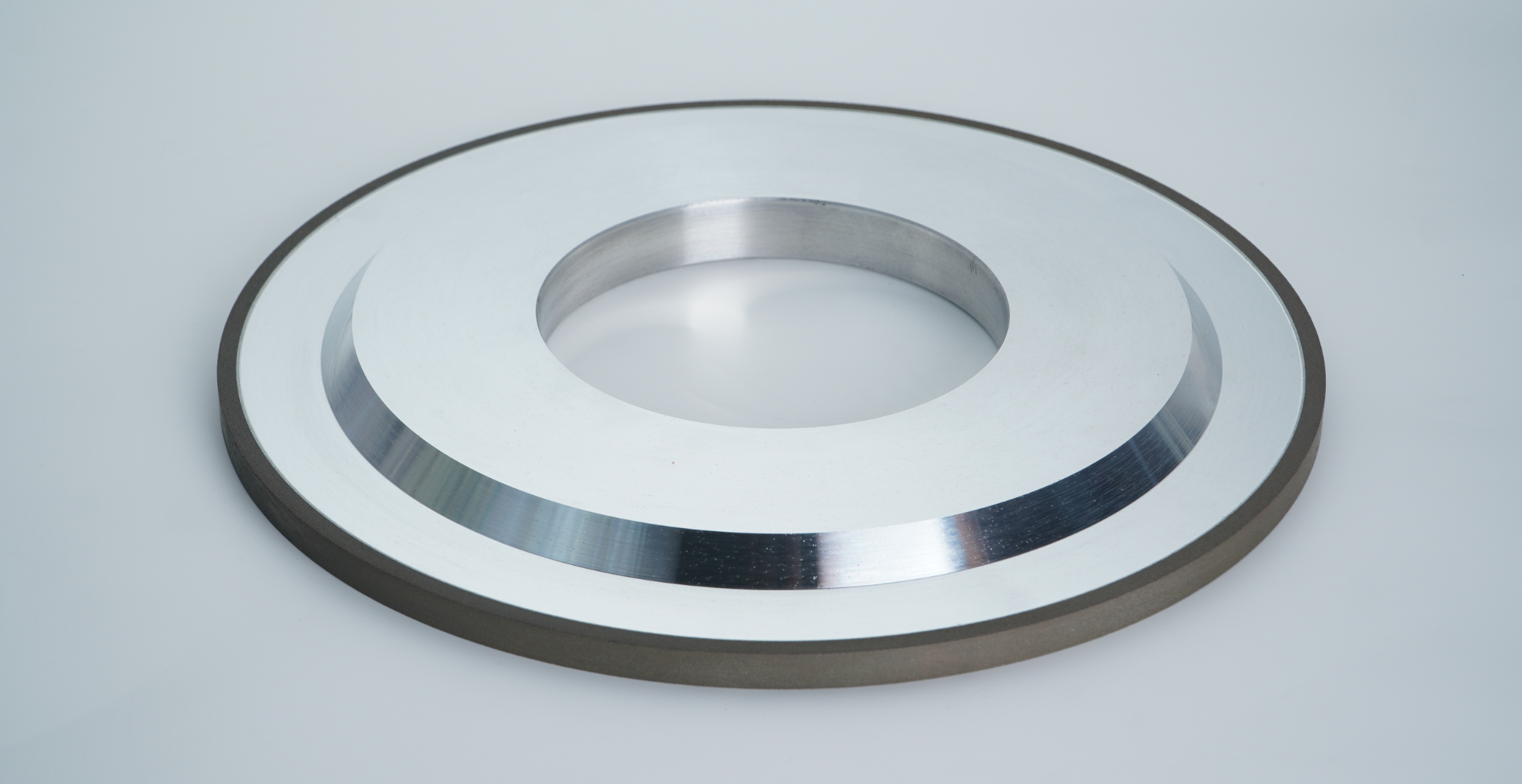

Grinding wheel performance relies on many important factors. These include abrasive material, grain size, wheel structure, bonding strength, and how the wheel is used. Studies show that grinding speed and feed rate can change the surface finish. They also affect how long the tool lasts. Knowing about these factors helps people work better and make better products. Simple steps for each factor can help find the best solution for each grinding job.

Key Takeaways

Picking the right grinding wheel depends on what you are working on, the abrasive type, and the wheel structure. This helps you get a good finish and makes the tool last longer.

Good grinding settings like wheel speed, feed rate, and pressure help control heat. They also affect how smooth the surface is and how fast the wheel wears out. This keeps grinding steady and efficient.

Using the right coolant and putting it on the right way keeps the wheel cool. It also helps the wheel last longer and makes grinding more accurate and safe.

Machine power, alignment, and the workshop environment can change how stable grinding is and how long the wheel lasts. Checking these things often and keeping the workshop in good shape helps keep grinding working well.

