When you pick a Grinding Wheel for Stainless Steel, choose ones made with ceramic alumina or high-density zirconia. These wheels deal with heat well and work fast. They also give you clean results. Stainless steel can be hard to work with. It can get harder as you grind it. It is sensitive to heat and can get dirty easily. You need to use the right grinding wheel for your job and the type of stainless steel. Always pick contaminant-free wheels made for stainless steel. This stops rust and keeps your work strong.

Key Takeaways

-

Pick grinding wheels made with ceramic alumina or high-density zirconia. These wheels cut fast and stay cool. They also give a clean finish on stainless steel. – Use wheels that say they are for stainless steel only. This stops contamination that can cause rust. It also keeps your work strong. – Choose softer bonds and open-structure wheels. These help control heat and stop clogging. They make grinding smooth and safe. – Match the grit size to your job. Use coarse grits to remove material fast. Use medium grits to smooth the surface. Use fine grits to polish and make it shine. – Always use coolant and wear the right safety gear. Dress your wheels often to keep them working well. This helps your wheels last longer and gives better results.

Stainless Steel Grinding Challenges

Material Properties

When you grind stainless steel, you face some special problems. This is because stainless steel has different material properties than carbon steel. The table below shows how stainless steel and carbon steel are not the same:

|

Material Property |

Stainless Steel |

Carbon Steel |

|---|---|---|

|

Chromium Content |

High (≥10.5%), forms corrosion-resistant oxide layer |

Low, prone to oxidation and rust |

|

Alloying Elements |

Includes nickel, manganese, affecting ductility and hardness |

Primarily iron and carbon, simpler alloying |

|

Hardness |

Varies; martensitic grades have high hardness but low ductility |

Generally higher tensile strength and hardness in high-carbon grades |

|

Corrosion Resistance |

High, due to chromium oxide layer |

Low, susceptible to rust and oxidation |

|

Work Hardening Tendency |

High, increases toughness and grinding difficulty |

Lower, easier to grind |

|

Thermal Conductivity |

Lower, leading to heat buildup during grinding |

Higher, dissipates heat better |

Stainless steel has more chromium and other elements. These things help it fight rust and make it strong. But they also make grinding harder. Stainless steel gets harder fast when you grind it. This makes your job more difficult. It does not move heat away well. So, heat builds up in the grinding spot. Too much heat can hurt your workpiece and your grinding wheel.

Tip: Always use coolants or lubricants when grinding stainless steel. This keeps things cool and helps your grinding wheel last longer.

Common Issues

When you grind stainless steel, you might have some problems:

-

Stainless steel is tough, so it takes longer to grind than softer metals.

-

Heat builds up fast and can bend your workpiece or cause carbide precipitation. This can make the steel less resistant to rust.

-

Grinding wheels can get clogged with stainless steel bits. This makes grinding slower and can be unsafe.

You should watch for these problems and change how you grind if needed. Using the right wheel and keeping things cool will help you avoid most of these issues.

Grinding Wheel for Stainless Steel

Abrasive Types

When picking a Grinding Wheel for Stainless Steel, you should look at the abrasive material. The right abrasive helps you cut faster and keeps the metal cool. It also gives you a smooth finish. Ceramic alumina and high-density zirconia are the best choices. These abrasives stay sharp longer and handle heat better than aluminum oxide. Some wheels, like FIRESTORM II CERAMIC and FIRESTORM EXTREME ‘Actirox’, use special ceramic grains. These grains remove more metal and leave fewer scratches. You get a cleaner and smoother surface with less work.

Diamond edge wheels, like Lenox MetalMax, last much longer than regular wheels. They keep their shape and size, so your cuts stay steady and exact. These wheels also make less dust and smell, which keeps your workspace cleaner.

Note: Always use contaminant-free wheels made for stainless steel. Wheels with iron, chlorine, or sulfur can hurt the protective layer on your metal. This can cause rust and make your work weaker.

You should not use silicon carbide wheels. They do not cut stainless steel well and can burn or stain it. Never use a wheel that has touched carbon steel, because it can leave behind bad particles.

Here is a quick look at some common abrasive materials:

|

Abrasive Material |

Key Features |

Best Use for Stainless Steel |

|---|---|---|

|

Ceramic Alumina |

Self-sharpening, cool grinding, long life |

Heavy grinding, finishing |

|

Zirconia Alumina |

Aggressive, durable, good for tough jobs |

Stock removal, roughing |

|

Aluminum Oxide |

Economical, blends well, moderate performance |

Light grinding, general use |

|

Diamond Edge |

Longest life, precise, low dust |

Cutting, fine finishing |

Bond and Structure

The bond in a Grinding Wheel for Stainless Steel holds the abrasive grains together. The right bond helps you control heat and get a better finish. Resin bonds work well for most stainless steel jobs. They give a smooth grind and help grains come off quickly. This keeps the wheel cool and stops it from clogging. Metal bonds are stronger and last longer, but they can make more heat. Use them when you need a sharp cut and a long-lasting wheel.

