Keeping your knives sharp helps you stay safe in the kitchen and at work. Dull blades cause more accidents than most people realize. About one-third of all reported injuries in restaurant settings come from cuts, punctures, or scrapes, often because of dull knives. Sharp edges need less force to cut, which lowers the risk of slips and injuries. Honing sticks and stones play a big part in this process. When you use a honing rod or honing steel, you do not sharpen the knife but realign its edge. Honing and sharpening are not the same. Honing keeps the edge straight, while sharpening removes metal to create a new edge. Learning how to hone a knife with a honing stick or honing rod means you can keep your knives sharp and ready. Honing a knife often, even before or after use, will make your blades last longer and safer. With the right honing steel or honing rod, you can master how to hone a knife and protect your blades.

Key Takeaways

Honing stones fix your knife’s edge. They do not take away metal. This helps your blade stay sharp and safe for longer.

Pick the right honing stone for your knife. Think about knife material, abrasive type, grit size, and bond. This helps you get the best sharpening.

Use steady pressure when you hone. Move the knife in a controlled way. Make a cross-hatch pattern. This pattern holds oil and helps the blade work better.

Clean your honing stone often. Dress and care for it to stop clogging. This makes the stone last longer and keeps sharpening even.

Use the right lubricant for your honing stone. Use water for waterstones. Use oil for oil stones. This stops damage and helps you sharpen better.

What is Honing Stone?

Definition and Basic Concept

A honing stone is a tool you use to keep your knife sharp and safe. You may hear people call it a sharpening stone, but these two tools have different jobs. A honing stone helps you realign the edge of your knife. It does not remove much metal. A sharpening stone, on the other hand, cuts away metal to create a new edge. Honing stones are made from hard materials like diamond or silicon carbide. You use them to smooth and straighten the blade. This keeps your knife working well and makes cutting easier.

Role in the Honing Process

When you use a honing stone, you help your knife stay sharp for longer. The honing process works in several steps:

1. Shedding cutting: At first, the rough surface of the honing stone wears down the blade and exposes new sharp grains. 2. Crushing cutting: As you keep honing, the surface gets smoother. The stone breaks off small pieces to form new edges. 3. Blocking cutting: Over time, fine chips build up. The stone becomes smooth and less effective. If you keep honing too long, you may polish instead of sharpen.

You move the knife across the honing stone in a special way. The stone and the blade wear together. This helps both keep their shape. The motion also creates a cross-hatch pattern on the blade. This pattern holds oil and helps the knife last longer. You can use honing to get a better finish than most machines can give.

Tip: Use steady pressure and move the knife in a controlled motion for best results.

