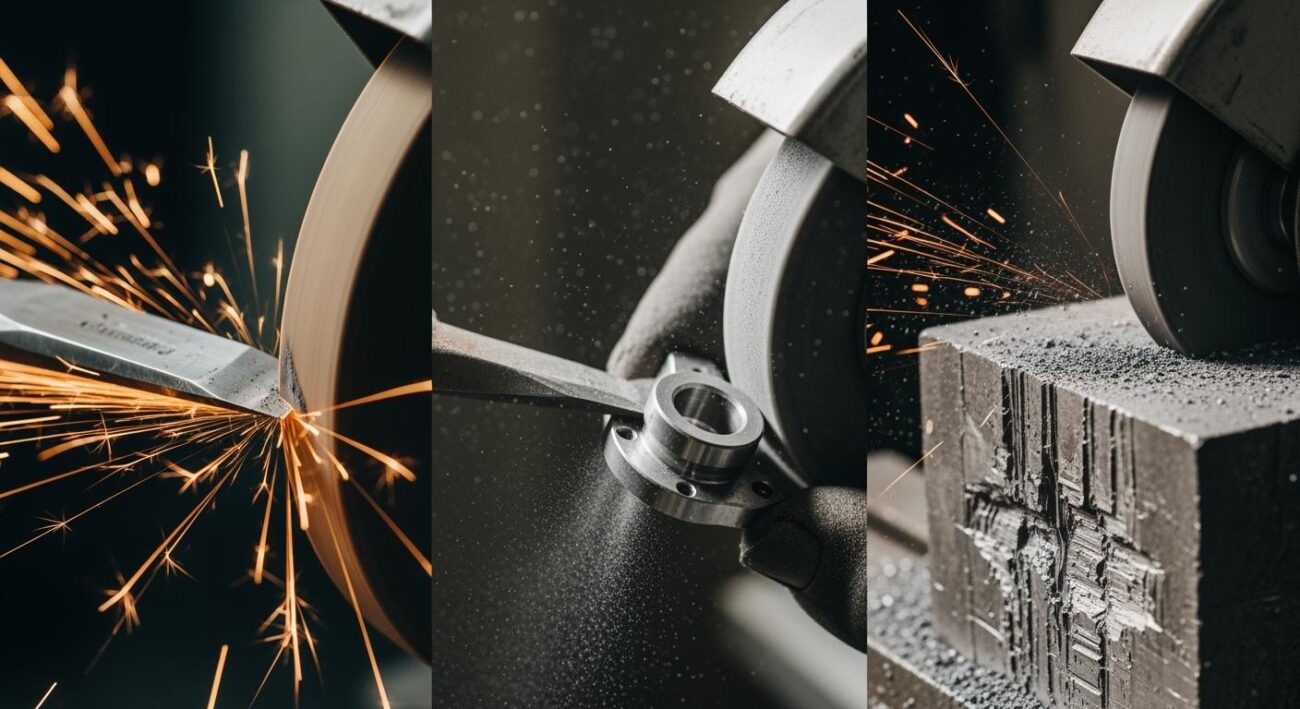

The DIY movement is growing rapidly, making the right grinder accessories essential for your workshop. Your grinder becomes a powerhouse with the correct accessories. A core set of five grinding wheels lets you tackle nearly any project. This guide helps you select the perfect wheel for your job.

Your Essential Toolkit:

- Aluminum Oxide

- Silicon Carbide

- Wire Wheels

- Flap Discs

- Diamond cut-off wheels

This kit covers most angle grinder uses, from grinding metal and cutting metal to cleaning metal. You will be ready for any grinding or precision cutting task.

Key Takeaways

- Use an aluminum oxide wheel for general metal tasks like sharpening tools or smoothing steel.

- Choose a silicon carbide wheel for hard materials such as concrete, stone, or very hard metals.

- Wire wheels clean surfaces by removing rust and paint, preparing metal for new coatings.

- Flap discs are good for both removing material and making surfaces smooth, especially on metal and wood.

- Diamond wheels cut very hard materials like tile and concrete with great precision.

