You decide how well grinding works by picking the right grinding wheel rpm. Think about setting up a grinding job and seeing your results change when you adjust rpm. A faster wheel can cut more and remove more material, but it can make the surface rough or less safe. The Preston equation says grinding wheel rpm is tied to how much material you take off and how smooth the finish is. Tests show that the best rpm can make the difference between a rough cut and a shiny surface. The table below shows how grinding wheel rpm changes machining quality:

Machining Outcome | Optimal Grinding Wheel RPM | Additional Parameters | Notes |

|---|---|---|---|

Minimum Surface Roughness | 2000 rpm | Workpiece speed: 80 rpm, Feed rate: 275 mm/min, Depth of cut: 0.06 mm | Based on Taguchi method experiments on EN15AM steel cylindrical grinding. |

Optimized Material Removal Rate | 1800 rpm | Workpiece speed: 155 rpm, Feed rate: 275 mm/min, Depth of cut: 0.04 mm | Design of Experiments on EN15AM steel; grinding wheel speed is a key factor for MRR. |

Grinding wheel rpm is more than just a number. You need to balance cutting, wheel speed, and safety every time you grind. Picking the right rpm changes your results and keeps grinding safe.

Key Takeaways

Picking the right grinding wheel RPM helps cutting go faster, makes the surface smoother, and keeps you safe. – The best RPM depends on wheel size, what it’s made of, how strong the machine is, and how the wheel is built. – Surface Feet Per Minute (SFPM) tells how fast the edge of the wheel moves and helps you pick the right RPM for smooth work. – If the RPM is too high or too low, the surface will look bad, the wheel will wear out faster, and it can be dangerous because the wheel might break. – Always use the RPM the maker says, look at your wheel before you use it, and change the RPM to fit the wheel size and how you are grinding.

Grinding Wheel RPM Basics

What Is Grinding Wheel RPM

You need to know what grinding wheel rpm means before you start any grinding job. Grinding wheel rpm tells you how many times the wheel spins in one minute. This number helps you understand how fast the wheel moves against your workpiece. You can measure wheel speed in two ways: revolutions per minute (rpm) or surface feet per minute (SFM).

Wheel speed can also mean how fast the edge of the wheel moves. This is called peripheral speed.

To find peripheral speed, you multiply the wheel’s circumference by its rpm.

When you set up a grinding machine, you must check the spindle rpm. The spindle rpm tells you how fast the machine turns the wheel. Both grinding wheel rpm and spindle rpm work together to control the cutting action. If you use the right rpm, you get better cutting speed and smoother results.

Why RPM Matters

Choosing the right rpm for your grinding wheel is very important. The rpm affects how well the wheel cuts, how much material you remove, and how safe the process is. If you use the wrong rpm, you can face many problems.

Tip: Always follow the manufacturer’s recommended rpm for your grinding wheel. Never go above the maximum rpm.

Here are some reasons why rpm matters in grinding:

Using the appropriate rpm keeps the wheel stable and safe.

Too high an rpm can make the wheel break or explode.

Too low an rpm can cause poor cutting and rough surfaces.

The right rpm improves cutting speed, material removal, and surface finish.

Grinding wheel rpm also affects the spindle rpm and the overall performance of your machine.

A study shows that grinding wheel diameter, material, and how you install the wheel all change the spindle rpm and the machine’s stability. Larger wheels need lower rpm. Different wheel materials, like steel or aluminum, change how the spindle reacts at different speeds. If you pick the correct grinding wheel rpm, you get better cutting, smoother finishes, and safer grinding.

Factors Affecting Ideal Grinding Wheel RPM

When you start grinding, you need to think about many things. These things help you pick the best grinding wheel rpm. Each thing changes how your grinding wheels work and how safe you stay. Let’s see what matters most.

Wheel Diameter

Wheel diameter is very important for picking rpm. Bigger wheels need lower rpm to stay safe. If you use a big wheel with high rpm, it can be dangerous. You might go past the safe speed. This can break the wheel or cause accidents.

