The life of a metal bond grinding wheel depends on three things: its materials, its bond, and its use during grinding. Understanding these areas is essential for cost-effective grinding. This knowledge directly impacts the life expectancy of grinding wheels. It helps operators maximize the longevity of their wheels.

Key Takeaways

- The right abrasive type is important. Diamond works best for hard, non-metal materials. CBN is good for steel.

- The bond holds the abrasive grains. A strong bond keeps the grains in place longer. This makes the wheel last longer.

- Grinding speed and feed rate affect wheel life. Too fast can cause too much heat or stress. This wears out the wheel quickly.

- Coolant is very important. It cools the wheel and workpiece. It also cleans away debris. This prevents damage and helps the wheel last.

- Regular maintenance helps. Truing makes the wheel round. Dressing sharpens it. This keeps the wheel working well.

Abrasive Selection for Grinding Wheels

The choice and quality of abrasive grains are fundamental to a grinding wheel’s effectiveness and lifespan. The abrasive type, grit size, and concentration all work together to determine the tool’s cutting ability and durability. Making the right selection ensures optimal performance for specific materials and applications.

Abrasive Type: Diamond vs. CBN

The two primary superabrasives used in metal bond grinding wheels are Diamond and Cubic Boron Nitride (CBN). The correct choice depends entirely on the material being worked on.

- Diamond is the hardest known substance. It excels at grinding hard, brittle, and non-ferrous materials. These include ceramics like Alumina and Zirconia, composites, and hard alloys.

- CBN is the second hardest material. It is the ideal choice for grinding ferrous metals like hardened steel because it remains chemically stable at high temperatures.

Specialized brands like Aimgrind offer high-performance diamond grinding wheels designed for precision and durability in demanding industries such as glass processing, aerospace, and electronics. Expert guidance ensures the right abrasive is matched to the job, extending the longevity of the wheels.

| Feature/Material | Diamond Abrasives | CBN Abrasives |

|---|---|---|

| Tungsten Carbide | Superior choice; no chemical reaction. | Not ideal. |

| Hardened Steel | Limited; reacts with iron at high heat. | Ideal choice; chemically inert with iron. |

| Thermal Stability | Limited when grinding ferrous metals. | Excellent; stable above 1200°C. |

The Role of Grit Size

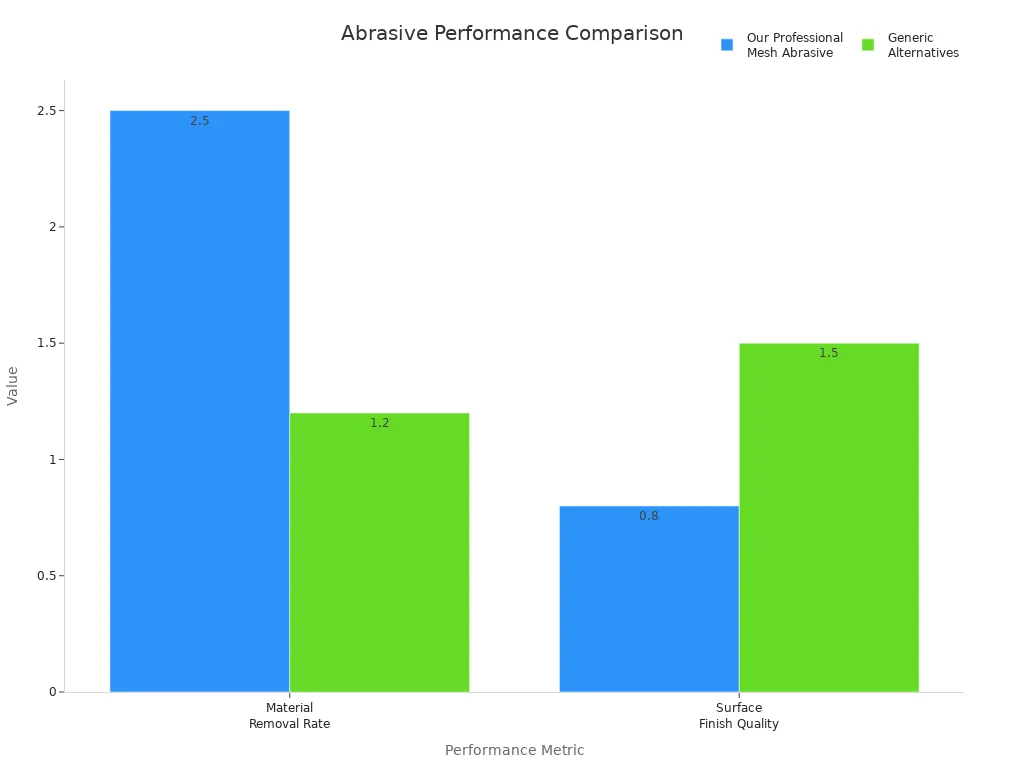

Grit size refers to the size of the individual abrasive particles. It creates a trade-off between the material removal rate and the surface finish quality.