Aluminum Oxide: The General-Purpose Wheel

Think of aluminum oxide grinding wheels as the workhorse of your workshop. They are the standard choice for working with ferrous metals. This category includes common materials like carbon steel, alloy steel, and cast iron. You will use this wheel for many of your metal projects.

What It Is

Aluminum oxide is a very tough and durable abrasive material. Its unique structure allows it to break down during use. This process exposes fresh, sharp cutting edges, which gives you a consistent grinding performance. This self-sharpening quality means the wheel lasts longer and works efficiently. The material is also chemically inert with ferrous metal. This property prevents bad reactions, ensuring a clean grinding process on any steel metal you are working on. It is the perfect tool for shaping hard metal.

Shaping and Deburring Metal

You can use this wheel for many common DIY tasks. It is excellent for sharpening your lawnmower blades, garden shears, and chisels. You can also use it to clean up the rough edges on a piece of metal after you make a cut. For a lawnmower blade, you will secure the blade and run the grinder along the cutting edge until it is sharp. This simple maintenance keeps your tools in top shape. The process of grinding metal creates sparks and dust.

Safety First! 🛡️

Always protect yourself when using a grinder. Wear safety glasses, gloves, and a dust mask. Before you start, check that your tool rest is adjusted correctly and that the wheel is secure. Stand to the side when you turn the grinder on.

Recommended Type

For a versatile DIY toolkit, you should start with a 60-grit, vitrified bond aluminum oxide wheel. The 60-grit level offers a great balance. It removes metal effectively but also leaves a reasonably smooth finish. The vitrified bond is strong and porous, which helps with heat dissipation during grinding. This all-around wheel prepares you for most general-purpose metal tasks.

Silicon Carbide: For Masonry and Hard Materials

When your projects involve materials harder than steel, you need a tougher abrasive. Silicon carbide grinding wheels are the perfect solution for these demanding jobs. They excel at working with masonry, stone, and very hard metals.

What It Is

Silicon carbide is a synthetic material harder and sharper than aluminum oxide. Its sharp, brittle grains fracture easily. This action constantly exposes new cutting edges, which makes it excellent for grinding hard, brittle materials. You can see its hardness advantage in a direct comparison.

| Material | Mohs Hardness |

|---|---|

| Silicon Carbide | 9–9.5 |

| Aluminum Oxide | ~9 |

This extra hardness allows the wheel to slice through tough surfaces with less effort. It is the go-to choice for non-metal applications.

Masonry and Tool Grinding

You will find this wheel incredibly useful for a variety of tasks around your home and workshop. Its primary job is cutting and shaping masonry.

- Use it for cutting bricks, concrete pavers, or ceramic tiles.

- It is also great for grinding non-ferrous metals like aluminum and brass. The material resists loading, so soft metals will not clog the wheel.

- You can even perform light sharpening on tungsten carbide-tipped tools. It is an affordable option for occasional tool maintenance before you need a diamond wheel.

This versatility makes it a key part of your grinder toolkit for both construction and fine-tuning tasks. The grinding process on these materials requires a steady hand for clean cutting.

Recommended Type

You should have two types of silicon carbide wheels for your grinder. For general masonry cutting and rough grinding, a black, 36-grit silicon carbide wheel is ideal. It removes material quickly. For sharpening carbide tools or achieving a finer finish, you need a green, 80-grit silicon carbide wheel. The green version is purer and better for precision work. Having both prepares you for a wide range of hard-material projects.

Wire Wheels: For Cleaning and Surface Prep

Sometimes, your project is less about removing material and more about cleaning a surface. Wire wheels turn your grinder into a powerful cleaning and stripping machine. They are essential for surface preparation before you paint or weld.

What It Is

A wire wheel is a brush attachment made of metal bristles. Unlike grinding wheels, its job is to scrub surfaces, not reshape them. The bristles do the hard work of scouring away unwanted coatings. You can find wheels made from several materials for different jobs.

- Carbon Steel: The most common type, great for general work on steel and iron.

- Stainless Steel: Use this on stainless steel and aluminum to prevent contamination.

