Worn grinder spindle bearings are a primary cause of poor grinding process stability. This instability appears as increased spindle vibration and runout. Such bearing wear directly degrades product quality, causing poor surface finishes and dimensional inaccuracies during the grinding process. A failed bearing can halt production, costing thousands per hour in lost value. Ultimately, ignoring the condition of each bearing compromises the entire grinding operation’s reliability and precision.

Key Takeaways

- Worn spindle bearings cause grinding problems. They lead to poor surface finish and wrong part sizes.

- Look for signs of wear. Check for wavy marks on parts or unusual noises from the machine. These show bearing issues.

- Test your spindle for wear. Use a runout test or vibration analysis. This helps find problems early.

- Keep bearings well-oiled. Good lubrication prevents wear. It makes bearings last longer.

- Fix worn bearings quickly. Replace them or rebuild the spindle. This keeps your grinding stable and accurate.

How Spindle Bearing Wear Impacts Grinding Process Stability

The health of spindle bearings is directly tied to the quality of a grinding operation. As these critical components degrade, they introduce mechanical faults that undermine the entire system. This wear manifests as runout, vibration, and stiffness loss, each contributing to a decline in grinding process stability and final part quality.

Spindle Runout and Inaccuracy

Spindle runout is a deviation from the ideal axis of rotation. A worn bearing allows the spindle to wobble, creating inaccuracies. This phenomenon includes two primary types of deviation:

- Circular Runout: This measures the radial variation, or “wobble,” at a specific point during one full rotation.

- Axial Runout: This measures the side-to-side shift along the axis of rotation.

Even microscopic deviations can ruin a precision grinding job. High-performance spindles operate under extremely tight tolerances. A worn bearing easily pushes a spindle beyond these critical limits, leading to dimensional errors in the workpiece.

Vibration, Chatter, and Poor Finish

The runout caused by bearing wear generates excessive vibration. During the grinding process, this instability often results in “chatter”—a harmonic vibration that leaves distinct, wavy marks on the part’s surface. This effect severely degrades the surface finish. An unstable grinding wheel cannot maintain consistent contact with the workpiece, making a smooth, reflective finish impossible to achieve. This poor performance directly impacts the final quality and aesthetic of the ground component.

Loss of Stiffness and Deflection

A healthy machine tool spindle assembly is extremely rigid. The bearings are essential for maintaining this stiffness. As bearing wear progresses, internal clearances increase, and the spindle loses its structural rigidity.

Note: A less stiff spindle is more susceptible to deflection when grinding forces are applied. This means the spindle can bend or shift away from the workpiece, compromising dimensional accuracy.

Engineers can measure this critical property using advanced non-contact methods, like electromagnetic loading devices and displacement sensors. A loss of stiffness due to bearing wear ultimately reduces the stability and precision of the entire grinding system.

Identifying Instability from Spindle Bearings Wear

Detecting bearing wear early is crucial for maintaining grinding performance. Operators can identify instability by observing the finished parts, monitoring the grinding process, and performing specific diagnostic checks. Recognizing these signs helps prevent costly downtime and scrap.

On-Part Quality Indicators

The workpiece itself often provides the first clues of bearing problems. A careful inspection can reveal defects that point directly to spindle instability. These indicators compromise the final quality of the component.

Common visual defects include:

- Poor Surface Finish: Vibrations from a worn bearing create chatter marks. These are wavy or uneven patterns on the ground surface.

- Reduced Accuracy: Worn spindle bearings lead to dimensional inconsistencies. Parts may not meet the required size or shape specifications.

Out-of-roundness is a specific dimensional error linked to bearing wear. The rotation error of the spindle causes displacement of the bearing’s outer ring. This movement results in a part that is not perfectly circular. Excessive spindle clearance is a primary cause of this issue. A part with a taper error is another sign, as the spindle taper requires extremely tight tolerances that a failing bearing cannot maintain.

In-Process Grinding Indicators

Operators can also spot signs of bearing wear during the grinding operation. These in-process indicators often appear before part quality degrades noticeably. Paying attention to machine behavior is key.