A coarse grit (a smaller number, like 80) removes material quickly but leaves a rougher surface. A fine grit (a larger number, like 400) removes material slowly but produces a very smooth finish.

Selecting the correct grit size is essential for efficient grinding. Coarse grits are for heavy stock removal, while fine grits are for finishing operations.

Impact of Abrasive Concentration

Concentration is the amount of abrasive (diamond or CBN) contained within the grinding layer of the wheel. It is often measured by a code, where C100 is a standard baseline.

| Concentration | Abrasive Content (carats/cm³) |

|---|---|

| C75 | 3.3 |

| C100 | 4.4 |

| C125 | 5.5 |

| C150 | 6.6 |

A higher concentration means more cutting points are engaged during grinding. This generally improves wheel performance and extends tool life. However, a higher concentration also increases the initial cost of the wheel. Balancing concentration with the specific grinding task is key to achieving cost-effective results.

Properties of a Metal Bond Grinding Wheel

The bond is the matrix that holds the abrasive grains in place. For a metal bond grinding wheel, this matrix is the hardest available, which is a primary reason for its exceptional durability. The bond’s characteristics, including its hardness and composition, directly influence grit retention, wear resistance, and the overall longevity of the tool.

Bond Hardness and Grit Retention

Bond hardness in grinding wheels does not refer to the physical hardness of the material itself. Instead, it describes the bond’s ability to hold onto the abrasive grains during the grinding process. The abrasive industry uses a letter scale from ‘A’ (very soft) to ‘Z’ (very hard) to classify this property.

A harder bond provides superior grit retention. It holds abrasive particles more firmly, which is crucial when grinding very hard or brittle materials. This strong grip extends the life of the wheels and helps them maintain their precise shape, reducing the need for frequent dressing. However, the ideal hardness involves a balance.

Finding the Balance ⚖️

The bond must wear away just as the abrasive grains become dull. This process, known as self-sharpening, exposes new, sharp grains. If a bond is too hard for an application, it can lead to glazing, where dull abrasives remain on the surface and lose their cutting ability.

| Bond Hardness | Effect on Self-Sharpening | Best For… |

|---|---|---|

| Softer Grades | Releases dull grains easily, exposing fresh ones. | Grinding very hard materials; preventing wheel loading. |

| Harder Grades | Holds grains longer for extended wheel life. | Maintaining precise profiles; grinding softer materials. |

Bond Composition and Wear Resistance

The specific metals used in the bond matrix determine its wear resistance. The bond type used in grinding wheels is chosen to match the demands of the grinding application. Bronze alloys, often made of copper with about 10% tin, are a common choice due to their high wear resistance and low friction. For other applications, such as electroplating, manufacturers use nickel or nickel-based alloys.

Metal bonds are the toughest and most wear-resistant bond type. This extreme hardness allows a metal bond grinding wheel to hold superabrasive grains securely even under intense grinding conditions. The composition is key to performance.

| Metal Bond | Common Composition | Key Properties |

|---|---|---|

| Bronze | Copper, Tin (CuSn10) | High wear resistance, low friction |

| Steel | Iron, Chromium, Nickel | High strength, corrosion resistance |

| Carbide | Tungsten, Cobalt (WC-Co) | Extreme hardness, high wear resistance |

Choosing the correct bond composition ensures the wheel withstands the forces of the operation, maximizing its useful life.

Operational Factors and Wheel Longevity

Beyond the wheel’s composition, how it is used in the workshop directly impacts its lifespan. Operational factors like speed, coolant application, and maintenance routines are critical. Proper management of these variables ensures maximum longevity and consistent performance from metal bond grinding wheels.

