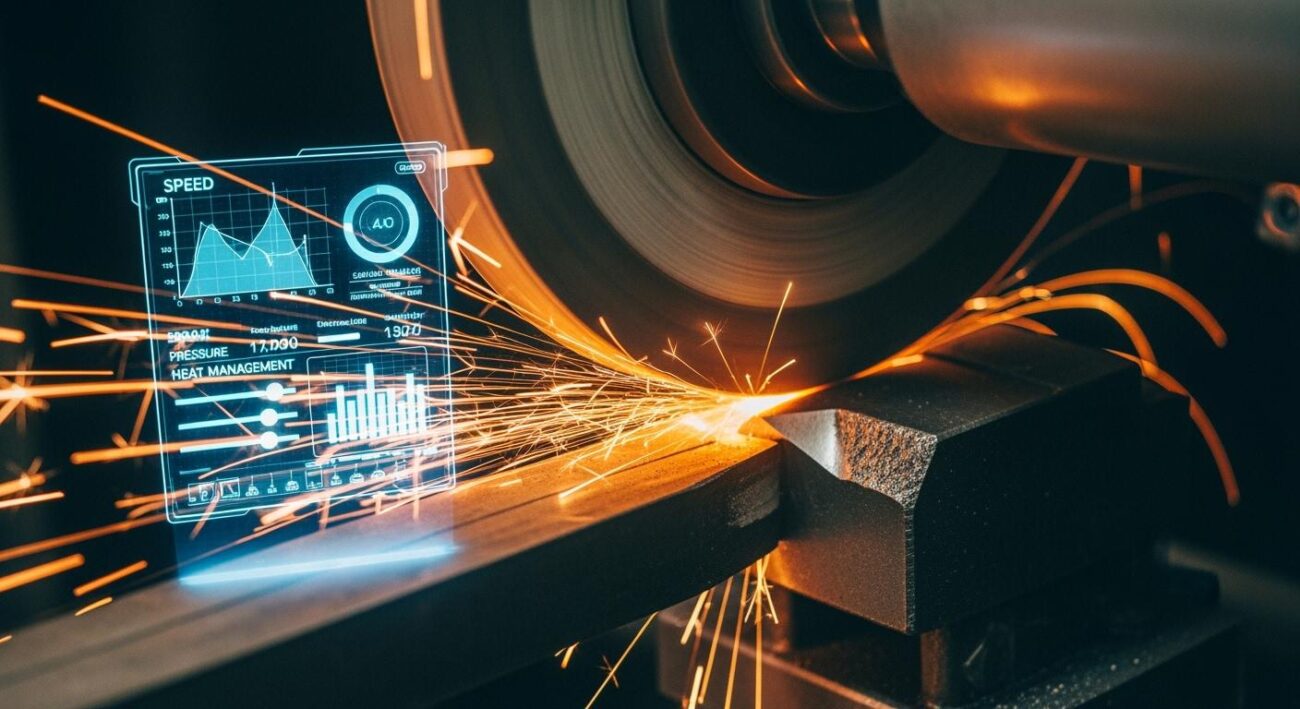

Friction during the grinding process creates excessive heat. This condition often results in grinding burn, a serious issue damaging the workpiece. The key causes of this burn are clear and directly related to the grinding setup.

Primary Factors Leading to Grinding Burn:

- Incorrect grinding parameters

- A poorly chosen grinding wheel

- Ineffective coolant application

Solutions require optimizing the grinding operation, selecting the correct grinding wheel, and implementing proper maintenance to prevent grinding burn.

Key Takeaways

- Grinding burn happens when too much heat builds up during grinding. This heat can damage the metal part.

- Incorrect settings, the wrong grinding wheel, or poor cooling cause grinding burn. These issues make the grinding process too hot.

- To stop grinding burn, adjust machine settings, pick the right grinding wheel, and use good coolant. Also, keep the grinding wheel clean and sharp.

- Special grinding wheels, like CBN wheels, help keep things cool. They pull heat away from the metal part, which prevents damage.

Uncovering the Key Causes of Grinding Heat

Nearly all energy used in a grinding operation transforms into heat, which becomes highly concentrated in the cutting zone. This intense thermal energy is a primary source of grinding problems. When not managed, it causes thermal damage, metallurgical changes, and visible defects on the workpiece. Understanding the key causes of this heat buildup is the first step toward prevention.

How Incorrect Parameters Cause Grinding Burn

The parameters of the grinding process directly control the amount of friction and energy generated. Setting them incorrectly is one of the most common key causes of grinding burn.

Wheel Speed: High-speed grinding can improve efficiency. However, it also significantly increases frictional heat.

The temperature at the contact surface between the grinding wheel and the workpiece rises rapidly, generating grinding heat.

This rapid temperature spike can easily lead to a burn. An incorrect speed can create defects and compromise the part’s integrity.Depth of Cut: A deep cut removes more material, but it also creates heavy loads. These loads can generate excessive heat and chip the cutting edges. This action can produce severe defects, including cracks that weaken the final product. The grinding process becomes less about precise cutting and more about forceful rubbing.