You can use a simple math formula to find the right rpm:

n = (Vc * 1000) / (π * d)

Where:

n = spindle speed (rpm)

Vc = peripheral speed (m/s)

d = wheel diameter (mm)

π ≈ 3.14

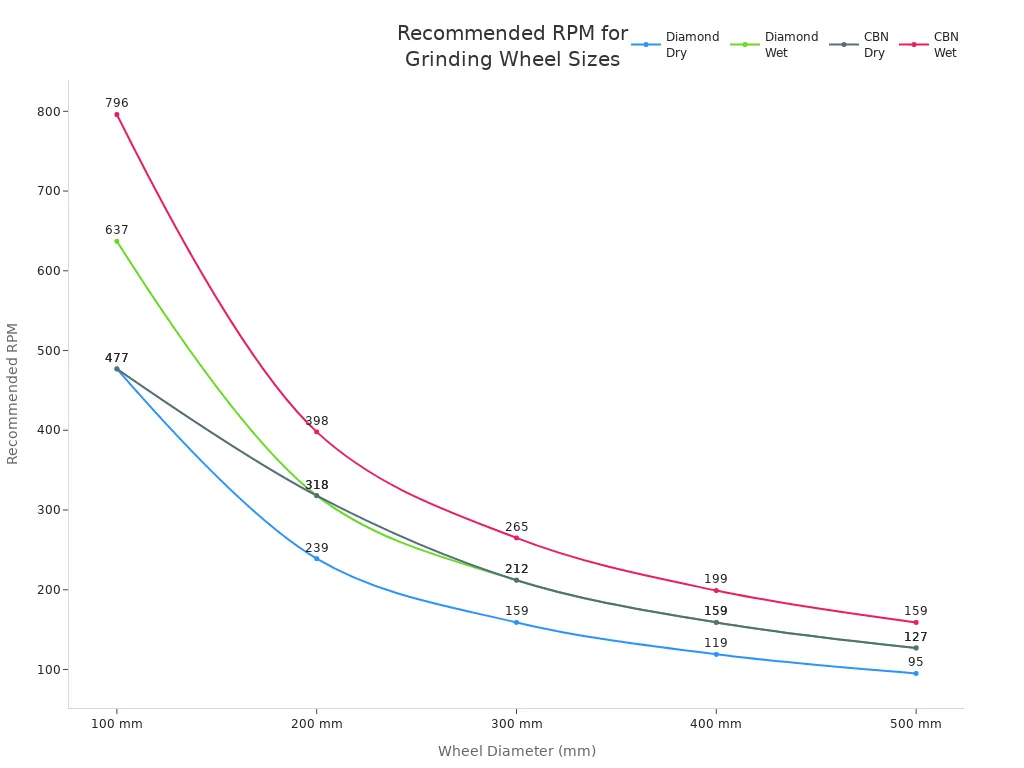

Manufacturers give different rpm numbers for each wheel size and material. The table below shows speed ranges for diamond and CBN grinding wheels:

Abrasive Material | Dry Speed Range (m/s) | Wet Speed Range (m/s) |

|---|---|---|

Diamond | 15 to 20 | 20 to 40 |

CBN | 15 to 30 | 25 to 50 |

Note: If you use vitrified bonds on ceramic bodies, do not go over 35 m/s. For faster speeds, use aluminum wheel bodies.

Wheel diameter and material change the rpm you pick. Always look at the maximum rpm marked on your grinding wheels before you start.

Wheel Material

The grinding wheel material changes how fast you can use it. Super-abrasive wheels like diamond and CBN can run faster and cooler than aluminum oxide wheels. The bond type also matters. Vitrified wheels keep their shape but need lower rpm. Resinoid bonded wheels work safely at higher rpm and are less likely to break.

Super-abrasive wheels (diamond, CBN) can use higher rpm and cut better.

Vitrified wheels need lower rpm for safety.

Resinoid wheels work well with higher rpm and heavy cutting.

Safety tip: Never go past the maximum safe speed marked on your wheel. This keeps you safe and your wheel working well.

Machine Horsepower

Machine horsepower tells you how hard you can use your grinding wheels. More horsepower lets you take off more material and use higher rpm. If your grinder does not have enough power, you can hurt your part or bend it. Heavy cutting needs more horsepower, but you must match this with the wheel’s maximum rpm and grinding conditions.

Grinding works best when you balance grinding power, grinding ratio, and specific energy. You can use spindle motor load meters and listen to machine sounds to check if your wheel speed matches your machine’s horsepower. If you push the wheel too hard, you may see bad parts or rough surfaces.