Doing regular maintenance, installing the wheel the right way, balancing it, and having a skilled operator are all important. These steps stop the wheel from getting damaged, keep people safe, and help get the same good results every time.

Key Influencing Factors

Grinding wheel performance is affected by several important things. Each one changes how well and safely the grinding works. Knowing about these things helps people get smoother finishes and longer tool life. It also helps them get the same results every time. The next parts explain the most important things before talking about them more.

Workpiece Material

The material being ground is very important for grinding wheel performance. Different materials have different hardness, toughness, and makeup. These things change how the wheel touches the surface. Harder materials make grinding forces and wear go up. Softer materials can clog the wheel and fill the abrasive grains. For example, steel does not bend easily but can make machines work harder. Aluminum spreads heat well but can lose accuracy because it grows when hot. The table below shows how different materials change grinding and wear:

Core Material | Key Properties Affecting Grinding Performance | Impact on Wear and Efficiency |

|---|---|---|

Steel | High stiffness, low mechanical expansion, heavy weight | Resists deformation under high grinding forces, but heavy weight can strain machinery and reduce efficiency. |

Aluminum | Lightweight, high thermal conductivity, higher thermal expansion | Good heat dissipation improves wheel life; thermal expansion may reduce precision in tight tolerance work. |

Copper | Excellent thermal conductivity, high stiffness, heavy and costly | Efficient heat removal reduces wear; weight and cost limit use in large wheels. |

Ceramic | Lightweight, low expansion, brittle, low thermal conductivity | Maintains dimensional stability but may suffer from brittleness and heat buildup affecting wheel life. |

Resin Composites | Lightweight, low stiffness, low thermal conductivity | Prone to expansion and heat buildup, reducing efficiency in high-force grinding. |

Carbon Fiber | High stiffness, lightweight, traps heat, expensive | Ideal for demanding applications needing precision; heat retention can affect wheel wear if not managed well. |

Choosing the right grinding wheel for the material helps avoid fast wear or bad finishing.

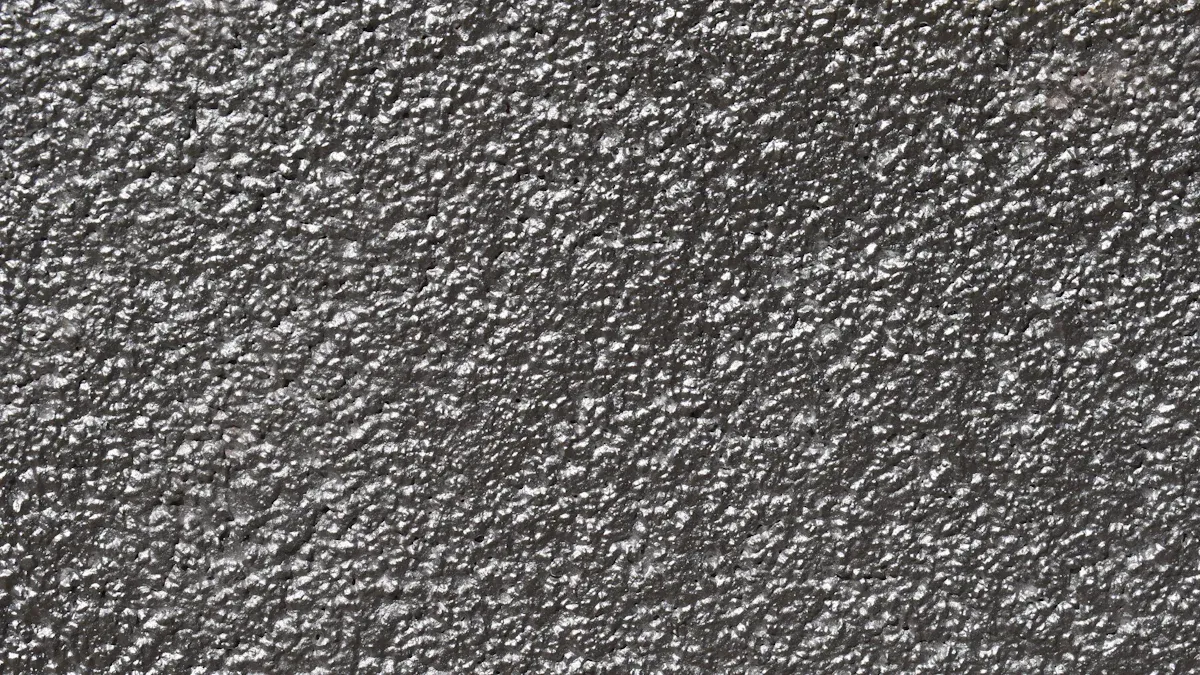

Abrasive Grain Type

Abrasive grain type is a big part of what makes a grinding wheel work. Common types are aluminum oxide, silicon carbide, diamond, and CBN. Each type cuts differently and lasts a different amount of time. Diamond grains cut hard things well. Aluminum oxide works best on steel. How tough the grains are and how they are held together affects self-sharpening. The shape and size of the grains change how well the wheel cuts, how smooth the finish is, and how long the wheel lasts. If grains wear out too fast, grinding gets harder and hotter, and the tool does not last as long. Picking the right grain type helps the wheel work best for each job.

