You stand before a wall of cut off wheel options, feeling unsure. The task of choosing the right cut off wheel can seem complex. However, the process is actually very simple.

You can find the ideal cut off wheel by following a few key steps. This guide shows you how to match a cutting wheel to your material, tool, and specific cutting job. Your reward will be safer cutting, better results, and greater efficiency.

Key Takeaways

- Match your cut off wheel to the material you are cutting. Use aluminum oxide for standard steel. Use zirconia or ceramic alumina for stainless steel. Use silicon carbide for aluminum and soft metals.

- Choose the right wheel type, thickness, and grit. Flat wheels are for straight cuts. Depressed center wheels are for angled cuts. Thin wheels cut fast. Thick wheels last longer. Coarse grit cuts fast. Fine grit gives a smooth finish.

- Always check the wheel’s RPM rating. Make sure it is higher than your tool’s RPM. Match the wheel’s diameter and arbor size to your grinder. Never use a damaged wheel.

- Never use a cut off wheel for grinding. These wheels are only for straight cuts. Side pressure can break the wheel and cause injury.

Match Your Cut Off Wheel to the Material

Your first step is to match the wheel’s abrasive material to your workpiece. The abrasive grains on a cutting wheel do the actual work. Choosing the right grain ensures clean cuts, better safety, and excellent performance. Different metals require different abrasives for the best results.

For Standard Steel

You will most often work with standard steels like carbon steel or mild steel. For these common jobs, an Aluminum Oxide cut off wheel is your best choice.

- Abrasive: Aluminum Oxide

- Why it works: This abrasive is tough and durable. It provides a great balance of cutting speed and wheel life for general-purpose steel cutting. It is a cost-effective solution for many projects.

- Common Uses:

- Cutting rebar on a construction site.

- Making long, straight cuts on sheet metal.

- Slicing through steel pipes or angle iron.

These versatile abrasive wheels are perfect for everyday tasks. They deliver reliable cutting performance across a wide range of applications.

For Stainless and Hard Metals

Stainless steel, titanium, and other hard alloys need a more advanced cutting wheel. Using a standard wheel on these materials leads to poor results and potential damage.

Avoid Cross-Contamination!

Never use a cutting wheel on stainless steel if you have already used it on carbon steel. Doing so transfers iron particles, which will cause the stainless steel to rust and discolor.

For these tough jobs, you need a wheel with a high-performance grain.

- Abrasives: Zirconia Alumina or Ceramic Alumina

- Why they work: These grains are self-sharpening. As the wheel wears down, new, sharp cutting points are constantly exposed. This feature provides an aggressive, fast cut throughout the life of the wheel. Ceramic abrasives also generate less heat, which reduces the risk of heat discoloration on your workpiece. This leads to better cutting efficiency and superior performance.

- Benefits:

- Longer Life: They last much longer than standard wheels on hard metals.

- Faster Cutting: Their self-sharpening ability ensures consistent cutting speed.

- Cooler Cuts: Reduced heat prevents warping and damage to the metal.

When you need the best cutting performance on tough materials, choose cutting wheels for stainless steel made with Zirconia or Ceramic Alumina.

For Aluminum and Soft Metals

Aluminum, copper, and other soft, non-ferrous metals present a unique cutting challenge. These materials can clog, or “load,” the surface of a standard cut off wheel. This buildup reduces cutting efficiency and can make the wheel ineffective.

- Abrasive: Silicon Carbide

- Why it works: Silicon Carbide has an extremely sharp crystal structure. It is harder than Aluminum Oxide, allowing it to slice through soft metals cleanly without generating excessive heat.

- Special Features: Wheels designed for aluminum often include special treatments to prevent loading. These anti-clog properties ensure the wheel keeps cutting smoothly. The material turns to a fine dust instead of gumming up the wheel, boosting your overall efficiency.