Core Material and Construction

The wheel’s core material and how it is made affect safety and how well it works. Ceramic bodies with vitrified bonds should not go above 35 m/s. Aluminum wheel bodies can go faster and cut better. The bond type and abrasive material decide the wheel’s strength and how fast it wears out.

Vitrified wheels are strong but can break at high rpm.

Resinoid wheels work safely at higher rpm.

Super-abrasive wheels cost more but run cooler and faster.

Always check the manufacturer’s rules for your grinding wheels. Books like the “Handbook of Machining with Grinding Wheels” and “Grinding Technology” by Stephen Malkin and Changsheng Guo give good advice on rpm and grinding wheel performance.

Common Factors That Affect Ideal Grinding Wheel RPM

Wheel diameter

Wheel material and bond type

Machine horsepower

Core material and wheel construction

How hard you grind

Feed rate and workpiece hardness

Safety limits and maximum rpm

You need to balance all these things to pick the best grinding wheel rpm for your job. This helps you get good cuts, longer wheel life, and safe grinding.

SFPM and Surface Feet Per Minute

What Is SFPM

When you work with grinding machines, you often hear about sfpm. SFPM stands for surface feet per minute. This number tells you how fast the edge of your grinding wheel moves past the workpiece. You measure sfpm by looking at the speed of the wheel rim as it touches the material. This is called the wheel rim speed.

You use sfpm to check if your grinding wheel is running at the right speed. If you keep sfpm in the correct range, you get better results. You avoid burning, glazing, or even breaking the wheel. The formula to find sfpm is:

SFPM = 0.262 × Diameter (in inches) × RPM

You can see that both the wheel diameter and the rpm matter. If you use a bigger wheel or spin it faster, the sfpm goes up. Always check the recommended sfpm for your grinding wheel. For example, vitrified wheels work well up to 6,500 sfpm, and sometimes up to 12,000 sfpm. Resinoid wheels can go up to 16,500 sfpm. Knowing the right sfpm helps you pick the best wheel and bond for your job.

Tip: Always stay within the safe sfpm range for your grinding wheel. This keeps your work safe and your finish smooth.

Relationship Between RPM and SFPM

You need to understand how rpm and sfpm connect. Rpm tells you how many times the wheel spins in one minute. Sfpm tells you how fast the wheel’s edge moves. The two are linked by the wheel’s diameter. If you keep the rpm the same but use a bigger wheel, the sfpm increases. If you use a smaller wheel, the sfpm drops.

The formula that links them is:

SFPM = (π × Diameter in inches × RPM) / 12

Or, you can use a simple version:

SFPM ≈ (Diameter in inches × RPM) / 4

This means that for the same rpm, a larger wheel gives you a higher sfpm. You must always check both the rpm and the wheel size to keep the sfpm in the ideal range. If you ignore sfpm, you might run the wheel too fast or too slow. This can cause poor grinding, bad finishes, or even safety problems.

Note: Always adjust your rpm when you change wheel sizes. This keeps your sfpm steady and your grinding results consistent.

Calculating RPM from SFPM

You can also work backwards. If you know the sfpm you want, you can find the right rpm for your grinding wheel. This helps you set up your machine for the best results. The formula is:

RPM = (SFPM × 12) / (π × Wheel Diameter in inches)

Let’s look at an example. If you want a sfpm of 2,500 and your wheel is 13.25 inches in diameter, you use the formula:

RPM = (2,500 × 12) / (13.25 × π) ≈ 721 RPM

This tells you to set your machine to about 721 rpm to reach your target sfpm. You can use this method for any wheel size or sfpm. Always check the wheel’s maximum safe rpm before you start.

Best Practices for Achieving Ideal SFPM

You want to keep your sfpm in the ideal range for your grinding job. Here are some best practices:

Use the formula: SFPM = RPM × 0.262 × Diameter (in inches) to find your current sfpm.

Adjust your rpm or wheel size to match the material and finish you need.

Pick the right belt grit and type for your grinding task.

Keep your belt or wheel tight to avoid slipping and keep sfpm steady.

Use a motor that can hold the rpm you need without getting too hot.

Change your grinder speed during work to balance heat and wear.

Practice and experience help you set the best rpm and sfpm for each job.

Machines with variable speed controls make it easier to reach your ideal sfpm.

Callout: Keeping your sfpm in the right range helps you get a smooth finish, avoid burning, and make your grinding wheels last longer.