Wheel Structure

Wheel structure means how the grains, bonding, and pores are arranged. Porosity and density are important for scratching and finishing. Open pores help chips leave and let coolant flow. This stops the wheel from getting clogged and too hot. Wheels with more pores sharpen themselves better and are easier to dress, but they might not be as strong. New ways to make wheels let people control pore size and where they are. This helps make the best wheel for each material. A good wheel structure keeps the wheel strong, cool, and able to remove chips, so grinding stays steady.

Grinding Parameters

Grinding parameters like wheel speed, feed rate, and depth of cut change how well the wheel works and how smooth the finish is. The best settings give a better finish and make the tool last longer. For example, a wheel speed of 1400 r.p.m. often gives the best results. Changing how deep or fast you grind can make a big difference. Surface grinding usually makes smoother surfaces than cylindrical grinding because there is less shaking. Changing the grinding settings helps control how much material is removed, how good the surface is, and how fast the wheel wears out.

Coolant and Lubrication

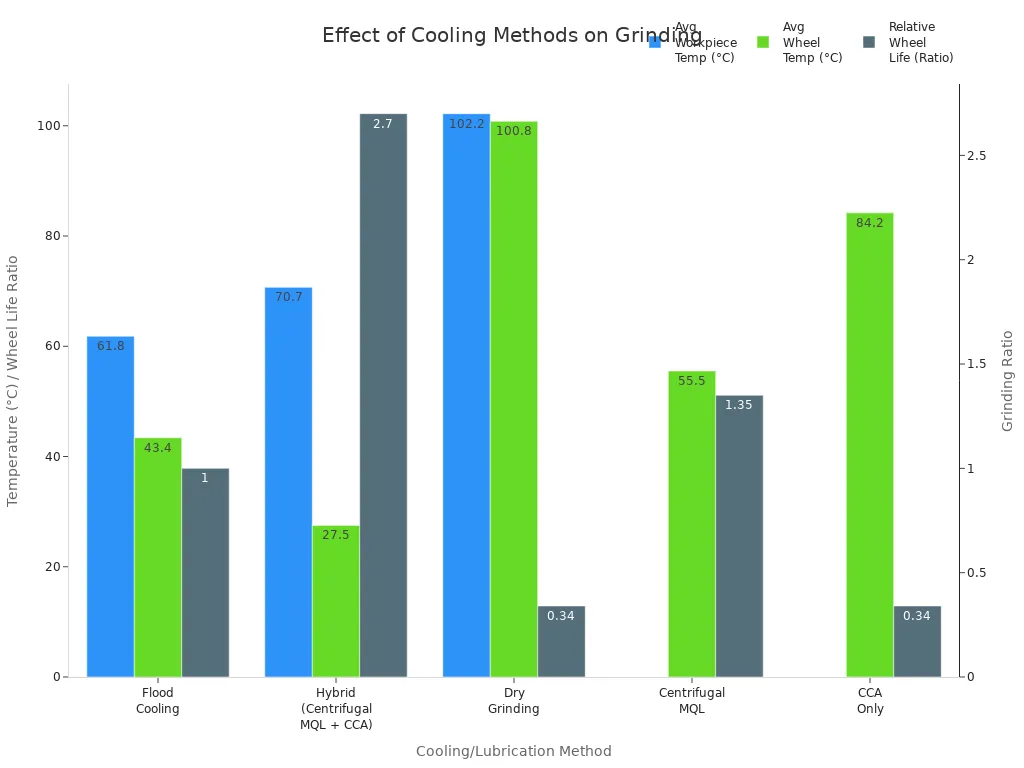

Coolant and lubrication are very important for keeping the wheel cool and making it last longer. Using the right cooling fluid and putting it on the right way lowers the heat and stops damage from getting too hot. The table below compares different ways to cool and lubricate:

Cooling/Lubrication Method | Average Workpiece Temperature (°C) | Average Grinding Wheel Temperature (°C) | Relative Wheel Life (Grinding Ratio) | Notes on Performance |

|---|---|---|---|---|

Flood Cooling | 61.8 | 43.4 | Baseline (1x) | Lowest temperatures; moderate wheel life (15 rings) |

Hybrid (Centrifugal MQL + CCA) | 70.7 | 27.5 | ~2.7x flood and centrifugal MQL; 8x CCA only/dry | Longest wheel life (40 rings); reduced grinding wheel temperature by ~50% vs dry grinding |

Centrifugal MQL | 152.4 – 170.9 (range) | 55.5 | ~1/2 of hybrid | Higher temperatures; shorter wheel life than hybrid |

CCA Only | 152.4 – 170.9 (range) | 84.2 | Much shorter than hybrid | Higher grinding wheel temperature; short wheel life |

Dry Grinding | 102.2 | 100.8 | Shortest wheel life | Highest temperatures; poorest durability |

The hybrid method keeps the wheel cooler and makes it last the longest. Dry grinding gets the hottest and makes the tool wear out fastest.

