Choosing the right grinding wheel is important for your project. There are many types. Each one is made for a certain grinding wheel application. For example, you can use a straight grinding wheel to sharpen tools. You can use a diamond wheel to work with hard materials. Here is a quick look at some common types:

|

Grinding Wheel Type |

Common Use |

|---|---|

|

Straight Grinding Wheels |

Sharpening tools and blades |

|

Grinding Cup Wheel |

Polishing stone or concrete |

|

Segmented Grinding Wheel |

Fast material removal |

|

Diamond Wheels |

Shaping hard materials |

Picking the right grinding wheel application keeps you safe. It also helps you get better results. It does not matter if you are new or have experience. Knowing your choices helps you do a better job.

Key Takeaways

-

Pick the right grinding wheel type and material for your project. This helps you get better results and stay safe.

-

Use aluminum oxide wheels for steel and hard metals. Use silicon carbide wheels for soft metals. Use diamond wheels for hard, brittle things like glass.

-

Look at the grinding wheel for cracks or damage before you use it. Change it if you see wear or hear strange sounds.

-

Wear safety gear like gloves, safety glasses, and dust masks. Always use the safety guard on your grinder.

-

Keep grinding wheels flat in a cool, dry place. Handle them gently so they stay safe and work well.

Quick Reference Table

Wheel Types and Applications

You can find many types of grinding wheels. Each one works best for certain jobs. The table below shows the most common types. You can see their shapes, best angles, and uses.

|

Wheel Type |

Description |

Profile and Shape |

Typical Grinding Angles |

Common Uses |

|---|---|---|---|---|

|

Type 1 |

Flat, straight toolroom wheel |

Flat, straight |

N/A (used mainly for snagging) |

Snagging, rough grinding, small diameter (2-4 inches) |

|

Type 27 |

Most common abrasive grinding wheel |

Flat with depressed center |

0 to 45 degrees (optimal 25 to 30 degrees) |

General grinding with clearance for angled work |

|

Type 28 |

Saucer wheel with concave depressed center |

Concave/saucer-shaped depressed center |

0 to 30 degrees (best 0 to 15 degrees) |

Access to tight areas, corners, fillets, low-angle grinding |

Tip: Always check the grinding wheel type before you start your project. The right choice helps you work faster and safer.

How to Use the Table

You can use this table to pick the best grinding wheel for your task. Here is how:

-

Look at the “Wheel Type” column. Find the type that matches your tool or project.

-

Read the “Description” and “Profile and Shape” columns. These tell you what the wheel looks like and how it fits your grinder.

-

Check the “Typical Grinding Angles.” This helps you set the right angle for your work.

-

See the “Common Uses” column. Make sure the grinding wheel fits your job, like rough grinding or working in tight spaces.

If you match your grinding wheel to your project, you get better results. You also keep yourself safe. Always use the table as a quick guide before you begin.

Types of Grinding Wheels by Shape

Straight Wheels

Straight wheels are the most common in workshops. They look like thick, flat discs. You use straight wheels to sharpen tools like chisels and lawnmower blades. These wheels are good for grinding flat surfaces. They also work on both outside and inside circles of metal and non-metal. Many industries use straight wheels for sharpening and grinding. You can pick different abrasive materials and bonds for your project. For example, aluminum oxide is for steel. Diamond is for hard, brittle materials.

-

Most basic and used type

-

Great for sharpening blades and chisels

-

Good for flat and round grinding

Tip: Straight wheels help you sharpen and shape tools with accuracy.

Cylinder Wheels

Cylinder wheels look like big, hollow tubes. You use them to grind flat surfaces on special grinders. These wheels do not have a hole in the center. You mount them on the edge instead. Cylinder wheels are strong and handle tough jobs. You often see them in big metal shops for fast material removal.

-

Best for large, flat surface grinding

-

Used in heavy industry

Cup Wheels

Cup wheels look like cups with flat faces and tall sides. You use cup wheels to polish stone or concrete. They also remove paint, glue, and coatings from surfaces. Cup wheels come in types like diamond resin bond, turbo, and double row. Each type does a special job, like fast cutting or fine grinding. Cup wheels are best for getting surfaces ready and finishing tasks.

-

Shine and polish stone or concrete

-

Remove paint, glue, and coatings

-

Prepare surfaces for new finishes

Note: Cup wheels work better than straight or dish wheels on big, flat areas and tough coatings.