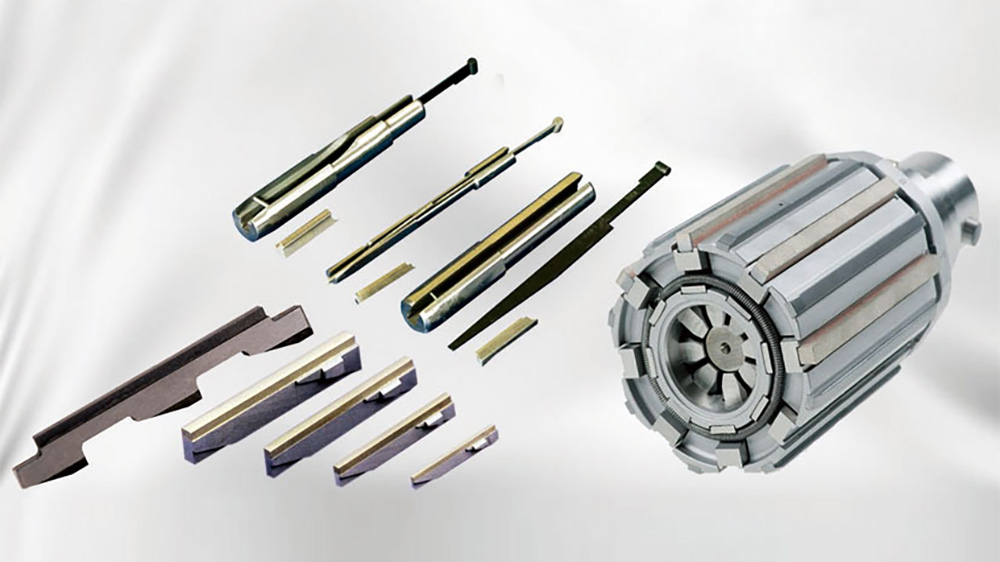

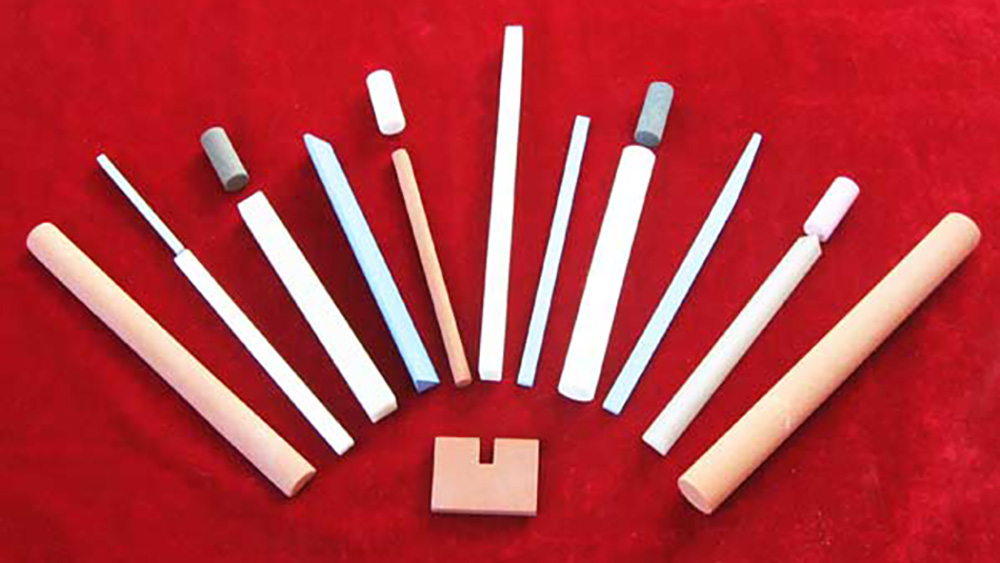

Physical Form and Installation

You can find honing stones in many shapes and sizes. Some look like flat blocks, while others are round or stick-shaped. Most sharpening stones are rectangular and easy to hold. You can use a honing stone by hand or mount it in a holder. Some machines use honing stones with hydraulic or pneumatic pressure. This keeps the stone in contact with the blade and helps it adjust to the shape. Always make sure your honing stone is clean and secure before you start. This will help you get the best results and keep your knife safe.

Core Components of Honing Stones

Abrasive Materials

It is important to know about abrasive materials before picking a honing stone. Each type works best for certain tasks and has good and bad points. The most common types are aluminum oxide, silicon carbide, diamond, and CBN. Many people also use a ceramic honing rod to care for knives.

Here is a table that lists the good and bad sides of popular abrasive materials:

Abrasive Material | Advantages | Disadvantages |

|---|---|---|

Aluminum Oxide (Synthetic Whetstones) | Easy to find; sharpens fast; cleans with water better than oil | Wears out faster than some; some need soaking first |

Ceramic | Was used instead of natural stones; sharpens well | Quality is not always the same; needs soaking for 10 minutes; can work differently each time |

Diamond | Very hard; cuts fastest; stays flat; easy to care for | Can scratch blades if not used right; not a real stone but a metal plate with diamond on top; takes skill to use |

Alumina Oxide (For Steel)

Alumina oxide is found in many honing stones. It works well for steel blades. It sharpens fast and is easy to clean with water. You can use a ceramic honing rod with alumina oxide for daily care. Some stones need to soak first, and softer ones wear out sooner.

Silicon Carbide (For Cast Iron, Aluminum)

Silicon carbide is a strong abrasive. It is best for cast iron and aluminum. It cuts quickly and works on hard metals. Silicon carbide stones wear down faster than diamond stones. Many ceramic honing rods use silicon carbide for softer metals.