Machine Power

Machine power and how steady it is change how well the grinding wheel works. More powerful machines can handle harder materials and deeper cuts. Machines that are lined up right and do not shake make smoother finishes and help the wheel last longer. The machine must fit the grinding job to keep results the same.

Environmental Conditions

Environmental conditions like temperature, humidity, dust, and air flow affect how well and safely the wheel works. High temperatures make wheels get bigger, which can mess up balance and lower performance. Humidity makes coolants work worse and can hurt the wheel. Dust and water can block the wheel’s pores, making it cut less well and causing health problems. Storing wheels in cool, dry places and having good air flow helps them last longer.

Tip: Use dust collectors and dehumidifiers to keep the area safe and protect both the machines and people.

Wheel Loading

Wheel loading happens when material from the workpiece sticks to or fills the abrasive grains. This makes the wheel grind less well and raises the force and heat. It can happen because of chips sticking, getting stuck, or being pressed into the wheel. How you grind and the settings you use also change wheel loading. Too much loading causes shaking, heat damage, and faster wear. Dressing the wheel often brings back its grinding ability and keeps it working well.

Installation and Balancing

Installing and balancing the wheel the right way is needed for safe and steady grinding. Here are the steps to do it right:

Clean the flanges, arbor, and wheel hub to get rid of dirt.

Use flanges that match and check for any damage.

Tighten the nuts evenly so the wheel does not bend.

Put the wheel on gently so it is even.

Use a balancing arbor to find heavy spots and fix them.

Add balance weights if needed.

For very exact work, use a dynamic balancer.

Check the balance again after dressing and while using it.

Always wear safety gear and look for damage.

Doing these steps stops shaking, uneven wear, and accidents, so the grinding wheel works its best.

Workpiece Material Impact

Material Hardness

How hard the material is changes how grinding works. If the workpiece is hard, the grinding wheel must push harder. This makes the wheel wear out faster. Harder materials often need wheels with smaller grit. Smaller grit helps make the surface smoother. A hard grinding wheel can make the finish better. It can also lower rough spots and stress. But if the speed or coolant is wrong, the wheel can wear out quickly. Softer materials can block the wheel. When this happens, grinding does not work as well. The surface can look bad. Workers need to pick the right wheel hardness. They also need to think about how much material to remove and how smooth they want the surface. This helps keep grinding fast and good.

Note: How hard the wheel is and how hard the material is will change the finish and how long the wheel lasts.

Key points to remember:

Harder materials need wheels with smaller grit for smooth surfaces.

Softer materials can block the wheel and make grinding worse.

Changing wheel hardness and grinding settings helps control wear and finish.

Material Composition

What the workpiece is made of also matters a lot. Different materials work best with certain abrasive grains and wheel types. For example, steel and steel alloys use aluminum oxide or zirconia alumina. Cast iron and metals that are not iron need silicon carbide. Hard and brittle materials do better with small grit and soft wheels. This lets old grains break off and new ones cut. Softer and bendy materials need bigger grit and harder wheels. This helps remove more material faster.

A table can help show the best wheels for each material:

Workpiece Material Type | Recommended Abrasive | Grit Size | Wheel Grade | Bond Type |

|---|---|---|---|---|

Steel/Alloy | Aluminum Oxide | Fine | Soft | Vitrified |

Cast Iron | Silicon Carbide | Medium | Medium | Vitrified |

Non-Ferrous Metals | Silicon Carbide | Coarse | Hard | Resin/Rubber |

Ceramics | Diamond/CBN | Fine | Soft | Vitrified/Resin |

Picking the right wheel for the material gives better surfaces and makes the wheel last longer. Knowing what changes scratching and grinding helps workers choose the best way to do each job.