Listen for unusual noises coming from the spindle. These sounds can signal a developing issue:

- A high-pitched squeal may occur just before a spindle locks up.

- A dragging or slipping sound indicates internal friction.

- A “skate” noise suggests the bearing is running dry due to poor lubrication.

Another critical indicator is the need for frequent wheel dressing. A stable grinding process allows the grinding wheel to maintain its cutting edge for a longer period. When a bearing is worn, the resulting vibration causes the wheel to lose its sharpness quickly. This leads to rapid wheel wear and requires the operator to dress the wheel more often to restore its cutting ability.

Diagnostic Checks for Worn Bearings

When you suspect bearing wear, specific tests can confirm the diagnosis. These checks help isolate the root cause of poor grinding performance.

Note: It is important to rule out other sources of vibration. An imbalanced grinding wheel can produce symptoms similar to a worn bearing. Start your diagnosis by using a high-quality, precision-balanced wheel. A premium diamond grinding wheel from Aimgrind ensures that any observed instability is from the spindle, not the wheel itself.

Once the wheel is ruled out, perform these diagnostic checks:

-

Runout Test: This test measures the spindle’s deviation from its ideal axis.

- Insert a precision test bar into the spindle.

- Place a dial indicator against the bar.

- Slowly rotate the spindle by hand.

- The total indicated runout (TIR) on the dial shows the extent of the wobble. A high TIR often confirms bearing wear.

-

Vibration Analysis: This advanced method uses sensors to detect bearing defect frequencies.

- Specialized sensors are attached to the spindle housing.

- Software analyzes the vibration data to identify patterns characteristic of bearing wear. This can detect a failing bearing before it impacts grinding quality.

-

Drawbar Force Test: Low drawbar force can cause tool holder movement and mimic bearing issues. A quick test can verify its strength.

- Insert a grip force meter into the spindle.

- Engage the drawbar to clamp the meter.

- Read the force displayed and compare it to the manufacturer’s specification.

| Machine Type | Ideal Force (lbs) |

|---|---|

| Belt Drive | 1,000 – 1,500 |

| Super Speed | 2,000+ |

Regularly performing these checks helps identify bearing wear early, protecting your grinding operations and ensuring consistent part quality.

Restoring Stability by Managing Bearing Wear

Once you identify the signs of bearing wear, the next step is to take corrective action. Restoring stability to your grinding process involves a combination of proactive care, professional repair, and modern technology. Adopting these strategies will minimize downtime, improve part quality, and extend the life of your machinery.

Proactive Lubrication and Maintenance

Proper lubrication is the first line of defense against premature bearing failure. A consistent lubrication schedule is a core part of any effective preventative maintenance program. For high-speed grinding applications, oil-based lubrication is essential. It excels at dissipating heat and provides a continuous supply of fresh lubricant to critical components.

Different applications may require specific lubrication systems. Each has unique advantages for maintaining optimal machine performance.

| Lubrication System | Description | Advantages | Disadvantages |

|---|---|---|---|

| Oil Mist Lubrication | Creates a continuous stream of fine oil droplets in air. | Cost-effective for continuous lubrication. | Can cause air contamination; prone to venturi clogging. |

| Oil Injection (Air-Oil) | Meters precise oil drops into an air stream. | Enables very high speeds with less oil consumption. | Oil can settle in lines; injector failures may go undetected. |

| Under-Raceway Lubrication | Delivers oil directly to bearing raceways via internal channels. | Allows for extreme speeds and precision. | Involves proprietary bearings; complex and costly systems. |

Choosing the right lubrication and adhering to a strict maintenance schedule are fundamental to bearing longevity. This simple practice ensures your grinding equipment operates smoothly and reliably.

Professional Spindle Rebuilding and Bearing Replacement

When a bearing shows significant signs of wear or has already failed, a professional spindle rebuild is often the most effective solution. This process is more than just a repair; it restores the spindle to its original factory specifications. The rebuilding process is meticulous and typically follows three critical steps:

- Evaluation: The spindle is carefully disassembled. Technicians clean each component and perform a detailed inspection to diagnose the root cause of the failure.