Diamond (Super Abrasive for Hard Materials)

Diamond is the hardest abrasive you can get. It is best for very hard things like ceramics, copper, and carbides. Diamond stones cut fast and stay flat for a long time. You need skill to use diamond stones because they can scratch blades if used wrong. Some ceramic honing rods have a diamond layer for extra power.

CBN (Super Abrasive for Ferrous Metals)

CBN means cubic boron nitride. You should use CBN stones for alloy steels and hard chromium. CBN cuts well and lasts a long time. Some advanced ceramic honing rods use CBN for tough jobs.

Bond Types

The bond keeps the abrasive grains together in your honing stone. The bond type changes how the stone works and what it can do. There are three main types: vitrified, resinoid, and metallic.

Here is a table that explains what each bond type does and where it works best:

Bond Type | Key Properties | Performance Impact | Suitable Applications |

|---|---|---|---|

Resin Bond | Flexible, bends a little | Handles small bumps, less noise, sharpens itself | Good for general grinding and nice finishes |

Metal Bond | Very strong, does not wear out fast | Handles hard jobs and big hits | Used for hard and odd-shaped materials |

Ceramic Bond | Very hard, does not get hot easily | Cuts well even when hot | Good for fast and dry honing |

Vitrified Bond (Most Common)

Most honing stones use vitrified bonds. This bond uses ceramic to hold the grains. Vitrified bonds work for many jobs and cut well. Many ceramic honing rods use vitrified bonds for long life.

Resinoid Bond (For Fine Finishing)

Resinoid bonds use resin to hold the grains. Pick resinoid bonds for fine finishing. These stones handle small changes and make less vibration. Some ceramic honing rods use resinoid bonds for smoother edges.

Metallic Bond (For Super Abrasives)

Metallic bonds use metal to hold the grains. Use metallic bonds for hard jobs and super abrasives like diamond and CBN. These stones handle strong cutting and last longer. Some advanced ceramic honing rods have metallic bonds for more strength.

Grit Size and Its Impact

Grit size tells you how big the abrasive pieces are in your honing stone. Grit size changes how much you remove and how smooth the blade gets. You need to pick the right grit size for your job.

Tip: Coarse grits take off material fast but leave a rough edge. Fine grits make a smooth edge but work slower.

Coarse Grit (For Roughing)

Use coarse grit stones for rough work. These stones have big abrasive pieces. They remove material quickly and shape the blade. Coarse grit is good for fixing damage or changing the blade shape. Some ceramic honing rods have coarse grit for quick fixes.

Medium Grit (For Semi-Finishing)

Medium grit stones are a balance of speed and smoothness. Use medium grit for regular care and semi-finishing. These stones smooth rough edges and get the blade ready for fine finishing. Many ceramic honing rods have medium grit for daily sharpening.

Fine Grit (For Precision Finishing)

Fine grit stones have small abrasive pieces. Use fine grit for careful finishing. These stones make a smooth, shiny edge. Fine grit is best for final touches and super smooth edges. Ceramic honing rods with fine grit help you get a razor-sharp blade.

Hardness and Structure

The hardness of your honing stone is important. It changes how well the stone cuts and how long it lasts. You need to match the stone’s hardness to what you are honing.

Softer honing stones are best for hard materials. They do not clog and keep cutting well.

Harder honing stones are good for softer materials. They help you remove material fast.

Stones with even hardness help you keep a smooth finish and shape.

Diamond honing stones are good for ceramics, copper, and cast iron. CBN stones are best for alloy steels and hard chromium.

Pick the right grain size and hardness for your honing job. Coarse grains are for rough work. Fine grains are for finishing.

Many ceramic honing rods come in different hardness levels. You can choose the one that fits your knife and your needs.

Key Functions and Purpose

Achieving Dimensional Accuracy

You can use honing stones to reach a level of precision that most other finishing tools cannot match. When you move the stone across the surface, it follows a path that helps both the stone and the workpiece take on an average shape. This process lets you achieve dimensional accuracy that often goes beyond what the original machine tool can do. For example, after grinding sets the size, honing can improve the shape and size even more. You can reach cylindricity within 0.001 mm, roundness within 0.002 mm, and straightness within 0.01 mm per meter. These tight tolerances help you keep your blades and other parts working at their best sharpness.