Dish Wheels

Dish wheels look like shallow cups with thin edges. You use dish wheels to grind in slots or tight spaces. These wheels are great for careful work, like cutter and jig grinding. You also see them in car and airplane shops for engine parts. Dish wheels help smooth curved surfaces and reach hard spots.

-

Reach tight slots and crevices

-

Smooth curved surfaces

-

Used for tool and engine part grinding

Type 1, 27, and 29 Wheels

You will see Type 1, Type 27, and Type 29 wheels in many projects. Each type has its own shape and job.

|

Grinding Wheel Type |

Design Characteristics |

Typical Applications |

|---|---|---|

|

Type 1 (Straight) |

Flat, straight wheel. Made with fiberglass or steel rings and fine grits. |

Used for rough and fine grinding on steel, stainless steel, cast iron, aluminum, bronze, brass, concrete, stone, terrazzo, and ceramics. Works with angle, die, and bench grinders for sharpening tools. |

|

Type 27 (Depressed Center) |

Has a lowered center for mounting. Flat profile. Made for rough grinding and removing lots of material. |

Used in factories and construction for grinding castings, welds, and fixing metal problems. |

|

Type 29 (Conical/Angled Depressed Center) |

Has an angled center and bends over curves. |

Best for grinding curved surfaces, welds, blending, removing rust, and finishing flat or shaped surfaces. |

Tip: Pick the right type for your job. Type 1 is for general grinding. Type 27 is for tough jobs. Type 29 is for curved or shaped surfaces.

Types of Grinding Wheels by Material

Grinding wheels use different abrasive materials. Each one works best for certain jobs. You need to match the abrasive to your project for the best results.

-

Aluminum Oxide: Best for grinding strong metals like steel and iron. You use these wheels in metal shops, car repair, and woodworking. They help grind, polish, remove rust, and smooth welds.

-

Silicon Carbide: Hard and sharp but breaks easily. You use silicon carbide wheels for grinding soft metals like aluminum, copper, and brass. They also work for ceramics and other hard, brittle things.

-

Diamond: The hardest abrasive. You use diamond wheels for grinding hard things like ceramics, glass, and carbide. These wheels last long and give smooth finishes.

-

CBN (Cubic Boron Nitride): Almost as hard as diamond. You use CBN wheels for grinding hard steel. They last long and handle heat well.

Note: The bond that holds the abrasive together matters too. Vitrified bonds are strong and resist heat. Resinoid bonds are for rough grinding. Metal bonds are used with diamond wheels for special jobs.

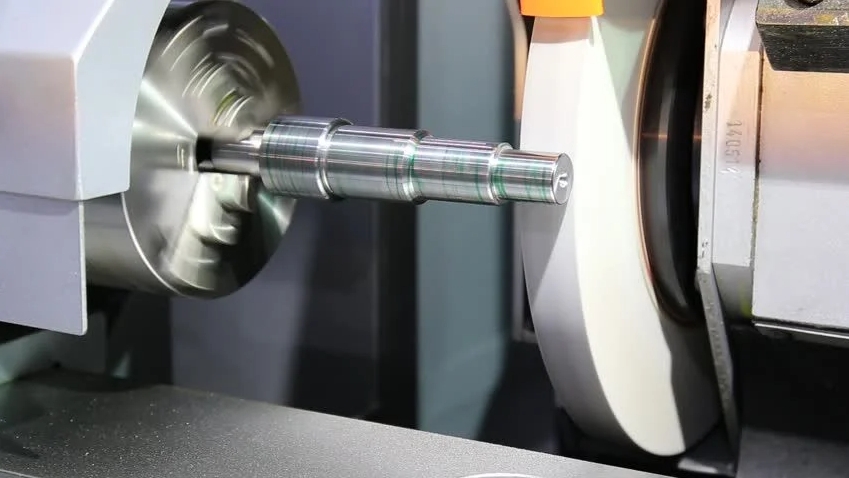

Diamond Wheels

Diamond wheels are the hardest and last the longest. You use them for grinding hard things like carbide, ceramics, and glass. Diamond wheels last longer and need less fixing. They also make less heat, so your work does not get damaged. You find diamond wheels in places like airplane, medical, and electronics shops where you need strong and precise tools.