- Part Breakdown: Each individual component, including every bearing, seal, and bushing, is thoroughly inspected for damage, contamination, or improper fit.

- Repair Quote: After the inspection, the technicians create a detailed repair plan and cost estimate. The repair only proceeds after the client approves the plan, ensuring transparency.

A key part of any rebuild is the selection of replacement bearings. While OEM parts are an option, upgrading to high-quality bearings can significantly enhance machine performance.

| Feature | OEM Bearings | Aftermarket Bearings |

|---|---|---|

| Origin | Made by or for the original equipment manufacturer. | Made by a third-party company. |

| Quality | Guaranteed to meet original specifications. | Quality can vary, but premium options often exceed OEM standards. |

| Availability | May have longer lead times. | Often more readily available from various suppliers. |

| Cost | Typically higher priced. | Can be more cost-effective. |

Pro Tip: Consider upgrading to hybrid ceramic bearings during a rebuild. Their unique properties offer substantial benefits for high-speed grinding applications.

- Higher Speeds: Ceramic balls are over 40% lighter than steel, reducing centrifugal force and allowing the spindle to run faster with less friction.

- Longer Bearing Life: The extreme hardness of ceramic material resists wear from contamination and can extend bearing life by up to three times compared to all-steel options.

- Cooler Operation: Hybrid bearings generate less heat, which reduces thermal expansion and helps maintain preload and dimensional stability during long grinding cycles.

- Electrical Insulation: The ceramic material is a natural insulator, preventing electrical arcing that can damage the bearing and other spindle components.

Investing in a professional rebuild with upgraded bearings can restore your spindle’s precision and dramatically improve its long-term performance and reliability.