Correcting Geometric Form (Roundness, Cylindricity)

Honing stones help you fix small errors left by earlier machining steps. You can remove tiny amounts of material—about 0.005 mm—to correct bore size and shape. This fine-tuning is important for parts that need to be very round or straight, like engine cylinders or hydraulic tubes. You often see improvements such as:

Achieving tolerances as tight as ±0.002 mm

Getting a surface finish around Ra 0.2 µm

These corrections help you keep the edge of your blades in top shape and make sure your tools last longer.

Improving Surface Finish (Reducing Roughness)

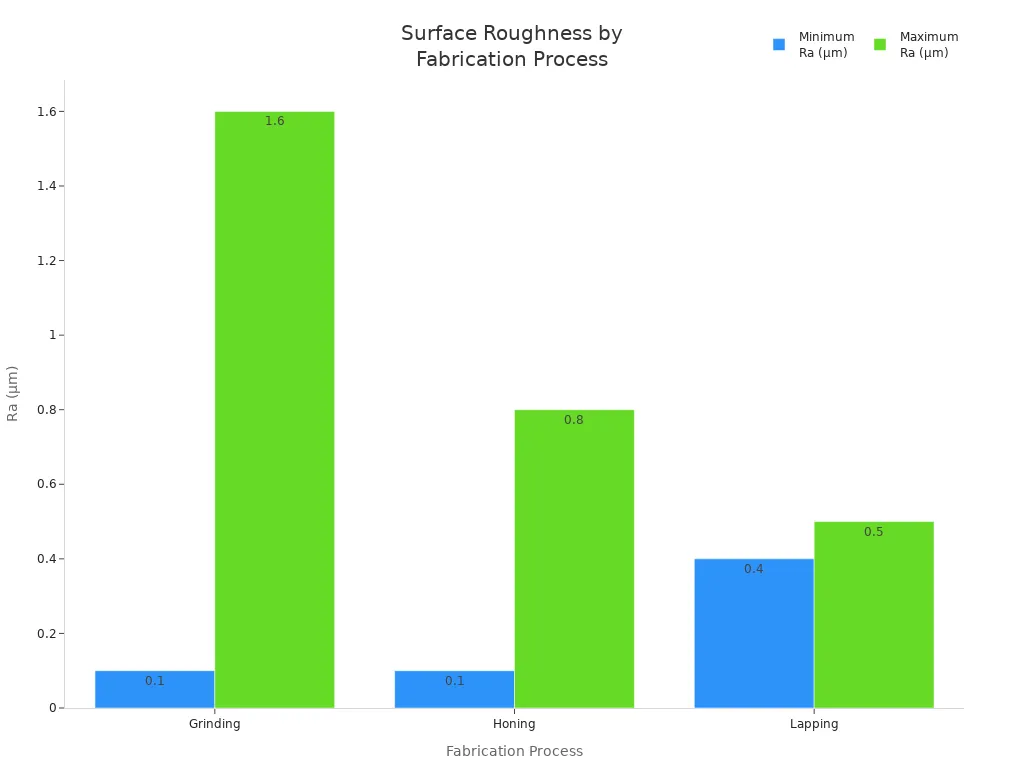

Honing does more than just shape your workpiece. It also makes the surface much smoother. When you compare honing to grinding or lapping, you see that honing gives you a better finish. Look at the table below:

Fabrication Process | Minimum Ra (µm) | Maximum Ra (µm) |

|---|---|---|

Grinding | 0.1 | 1.6 |

Honing | 0.1 | 0.8 |

Lapping | 0.4 | 0.5 |

You can see that honing often gives you a smoother surface than grinding and even lapping. This smoother finish helps you polish your edge and keep the sharpness of your blades. Honing can improve surface finish by about 30% compared to lapping and can make your edge up to 10 times smoother than grinding.