Wheels with a porous or open structure let coolant reach the grinding area. This helps keep the metal cool and stops heat from building up. Porous wheels also stop the wheel from filling up with metal bits. You can dress the wheel often with a diamond dresser to keep it sharp and clean.

Tip: Pick a wheel with a softer bond for stainless steel. Softer bonds let grains come off faster, which helps control heat and keeps your work safe.

Here is a table to help you compare bond types:

|

Bond Type |

Features and Benefits |

Use for Stainless Steel |

|---|---|---|

|

Resin Bond |

Flexible, cool grinding, easy grain release |

General grinding, finishing |

|

Metal Bond |

Strong, precise, long life, more heat |

Precision grinding, long jobs |

|

Electroplated |

Thin, accurate, ultra-fine finish |

Delicate, high-quality finishing |

|

Rubber Bond |

Smooth action, good surface finish |

Light surface work |

Grit and Grade

Grit size and grade decide how rough or smooth your finish will be. Coarse grits, like 80 or 120, take off metal fast but leave a rough surface. Medium grits, like 150-180, balance speed and smoothness. Fine grits, like 220-320, give you a smooth finish. Very fine grits, like 400-600, make the metal shine.

For rough work, start with a medium grit, like 150 or 180. This helps you remove burrs and shape the metal without wearing out your wheel too fast. For finishing, use finer grits, like 240 or 320, to get a smooth, clean look. If you want a shiny surface, use 400 grit or higher.

The grade tells you how hard or soft the wheel is. Softer wheels work better for stainless steel. They stop the wheel from clogging and keep the metal from burning. If you use a wheel that is too hard, it can get too hot and hurt your work.

|

Grit Size |

Typical Use |

Surface Finish Quality |

|---|---|---|

|

150-180 |

Roughing, initial smoothing |

Moderate |

|

220-320 |

Finishing, fine smoothing |

Smooth |

|

400-600 |

Polishing, mirror finish |

Very smooth, reflective |

Alert: Always use coolant or lubricant when grinding stainless steel. This keeps the wheel cool and helps you get the best finish.

A Grinding Wheel for Stainless Steel with the right abrasive, bond, grit, and grade will help you work faster and safer. You will also get better results. Choose wheels labeled for stainless steel or “inox” to avoid contamination and keep your metal strong.

Wheel Types and Applications

Wheel Shapes

You can find many wheel shapes for grinding stainless steel. Each shape works best for certain jobs. The most common shapes are Type 1 (straight), Type 27 (depressed center), Type 28 (saucer), and Type 29 (flexible). These shapes help you handle different tasks like stock removal, weld smoothing, and grinding on flat or curved surfaces.