- Brass: A softer metal, ideal for surfaces you do not want to scratch, like brass or copper.

Choosing the right bristle material protects the base metal you are working on.

Key DIY Uses

You will reach for a wire wheel for many restoration and fabrication tasks. Its main purpose is aggressive cleaning. Use it to strip thick rust and stubborn paint from any metal surface. It is also perfect for cleaning up weld spatter and scale after you join two pieces of metal. This cleaning metal process prepares a surface for a new coat of paint or a fresh weld. You can also perform light polishing on certain materials, though dedicated polishing pads are better for a mirror finish. This tool is a must-have for polishing metal to a clean, workable state.

Safety is Non-Negotiable! ⚠️

Wire wheels can shed small, sharp wires at high speed. Always wear safety glasses, a face shield, thick gloves, and durable clothing. These wires can easily penetrate skin and cause serious injury.

Recommended Type

You should have two main types of wire wheels in your toolbox.

- Crimped Wire Wheel: The wires on this wheel are bent and bundled, giving it flexibility. It is your best choice for general-purpose cleaning, light rust removal, and surface polishing. It conforms well to irregular surfaces.

- Knotted Wire Wheel: This is the heavy-duty option. The wires are twisted into tight knots, making them very stiff and aggressive. Use this type for stripping extreme rust and thick paint from a metal surface. Be extremely careful, as this powerful wheel can catch on edges, causing the grinder to kick back violently.

Always match the wheel’s RPM rating to your grinder’s speed for safe operation.

Flap Discs: Essential Grinder Accessories

Flap discs are versatile grinder accessories that combine the material removal of a grinding wheel with the smooth finish of sanding discs. They are essential angle grinder accessories for any DIYer working with metal or wood. These powerful accessories will expand your grinder’s capabilities beyond just cutting metal.

What It Is

A flap disc is an abrasive tool made from multiple, overlapping pieces of abrasive cloth, called a flap. These flaps are arranged in a circular pattern and attached to a rigid backing plate. The unique design of flap discs is their biggest advantage. As you use the grinder, the top layer of each flap wears away, exposing a fresh, sharp layer of abrasive underneath. This self-renewing action ensures you get a consistent cut and finish throughout the life of the disc. The space between each flap also allows these accessories to conform to curves and contours without digging in.

Common Angle Grinder Uses

You will find many uses for angle grinders with these accessories. In metalworking, flap discs are perfect for grinding down welds, blending surfaces, deburring sharp edges, and removing rust from metal. These are some of the most common angle grinder uses for metalwork. You can also use them for light polishing tasks. For woodworking projects, you can use a flap to smooth, shape, and sand hardwood surfaces. Their flexibility makes them great for working on curved pieces where other sanding discs might gouge the wood. The wide range of angle grinder uses makes these accessories a workshop staple.

Recommended Type

Choosing the right flap disc depends on your project. You will find two main shapes and various grits.

- Type 27 (Flat): These have a flat profile and are best for finishing and blending on flat surfaces. You should hold your grinder at a 0-15 degree angle.

- Type 29 (Conical): These have an angled shape, making them ideal for aggressive material removal on contours and edges. You will use a steeper 15-25 degree angle.

For a starter kit, a Type 27, 80-grit flap disc is a great all-around choice for general metal finishing. As you expand your collection of grinder accessories, consider adding different grits.

| Your Task | Best Grit | What It Does |

|---|---|---|

| Heavy weld grinding, fast rust removal | 40 Grit | Removes the most material quickly but leaves a rough finish. |

| General blending, deburring, shaping metal | 80 Grit | Offers a good balance of material removal and a clean finish. |

| Final finishing before painting | 120 Grit | Creates a smooth surface ready for coatings. |

Having a few of these sanding discs in your toolbox prepares you for nearly any finishing job.

Aimgrind Diamond Grinding Wheels for Precision

When you face the hardest materials, you need the ultimate cutting tool. Diamond grinding wheels are the premium solution for cutting and grinding materials that other wheels cannot handle. Brands like Aimgrind specialize in these high-performance, high-quality accessories, delivering exceptional results for your most demanding diy projects.