Creating Cross-Hatch Pattern for Lubrication

When you use a honing stone, you create a special cross-hatch pattern on the surface. This pattern has tiny peaks and valleys. The valleys hold oil or other lubricants. This helps keep your blades and moving parts working smoothly. The cross-hatch spreads oil evenly, protects seals, and reduces friction. You get a better seal and less wear on your parts. The angle of the pattern, usually between 30° and 45°, is important for holding just the right amount of oil. If you polish the surface too much, you might lose these valleys, so always balance polishing your edge with keeping enough texture for lubrication.

Tip: A good cross-hatch pattern means your tools will run smoother, last longer, and keep their sharpness.

Main Application Industries

Automotive Engine Manufacturing (Cylinder Bores)

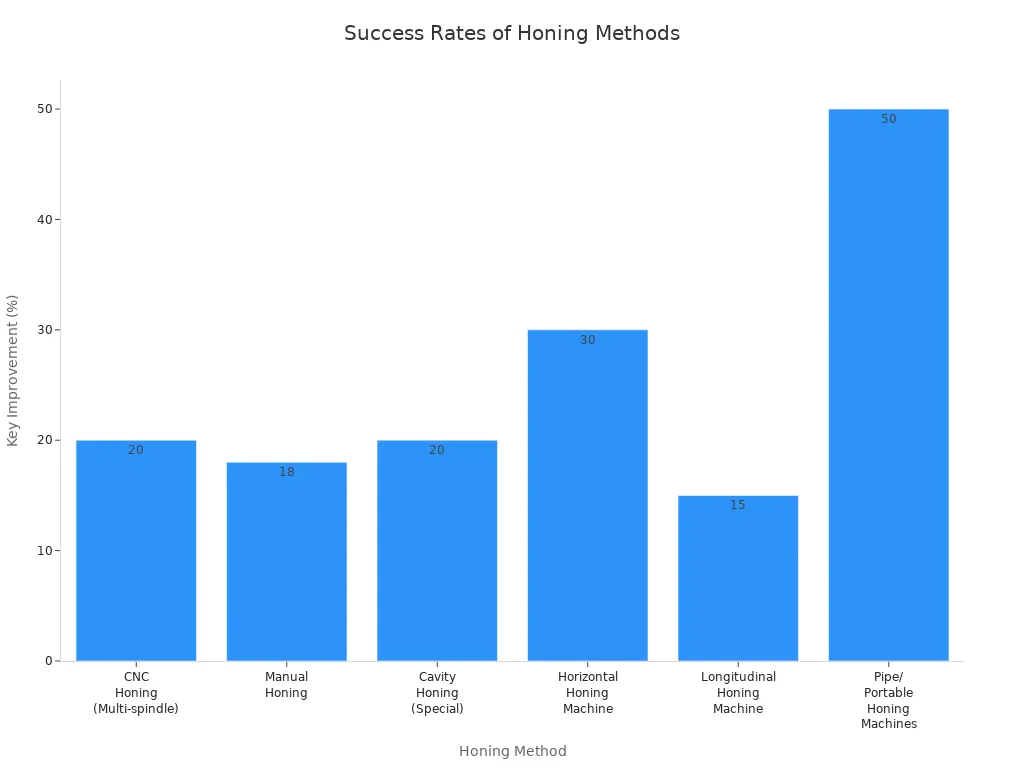

Honing stones are used in almost every engine shop. About half of all cylinder bores now use diamond honing stones. This number has gone up a lot in the last ten years. Diamond stones cut faster and last much longer than old types. They can last up to 50 times longer. You get a smoother bore finish, so piston rings fit better and last longer. Diamond honing can even take the place of boring bars for rough work. Machines must be strong enough for diamond stones. After honing, a final step removes dirt and makes the surface smooth. This helps engines wear less and work better.

Hydraulic and Pneumatic Systems (Cylinder Tubes)

Honing stones finish the inside of hydraulic and pneumatic tubes. The honing head spins and moves back and forth in the tube. This takes off tiny bits of metal and fixes the shape. The process makes a cross-hatch pattern that holds oil and lowers friction. This helps seals and cylinders last longer. Diamond honing makes surfaces smoother and can save oil and fuel. You must watch the process closely to stop extra wear. Plateau honing takes off high spots and gives more area for oil. This keeps things slippery and cuts down on wear. Changing the honing force, stroke, and speed can make the surface better and save time.