|

Wheel Type |

Description |

Typical Applications |

|---|---|---|

|

Type 1 (Straight) |

Flat and simple, used for general grinding |

Surface grinding, sharpening, cutting |

|

Type 27 (Depressed Center) |

Has a raised center for strength |

Heavy stock removal, rough grinding |

|

Type 28 (Saucer) |

Curved like a saucer, good for low angles |

Beveling, weld smoothing |

|

Type 29 (Flexible) |

Slightly curved, bends over surfaces |

Blending, finishing, curved surfaces |

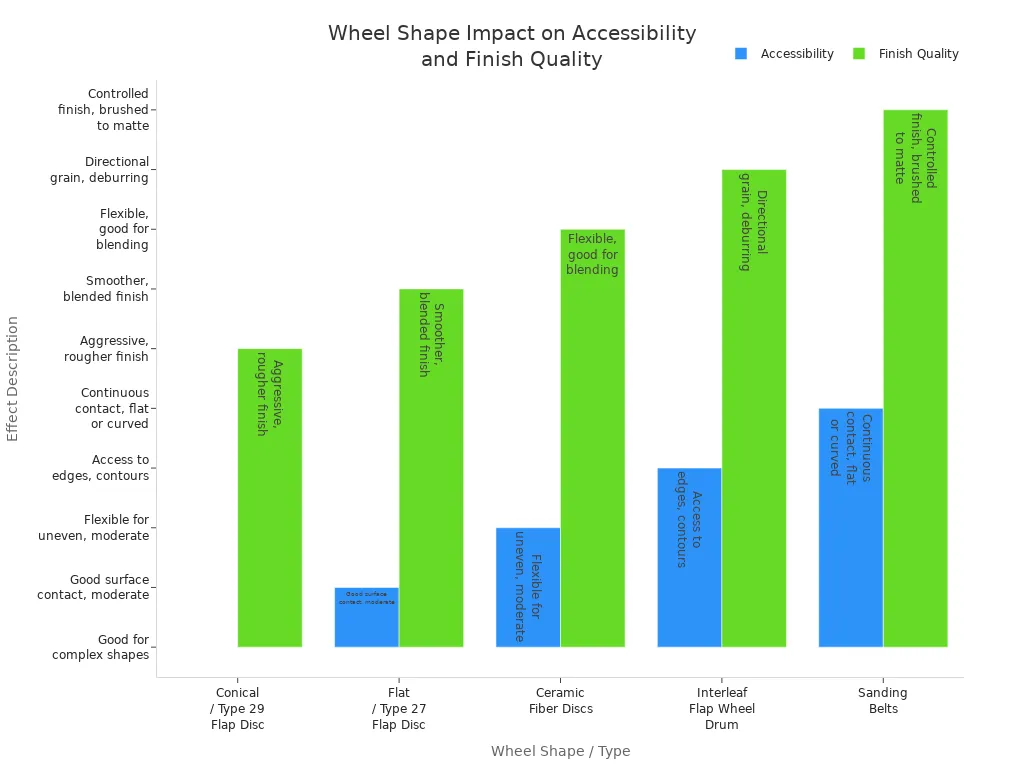

Some wheels, like Type 29 flap discs, help you reach tricky spots and shape parts before welding. Type 27 wheels work well for grinding flat areas and removing lots of metal fast. Multi-granular wheels, which mix different grain sizes, give you a smoother finish and help the wheel last longer. You can see how different wheel shapes affect accessibility and finish quality in the chart below:

Operation-Specific Choices

You should always match your wheel choice to your task. For weld removal, use a Grinding Wheel for Stainless Steel with ceramic or zirconia grains. These grains cut fast and stay cool. For surface finishing, pick a finer grit and a flexible wheel like a Type 29 flap disc. This helps you get a smooth, even look.

Tip: Always use wheels labeled for stainless steel or “inox.” This prevents rust and keeps your work strong.

When you work on thin stainless steel, start with a finer grit to avoid grinding through the metal. For heavy jobs, use coarser grits and stronger wheels. Keep your grinder moving and use steady pressure. This stops heat from building up and keeps your finish clean. Flap wheels can save you time and money because they combine grinding and finishing in one step. They also make less dust and give you a smoother surface.

You can boost your productivity and lower costs by picking the right wheel for each job. Always keep separate wheels for stainless steel to avoid contamination from other metals.

Selection Guide

Assessing Needs

Before you choose a Grinding Wheel for Stainless Steel, you need to look at a few important things. Each job and each type of stainless steel needs a different approach. Here are the main points you should check:

-

Type of Stainless Steel

-

Austenitic (like 304 or 316) is tough and work-hardens fast.

-

Martensitic (like 410 or 440) is harder but less ductile.

-

Ferritic (like 430) is easier to grind but can be abrasive.

-

-

Abrasive Type

-

White corundum works well for martensitic and ferritic grades.

-

Single crystal corundum is best for austenitic grades because it stays sharp.

-

Ceramic grains and cubic boron nitride (CBN) offer high hardness and low heat, making them good for all grades.

-

-

Grit Size

-

Use a slightly coarser grit to stop the wheel from clogging.

-

Coarse grits remove material fast. Fine grits give a smooth finish.

-

-

Bond Type

-

Ceramic bonds give strength and resist heat.

-

Resin bonds help reduce surface roughness, especially for inner holes.

-

-

Wheel Hardness

-

Pick a wheel that is softer than what you use for regular steel.

-

If the wheel is too soft, it will wear out fast. If it is too hard, it can burn the metal.

-

-

Operation Details

-

Think about the speed of your grinder and the depth of your cuts.

-

Use a moderate speed to keep the wheel sharp and avoid burns.

-

Tip: Always use a wheel made for stainless steel. This helps prevent rust and keeps your work strong.

Step-by-Step Process

You can follow these steps to pick the right Grinding Wheel for Stainless Steel:

-

Clean the Workpiece

Make sure the stainless steel is free from oil, dirt, and other metals. This stops impurities from getting into your work. -

Pick the Abrasive Grain

Choose ceramic grains for tough jobs. They last long and handle heat well. For general work, alumina or white corundum also works. -

Start with a Coarse Grit

Use a 40-60 grit wheel for removing welds or shaping the metal. This step helps you get rid of rough spots quickly. -

Move to Medium Grit

Switch to 80-120 grit to smooth the surface after rough grinding. Flap discs work well for this step. -

Finish with Fine Grit

Use 150-220 grit for a smooth finish. For a mirror-like shine, go even finer. -

Match the Wheel to the Job

For thin sheets, start with a finer grit to avoid grinding through the metal. For heavy stock removal, use a coarser grit and a strong wheel. -