Abrasive Type and Wheel Structure

Abrasive Grain Selection

Choosing the right abrasive grain depends on the job and material. Each abrasive works best for certain materials. Aluminum oxide is good for strong metals. Zirconia alumina is used for tough jobs on metals. Silicon carbide works well on soft or non-metal materials. Each grain type changes how fast it cuts and how smooth the finish is. Grain size matters too. Big grains take off more material but make rougher surfaces. Small grains make smoother finishes but work slower. The table below shows what to look for when picking an abrasive:

Criteria | Description & Role in Selection |

|---|---|

Type of Abrasive | Aluminum oxide for alloys; ceramic and zirconia for ferrous metals; silicon carbide for softer woods and non-ferrous metals. |

Grit Size | Coarse grits for heavy removal; fine grits for finishing. |

Wheel Shape | Cylinder, cup, straight, and mounted wheels suit different jobs. |

Coating Type | Open or closed coatings affect loading and cutting. |

Grade (Bond Hardness) | Soft bonds for hard materials; hard bonds for soft materials. |

Backing Type | Cloth, paper, or plastic film changes flexibility and durability. |

Application Factors | Material type, removal amount, speed, and machine power guide selection. |

Resin and Binder Formulation

The bond holds the abrasive grains together in the wheel. Resin bonds are strong and bend easily. They let the wheel grind fast and handle heavy work. Resin bonds help the wheel stay sharp and cool. Fillers like graphite can make the finish better. Metal bonds are tough and resist heat. Vitrified bonds keep their shape and are stiff. Silicone resin binders make wheels stronger and handle heat better. These things help the wheel last longer and work well in hard jobs. Resin bond wheels also do not load up or wear out fast.

Resin bonds are flexible and strong.

Metal bonds last long and resist heat.

Vitrified bonds keep their shape and sharpen themselves.

Resin bond wheels spread abrasive grains evenly and clean themselves.

Wheel Hardness and Grade

Wheel hardness and grade show how well the wheel holds its grains. Hard wheels keep grains longer, which is good for soft materials. Soft wheels let old grains break off, which helps with hard materials. Picking the right hardness makes grinding better and helps the wheel last longer. Hard abrasives like diamond or CBN are best for hard materials. Aluminum oxide is good for medium-hard materials. Softer abrasives work for soft materials. The bond type, like vitrified or resin, also changes how well the wheel works and lasts.

Tip: Always pick the right wheel hardness for the material to get the best results and make the wheel last longer.

Grain Size and Spacing

Grain size and spacing change how much the wheel removes and the finish it leaves. Big grains cut fast but make rough surfaces. Small grains make smooth finishes but remove less. Open wheel structure has more space between grains. This lets chips leave and allows deeper cuts. Closed structure packs grains close together for a finer finish. Changing grain size and spacing helps balance how fast you remove material and how smooth the surface is. The wheel structure must fit the job to stop overheating and bad finishes.

Grinding Parameters and Performance

Grinding parameters are very important for how well the grinding wheel works. Workers need to control wheel speed, feed rate, grinding pressure, and depth of cut. These things help get the best results. Each one changes how much material is removed, how smooth the surface is, and how long the wheel lasts.

Wheel Speed

Wheel speed means how fast the grinding wheel spins. Faster wheel speed can make grinding better. It can make cracks smaller and help remove material smoothly, especially for hard things like ceramics. For example, if you make the wheel go from 30 m/s to 40 m/s, cracks can get much smaller. The crack depth can go from 18.4 μm to 7.6 μm. This happens because faster speed makes the grinding hotter. More heat makes the material tougher and stops cracks. If you make the wheel go faster but keep the depth and feed rate the same, grinding force and roughness go down. This makes the work more accurate. But if you also remove more material and make the wheel go faster, grinding force and heat go up. This can make the surface worse and wear out the tool faster. Workers should use more coolant and watch the process to keep things cool when grinding fast.

Wheel Speed Change | Effect on Performance |

|---|---|

Increase only | Makes cracks smaller, improves accuracy |

Increase + removal rate | Makes force and heat go up, may hurt quality |

Feed Rate

Feed rate is how fast the workpiece moves into the grinding wheel. This changes how accurate the grinding is, how fast the wheel wears out, and how smooth the surface looks. If you use a higher feed rate, you can take off more material quickly. This helps get the job done faster. But it can make the surface less smooth and less exact. Workers need to balance feed rate with wheel speed and depth of cut. This keeps grinding steady and good. Changing feed rate helps control how fast the wheel wears out and keeps grinding working well.

Feed rate decides how much material is taken off.

High feed rate makes work faster but can make the finish worse.

Picking the right feed rate keeps grinding accurate and helps the wheel last longer.

Grinding Pressure

Grinding pressure is the push between the wheel and the workpiece. This changes how strong the surface is, how much stress is left inside, and how hard the surface feels. If grinding pressure is high, heat goes up. This can make the surface softer and cause stress that pulls the material apart. Lower pressure or using different wheels can make stress that pushes the material together. This helps the part last longer. Workers should pick grinding pressure carefully. This helps control how rough the surface is, how hard it is, and how much damage is under the surface. Balancing grinding pressure with wheel speed and depth of cut makes grinding work better and helps the wheel last longer.

Tip: Always check grinding pressure and change it with other settings. This helps keep the surface strong and stops damage.

Coolant Use and Effects

Grinding makes a lot of heat. Using the right coolant helps keep things cool. It also lowers friction and helps the grinding wheel last longer. The workpiece lasts longer too. Picking the right coolant and how to use it is important. This helps get good results and stops damage.