Aerospace Industry (Actuator Cylinders)

Aerospace actuator cylinders need very high accuracy. Honing stones must make bores with very tight tolerances. The space between moving parts is kept very small. This is important for hydraulic valves and actuators. Special honing machines use controlled force for each part. This gives perfect roundness, straightness, and a smooth finish. The process keeps an oil layer and removes flaws that could cause cracks. Aerospace honing stones use harder bonds to meet strict safety rules.

General Precision Machining

Honing stones are used for very precise bore work in many fields. Honing fixes the size, shape, and finish of bores. It is used for final sizing and to make cross-hatch patterns for oil. Honing machines remove material, make finish patterns, and keep bores straight and round. You see honing in engine cylinders, hydraulic parts, and medical tools. Single-pass honing gives the same results every time, often using diamond or CBN stones. The process saves money and helps you get tight tolerances for top-quality parts.

Tip: Pick the right honing stone and method for your job. This helps you get the best accuracy, strength, and performance.

Selection Guide and Usage Tips

How to Choose Based on Workpiece Material

You need to match your honing stone to the material you want to sharpen. If you work with steel knives, choose alumina oxide stones or a ceramic honing rod. For cast iron or aluminum, silicon carbide stones work best. Diamond stones help you sharpen hard materials like ceramics or carbide blades. CBN stones are great for alloy steels. Always check the manufacturer’s guide before you start honing. This helps you pick the right stone for your knife and keeps your edge sharp.

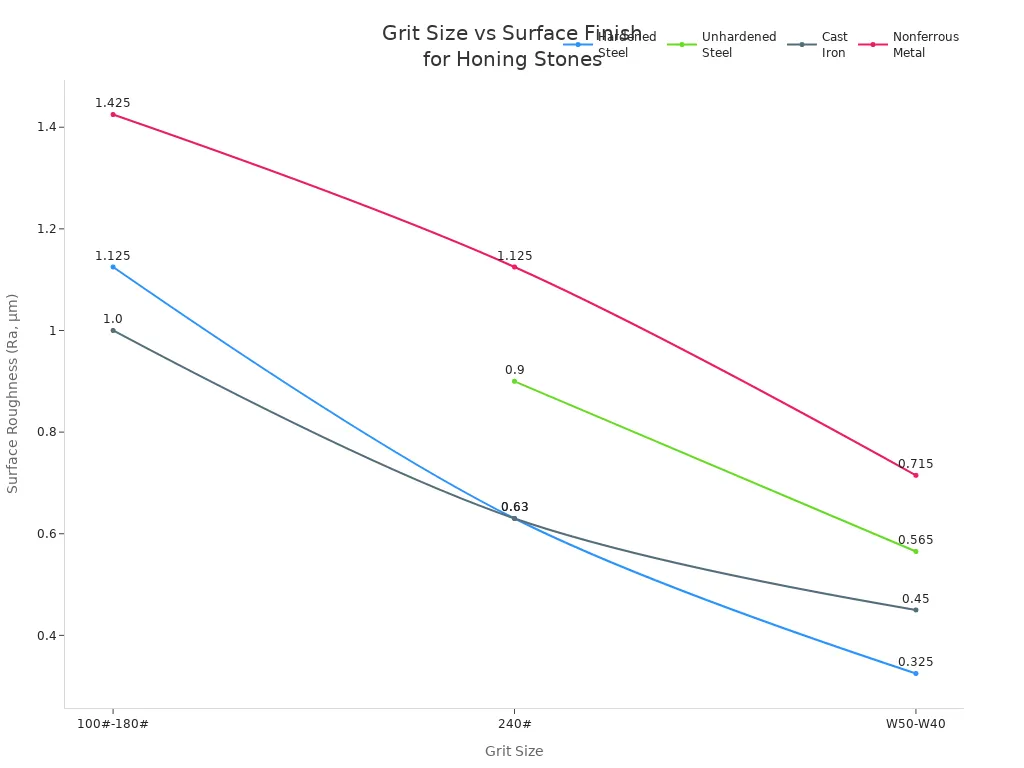

Selecting Grit Size for Required Finish

The grit size of your honing stone decides how smooth your knife edge will be. Coarse grits remove material quickly but leave a rough surface. Fine grits make your edge smooth but work slower. If you want a polished finish, use a finer grit. For rough sharpening, pick a coarse grit. The table below shows how grit size matches different materials and surface finishes:

Material | Typical Grit Size Range | Approximate Surface Roughness (Ra, μm) |

|---|---|---|

Hardened Steel | ~1.25 – 1.0 | |

240# (semi-finish) | ~0.63 | |

W50 – W40 (finish) | ~0.4 – 0.25 | |

Cast Iron | 100#-180# | ~1.0 |

240# | ~0.63 | |

W50 – W40 | ~0.5 – 0.4 | |

Nonferrous Metal | 100#-180# | ~1.6 – 1.25 |

240# | ~1.25 – 1.0 | |

W50 – W40 | ~0.8 – 0.63 |

You can see that finer grit stones give you a smoother finish. If you want to learn how to hone a knife for a razor-sharp edge, start with a medium grit and finish with a fine grit. The chart below shows how surface roughness drops as grit size gets finer:

Choosing Hardness and Bond Type

You must select the right hardness and bond type for your honing stone. The choice depends on your knife material, the finish you want, and your sharpening technique. Harder stones work well for softer metals. Softer stones suit harder blades. Vitrified bonds last long and resist heat. Resinoid bonds give a fine finish. Metal bonds handle tough jobs. If you use a ceramic honing rod, check its bond type for best results. The right combination helps you sharpen your knife and keep the edge strong.

Match stone hardness to your knife material.

Pick a bond type that fits your sharpening needs.

Use the proper technique for honing at the correct angle.

Coolant and lubrication Importance

Coolant and lubrication play a big role in honing. Good coolant keeps your honing stone cool, flushes away chips, and helps you sharpen faster. Poor lubrication makes your honing rod wear out quickly and lowers cutting efficiency. Water-based polymer coolants work better than mineral oils. They give you smoother edges and help you sharpen more knives. Always check the coolant’s pH and concentration. This keeps your honing steel and sharpening stone working well and extends their life.

Tip: Continuous coolant monitoring improves performance and saves money.

Dressing and Maintenance Tips

You need to dress and maintain your honing stone to keep it sharp. Dressing smooths the stone and reduces micro-chipping. If you want more aggressive sharpening, roughen the stone surface. Use abrasive papers with different grit sizes for fine or coarse dressing. For example, use 600/800WD for fine and 200/400WD for coarse. You can also use silicon oxide grains on a flat tile with oil. Buffer wheels help condition the stone after lapping it flat. Always use your stone as designed, whether it is a water, oil, or diamond stone. These honing tips help you get the best results and extend the life of your sharpening stone.

Note: Regular maintenance is key for proper use of honing rods and knife maintenance.

Troubleshooting Common Problems (Q&A)

Q1: Stone Loading and How to Prevent It

Stone loading happens when metal bits block your honing stone. This usually happens if you use water on oil stones. Water cannot lift iron bits, so they get stuck. Your sharpening stone will feel smooth and stop working well.

To stop stone loading, do these things:

Use the right lubricant. Oil stones need oil. Waterstones need water. Oil stops metal bits from sticking.

Clean your stone often with soap and water. This washes away swarf and keeps the stone open.

Flatten your stone with a flattening stone, diamond plate, or sandpaper on glass. This removes glazing and keeps it flat.

Never use water on oil stones. Oil stones work best with oil only.

Try diamond stones if you want less loading. Diamond stones stay flat and do not clog easily.

Tip: Keeping your honing stone clean and using the right lubricant helps you keep sharp edges and makes sharpening easier.

Q2: Selecting the Right Stone for Different Materials

Picking the right honing stone for your knife is important. If you choose the wrong abrasive, you get a bad finish and your stone wears out fast. Here are some tips:

Use diamond stones for non-heat-treated stainless steel. They cut fast and make a smooth edge.