-

Lasts long and is precise

-

Makes less heat and protects your work

CBN Wheels

CBN wheels use cubic boron nitride as the abrasive. You use CBN wheels for grinding hard steel. They cost less than diamond wheels but still last long. CBN wheels help you get smooth finishes and high accuracy. You see them in tool shops, car factories, and other places that grind tough metals.

-

Great for hard metals

-

Long life and steady work

-

Saves money for big jobs

Aluminum Oxide Grinding Wheels

Aluminum oxide wheels are very popular. You use them to grind and polish metal, remove rust, and smooth welds. They also work for sanding wood, taking off old paint, and getting surfaces ready. Aluminum oxide wheels are used in metal shops, car repair, and woodworking. You can use them for cutting, shaping, and getting surfaces ready.

-

Good for metal and wood jobs

-

Great for grinding, polishing, and prep

-

Used in many industries

Silicon Carbide Grinding Wheels

Silicon carbide wheels are harder and break easier than aluminum oxide. You use them for grinding soft metals like brass, copper, aluminum, and magnesium. They also work for ceramics and other hard, brittle things. Silicon carbide wheels cut fast and give a smooth finish. Their sharp grit makes them good for quick, careful grinding.

-

Best for soft metals and ceramics

-

Fast, careful grinding with smooth finish

-

Handles heat well for sensitive jobs

Specialty Wheels

Some jobs need special grinding wheels. These wheels have special shapes or materials for unique tasks.

-

Diamond Cup Wheels: Used for polishing stone and removing tough coatings. Come in big sizes for floor grinders and small ones for hand tools.

-

Diamond Dish Wheels: Made for grinding thin spots and tight holes. They help make smooth, even surfaces.

-

Diamond Segmented Wheels: Have lots of diamonds for smooth floor finishes. Come in different grit levels.

-

Tungsten-Carbide Wheels: Have carbide tips and slanted edges. You use them to take off thick layers without scratching stone.

-

Camshaft and Crankshaft Grinding Wheels: Used in making engines for rough to smooth grinding of steel parts.

-

Gear Grinding Wheels: Give high accuracy for grinding gears.

-

Microfinishing Wheels: Use tiny abrasives for even, repeatable finishes.

Tip: Special wheels help you do unique jobs, like polishing concrete or grinding gears. Always pick the right wheel for your job.

Grinding Wheel Applications

Metal Grinding

In shops and factories, you often grind steel or iron. For these jobs, pick a grinding wheel with aluminum oxide, ceramic alumina, or zirconia alumina. These abrasives cut hard metals and last long. Type 27 wheels are flat with a center dip and are good for most grinding. Type 28 wheels are curved and fit tight spaces or sharp angles. Cut-off wheels are best for cutting metal bars fast.

The bond that holds the abrasive grains is important. Vitrified bonds are strong and resist heat. Resin bonds help remove material quickly and absorb shocks. Check the table below for a quick guide:

|

Grinding Wheel Aspect |

Types / Examples |

Description / Application |

|---|---|---|

|

Vitrified, Resin, Silicate, Shellac, Rubber |

Vitrified bonds are strong and resist heat. Resin bonds remove material fast and absorb shocks. |

|

|

Abrasive Grains |

Aluminum Oxide, Ceramic Alumina, Zirconia Alumina, Silicon Carbide |

Aluminum oxide is best for steel and iron. Ceramic alumina gives high accuracy. Zirconia alumina is tough and self-sharpening. Silicon carbide cuts fast but is less tough. |

|

Wheel Design Types |

Type 27, Type 28 |

Type 27 is good for stock removal at 25-35° angles. Type 28 fits narrow spots and works at 0-15° angles. |

|

Functional Categories |

Cut-off wheels, Roughing wheels, Finishing wheels |

Cut-off wheels cut metal. Roughing wheels remove lots of material. Finishing wheels smooth the surface. |

Tip: Always match the grinding wheel application to the metal and job. Using the wrong wheel can give bad results or cause accidents.

Some people pick the wrong abrasive or bond. This can make the wheel overheat, wear out fast, or be unsafe. Always check your wheel before use and follow the instructions.

Non-Ferrous Materials

When you grind non-ferrous metals like aluminum or copper, you face new problems. These metals are soft and can clog the grinding wheel. For these jobs, silicon carbide wheels work best. They cut fast and do not clog as much. Pick wheels with open spaces and soft bonds to clear chips and keep things cool.