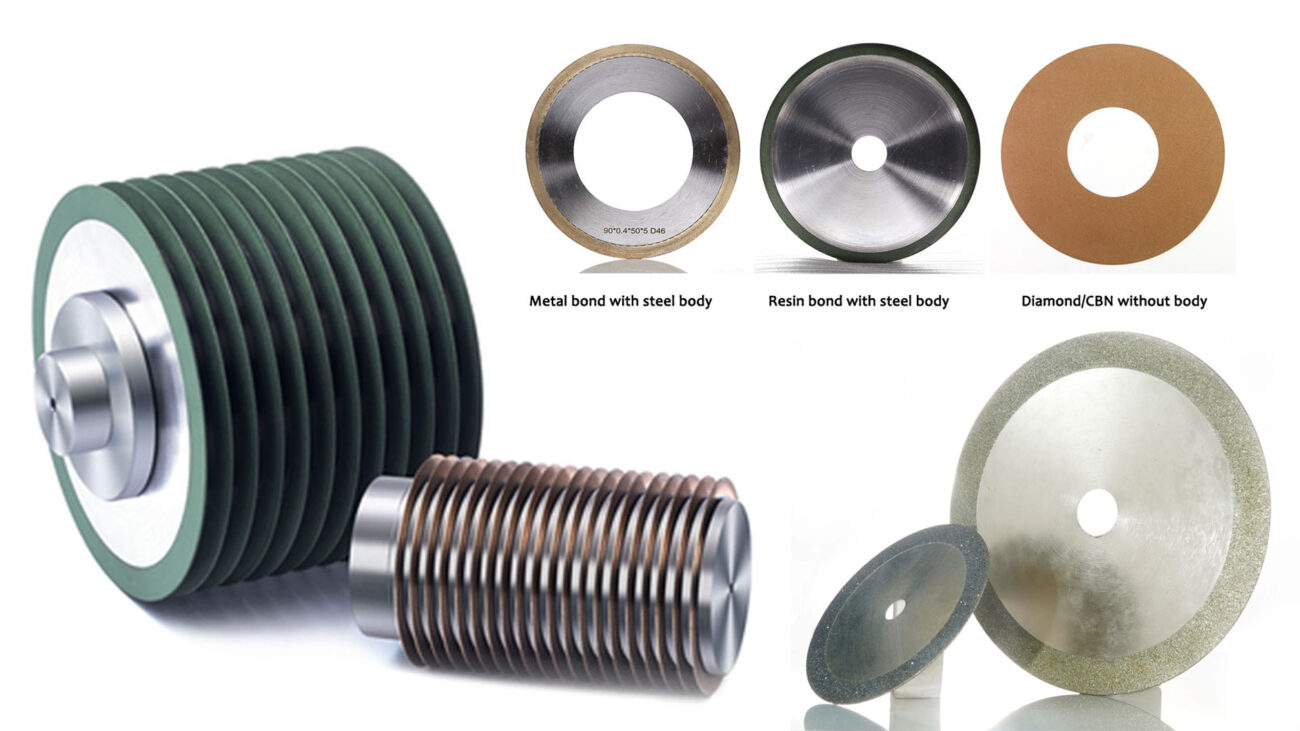

For specialized projects involving unique materials like ceramics or composites, you may need a custom solution. Suppliers like Aimgrind offer customized formulas and a wide range of abrasive wheels to ensure optimal performance for any material you need to cut.

Key Cutting Wheel Characteristics

After matching the abrasive to your material, you need to look at the wheel’s physical properties. The shape, thickness, and grit of a cutting wheel all change how it performs. Choosing the right features will help you make the perfect cut for your job. These details affect cutting speed, precision, and the wheel’s lifespan.

Wheel Type: Flat vs. Depressed Center

You will find two main cutting wheel types on the shelf: Type 1 and Type 27. Each has a unique shape designed for different kinds of cutting.

- Type 1 (Flat) Wheels: These are completely flat. This design gives you the most cutting surface for straight, precise cuts. You should choose a Type 1 wheel when you need a clean cut and maximum control.

- Type 27 (Depressed Center) Wheels: These wheels have a raised hub in the middle. This shape allows the locking nut of your grinder to sit inside the wheel. This gives you more clearance, so you can cut at a slight angle or get into tight corners without the tool getting in the way.

Here is a simple breakdown of the two cutting wheel types:

| Feature | Type 1 Cutting Discs | Type 27 Cutting Wheels |

|---|---|---|

| Design | Flat, straight edge | Depressed center, concave shape |

| Best For | Straight, precise cutting | Flush cutting and better clearance |

| Advantage | Maximum cutting surface | Allows cutting at an angle |

Wheel Thickness: Thin vs. Thick

The thickness of your cut off wheel directly impacts its cutting speed and durability. You must choose a thickness that balances your need for speed with the demands of the material.

Thin Wheels (e.g., 1mm or .045″) Thin wheels are the champions of speed and precision.

- Faster Cutting: A thinner wheel removes less material, so it slices through metal much faster. A 1mm wheel will cut sheet metal significantly quicker than a 3mm wheel.

- Cleaner Results: They create less heat and friction. This reduces burn marks and discoloration on your workpiece, giving you a better finish that requires less cleanup.

- Best Uses: Ideal for cutting sheet metal, thin tubes, and other delicate materials where a fast, clean cut is your top priority.

Thick Wheels (e.g., 1/8″) Thicker wheels offer greater durability and stability.

- Longer Life: They contain more abrasive material, so they last longer, especially during demanding jobs. This makes them a great choice for heavy-duty cutting tasks.

- Increased Durability: Their robust build makes them less likely to break under pressure. Many thick abrasive wheels also feature reinforced bonds for higher safety and reduced vibration, boosting their performance on tough metals.

- Best Uses: Perfect for aggressive cutting on thick, tough materials like rebar, angle iron, or thick steel plate.

Pro Tip: For most everyday cutting jobs on stainless or mild steel, a 1mm or 1.6mm cutting wheel offers a great combination of speed and durability.

Wheel Grit Size

Grit size refers to the size of the abrasive particles on the wheel. This choice affects both your cutting speed and the finish of your cut. Grit is measured by a number; a lower number means larger, coarser grains, while a higher number means smaller, finer grains.