Types of Coolants

Shops use different coolants for grinding. Each one works best with certain wheels and materials.

Oil-based coolants give strong lubrication. They work well with high-speed steel and carbide wheels. These coolants lower heat and let you remove more material. They also stop cobalt from leaking out of tungsten carbide.

Water-miscible coolants are good at cooling. They cost less but need more care to stop bacteria. These coolants work for surface and profile grinding. But they are not good for superabrasive wheels.

Diamond and CBN wheels need clean coolant. Clean coolant stops heat damage and helps the wheel last longer. Dirty coolant can make the wheel overheat and wear out. This gives a rough finish and makes grinding less efficient.

The best coolant depends on the job, the wheel, and what the customer wants.

Application Methods

How coolant is used changes how well grinding works. Good coolant flow washes away chips and dirt. This stops the wheel from getting clogged. It keeps the abrasive surface sharp.

Coherent-jet nozzles that match wheel speed help coolant get in. They break the air around the wheel. This cools better and makes the wheel last longer.

Pressure, flow, and direction all matter. High pressure and the right direction help coolant reach the grinding area. Shops should set up nozzles the best way.

Checking coolant strength often keeps cooling good. It also stops the coolant from getting dirty.

Tip: Good coolant flow and nozzle setup mean you do not have to dress the wheel as much. You can also remove more material without hurting the wheel.

Cooling Efficiency

Cooling efficiency shows how well coolant controls heat. Only some of the coolant cools the grinding area. Shops can make cooling better by matching jet speed to wheel speed. Scrapers can also help by breaking the air around the wheel.

Good cooling means:

Lower temperatures for the workpiece and wheel

Less heat damage

Longer wheel life

Better cutting accuracy

Picking the right coolant and using it well keeps grinding steady and productive.

Machine Power and Stability

Spindle Horsepower

Spindle horsepower is very important for grinding wheels. Machines with more horsepower can do harder jobs. They can also use harder wheels and stronger abrasive grains. The extra power helps break old grains and keeps the wheel sharp. This makes grinding work better and helps the wheel last longer.

More spindle horsepower lets you use harder wheels and grains. This makes grinding more stable.

Harder wheels keep their shape and last longer when pushed hard.

Machines with less horsepower cannot break down the wheel well. Dull grains stay on and can burn or damage the surface.

Softer wheels and grains that break easily are better for weak machines. These wheels let go of dull grains fast and keep grinding working well.

Spindle horsepower changes what wheel bond and grain you should pick. This changes how long the wheel lasts and how good the grinding is.

Tip: Always pick a grinding wheel that matches your machine’s horsepower. This gives the best results and stops damage.

Machine Alignment

Machine alignment is important for good grinding and wheel life. Good alignment keeps grinding steady and results the same each time. If machines are not lined up right, many problems can happen:

Bad or broken spindle bearings make the machine shake. This gives rough surfaces and wears out the wheel faster.

Coolant systems that are not lined up or are dirty make the wheel hot. This makes the wheel wear out faster.

Bad clamping makes the machine shake and move. This can bend the wheel.

Belt drive problems make the wheel spin unevenly. This causes rough grinding and more wheel wear.

Checking and fixing alignment often stops uneven wear and keeps grinding accurate.

Operators should check the work rest blade, the angle of the regulating wheel, and where the grinding wheel sits. Good alignment holds the workpiece steady and keeps grinding forces even. Bad alignment can make parts the wrong size and cause more waste. Checking and fixing alignment often helps keep grinding good and makes the wheel last longer.

Note: Good alignment saves money, makes machines work better, and gives better grinding results.

Environmental and Operational Factors

Temperature and Humidity

Temperature and humidity are very important for grinding wheels. If it gets too hot, the wheel can get bigger. This can make the wheel shake and not spin evenly. When this happens, grinding is not as accurate and the finish looks worse. Humidity can hurt both the wheel and the coolant. Too much water in the air can make resin or vitrified wheels weak. These wheels might break or wear out faster. Humid air also makes the coolant work less well. This means more heat and the wheel wears out quicker.

Operators should keep grinding wheels in cool, dry places. They should not put wheels in sunlight or wet spots. Using air conditioning or heaters helps keep the workshop steady. Checking the temperature and humidity helps grinding stay the same and makes wheels last longer.

Factor | Impact on Grinding Wheel | Recommended Action |

|---|---|---|

High Temperature | Wheel gets bigger, shakes more | Use air conditioning, check wheel size |

High Humidity | Wheel gets weak, coolant works worse | Keep wheels dry, check coolant often |

Tip: Always use gauges to check the workshop’s temperature and humidity. This helps stop problems with grinding.

