also ensures the wheel cuts efficiently. An incorrect speed can lead to poor performance, glazing, or excessive wheel wear.

Using Coolant to Manage Heat

Grinding generates intense heat at the point of contact. Without proper cooling, this heat can damage both your workpiece and the grinding wheel. Using a coolant is essential for managing thermal buildup.

Insufficient coolant flow can lead to several problems, including warping, burn marks, or even cracks in the material. It also accelerates tool wear, forcing you to replace your wheels more often. The ideal flow rate depends on your application. Light roughing may only need 10-20 liters per minute (LPM), while aggressive, high-speed grinding might require 30-50 LPM or more to effectively dissipate heat and ensure a quality finish.

Infeed and Traverse Rate Impacts

The infeed and traverse rates control how quickly you remove material.

- Infeed Rate: This is how deep the wheel cuts into the workpiece on each pass.

- Traverse Rate: This is how fast the workpiece moves past the grinding wheel.

You must balance these two rates to meet your goals. A faster rate removes material quickly, boosting productivity. However, it may leave a rougher surface finish. A slower rate generally produces a much better surface finish but extends the grinding time. Finding the right combination helps you optimize for both speed and quality.

Factor 4: Decode the Wheel Specification

Finally, you need to understand the language written on the wheel itself. The combination of letters and numbers on a grinding wheel is not random. It is a code that tells you everything about its composition and purpose. Learning to read these grinding wheel specifications helps you confirm you have the right tool for the job.

Understanding the Standard Marking System

Most grinding wheels use a standard marking system. This code tells you the abrasive type, grit size, hardness, and bond type. You can use this information to verify a wheel’s characteristics at a glance.

The table below breaks down what each part of the code means.

| Component | Description |

|---|---|

| Primary grain used to make the wheel | A = Aluminum Oxide, C = Silicon Carbide, SG = Seeded Gel |

| Size of the abrasive grain | Coarse (e.g., 10, 12) to Very Fine (e.g., 400, 500) |

| Hardness of the bond | Soft (A-N), Medium (R-T), Hard (Z) |

| Type of bond used | V = Vitrified, B = Resinoid, E = Shellac, R = Rubber |

For example, different codes are better suited for specific tasks.

| Grinding Wheel Marking | Application for Cylindrical Grinding | Application for Surface Grinding |

|---|---|---|

| 10A | Suited for unhardened steels | N/A |

| FA, 57A | Suitable for steel parts | N/A |

| PA | N/A | Suitable for tool grinding |

Creating a Checklist for Your Supplier

When you contact a supplier, you should have a few questions ready. This helps ensure you get a high-quality wheel that delivers consistent precision.

💡 Pro Tip: A good supplier will welcome your questions. It shows you are serious about quality.

Here are some key things to ask:

- What quality control tests do you perform on your wheels?

- How do you ensure your testing equipment is accurate?

- Can you provide documentation for traceability and compliance?

- How do you work with customers to reduce scrap and improve processes?

Balancing Performance and Cost

The cheapest wheel is not always the most cost-effective. You should consider the total cost of ownership. A higher-priced wheel may offer better performance and a longer life, saving you money in the long run.

Think about these factors:

- Actual Tool Life: How many parts can the wheel grind before it needs replacement? A durable wheel reduces purchase frequency.

- Tool Maintenance: How often does the wheel need dressing? Less maintenance means lower labor costs and less downtime.

A quality wheel provides greater precision and efficiency. This balance between initial cost and long-term value is key to optimizing your operations for high precision.

Choosing the right wheel is simple when you follow a clear process. You must consider your material, finish goals, and machine settings. Use this knowledge to consult an expert supplier like Aimgrind for your specific needs. We provide personalized selection and custom formula design to guarantee optimal results for your application.

Grind with Passion, Achieve with Aim.

FAQ

What materials can I grind with a vitrified bond wheel?

You can use these wheels on very hard materials. They work well for grinding hard metals, ceramics, and composites. Their strong bond makes them perfect for tough jobs where you need high precision.

Are these wheels suitable for high-speed grinding?

Yes, they are. Aimgrind designs its vitrified bond wheels for high-speed use. You can expect consistent performance and reliable results. This helps you work efficiently and safely at higher speeds.

How do vitrified bond wheels manage heat during grinding?

The vitrified bond helps dissipate heat effectively. This structure pulls heat away from your workpiece. It minimizes thermal damage and helps you achieve a smooth, high-quality finish without burns or cracks.

What makes a vitrified bond different from other bonds?

A vitrified bond is like a strong glass that holds the abrasive grains together. This creates a very rigid and porous wheel.

This structure provides exceptional hardness and thermal stability. You get better shape retention for high-precision grinding tasks.

See Also

Selecting Optimal Bench Grinding Wheel Material for Specific Requirements

Guiding Your Choice: The Perfect Metal Grinding Wheel for Projects

Picking the Ideal Grinding Wheel for Your Circular Saw Blade

Optimal Grinding Wheel Selection for Sharpening Your Carbide Tools

Finding the Correct Grinding Wheel for Stainless Steel Applications

Contact Us

For More Grinding Solution or Customized Abrasive Tools