Pick CBN stones for heat-treated or hard stainless steel. CBN works well with heat and keeps your edge strong.

Use aluminum oxide for regular steel knives. It sharpens well and is easy to use.

Material Condition | Recommended Abrasive | Reason / Advantages | Consequences of Incorrect Selection |

|---|---|---|---|

Non-heat-treated stainless | Diamond | Fast, smooth sharpening, high hardness | Poor finish, thermal damage |

Heat-treated stainless | CBN | Handles heat, resists wear, stable edge | Tool wear, bad surface |

General stainless | CBN (preferred) | Good for heat and corrosion, stable sharpening | Short tool life, rough finish |

If you use the wrong stone, you can hurt your knife. You might get thermal damage, uneven wear, and a dull blade. Always match the stone to your knife for the best results.

Q3: Achieving Required Surface Roughness

You want your knife edge to be smooth and sharp. To get the right surface roughness, control the crosshatch angle when honing. This angle helps oil stay on the blade and keeps the edge in good shape. You can measure the angle with a protractor or special software. Standards like ISO 1302 and ISO 4287 help you check roughness using Ra, Rz, and Rq values.

Use fine-grit stones for a smoother finish.

Keep the crosshatch angle between 30° and 45° for best oil flow.

Check your edge for torn or folded metal. Use a magnifier or digital tools if needed.

Note: Good surface roughness means your knife will cut better and last longer.

Q4: Short Stone Life and Rapid Wear

If your honing stone wears out quickly, check these things:

Factor | Impact | Solution |

|---|---|---|

Stone type | Softer stones wear faster | Use diamond stones for longer life |

Honing speed and pressure | High speed or pressure causes fast wear | Use correct speed and gentle pressure |

Lubrication | Wrong lubricant increases wear | Use oil or water as recommended |

Cleaning and storage | Dirty or poorly stored stones wear faster | Clean after use and store in a safe place |

Diamond stones last much longer than regular stones. They can sharpen up to 12,000 cylinder bores. Vitrified stones wear out after about 200. Always use the right sharpening method and keep your stone clean to make it last longer.

Q5: Correcting Dimensional and Form Errors

You can fix size and shape mistakes during honing by changing your method and tools. Use CNC honing for tight control. Use manual honing with fine diamond stones for small fixes. Good settings help you keep the edge straight and the blade sharp.

Set the right cutting speed and feed rate.

Use the correct abrasive for your knife.

Check your work often to catch mistakes early.

When you use the right honing method, you get better accuracy, longer product life, and easier blade repairs.

To get the best results, follow these steps when choosing and using honing sticks:

Pick the right abrasive and grit for your needs.

Use two grit sizes for a razor-sharp edge.

Adjust pressure and stone count for stability.

Regular honing with honing sticks keeps your tools sharp and safe. Make knife maintenance a habit. You will enjoy easier cutting and longer-lasting blades.

FAQ

How often should you hone your knife?

You should hone your knife every few uses. Regular honing keeps the edge straight and sharp. If you cook daily, hone your knife once a week.

Tip: Honing does not replace sharpening. You still need to sharpen your knife when it gets dull.

Can you use water instead of oil on a honing stone?

You must use the correct lubricant for your stone. Water works for waterstones. Oil works for oil stones.

Using the wrong liquid can damage the stone.

Always check the manufacturer’s instructions.

What is the difference between honing and sharpening?

Honing | Sharpening |

|---|---|

Realigns edge | Removes metal |

Quick process | Takes longer |

Use often | Use less often |

You hone to keep the edge straight. You sharpen to create a new edge.

Why does your honing stone feel smooth and stop working?

Your stone may be loaded with metal bits. Clean it with soap and water. Use the right lubricant.

Note: A loaded stone cannot sharpen well. Regular cleaning helps your stone last longer.

See Also

Different Grinding Wheel Varieties And Their Common Uses

Finding The Ideal Grinding Wheel Dresser For Your Needs

Safe And Efficient Techniques For Using A Dremel Wheel

Contact Us

For More Grinding Solution or Customized Abrasive Tools