Operator Skill

Operator skill is very important for grinding wheels. Good operators watch the workpieces and see problems fast. They take out bad parts so quality stays high and there is less waste. Operators use gauges to check sizes and make changes quickly. This helps lower mistakes and makes machines work better. Good metalworking skills help parts meet tough rules and standards.

Good operators find problems early and keep things working right.

They change machine settings using correct measurements, so there are fewer mistakes.

Their skills mean fewer bad parts and better grinding wheel use.

A trained operator keeps grinding running well. They know how to set up the machine, use coolant, and take care of equipment. Training and practice help operators learn new things and stay good at their jobs.

Note: Training operators makes products better, stops delays, and helps grinding wheels last longer.

Wheel Loading and Maintenance

Causes of Wheel Loading

Wheel loading happens when bits from the workpiece stick to the wheel. This blocks the abrasive grains and makes cutting harder. Soft metals like aluminum and copper cause this problem a lot. They smear and fill the wheel’s pores. Grinding fast or using slow wheel speeds makes loading worse. Operators see loading when the wheel stops cutting well and starts to shake. Bad coolant flow and wrong grinding pressure also make loading worse. When loading happens, grinding gets harder and the wheel wears out faster.

Preventing Clogging

Operators can stop wheel loading by picking the right wheel for each job. Wheels with open spaces let chips escape and lower loading. Dressing the wheel often shows new abrasive grains and clears clogged spots. Using good coolant and lubrication keeps the wheel cool and washes away dirt. Changing grinding speed and pressure helps control loading. Shops should not grind soft metals with wheels made for hard materials. Good care and setup lower the chance of wheel loading and keep grinding working well.

Tip: Check and dress the wheel often to stop loading and help it last longer.

Maintenance Practices

Good maintenance keeps grinding wheels safe and working well. Operators do these things to help wheels last longer:

Look at wheels before using them for cracks or chips.

Pick wheels with the right grit, hardness, and material.

Handle wheels gently and store them in dry places.

Dress wheels often to keep their shape and cutting power.

Use steady force when grinding to avoid uneven surfaces.

Run wheels at the right speed to stop overheating.

Follow maker rules and check wheels regularly.

Shops use better cooling and lubrication to stop heat damage and clear away dirt. Learning about new abrasive materials and wheel designs helps wheels last longer. Operators set the best grinding speed, feed rate, and pressure to make wheels last. These steps lower wheel loading and keep grinding steady.

Installation, Balancing, and Safety

Proper Installation

Putting a grinding wheel on the right way keeps everyone safe. Operators need to look for cracks or chips before putting the wheel on. They should clean the spindle, flanges, and where the wheel goes to get rid of dust. Using flanges that match helps spread out the pressure. Operators should tighten the nut by hand, not too tight, so the wheel does not break. They must follow the maker’s rules for which way to put the wheel on and how fast it can spin. After putting the wheel on, operators should let it spin at working speed for at least one minute before using it. This helps find any hidden problems.

Tip: Always keep grinding wheels in a dry, safe place so they do not get damaged before use.

Wheel Balancing

Balancing the wheel stops shaking and makes the finish better. If the wheel is not balanced, it can wear out unevenly, make noise, or even cause accidents. Operators should use a balancing arbor or stand to check the wheel before using it. They can put small weights on the lighter side to make it even. For very careful work, dynamic balancing might be needed. Balanced wheels spin smoothly and last longer. Checking balance often helps keep the wheel working well.

Steps for Wheel Balancing:

Put the wheel on a balancing arbor.

Set the arbor on a balancing stand.

Turn the wheel and let it stop.

Mark the heavy side.

Add weights to the other side.

Do this again until the wheel stays level.

Safety Checks

Safety checks keep people and machines safe. Operators must wear safety goggles, gloves, and hearing protection. They should check that guards and shields are in place and tight. Before starting, operators must make sure the wheel matches the machine’s speed. They should never use a wheel that looks damaged. Emergency stops and fire extinguishers should be easy to reach in the grinding area.

Safety Gear | Purpose |

|---|---|

Safety goggles | Keep eyes safe from flying bits |

Gloves | Protect hands from sparks |

Hearing protection | Make loud sounds quieter |

Note: Training on safety helps everyone remember the best ways to work and lowers the chance of accidents.

Choosing a Grinding Wheel

Selection Criteria

Picking a grinding wheel takes careful thought about many things. The right wheel makes the finish better and helps tools last longer. It also keeps the surface even each time. Operators should check the grinding wheel specification for every job. Here are some things to think about:

Material Being Ground: The workpiece type and how hard it is decide the abrasive grain and bond. For example, aluminum oxide is good for steel. Silicon carbide works for non-ferrous metals.

Required Finish and Precision: Finer grit and harder bonds help make smooth surfaces and tight fits. For very exact work, vitrified or metal bonds are best.

Grinding Pressure: High pressure jobs need tougher grains and harder grades. Softer grades and friable grains work for lighter pressure.