Here are mistakes you should avoid:

-

Do not use wheels that are too hard or have the wrong bond. This causes clogging, especially with aluminum.

-

Avoid wheels not made for non-ferrous metals. They wear out fast and grind poorly.

-

Watch out for heat. Too much heat can warp or crack the metal.

-

Do not use wheels with closed structures. These trap chips and cause overheating.

-

Always pick abrasives and bonds made for non-ferrous metals. Softer bonds and open structures work best.

Soft metals can clog the wheel. If you see this, stop and switch to a wheel made for non-ferrous work. This keeps your grinding wheel application safe and working well.

Hard and Brittle Materials

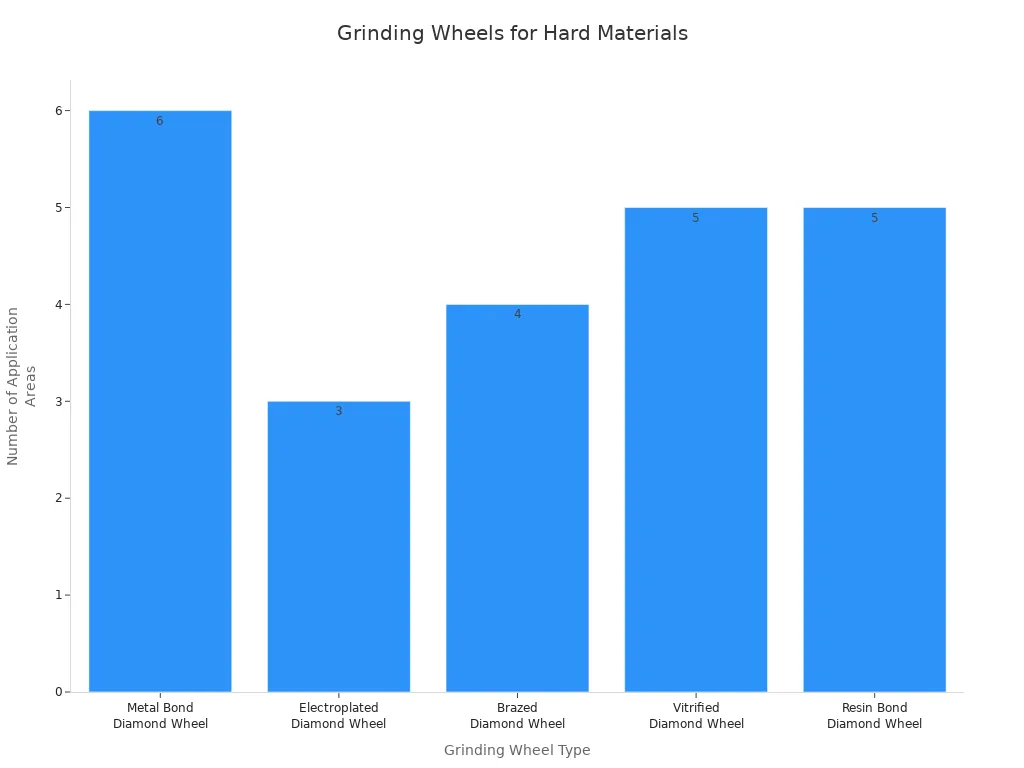

Grinding hard and brittle things like glass or ceramics needs special wheels. Diamond grinding wheels are the best choice. Diamond is the hardest material and stays sharp even in tough jobs. It also moves heat away, which protects your wheel and your project.

You can choose from different diamond wheel types:

|

Grinding Wheel Type |

Key Features |

Applications for Hard & Brittle Materials (Glass, Ceramics) |

|---|---|---|

|

Metal Bond Diamond Wheel |

High grinding efficiency, long life, keeps its shape, strong, resists heat |

General grinding of glass, ceramics, tile, stone, quartz |

|

Electroplated Diamond Wheel |

Strong, wears well, tough |

Precision grinding, drilling, chamfering glass panels |

|

Brazed Diamond Wheel |

Fast, high-speed grinding, lasts long |

Granite, marble, tile surface grinding, edge work |

|

Vitrified Diamond Wheel |

Very efficient, resists wear, low heat, high accuracy |

Precision grinding of glass, ceramics, stone, marble |

|

Resin Bond Diamond Wheel |

Runs smooth, high speed, strong |

Ceramics, glass, quartz industries; surface and fine grinding |

Note: Do not use CBN wheels for glass or ceramics. CBN is better for hard metals, not brittle things.