Feed Rate: An overly aggressive feed rate forces the abrasive grains to plow through the material instead of performing a clean cutting action. This plowing generates excess vibration and heat. The heat causes thermal expansion, which can lead to misalignment, more friction, and ultimately, a burn. This is a frequent cause of grinding cracks and a poor surface finish.

Improper Grinding Wheel Selection

Choosing the right grinding wheel is critical for a successful grinding operation. A mismatch between the wheel and the workpiece is another of the key causes of thermal damage.

A common issue is using a wheel with the wrong bond hardness. A grinding wheel that is too hard will not self-sharpen effectively. The abrasive grains become dull but do not break away to expose fresh, sharp grains. This dullness increases friction and raises the grinding temperature, which can cause a burn on the workpiece surface. This is a classic wheel not cutting scenario.

Another major source of grinding problems is a mismatch between the abrasive material and the workpiece. This is especially true when grinding materials with low thermal conductivity, like stainless steel or superalloys. These materials do not dissipate heat well. The heat builds up in the cutting zone and transfers back into the grinding wheel, which can lead to rapid wheel wear and workpiece defects. The result is often a poor surface finish and a failed part.

Ineffective Coolant Application

Coolant plays a vital role in managing heat during grinding. When its application is ineffective, temperatures can quickly spiral out of control.

| Coolant Issue | Consequence |

|---|---|

| Insufficient Flow Rate | Leads to inadequate cooling. This causes overheating, oxide formation, and potentially warping or cracks in the workpiece. |

| Incorrect Nozzle Position | If the coolant stream does not precisely target the cutting zone, it fails to remove heat where it matters most. This insufficient heat removal directly increases the risk of grinding burn. |

| Wrong Coolant Type | An incompatible coolant may have a low boiling point, causing it to evaporate instead of cool. It might also lack the right lubricating properties, increasing friction and leading to a rough finish. |

Without proper coolant delivery, the intense heat generated during grinding can cause severe defects and ruin the workpiece.

Poor Grinding Wheel Condition

Even with the right wheel and parameters, a poorly maintained grinding wheel will cause problems. A wheel in bad condition is one of the final key causes of excessive heat.

Wheel glazing is a frequent problem where the abrasive grains become dull and smooth from wear. A glazed wheel stops cutting material effectively and starts rubbing against the workpiece. This rubbing action generates immense friction and heat, leading to a burn. This is another situation where the wheel is wheel not cutting as intended.

Furthermore, an improperly dressed or out-of-balance grinding wheel can cause localized overheating. These conditions create uneven contact with the workpiece, leading to issues like grinding chatter and inconsistent material removal. The increased friction in certain spots causes discoloration, changes in hardness, and internal tensile stresses that can form grinding cracks. These grinding defects compromise the part’s structural integrity and can lead to wheel life too short. A well-maintained wheel is essential for a quality finish.

Actionable Solutions to Prevent Grinding Burn

Preventing grinding burn requires a systematic approach that directly counters its root causes. By taking control of parameters, wheel selection, coolant, and maintenance, operators can eliminate thermal damage and achieve consistent, high-quality results. These actionable solutions transform the grinding process from a source of defects into a reliable manufacturing step.

Optimizing Grinding Parameters

Adjusting grinding parameters is the first line of defense against excessive heat. Each setting offers an opportunity to reduce friction and prevent the conditions that lead to a burn.

Control Wheel Speed: While higher speeds can seem efficient, they often generate more heat. Reducing the surface speed (SFM) can significantly lower the temperature at the cutting point. This adjustment helps the cutting edges stay sharp longer and prevents thermal damage. A balanced speed maintains a sharp cutting edge without creating the intense friction that causes a burn.

Adjust Feed Rate and Depth of Cut: To avoid grinding burn, operators should increase the feed rate (table speed) rather than the depth of cut. A deeper cut creates heavy loads and severe heat, leading to defects and cracks. A faster feed rate with a shallower cut produces a smaller temperature increase, promoting a healthier grinding action.

Incorporate Spark-Out Passes: At the end of a grinding cycle, adding spark-out passes is a crucial step. This technique involves moving the grinding wheel across the workpiece for one or two rotations with zero in-feed.

This process relieves residual stress, removes minor peaks, and corrects form deviations. The absence of a spark-out pass is a common reason for high grinding stress, which can cause part warpage and cracks. Including this step dramatically improves surface integrity and grinding quality.

Choosing the Right Grinding Wheel

Selecting the correct grinding wheel is essential for managing heat and achieving efficiency. A wheel that is well-matched to the material and application will cut freely, generate less friction, and reduce the risk of grinding problems.

The choice of abrasive must balance three key properties: hardness, toughness, and friability. Hardness allows the abrasive to cut difficult materials, while toughness helps it resist breaking under pressure. Friability is the grain’s ability to fracture and expose new, sharp cutting edges, which is vital for self-sharpening and cool cutting. For hard-to-grind materials like tool steels and superalloys, a mismatch in these properties is one of the key causes of grinding burn.