- Coarse Grit (Lower Numbers, e.g., 36, 46): Wheels with coarse grit remove material very quickly. The large grains are aggressive, making them great for fast, rough cutting where the finish quality is not the main concern.

- Fine Grit (Higher Numbers, e.g., 60): Wheels with fine grit produce a much smoother, more polished surface. The smaller particles remove material more gently, resulting in a cleaner finish. This is important when the appearance of the cut edge matters.

The bond holding the grains also affects performance. A harder bond holds grains longer, increasing durability, while a softer bond releases dull grains faster for more aggressive cutting. This balance ensures top efficiency.

Here are some common grit sizes for metal cutting:

| Material / Application | Recommended Grit Size |

|---|---|

| Copper | 36 (Coarse) |

| Stainless Steel (General) | 46 to 60 (Medium to Fine) |

| Stainless Steel (Fast, Burr-Free Cutting) | 60 (Fine) |

Choosing the right grit helps you balance the need for rapid material removal with the desire for a smooth, finished look.

Final Safety and Compatibility Checks

You have chosen the right abrasive and wheel characteristics. Now, you must complete the most important step: safety and compatibility checks. This final review ensures your cutting wheel works correctly with your tool. Proper checks prevent accidents and guarantee safe, efficient cutting. Before every use, you should also inspect your wheel for any damage.

Pre-Use Inspection Checklist 🔍 Never use a cutting wheel with visible damage. Check for:

- Cracks, chips, or uneven surfaces.

- Worn or faded labels that hide the RPM rating.

- Signs of moisture damage or warping.

Check the RPM Rating

Every cutting wheel has a maximum safe speed, listed as RPM (Revolutions Per Minute). Your tool also has an RPM rating. For safe cutting, the RPM of your wheel must be higher than the RPM of your grinder.

Operating a wheel above its rated speed creates immense force. This can cause the wheel to shatter, leading to serious injury. Even slightly exceeding the RPM can create cracks that cause failure later. Remember that larger grinders often have lower RPMs. For example, a 9-inch grinder may run at 6,000 RPM, while a 4.5-inch grinder can reach 12,000 RPM. Always match the wheel to the tool for safe cutting.

Match Diameter and Arbor Size

The wheel’s diameter and arbor hole size must match your grinder’s specifications. A 4.5-inch wheel belongs on a 4.5-inch grinder. The arbor hole is the hole in the center of the wheel. In North America, a common arbor size is 5/8 inch. This must fit perfectly onto your grinder’s spindle for a secure connection.

Never force a wheel onto a tool that does not fit. Using adapter rings or forcing a fit can cause dangerous vibrations and misalignment. This can lead to catastrophic failure during a cutting job. A secure fit is essential for controlled and safe cutting.

Critical Safety Rule: No Side Grinding!

A cut off wheel is thin and designed only for straight-line cutting. You must never use it for grinding on its side or apply lateral pressure. This action can cause the wheel to break apart, sending fragments flying at high speed. Stick to straight cutting for your safety.

You now have the knowledge for successful cutting. Choosing the right cutting wheel improves your cutting efficiency and overall performance.

You can achieve a clean cut every time. Just follow these steps:

- Match the abrasive to your material.

- Select the right wheel characteristics.

- Check tool compatibility for safe cutting.

This process boosts your cutting performance and ensures safe cutting. Better cutting efficiency means better performance. With quality tools from Aimgrind, you can achieve precise, burr-free professional results and superior cutting performance. Your cutting projects will see improved efficiency and excellent performance.

FAQ

What happens if I use the wrong wheel for my metal?

You will experience poor results. Using the wrong wheel causes slow cutting, excessive heat, and rapid wheel wear. It can also be unsafe. For example, a standard wheel on stainless steel will contaminate the metal and cause it to rust. Always match the abrasive to your material.

How can I make my cut off wheel last longer?

You can extend wheel life with proper technique. Apply steady, moderate pressure without forcing the tool. Let the wheel do the work. Using a thinner wheel for thin materials also reduces stress and wear, helping it last longer while cutting faster.

Can I use a cutting wheel for grinding?

No, you must never use a cutting wheel for grinding. These wheels are thin and designed only for straight-line cutting. Applying side pressure can cause the wheel to shatter, creating a serious safety hazard. Always use the correct wheel for the job.

What if I need to cut a special material like ceramic?

Standard wheels may not work on unique materials. For specialized jobs involving ceramics, composites, or other hard materials, you need a custom solution. Brands like Aimgrind design specific abrasive formulas to ensure you get clean, efficient cuts on any material.

See Also

Selecting the Ideal Metal Grinding Wheel for Your Specific Project

Picking the Perfect Grinding Wheel for Your Circular Saw Blade

Selecting the Optimal Grinding Wheel for Your Carbide Tool Sharpening

Finding the Best Bench Grinding Wheel Material for Your Requirements

Discovering the Most Effective Grinding Wheel Dresser for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools