You want to achieve a perfect finish safely and efficiently. The process of choosing a grinding wheel is a science. It is not just guesswork. This guide demystifies selecting the right wheel for your specific application. You will learn a clear framework to help you pick the perfect precision grinding wheel. This ensures you get the best results from your grinding wheel every time.

Key Takeaways

- Match the abrasive type to your material. For example, use aluminum oxide for steel and silicon carbide for hard or brittle materials.

- Balance the grit size for speed and finish. Coarse grits remove material fast, while fine grits create a smooth surface.

- Choose the right bond grade. Use a soft bond for hard materials and a hard bond for soft materials.

- Always check your grinding wheel for damage. Perform a ring test before you use it to ensure safety.

Key Factors for Choosing a Grinding Wheel

Your success in any grinding project depends on a few key decisions. The process of choosing a grinding wheel involves more than just picking one off the shelf. You must consider the material, your desired finish, and the job’s demands. This systematic approach to grinding wheel selection ensures you get optimal results.

Match Abrasive to Workpiece Material

You must first match the abrasive to the material to be ground. The hardness difference between the abrasive and your workpiece is very important. A harder abrasive works best on a softer material. You should also consider the abrasive’s properties.

- Friability: This is the grain’s ability to fracture and self-sharpen.

- Hardness: This measures how well the bond holds the abrasive grains.

- Grain Size: This determines the final surface finish.

Common abrasives like aluminum oxide are durable and cost-effective for general use. Silicon carbide is extremely hard and sharp, making it ideal for brittle materials. The right abrasive type ensures efficient cutting and a longer life for your precision grinding wheel.

Balance Finish and Removal Rate

Next, you need to balance your need for a smooth finish with your need for fast material removal. The grit size of the grinding wheel directly impacts this balance.

The bond holding the abrasive grains also plays a role. A stronger bond supports the grains, helping them remove material more efficiently. Choosing a grinding wheel with the right grit and bond is key to balancing speed and quality for your application.

Find the Best Grinding Wheel for the Job

Finally, you combine this knowledge to find the best grinding wheel. For example, when sharpening High-Speed Steel (HSS) tools, a white aluminum oxide wheel (38A) often provides the best finish. For grinding stainless steel, you might need a specialized wheel to prevent overheating. Making the right choice is the most critical step. By carefully considering these factors, you can confidently find the best grinding wheel that delivers both performance and value.

Select Abrasive Type for Your Material

Choosing the right abrasive is the foundation for success. You need to match the abrasive’s properties to the material to be ground. This ensures efficient cutting, a great finish, and a longer-lasting wheel.

Aluminum Oxide for Steels

Aluminum oxide is a versatile and popular choice for a metal grinding wheel. You will find different types for various steel applications.

- Brown Aluminum Oxide: This is a great general-purpose abrasive for grinding carbon steel and other alloys.

- White Aluminum Oxide: This type is purer and harder. You should use it for precision work on

hard tool steelsto get a fine, contaminant-free surface. - Zirconia Alumina: This blend offers a higher removal rate, making it effective for stainless steel and carbon steel.

Silicon Carbide for Hard or Brittle Materials

When you work with materials harder or more brittle than steel, you need silicon carbide. This abrasive is extremely hard and sharp. Its grains fracture during use, creating new, sharp cutting edges. This makes it ideal for grinding:

- Cast iron

- Ceramics and glass

- Non-ferrous metals like brass, copper, and aluminum

Superabrasives for a Precision Grinding Wheel

For the most demanding grinding applications, you will need superabrasive grinding wheels. These advanced abrasive grinding wheels use Cubic Boron Nitride (CBN) or diamond.

Pro Tip: Use CBN for hard ferrous materials like tool steels and superalloys. Use diamond for extremely hard non-ferrous materials like ceramics, composites, and tungsten carbide.

These high-performance materials require the best grinding wheel to achieve tight tolerances. For these specialized jobs, a standard wheel may not be enough. A specialized provider like Aimgrind offers custom diamond and superabrasive grinding wheels. They can design a personalized formula for your specific material, ensuring your precision grinding wheel delivers superior performance and longevity in industries like aerospace and precision tooling.