Why Maintaining Correct SFPM Matters

You must keep your sfpm at the right level for good grinding. If your sfpm is too high, you risk burning the workpiece or breaking the wheel. If your sfpm is too low, you get rough surfaces and slow cutting. The ideal sfpm gives you the best balance of speed, finish, and safety.

Wheel Type | Typical SFPM Range |

|---|---|

Vitrified Bond | Up to 6,500 |

Vitrified Bond (max) | Up to 12,000 |

Resinoid Bond | Up to 16,500 |

Always check the manufacturer’s sfpm limits for your grinding wheels. This helps you avoid problems and keeps your grinding safe and effective.

Remember: The right sfpm is the key to quality grinding. Always calculate and adjust your rpm to reach your target sfpm before you start.

Consequences of Incorrect Grinding Wheel RPM

Poor Surface Finish

If you use the wrong grinding wheel RPM, your workpiece looks bad. You might see spiral lines or deep scratches on the surface. The grinding wheel does not cut evenly at the wrong speed. This causes many problems you can notice:

The surface gets uneven marks and spiral lines.

Cracks and broken spots show up more often.

Scratches look bigger when you use a microscope.

Cracks under the surface go deeper and make polishing harder.

When you match the grinding wheel speed with the workpiece speed, you get a smoother finish. There are fewer cracks. The best results come from picking the right speed for both the wheel and the workpiece.

Wheel Wear and Form Loss

Wrong RPM makes your grinding wheel wear out faster. It can also lose its shape. If you run the wheel too fast or too slow, you get more defects. The wheel does not last as long. Studies say the best RPM is between 2000 and 2500 rpm. This helps you avoid these problems. If you use a lower feed rate, you should also lower the RPM. This stops extra wear. If you do not follow these tips, your wheel wears unevenly and loses its shape. Your machine does not work as well. You might hear more noise and feel more shaking. This means your machine needs more repairs.

Safety Hazards

Safety is always most important when grinding. If you go over the maximum RPM, it is very dangerous. The wheel can break or even explode. Pieces can fly off and hurt someone badly. Rules like ANSI B7.1 say you must follow safety steps:

Always check your machine’s speed matches the wheel’s maximum RPM.

Use guards to protect yourself from sparks and broken wheels.

Store wheels safely and keep them dry.

⚠️ If you ignore safety, you can have accidents or damage your machine. You could even get hurt badly. Always follow the rules and manufacturer’s safety tips to keep everyone safe.

You make machining better and safer by picking the right grinding wheel RPM. Studies show that using the right wheel speed for your material and machine stops bad finishes and fast wear. You can watch the RPM with tools like tachometers, spindle controllers, or IoT sensors. These tools give you updates while you work. To help your grinding work well, try these steps:

Look at the wheel’s top speed before you start grinding.

Change the RPM with speed controls or by hand.

Check and clean your wheels often so they stay sharp.

Always think about RPM and SFPM when you grind. This gives you steady results and helps your machine last longer.

FAQ

What happens if you exceed the maximum rpm on a grinding wheel?

If you use a wheel faster than its top rpm, it can break. This is very dangerous and can hurt people. Always look at the wheel’s safe speed before you start grinding.

How do you calculate the ideal grinding wheel rpm for your application?

You can use this math formula:

RPM = (sfpm × 12) / (π × wheel diameter in inches)

This formula helps you pick the best rpm for your wheel size and how fast you want the edge to move.

Why does sfpm matter in grinding operations?

Sfpm means how fast the edge of the wheel moves. Keeping sfpm at the right number gives you a smoother finish. It also helps you cut faster and makes your wheel last longer.

What safety considerations should you follow during a grinding operation?

Always check your wheel for cracks before you use it. Use guards to protect yourself. Never go over the wheel’s top safe speed. Wear eye protection and keep your area clean. These steps help stop accidents and make grinding better.

Does machine horsepower affect grinding wheel rpm?

Yes. If your machine has more horsepower, you can use higher rpm and take off more material. But you still need to stay under the wheel’s top rpm to keep things safe and working well.

See Also

Finding The Most Affordable Crankshaft Grinding Wheel Options

Selecting The Ideal Metal Grinding Wheel For Your Work

Determining The Best Grinding Wheel Dresser For Your Needs

Choosing The Perfect Grinding Wheel For Stainless Steel Tasks

Contact Us

For More Grinding Solution or Customized Abrasive Tools