Wheel Speed and Machine Power: The wheel must fit the machine’s speed and horsepower. Vitrified bonds work at higher speeds. Resin bonds are better for lower speeds.

Coolant Use: Coolant changes how hard the wheel acts. Vitrified wheels act softer with coolant. Organic wheels act harder with coolant.

Economic Factors: Operators should think about how long the wheel lasts and its cost. Metal and vitrified bonds may last longer and need fewer changes.

A table can help show which wheel is best for each job:

Wheel Type | Best Use Case | Bond Type | Finish Quality |

|---|---|---|---|

Metal Bond | Rough grinding, hard materials | Metal | Moderate |

Vitrified Bond | Precision, dimensional accuracy | Vitrified | High |

Electroplated | Fine finishing, intricate profiles | Electroplated | Very High |

Tip: Always pick the grinding wheel specification that matches the material and the finish you want.

Common Mistakes

Sometimes operators make mistakes when picking a grinding wheel. These mistakes can make the surface look bad, wear out the wheel fast, or even hurt the machine.

Not thinking about the workpiece material and picking the wrong abrasive grain.

Forgetting about the finish needed and choosing the wrong grit size.

Not matching the wheel to the machine’s speed or power.

Using a wheel not made for the job, which can make the surface uneven.

Not using coolant or picking a wheel that does not work well with the coolant.

Operators should always check the grinding wheel specification and think about all the important points. Careful picking stops costly mistakes and makes the finish and surface better.

Balancing Conflicting Factors

Trade-offs in Performance

Grinding wheel performance often involves making choices between different goals. Operators may want a wheel that lasts a long time, but they also want a smooth surface finish. Hard wheels can last longer, but they may not give the best finish. Soft wheels can create a better finish, but they wear out faster. High wheel speed can remove material quickly, but it can also cause more heat and wear. Lower speed keeps the wheel cooler, but it slows down the process.

A table can help show some common trade-offs:

Goal | Benefit | Possible Drawback |

|---|---|---|

Long wheel life | Fewer wheel changes | Rougher surface finish |

Fast material removal | Higher productivity | More heat, faster wear |

Smooth finish | Better part quality | Slower grinding, more wheel changes |

Operators must decide which goal is most important for each job. They should consider the workpiece, the machine, and the desired result.

Optimization Strategies

Shops can use several strategies to balance these trade-offs. They can test different wheels and settings to find the best mix of speed, finish, and wheel life. Adjusting wheel speed, feed rate, and pressure helps control heat and wear. Using the right coolant and applying it well can keep the wheel cool and extend its life. Regular wheel dressing keeps the cutting surface sharp and reduces loading.

Operators can follow these steps for better results:

Test wheels with different hardness and grit sizes.

Adjust grinding parameters to match the job.

Monitor wheel wear and surface finish.

Use coolant systems that match the grinding process.

Train operators to spot problems early.

Careful monitoring and small changes can help shops get the best performance from their grinding wheels.

Grinding wheel performance is affected by many things. If operators know about these things, they can make tools last longer. They can also get a better finish on the workpiece. Picking the right wheel and checking the process often helps keep the finish the same. Teams should keep looking at how they work and make changes to get the finish they want.

Always trying to get better makes work safer and helps everyone get more done.

Check grinding settings often.

Pick wheels that fit the material and the finish you need.

FAQ

What causes a grinding wheel to wear out quickly?

A grinding wheel wears out fast if the wrong abrasive is used. High grinding speed can also make it wear quickly. Poor coolant flow makes the wheel get hot and wear faster. Heavy grinding pressure pushes the wheel too hard. Checking the wheel often helps stop early wear. Picking the right wheel for the job helps it last longer.

How does wheel balancing improve grinding results?

Balancing the wheel stops vibration and loud noise. A balanced wheel cuts smoother and lasts longer. Operators see better finishes and fewer mistakes. Shops use special tools to check and fix wheel balance before grinding.

Which coolant works best for grinding wheels?

Water-miscible coolants cool the grinding area well and cost less. Oil-based coolants help with tough jobs by giving more lubrication. Diamond and CBN wheels need clean coolant to keep from getting too hot. Operators pick coolant based on the wheel and the grinding job.

What safety steps should operators follow when installing a grinding wheel?

Operators look for cracks or chips before putting the wheel on. They clean flanges and spindles to remove dirt. Matching flanges are used for safety. Nuts are tightened by hand, not too tight. Safety goggles, gloves, and shields keep workers safe during setup and grinding.

See Also

Selecting The Best Metal Grinding Wheel For Your Needs

Different Grinding Wheel Varieties And Their Uses Explained

Finding The Ideal Grinding Wheel Dresser For Your Work

Choosing The Perfect Grinding Wheel For Stainless Steel Tasks

Contact Us

For More Grinding Solution or Customized Abrasive Tools