Inconsistent results in batch grinding are a common problem. Each failed batch creates waste, driving up costs and hurting your product quality. This lack of quality control can stop your progress.

You can achieve batch consistency. The solution is not guesswork; it is systematic control. This approach builds consistency into every single batch. Achieving batch consistency ensures you deliver consistent quality. You will produce a batch with excellent quality every time.

Key Takeaways

- Control energy and temperature during grinding. This helps make sure each batch is the same.

- Use good grinding tools. This makes sure your product is high quality.

- Follow clear steps for every task. This helps everyone do the job the same way.

- Use technology to watch your process. This helps you fix problems fast.

- Check your raw materials. This helps you make changes for a better product.

Foundations of Batch Consistency

You must understand the physical and material factors that create inconsistency. These are the common causes of variation in your process. Mastering these foundations helps you produce high-quality dispersions with every batch. True batch consistency starts with controlling the core elements of your grinding operation.

Standardize Energy Input and Shear

The energy you put into your mill directly impacts particle size reduction. Different energy levels produce a different particle size distribution. To achieve batch consistency, you must standardize the energy input for each batch. This gives you predictable control over the final particle size. Using specific energy measurements instead of just grinding time allows you to scale your process to larger mills. This makes your data more reliable and your results repeatable.

Shear forces also play a huge role in the quality of your dispersion. These forces break down particles within the material bed. Proper control of grinding pressure ensures you use energy efficiently for consistent particle size reduction. Measuring shear can be difficult, but you can control it indirectly by managing grinding pressure.

Pro Tip: For vertical mills, you can improve control over the dispersion process by following a few key steps. This helps you maintain the quality of each batch.

Here is how you can manage grinding pressure effectively:

- Set a baseline pressure for each material you process.

- Monitor trends in pressure, power, and product fineness.

- Perform regular maintenance on the hydraulic system.

- Use modern control systems to automate adjustments.

Control Temperature for Stable Results

Temperature changes can ruin your batch consistency. Heat affects the physical and chemical properties of your materials. For example, high temperatures can alter the structure of clays and rocks. Even seasonal temperature shifts can affect the stability and quality of your raw materials before they even enter the mill.

Uncontrolled heat during the grinding process can lead to unwanted chemical reactions or physical changes. This variability makes achieving a uniform dispersion difficult. You must implement temperature control to get stable results.

Here are some ways temperature affects material quality:

- It can change the structure of minerals.

- It can increase the silt content in clays.

- Extreme fluctuations impact thermal stability.

A stable temperature ensures that the only changes to your material come from the particle size reduction process itself. This control is essential for quality.

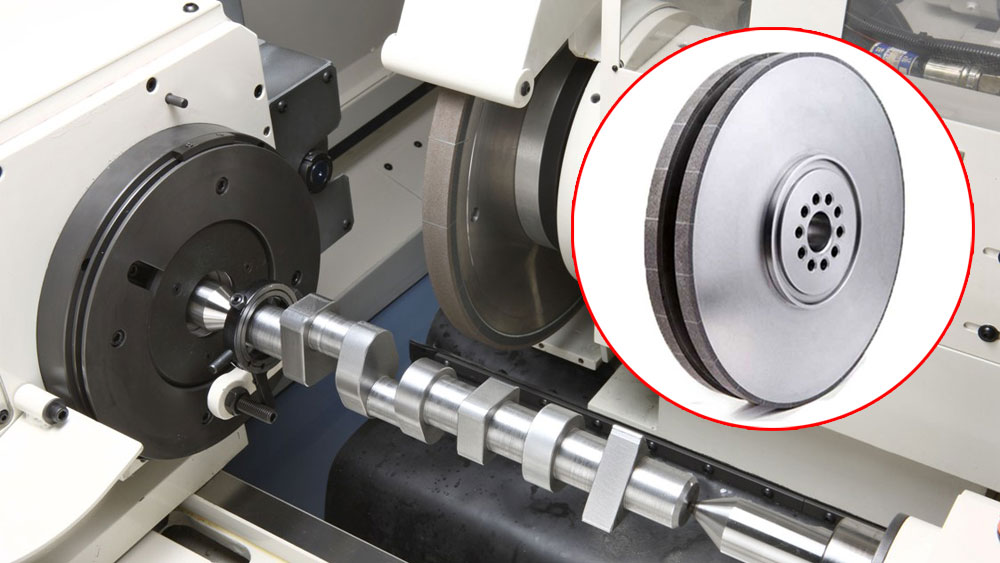

Optimize Your Grinding Media

The tools you use for grinding are critical for quality. The size, shape, and material of your grinding media determine the efficiency of the dispersion.