A common mistake is using the wrong wheel for hard, brittle materials. This can cause cracks or rough finishes. Always check the wheel type before starting your grinding wheel application.

Concrete and Masonry

Grinding concrete, brick, or stone needs tough wheels and careful steps. Diamond cup wheels are the best for these jobs. They cut hard surfaces and last a long time. Pick the right bond hardness for your concrete.

Follow these best practices:

-

Pick diamond tooling with the right bond for your concrete.

-

Spread sand on the slab to help open the diamond segments and remove residue.

-

Pre-soak the concrete to control heat and improve grinding.

-

Wear gloves, eye protection, and a dust mask.

-

Use multi-directional grinders to make your tooling last longer.

-

Add water to cool the surface, reduce dust, and help with cleanup.

-

If you are not sure, hire a trained professional to avoid damage.

Tip: Always use the correct grinding wheel for concrete or masonry. Using a metal or wood wheel can damage your tool and the surface.

Mistakes to avoid include using the wrong wheel, skipping safety gear, or grinding too fast. These errors can cause injury or ruin your project.

Precision Tool Grinding

Precision tool grinding needs special care. You want a smooth finish and exact shapes, especially for a cutting tool. For these jobs, cBN wheels work best. They handle hard tool steels and keep their shape. Use fine grit sizes for a better finish. Soft grade wheels work well for hard materials and slow grinding.

Check the table below for the best choices:

|

Parameter |

Recommendation for Precision Tool Grinding |

|---|---|

|

Abrasive Type |

Cubic Boron Nitride (cBN) superabrasive wheels preferred for tool steels. |

|

Grain Size |

Fine (small grit size) for better surface finish; higher grit numbers mean finer grains. |

|

Wheel Grade |

Soft grade wheels better for hard materials and low material removal rates. |

|

Bond Type |

Vitrified bonds preferred for precision finishing due to strength, rigidity, and coolant resistance; metal bonds also used for cBN wheels. |

|

Other Notes |

Aluminum oxide wheels less efficient and require frequent re-dressing; diamond wheels may be excessive; silicon carbide generally not recommended due to chemical incompatibility with steels. |

“Small grit sizes give smoother finishes. Bigger grains remove more material. You must choose between these goals when picking grit size. The hardness of your work also matters. Harder materials need smaller grains. Softer materials need bigger grains.”

“Vitrified bonds are made of baked clay and ceramic. Most grinding wheels use vitrified bonds. They are strong, resist heat, and are not affected by water or oil in grinding fluids.”

A common mistake is using aluminum oxide wheels for precision tool grinding. These wheels wear out fast and need frequent dressing. Diamond wheels may be too strong for steel tools, and silicon carbide does not work well with steel. Always choose cBN wheels with fine grit and vitrified bonds for the best results in your grinding wheel application.

Grinding Wheel Selection

Project Type

Think about your project before you pick a wheel. Every grinding job needs a special wheel. For rough jobs, zirconia alumina is a good choice. If you need to work on hard steel, use ceramic alumina. The wheel’s shape is important too. Straight wheels are best for flat things. Cup or cylinder wheels help with big areas. Always match the wheel’s shape and abrasive to your job.

-

Grit size

-

Bond type

-

Wheel composition

Tip: Pick these features to fit your project for the best results.

Material Compatibility

The thing you grind changes what wheel you need. Hard metals need softer bonds and bigger abrasives. Softer things do better with harder bonds and smaller grits. If you use the wrong wheel, you might get bad finishes or damage. Always check if your wheel fits the workpiece. Aluminum oxide is good for steel. Silicon carbide works better for non-ferrous metals.

-

Material compatibility changes how long the wheel lasts and the finish.

-

The right grit and bond make your results better.

-

Wet grinding helps keep things cool and controls dust.

Grit and Bond

Grit size and bond type decide how your wheel works. Coarse grits take off material fast but leave rough spots. Fine grits make things smooth. Vitrified bonds are strong and handle heat well. Resin bonds are bendy and good for fast, heavy jobs. Wheels with mixed grits can give both speed and a nice finish.

|

Grit Size |

Use Case |

Finish Quality |

|---|---|---|

|

Coarse |

Fast removal |

Rough |

|

Fine |

Smooth finish |

Smooth |

Finer grits and vitrified bonds give the best finish and tool life.