Define Grit Size and Bond Grade

After choosing your abrasive, you need to define the wheel’s grit size and bond grade. These two specifications work together to control how the wheel cuts and wears. Understanding the grinding wheel grit chart and grinding wheel grades is essential for achieving your desired outcome.

Coarse, Medium, and Fine Grit

Grit size refers to the size of the individual abrasive particles in the wheel. The number indicates how many particles can fit through a one-inch square mesh. A lower number means larger particles, while a higher number means smaller, finer particles.

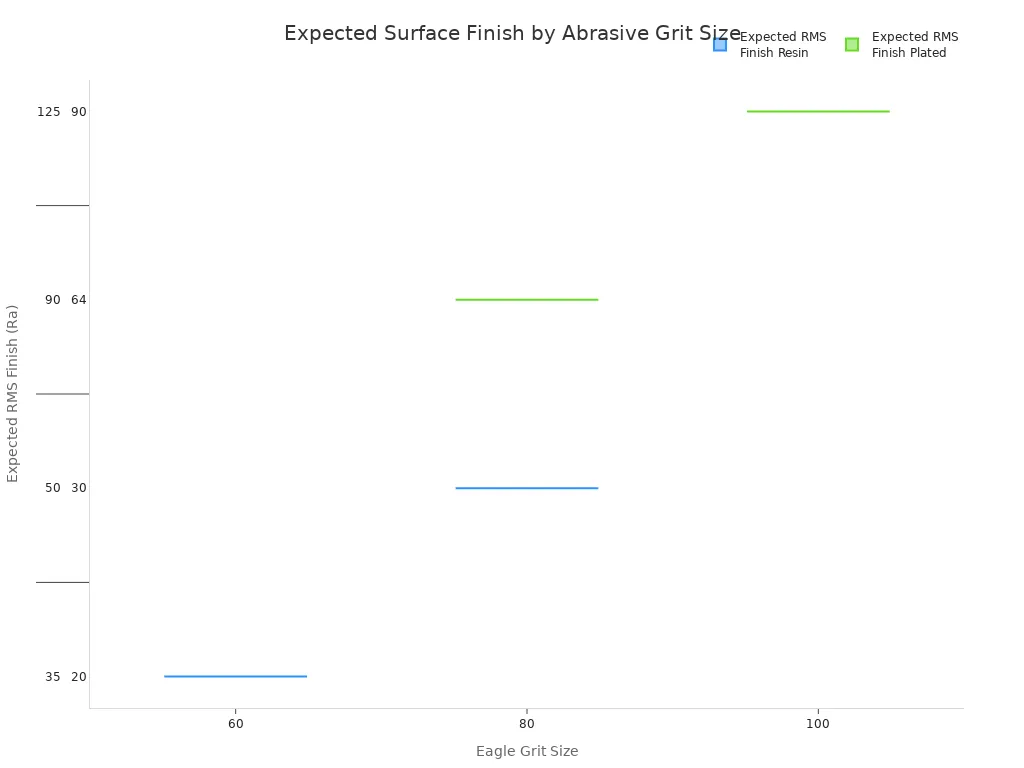

You must balance speed with finish. Coarse grits are best for rapid material removal, while fine grits produce a smoother surface. This simple grinding wheel grit chart breaks down the common ranges:

| Category | Grit Size Range | Primary Use |

|---|---|---|

| Coarse | 10 – 24 | Heavy stock removal |

| Medium | 30 – 60 | General-purpose grinding |

| Fine | 70 – 220+ | Finishing and polishing |

For example, a 60-grit wheel offers a good balance for general work. A 120-grit wheel is better for achieving a fine finish. Consulting a grinding wheel grit chart helps you make the right choice. The correct selection from a grinding wheel grit chart ensures you work efficiently.

Soft vs. Hard Bond Grades

The bond is the adhesive that holds the abrasive grains together. The bond’s hardness is called its grade. Grinding wheel grades are rated on a letter scale from A (softest) to Z (hardest).

Key Principle: Use a soft grade for hard materials and a hard grade for soft materials.

Here’s why: A soft grade (A-H) releases dull abrasive grains easily. This exposes new, sharp grains, which is perfect for grinding hard-to-grind materials. A hard grade (Q-Z) holds onto grains longer, which is ideal for softer materials that don’t dull the wheel as quickly. Medium grinding wheel grades (I-P) are used for general-purpose applications. Choosing the right bond grade prevents the wheel from loading up and ensures it cuts effectively. The correct grade is a crucial part of the overall grinding wheel grades specification.