What It Is

Diamond wheels are not simply coated with diamond dust. They are engineered tools built for extreme durability and quality. The manufacturing process involves bonding industrial diamonds to a metal core.

- Powdered metals are sintered, or fused, under intense heat and pressure.

- This process creates an incredibly strong bond for the diamond particles.

- The final product is an extremely tough wheel that holds its shape for precise grinding.

This advanced construction is why a diamond wheel provides superior quality and a longer lifespan when cutting hard substances.

Key DIY Uses

You will use these cut-off wheels for projects involving very hard, brittle materials. Their primary use is the clean cutting of masonry and tile. You can tackle jobs like cutting ceramic tile, porcelain, concrete pavers, and brick with ease. The quality of your cut-off is unmatched.

Pro Tip for Clean Tile Cutting:

To prevent chipping when cutting tile, make a shallow scoring cut about 1/16″ deep along your marked line first. This initial pass with the grinder guides the blade for the final, full-depth cutting, ensuring a clean edge.

This technique gives you professional-quality results every time.

Recommended Type

For durability and precision, you should choose high-quality diamond cut-off wheels. Aimgrind’s diamond grinding wheels are a top choice, offering excellent value by delivering clean cutting with minimal wear. Your choice of wheel depends on the job.

| Material You Are Cutting | Recommended Wheel Type | Why It Works |

|---|---|---|

| Ceramic & Porcelain Tile | Continuous Rim | Provides a smooth, chip-free cut for delicate materials. The solid edge ensures the highest quality finish. |

| Concrete, Brick, & Pavers | Segmented Rim | Designed for aggressive, fast cutting. The gaps help cool the blade and clear debris, making it ideal for dry grinding and rough cut-off tasks. |

Equipping your grinder with the right diamond wheel prepares you for any hard material cutting task.

Your essential toolkit is now complete. You have the right accessories for every job.

- Aluminum Oxide for grinding metal.

- Silicon Carbide for masonry.

- Wire Wheels for cleaning metal.

- Flap Discs for finishing metal.

- Diamond cut-off wheels for precision cutting.

These five grinder accessories prepare you for nearly all diy angle grinder uses. This collection of accessories ensures you can handle any grinding or cut-off task. From cutting metal to polishing metal, these grinder accessories and angle grinder accessories expand your capabilities.

Safety is Your Final, Most Important Tool 🛡️

Always follow safety rules for all angle grinder uses. Match the wheel’s max RPM to your grinder’s speed. Exceeding this rating creates dangerous force that can shatter grinding wheels. For any grinding or cutting job, wear proper safety gear. This includes ANSI Z87.1-rated eye protection and heavy-duty gloves.

FAQ

How do I match a wheel’s RPM to my grinder?

You can find the maximum RPM (Revolutions Per Minute) printed on the wheel’s label. Your grinder also has an RPM rating listed on its body. You must ensure the wheel’s RPM is higher than or equal to your grinder’s RPM. This prevents the wheel from breaking apart.

Can I use an aluminum oxide wheel on concrete?

You should avoid using aluminum oxide wheels on concrete or masonry. These wheels are designed for ferrous metals like steel. For concrete, brick, or stone, you need a silicon carbide wheel or a diamond wheel. Using the correct wheel ensures safety and better results.

When should I replace my grinding wheel?

You must replace a grinding wheel immediately if you see any cracks or chips. You should also discard a wheel when it wears down to the paper blotter or label near the center. A worn-out wheel loses its effectiveness and can become a safety hazard.

Quick Tip 💡

Perform a “ring test” on new vitrified wheels. Tap the wheel gently with a wooden handle. A good wheel makes a clear ringing sound. A dull thud may indicate a hidden crack, so you should not use it.

What is the difference between a grinding wheel and a cut-off wheel?

Grinding wheels are thick and designed for removing material from a surface, like shaping metal or sharpening tools. Cut-off wheels are very thin. You use them specifically for slicing through materials, such as cutting a metal pipe or a ceramic tile.

Contact Us

For More Grinding Solution or Customized Abrasive Tools