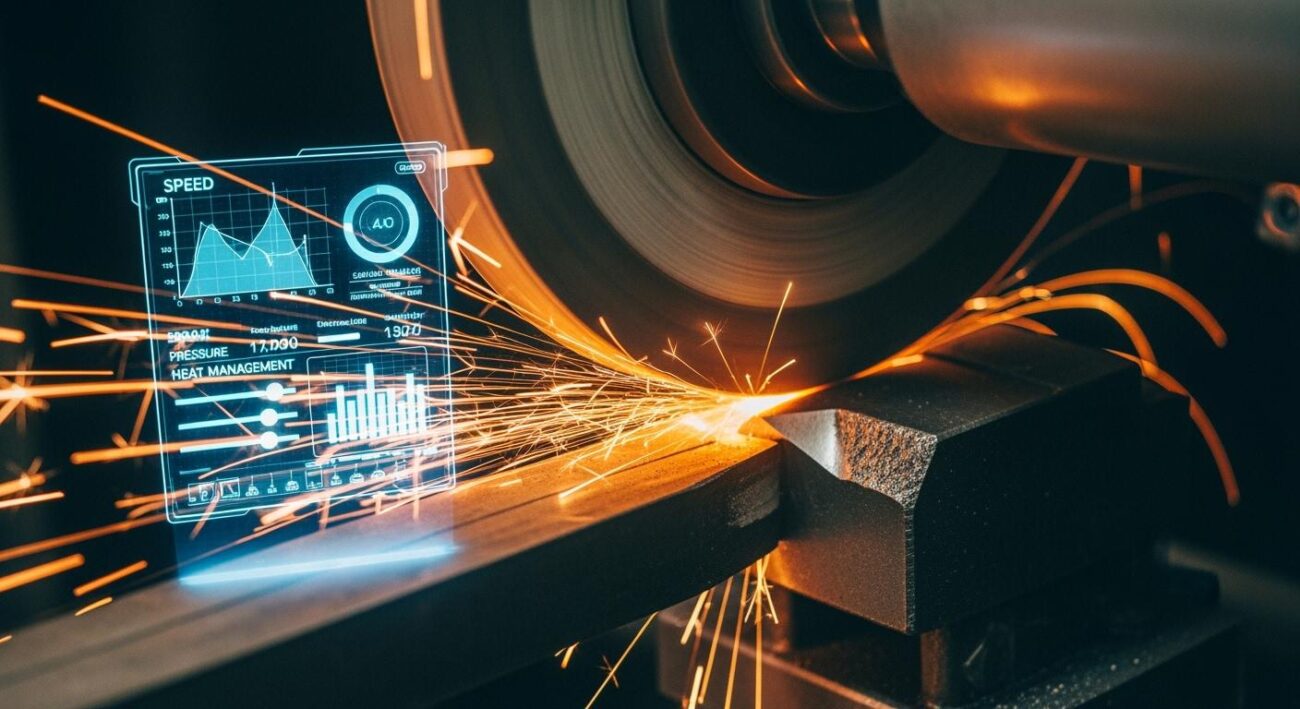

Predictive Maintenance with Condition Monitoring

The most advanced approach to managing bearing health is predictive maintenance. This strategy uses technology to monitor the condition of your equipment in real-time and predict failures before they happen. This data-driven maintenance approach helps prevent unexpected downtime and optimizes the entire grinding operation.

Predictive maintenance for a spindle relies on sensors to gather data on key health indicators like vibration, temperature, and sound. This information is then analyzed to identify patterns that signal a developing problem. For example, compact spindle vibration sensors are crucial for detecting the earliest signs of bearing wear, often long before an operator would notice a change in performance.

The process generally involves these steps:

- Data Acquisition: Sensors on the spindle collect real-time operational data.

- Data Processing: The data is sent to a central system where it is cleaned and prepared for analysis.

- Feature Extraction: Key characteristics, such as vibration frequency and amplitude, are isolated from the raw data.

- Pattern Recognition: Machine learning algorithms analyze these features to find patterns that indicate potential bearing wear or other issues.

- Predictive Modeling: The system uses historical and current data to forecast when a failure is likely to occur, allowing maintenance to be scheduled proactively.

Implementing a predictive maintenance program delivers a significant return on investment.

- One company saw a 30% reduction in equipment downtime in the first year by using predictive analytics to prevent breakdowns.

- Another organization used IoT sensors for real-time monitoring, leading to a sharp decrease in emergency repairs and substantial cost savings.

Most shops see measurable results within 6 to 12 months, primarily by avoiding catastrophic spindle failures. This modern approach to bearing maintenance transforms how you manage your grinding assets, shifting from reactive repairs to proactive optimization for maximum stability and productivity.

Healthy bearings are fundamental to grinding process stability. A worn bearing introduces runout and vibration, directly impacting the grinding operation. Identifying bearing wear early is key to preventing costly scrap and maintaining part quality. A proactive strategy combining maintenance and timely bearing repair is essential for reliable grinding. This approach protects your investment and ensures long-term grinding process stability, safeguarding the quality of every part.

FAQ

What is the first sign of a worn spindle bearing?

The most common first sign is a poor surface finish on your workpiece. You may see distinct wavy patterns, known as chatter marks. These defects indicate that spindle vibration is compromising the grinding process stability and part quality.

How can I tell if vibration is from the bearing or the wheel?

First, rule out the grinding wheel. Use a high-quality, precision-balanced wheel, such as a diamond grinding wheel from Aimgrind. If the vibration continues with a balanced wheel, the spindle bearings are the likely cause of the instability.

Is it worth upgrading bearings during a spindle rebuild?

Yes, upgrading is highly recommended. For instance, hybrid ceramic bearings allow for higher speeds and generate less heat. This upgrade can significantly extend the life of your spindle and improve its overall performance and reliability in demanding applications.

Why is proper lubrication so important for bearing life?

Proper lubrication is critical for preventing premature failure. It creates a protective film that reduces friction and dissipates heat between moving parts. Without it, bearings wear out quickly, leading to spindle instability and costly downtime for your operations.

Contact Us

For More Grinding Solution or Customized Abrasive Tools