Understanding Grinding Wheel Types and Safety

Choosing the right abrasive, grit, and bond is only part of the process. You also need to understand the different grinding wheel types and follow critical safety rules. This knowledge helps you work safely and effectively.

Common Grinding Wheel Shapes

The shape of your wheel determines how it contacts the workpiece. Each shape is designed for a specific task. For example, you use a straight wheel for surface grinding, while a saucer wheel is better for sharpening milling cutters. This table shows some common shapes and their uses.

| Wheel Shape | Primary Use |

|---|---|

| Straight Wheel (Type 1) | General surface, cylindrical, and bench grinding. |

| Straight Cup (Type 6) | Creating flat surfaces and sharpening tools on cutter machines. |

| Saucer Wheel | Sharpening milling cutters and twist drills. |

| Mounted Points | Deburring, inner diameter grinding, and mold correction. |

Choosing between a straight wheel and a cup wheel depends on your job. You might use a straight wheel for polishing small areas. You would use a cup wheel for removing tough materials over larger surfaces.

Critical Grinding Wheel Safety Checks

Safety should always be your top priority. Before you mount any new wheel, you must perform a “ring test.” This simple check helps you find hidden cracks or damage that could cause the wheel to break during use.

How to Perform a Ring Test:

- Make sure the wheel is clean and dry.

- Suspend the wheel through its center hole.

- Gently tap it with a non-metallic handle, like a screwdriver. A clear ring means the wheel is sound. A dull thud suggests a hidden flaw, and you should not use the wheel.

Preventing Wheel Loading and Contamination

Wheel “loading” happens when particles from your workpiece clog the wheel’s surface. This is common with soft metals like aluminum. A loaded grinding wheel stops cutting and starts rubbing, which creates excess heat.

You can prevent loading by using the right wheel. For soft metals, you should choose a hard-bonded wheel with a coarse grit and an open structure. This design provides space for chips to escape. If your wheel does become loaded, you must dress it. Dressing uses a special tool to remove the clogged material and expose fresh, sharp abrasive grains. This action restores the wheel’s cutting ability.

Your grinding wheel selection depends on matching the abrasive to the material and picking the right grit and bond. This systematic approach to choosing a grinding wheel ensures better efficiency and a safer workspace. You now have the knowledge for choosing a grinding wheel.

For complex jobs needing the best grinding wheel, like those requiring a custom precision grinding wheel with a hybrid bond, experts at Aimgrind can guide your final choice in choosing a grinding wheel.

This makes your final grinding wheel selection a science, not a guess.

FAQ

What should I do if my grinding wheel gets clogged?

Your wheel is “loaded” when it gets clogged with material. You must dress the wheel. This process uses a special tool to remove the clogged particles. It exposes fresh, sharp abrasive grains and restores the wheel’s cutting ability.

Which abrasive is best for steel versus ceramic?

You should use an aluminum oxide wheel for grinding most steels. For very hard or brittle materials like ceramics and tungsten carbide, you need a superabrasive. A diamond grinding wheel is the ideal choice for these demanding materials.

How does grit size affect my final surface finish?

Grit size directly controls your finish. You use a coarse grit (a low number) for fast material removal, which leaves a rougher surface. You select a fine grit (a high number) to create a smooth, polished surface for finishing work.

When do I need a custom diamond grinding wheel?

You need a custom diamond wheel for grinding superalloys, composites, or ceramics. These jobs demand extreme precision and performance. Specialized providers like Aimgrind design custom formulas to ensure optimal results and superior wheel life for your specific application.

See Also

Selecting the Optimal Metal Grinding Wheel for Your Specific Project Needs

Picking the Perfect Grinding Wheel for Effective Stainless Steel Work

Finding the Ideal Grinding Wheel for Your Circular Saw Applications

Identifying the Premier Grinding Wheel for Sharpening Carbide Tools

Selecting the Appropriate Bench Grinding Wheel Material for Your Requirements

Contact Us

For More Grinding Solution or Customized Abrasive Tools