- Larger media are great for breaking down coarse materials.

- Smaller media create a finer particle size reduction due to more contact points.

- Spherical media often provide better flow and packing.

- Irregularly shaped media can increase grinding action.

Using a mix of sizes can be effective. You might start with larger media and move to smaller media as the particle size decreases. The key is consistency. Using worn or low-quality media will harm your batch consistency and lower your product quality.

For reliable batch consistency, you need durable, high-quality abrasives. Tools like Aimgrind‘s conventional bonded abrasives are designed for this purpose. Made from hard materials like aluminum oxide and silicon carbide, they deliver reliable performance. Choosing the right media helps you achieve consistent quality and a better final product. This ensures every batch meets your quality standards.

Manage Raw Material Variability

Your raw materials are never perfectly identical from one batch to the next. They can vary in hardness, moisture content, and particle size distribution. You must have a system to manage this variability to maintain consistency. The first step is testing your materials to understand their properties. This knowledge allows you to make proactive adjustments.

You can adjust several parameters to compensate for raw material differences and ensure a quality dispersion. Advanced mills often have systems that monitor the process in real time. These systems can automatically adjust parameters to maintain a consistent particle size distribution. This level of control helps you produce a quality batch every time.

| Parameter | How to Adjust for Consistency |

|---|---|

| Feed Rate | Use an automated feeder to maintain a steady rate that matches the material’s properties. |

| Classifier Speed | Make small adjustments to control the final particle fineness. |

| Grinding Pressure | Find the optimal pressure for each material and monitor trends. |

| Airflow | Adjust airflow to manage moisture and transport fine particles efficiently. |

By actively managing these variables, you turn an unpredictable process into a controlled system. This ensures every batch meets your high standards for quality.

Building Systems for Repeatable Quality

Controlling your materials and energy input gives you a strong foundation. However, achieving true batch consistency requires building reliable systems for your people and processes. These systems turn good practices into standard habits. They are the bridge between knowing what to do and doing it correctly every single time. This focus on procedure is essential for repeatable quality in batch manufacturing.

Develop Standard Operating Procedures (SOPs)

You cannot leave quality to chance. Standard Operating Procedures (SOPs) are detailed instructions that ensure everyone performs a task the same way. Creating a consistent process with clear SOPs is critical for improving production quality. When every operator follows the same steps for every batch, you eliminate a major source of variation. This systematic approach to quality control helps you achieve predictable results. For example, major companies like Molson Coors cut their quality-related issues in half by implementing strong SOPs across their production.

A great SOP is more than just a checklist. It provides total clarity for the operator. Your SOPs for batch manufacturing should include:

- Objective: A clear statement of the procedure’s goal.

- Scope: Defines which machines or processes the SOP applies to.

- Instructions: Simple, step-by-step directions, often with pictures or diagrams.

- Tools and Equipment: A list of everything needed to do the job safely.

- Roles: Specifies who is responsible for each action.

- Version Control: A system to track updates so everyone uses the current document.

Implement In-Process Quality Checks

Waiting until a batch is complete to check its quality is a recipe for waste. You need to monitor the process while it is happening. In-process quality checks allow you to spot and fix problems early. This proactive quality control saves time and materials. It ensures each batch stays on track to meet your standards. This is a core part of any successful quality assurance program.

You can track several key metrics during the grinding process to maintain consistency. These checks give you real-time feedback on the health of your batch.

Pro Tip: Use a combination of these checks for the best control. A change in one metric, like temperature, can often explain a change in another, like viscosity.

Key in-process checks include:

- Particle Size Distribution (PSD): This is a direct measure of grinding effectiveness. Modern tools like online particle size analyzers can give you this data in real time.

- Viscosity: Changes in viscosity can signal issues with raw materials or energy input.

- Energy Input: Monitoring motor load or power draw helps confirm each batch receives the same amount of work.

- Temperature: Tracking temperature curves ensures the batch follows a consistent thermal path, which is vital for quality.

Ensure Proper Equipment Calibration

Your equipment must provide accurate measurements to enable effective control. If your sensors or gauges are wrong, your adjustments will be wrong, too. Proper equipment calibration ensures your machinery’s readouts are trustworthy. This step is fundamental for batch consistency and overall production quality. Improperly calibrated machines can lead to hidden costs from scrap, rework, and production delays. Even small errors can ruin an entire batch.

You should establish a regular calibration schedule based on professional recommendations and standards like ISO 9001.

- Calibrate instruments upon initial installation.

- Perform routine checks every six months for most equipment.

- Calibrate high-use or critical instruments every 3-6 months.

- Always recalibrate after a machine collision or component replacement.