Grinding Speed and Feed Rate

Grinding speed and feed rate are two of the most important process parameters. Finding the right balance is essential for efficient material removal without causing premature wear. A high cutting speed can increase the material removal rate, but it also generates more heat. An excessive feed rate places extreme mechanical stress on the abrasive grains, which can lead to chipping or pullout. This imbalance shortens the life of the wheels.

Operators must optimize these settings for each job. The goal is to maximize productivity while protecting the tool.

| Parameter | Effect of High Cutting Speed | Effect of High Feed Rate |

|---|---|---|

| Material Removal Rate | Increases material removal. | Directly increases material removal. |

| Tool Wear | Accelerates wear due to heat. | Increases mechanical stress and wear. |

| Vibration & Stability | Can cause tool vibration. | Can cause excessive load and vibration. |

The Critical Role of Coolant

Coolant does more than just cool the workpiece. It lubricates the grinding zone, flushes away chips, and prevents thermal damage to both the workpiece and the wheel. Improper coolant application can cause thermal shock, leading to micro-cracks on the wheel’s surface. A consistent and generous flow is necessary for effective grinding. Different coolants offer different benefits.

| Coolant Type | Composition | Best For… |

|---|---|---|

| Synthetic | Water-based, no oil. | High-speed grinding where maximum cooling is needed. |

| Semi-Synthetic | Oil and synthetic blend. | General-purpose use with balanced cooling and lubrication. |

| Straight Oil | 100% oil-based. | Demanding applications where lubrication is the priority. |

Influence of Workpiece Material

The material being ground significantly affects wheel wear. Harder materials like D2 tool steel are more resistant to abrasion and generate more heat during grinding. Softer materials are easier to cut but can sometimes load the wheel. When switching from a soft material to a very hard one, operators must adjust parameters. This often involves increasing the workpiece speed or depth of cut to make the wheel act softer, encouraging a healthy breakdown rate that exposes new, sharp abrasives.

Dressing and Maintenance Practices

Proper maintenance is key to extending the life of grinding wheels. The two main practices are truing and dressing. Truing makes the wheel perfectly round, while dressing sharpens its surface by removing old, dull grains and bond material.

Regular and skillful wheel dressing is a strategic investment. It restores the wheel’s sharpness, improves cutting performance, and ensures a high-quality surface finish. Untimely dressing leads to a dull wheel, which increases grinding forces and shortens its service life.

Frequent dressing removes less material each time, which helps maximize the overall longevity of the tool. Consistent maintenance ensures the wheels perform at their best for as long as possible.

The longevity of a metal bond grinding wheel depends on abrasive selection, bond properties, and operational parameters. Balancing these elements is key to optimizing grinding wheel durability. Investing in high-quality grinding wheels improves performance and can lead to significant cost reductions. Viewing the grinding operation as a complete process ensures maximum efficiency from your wheels.

Partnering with an expert supplier like Aimgrind helps you select the right metal bond grinding wheel for superior performance.

Grind with Passion, Achieve with Aim

FAQ

Why is bond hardness important for wheel life?

Bond hardness determines how well the wheel holds its abrasive grains. A harder bond provides superior grit retention. This quality is crucial when grinding tough materials. It extends the wheel’s life and helps it maintain a precise shape, reducing the need for frequent dressing.

How does coolant extend the life of a grinding wheel?

Coolant plays a vital role in wheel longevity. It cools the grinding zone, preventing thermal damage to the wheel. It also lubricates the cutting area and flushes away chips. Proper coolant use stops micro-cracks from forming and ensures consistent performance.

Can I use a diamond wheel on steel?

Operators should avoid using diamond wheels on ferrous metals like steel. The high heat from grinding causes a chemical reaction between the diamond’s carbon and the steel’s iron. This reaction makes the diamond abrasive wear out very quickly. CBN wheels are the correct choice for steel.

What is the first step to improve wheel lifespan?

💡 The first step is choosing the right wheel for the job. The abrasive type, grit size, and bond must match the workpiece material and the grinding operation. Partnering with an expert supplier like Aimgrind ensures you make the optimal selection from the start.

See Also

Selecting The Optimal Metal Grinding Wheel For Your Specific Project

Selecting The Ideal Bench Grinding Wheel Material For Your Requirements

Picking The Perfect Grinding Wheel For Stainless Steel Applications

Discovering The Best Crankshaft Grinding Wheel Within Your Budget

Selecting The Premier Grinding Wheel For Your Carbide Tooling Needs

Contact Us

For More Grinding Solution or Customized Abrasive Tools