This is where specialized solutions provide a distinct advantage. With nearly two decades of experience, Aimgrind excels at creating customized grinding solutions. Their products, such as their advanced CBN grinding wheels, are specifically engineered for cool grinding performance on tough ferrous materials.

Why Choose Aimgrind’s CBN Wheels?

CBN (Cubic Boron Nitride) has exceptional thermal conductivity, which pulls heat away from the workpiece, minimizing the risk of thermal defects and cracks. This makes CBN wheels ideal for heat-sensitive tool steels. Their superior hardness and thermal stability ensure they maintain structural integrity and cutting efficiency at high temperatures, delivering a superior finish and preventing grinding problems.

Furthermore, wheel structure plays a role. A grinding wheel with higher porosity allows for better coolant infiltration into the contact zone, which is critical for heat dissipation and chip removal. This improves overall performance and helps prevent a burn.

Improving Coolant Delivery

Effective coolant application is non-negotiable for preventing grinding burn. The goal is to get the fluid to the precise point of cutting, where it can lubricate, cool, and clean the area.

High-pressure coolant systems offer a powerful solution. A rotating grinding wheel creates a barrier of air that can block standard coolant flow. High-pressure jets have enough force to penetrate this air cushion, ensuring the fluid reaches the contact zone. This has several benefits:

- Reduces friction and heat generation.

- Effectively flushes away chips that cause loading.

- Prevents thermal overload and associated defects.

The right pressure and flow rate are critical for success. While settings vary by application, certain benchmarks provide a useful guide.

| Wheel Type | Recommended Coolant Pressure | Recommended Flow Rate |

|---|---|---|

| Bonded Wheels | 600–800 psi (2–5.6 MPa) | ~2 gpm per inch (0.3 L/min/mm) |

| Superabrasive Wheels | Up to 1500 psi (10.5 MPa) | ~1 gpm/hp (3.8 L/min/hp) |

Properly managed coolant flow contributes to longer wheel life, better surface finish, and consistent quality in the grinding process.

Implementing Wheel Maintenance

A well-maintained grinding wheel is a prerequisite for a quality finish. Two key procedures, dressing and truing, restore the wheel’s cutting ability and geometric accuracy, preventing the friction that leads to defects and cracks.

Dressing the Wheel Dressing is the process of sharpening a wheel by removing dull abrasive grains and clearing away loaded material. The frequency of dressing is not based on a fixed schedule but on performance. Operators should dress the wheel when they notice signs of glazing, increased vibration, or heat marks on the workpiece. Materials like hardened steels often cause the wheel to load faster, requiring more frequent dressing.

A Standard Dressing Procedure:

- Preparation: Ensure the wheel is securely mounted and all safety guards are in place.

- Positioning: Set the dressing tool at a slight angle against the wheel’s rotation.

- Application: With the wheel at operating speed, apply steady, moderate pressure and move the tool smoothly across the wheel face.

- Inspection: After stopping the wheel, check for a uniform, open texture. A successful dressing reveals sharp cutting edges ready for efficient grinding.

Truing the Wheel Truing restores the wheel’s geometric shape, ensuring it is perfectly round and concentric with the spindle. An out-of-true wheel causes vibration, leading to poor surface quality and localized overheating that can cause cracks. One common technique is to use a brake truing device, which grinds the wheel face with a conventional abrasive to restore its profile. Consistent maintenance ensures optimal performance, extends wheel life, and is fundamental to any strategy to prevent grinding burn.

Preventing grinding burn requires a four-part strategy. Operators must optimize parameters, select the correct grinding wheel, improve coolant delivery, and maintain the wheel. A systematic approach to the grinding process is the most effective way to eliminate this burn, boosting both efficiency and overall grinding quality. For tough jobs, specialized solutions like CBN wheels can dramatically improve results, with case studies showing cost-per-part reductions from $202 to just $11. To enhance your grinding efficiency and product quality, contact a specialist like Aimgrind for customized solutions that deliver superior quality.

FAQ

What is the main cause of grinding burn?

Excessive friction is the primary cause of grinding burn. This friction generates intense heat during the grinding process. Incorrect parameters, poor wheel selection, or ineffective cooling all contribute to this heat buildup, which damages the workpiece.

How does wheel speed affect the grinding process?

Wheel speed directly impacts heat generation. A higher speed increases friction at the contact point. This raises the temperature quickly. Optimizing the speed is crucial for a successful grinding operation and preventing thermal damage.

Why is choosing the right wheel important for cool grinding?

The right wheel cuts efficiently and generates less friction. A wheel matched to the material ensures a cool grinding action. For example, CBN wheels pull heat away from the workpiece, which is ideal for heat-sensitive grinding tasks.

How often should a grinding wheel be dressed?

Operators should dress a wheel based on its performance, not a fixed schedule. Signs like glazing, vibration, or burn marks indicate the need for dressing. This maintenance restores the wheel’s cutting ability for effective grinding.

Contact Us

For More Grinding Solution or Customized Abrasive Tools