Following a proactive schedule turns calibration into a tool for continuous improvement, not just a reaction to a problem. This discipline is a pillar of good batch manufacturing.

Train Operators for Consistency

Your operators are your first line of defense for quality. The best procedures and perfectly calibrated equipment are only effective in the hands of a well-trained team. Operator training is the final piece of the puzzle for achieving consistent quality. This training must go beyond simply showing someone which buttons to push.

Effective training explains the “why” behind each step. When operators understand how their actions affect the final batch, they become active partners in quality assurance. For instance, training should cover how to handle tools like Aimgrind’s abrasives properly to maximize their performance and lifespan. This knowledge empowers them to maintain a consistent process. Interactive training modules that use videos and quizzes can make these complex principles easier to understand. This investment in your team leads to better consistency, higher production quality, and continuous improvement in your entire operation.

Using Data for Batch-to-Batch Consistency

Strong systems and procedures set the stage for quality. You can elevate your process further by using data. Data gives you the power to achieve true batch-to-batch consistency. It transforms grinding from a reactive task into a predictable science. This control ensures every batch meets your high standards for quality.

Automate Process Controls

You can eliminate human error by automating your grinding process. Automated systems perform tasks with perfect repeatability, ensuring every batch gets the exact same treatment. This consistency is something manual operations cannot match. Robots and automated modules work without fatigue, which directly improves the quality of your output.

Common automated systems include:

- Grinding feed mill automation

- Integrated grinding and classifying systems

- Modules that adjust roller gaps for specific micron sizes

These precision controls create a stable production environment. The result is higher quality, less rework, and better batch consistency.

Use Sensors for Real-Time Monitoring

You need real-time information to maintain control over a batch. Sensors provide a live window into your grinding process. You can use instruments to track key variables and make immediate adjustments. This active monitoring helps you catch problems before they ruin a batch.

Pro Tip: Use sensor data to act fast. For example, a spike in power draw can signal a dull grinding wheel. You can change the tool immediately to prevent a drop in quality.

Sensors for temperature, pressure, and flow give you the data needed for this level of control. This ensures the quality of each batch remains high from start to finish.

Digitize Records to Eliminate Errors

Manual paper logs are prone to errors and create data you cannot easily use. You can solve this by digitizing your records. Digital systems enforce accuracy and create a perfect, traceable history for every batch. This visibility is essential for batch-to-batch consistency and continuous improvement.

| Benefit | Impact on Your Operation |

|---|---|

| Higher Efficiency | Operators can capture data in real time, boosting efficiency by up to 40%. |

| Improved Traceability | You gain structured reports and audit trails for stronger compliance. |

| Actionable Insights | Dashboards provide a clear view of trends, helping you make better decisions. |

This switch improves quality and provides the foundation for data-driven improvement.

Analyze Data for Continuous Improvement

Collecting data is only the first step. The real power comes from analysis. You can use the data from each batch to find opportunities for continuous improvement. Analyzing trends helps you optimize parameters, predict maintenance needs, and increase throughput. This focus on improvement makes your entire operation more efficient. This data-driven approach to continuous improvement ensures long-term consistency and quality. You turn historical information into a roadmap for future success, leading to constant improvement.

Achieving consistent quality in batch grinding is the direct result of mastering variables, standardizing procedures, and using data. You improve your production quality by taking control.

Key Takeaways for Better Quality:

- Control energy and temperature.

- Use high-quality abrasives to ensure process quality.

- Enforce clear SOPs for every task.

- Leverage technology for real-time monitoring.

By implementing these systematic controls, you shift from reactive adjustments to proactive, predictable production. This guarantees a higher level of quality and boosts your overall production quality.

FAQ

What is the first step to improve batch consistency?

You should start by controlling your core variables. Standardize the energy input for each batch to get a predictable particle size. You also need to manage temperature to prevent unwanted changes in your material. These two actions build a strong foundation for quality.

How often should I replace my grinding media?

You should focus on performance, not a strict schedule. Inspect your media regularly for wear and damage. Using high-quality, durable tools like Aimgrind’s conventional bonded abrasives ensures a longer lifespan and more consistent results, reducing the frequency of replacement.

Why are SOPs so important for grinding?

Standard Operating Procedures (SOPs) eliminate guesswork. They give every operator clear, step-by-step instructions for each task. This ensures everyone performs the process the same way every time.

Remember: Consistency in action leads to consistency in your product.

How do I handle differences in raw materials?

You should test your raw materials before you start grinding. This helps you understand their properties, like hardness or moisture. You can then adjust process parameters like feed rate or grinding pressure to ensure a uniform result, no matter the initial variation.

Contact Us

For More Grinding Solution or Customized Abrasive Tools