Grind Along the Grain

Always grind in the same direction as the grain of the stainless steel. This reduces scratches and gives a better finish. -

Choose Wet or Dry Grinding

Wet grinding is best for stainless steel. Coolant keeps the wheel and metal cool, extends wheel life, and gives a smoother finish. Dry grinding is faster but can cause more heat and rougher surfaces.Grinding Method

Advantages

Disadvantages

Wet Grinding

Less heat, longer wheel life, better finish

Needs coolant, more setup

Dry Grinding

Simple, quick setup

More heat, faster wheel wear, rougher finish

-

Use the Right Safety Gear

Wear gloves, goggles, and a dust mask. Grinding makes sparks and dust that can hurt you. -

Maintain Your Wheel

Dress your wheel often to keep it sharp. Store wheels in a dry place to stop them from breaking down.

Note: Always use a Grinding Wheel for Stainless Steel that is labeled “inox” or “stainless.” This keeps your work free from contamination.

By following these steps, you can match your wheel to your job, your equipment, and your stainless steel grade. You will get better results, save time, and keep your work safe.

Troubleshooting and Safety

Common Problems

When you grind stainless steel, some problems can happen. These problems can make your work harder and less safe. If you know about these issues, you can fix them fast.

|

Problem |

Root Cause |

Solution |

|---|---|---|

|

Contamination from carbon steel tools or dust |

Use dedicated tools and clean surfaces |

|

|

Scratches on surface |

Uneven abrasive grain size or debris |

Choose uniform abrasives and clean work area |

|

Wheel glazing or loading |

Wrong wheel hardness or clogged abrasives |

Dress the wheel and use correct hardness |

|

Excessive heat or discoloration |

High grinding speed or pressure |

Lower speed, use coolant, avoid heavy force |

|

Debris sticking to workpiece |

Grinding heat and improper technique |

Use coolant and smooth, steady motions |

Tip: Always use tools and wheels just for stainless steel. This stops rust and keeps your metal strong.

Rust spots can show up if you use tools that touched carbon steel. Iron dust in the air or dirty water can also cause rust. Clean your tools and workspace before you start working.

Best Practices

You can stop most problems and stay safe by following these tips:

-

Wear protective gear: Always wear gloves, goggles, and a dust mask. Make sure your safety gear fits and is not broken.

-

Use dedicated tools: Only use grinding wheels and brushes for stainless steel. Do not use them on other metals.

-

Check your grinding wheel: Look for cracks or damage before you use it. Replace any wheel that is worn or broken.

-

Store wheels properly: Keep grinding wheels in a dry, cool place. This stops them from getting wet or damaged.

-

Secure your workpiece: Use clamps to hold the metal still. This helps you control the grinder and avoid mistakes.

-

Maintain good technique: Start by pulling back, not pushing. Use smooth, steady moves and the right angle. Let the wheel do the work—do not push too hard.

-

Dress the wheel regularly: Clean and dress your wheel often. This keeps it sharp and stops it from getting clogged.

-

Keep your workspace clean: Remove dust and metal bits often. Good airflow helps get rid of dust and sparks.

Remember: Safe grinding keeps you and your stainless steel safe. Good habits help your work look better and last longer.

Choosing the right grinding wheel for stainless steel helps you get cleaner cuts, better finishes, and longer tool life. You need to match the wheel type, abrasive, and operation to your job. This choice controls heat, prevents rust, and keeps your work strong. Regular wheel maintenance also matters:

-

Dressing the wheel exposes fresh grains for smoother grinding.

-

Keeping the coolant system clean stops overheating.

-

Checking wheels often helps you avoid defects.

Test your wheels and adjust your machine settings for the best results every time.

FAQ

What is the best abrasive for grinding stainless steel?

You should use ceramic alumina or high-density zirconia abrasives. These materials stay sharp, cut fast, and handle heat well. They help you get a smooth finish and prevent damage to your stainless steel workpiece.

Can I use the same grinding wheel for stainless steel and carbon steel?

No, you should not. Using the same wheel can cause contamination. This can lead to rust on your stainless steel. Always keep separate wheels for each metal to protect your work.

Why does my grinding wheel clog when working on stainless steel?

Stainless steel can stick to the wheel because it is tough and generates heat. You can prevent this by using an open-structure wheel, applying coolant, and dressing the wheel often.

How do I avoid overheating stainless steel while grinding?

You should use a wheel with a soft bond and apply coolant. Keep your grinder moving and use light pressure. This helps you control heat and avoid discoloration or warping.

What safety gear do I need when grinding stainless steel?

Wear safety goggles, gloves, and a dust mask. You should also use hearing protection. These items protect you from sparks, dust, and loud noise during grinding.

Contact Us

For More Grinding Solution or Customized Abrasive Tools