Wheel Shape and Angle

Wheel shape and angle change how well you grind. Steep angles give more pressure and control but can shake. Flat angles are more stable and make smoother surfaces. Pick the wheel shape that fits your workpiece. Conical wheels are for angles. Radial wheels are for curves.

-

Change the angle for the best results.

-

Check and set the angle before you start.

Common Selection Errors

People often make mistakes when picking grinding wheels. You might pick the wrong wheel, grit, or bond. This can cause shaking, clogging, burning, or even break the wheel. Other mistakes are using the wrong speed, skipping coolant, or not cleaning the wheel.

-

Wrong wheel for the job or material

-

Wrong grit size or bond

-

Bad speed or pressure

-

Not using coolant or cleaning the wheel

-

Storing or handling the wheel badly

Always follow the maker’s rules and check your wheel before you use it to avoid problems.

Grinding Wheel Safety and Maintenance

Safety Practices

You should always think about safety when using grinding wheels. First, read the user manual and safety rules for your tool. Wear PPE like gloves, safety glasses, a face shield, ear protection, and a dust mask. Always use the safety guard as it was made. Never take it off or change it. Hold your workpiece tight and stand steady while grinding. Before you start, run the tool for 30 seconds in a safe spot. This helps you check for strange shaking. Only use abrasives for what they are made for. Never go faster than the wheel’s top speed. Good airflow helps keep dust and fumes away.

Tip: Always look at your grinding wheel for cracks or damage before you use it. Change any broken parts right away.

Storage and Handling

Storing and handling your grinding wheels the right way helps them last longer.

-

Keep wheels in a cool, dry place away from water and heat.

-

Store wheels flat with good support so they do not bend.

-

Use the original box or a safe container to keep out dust and damage.

-

Be gentle when you move wheels. Do not drop or hit them on hard things.

-

Always wear safety gear when you handle grinding wheels.

Maintenance Tips

Taking care of your grinding wheels keeps them safe and working well.

-

Check wheels before each use for cracks, chips, or other damage.

-

Dress the wheel often to keep its shape and sharpness.

-

Use the right speed so the wheel does not get too hot.

-

Have a pro check your wheels every 6 to 12 months.

A wheel that is cared for works better and helps prevent accidents.

Signs of Wear

You should know when it is time to get a new grinding wheel. Watch for these signs:

-

Cracks, chips, or shiny spots on the wheel

-

The wheel is not the right shape or size anymore

-

Your workpiece looks rough or uneven

-

You feel more shaking or hear odd sounds

If you see any of these problems, stop using the wheel and get a new one. This keeps you safe and your work looking good.

Picking the right grinding wheel helps you finish jobs faster. It also keeps you safe while you work. You get better results if you use the right wheel for your project. Here are some important reasons:

-

The correct wheel makes grinding work better and keeps your workpiece safe.

-

Choosing well saves you time and money.

-

Being careful and checking your wheel stops accidents.

-

If you use this guide for every project, your work will look good and your workspace will be safe. Knowing about wheel types, materials, and how to care for them helps you get great results every time.

FAQ

What is the best way to store grinding wheels?

Store grinding wheels flat in a cool, dry place. Keep them away from water and heat. Use the original box or a safe container. Handle wheels gently to prevent cracks or chips.

How do you know when to replace a grinding wheel?

Check for cracks, chips, or odd sounds. If the wheel feels shaky or grinding takes longer, replace it. A worn or damaged wheel can break and cause injury.

Can you use one grinding wheel for all materials?

No, you should not. Each material needs a specific wheel. For example, use aluminum oxide for steel and diamond for glass. Using the wrong wheel can damage your work or cause safety issues.

Why does my grinding wheel clog up?

Soft metals like aluminum can clog wheels. Use a wheel made for non-ferrous metals. Pick a softer bond and open structure. Clean the wheel often to keep it working well.

What safety gear should you wear when grinding?

Wear safety glasses, gloves, a face shield, and a dust mask. Ear protection helps with loud noise. Always use the safety guard on your grinder.

Contact Us

For More Grinding Solution or Customized Abrasive Tools