An electroplated grinding wheel is a very important tool for any workshop that needs to be exact and fast. Electroplated wheels use a special way to hold the abrasive grit tightly. This lets the grit stick out more and makes the surface rough. Because of this, users can work with steady accuracy and do not need to fix the wheel often. Many businesses like these wheels because they can work with many materials and give smooth, good results every time.

Micro-grooves on the electroplated wheel help coolant move better and remove chips.

These grooves make grinding easier, lower heat, and keep grinding steady, which keeps the tool and material safe.

Electroplated grinding wheels do not need much care, so workers can spend more time on careful work instead of fixing the wheel.

Key Takeaways

Electroplated grinding wheels hold abrasive grains very tightly. They stay sharp for a long time. They do not need dressing. This saves time and cuts down on downtime in workshops.

These wheels give precise and steady results for many materials. They work well with metals, ceramics, glass, and composites. This makes them great for detailed and quick grinding jobs.

They work well with CNC machines. This lets you cut and shape hard materials faster. It is safer and more accurate.

Electroplated diamond wheels are great for grinding hard and brittle materials. They can make detailed shapes with smooth finishes. They also cause less heat damage.

Using electroplated grinding wheels helps workshops save money. They lower maintenance needs and make tools last longer. They also help workshops work better overall.

Applications

Electroplated grinding wheels are important in many jobs. Their special design lets them do many things. They can grind with care or shape hard stuff. These wheels give the same results every time. This is why many workers like them. They want tools that are exact and can be trusted.

Precision Tasks

Electroplated grinding wheels are great for careful work. They keep their shape while you use them. This is needed for jobs that must be very exact. The wheels help with fine, surface, and form grinding. Each piece comes out just right.

Electroplated wheels use smart ways to place abrasive grains. This makes the surface almost 19% smoother. It helps make form grinding more exact. The wheels are also very hard and last a long time. This keeps work careful and steady.

The top five careful jobs for electroplated grinding wheels are:

Centerless grinding makes round shapes in ceramics, steel, and composites.

Periphery grinding makes flat sides on tapers, slots, and profiles.

Round tool grinding shapes drills, end mills, and reamers.

Profile grinding makes exact shapes and sizes.

Burr grinding shapes and smooths carbide rotary burrs.

These jobs need wheels that keep their shape. They must grind tiny shapes with care. Electroplated wheels do this well. They are needed for careful grinding work.

Industry Uses

Many jobs use electroplated grinding wheels. The wheels help in making things, crafts, and daily items. They can work with ceramics, glass, composites, and metals.

Precision Tasks and Applications | |

|---|---|

Electronics | Fine grinding and cutting of small parts like semiconductors and ceramic pieces that need tiny details. |

Tool and Die Making | Making molds, dies, and cutting tools with high care for small parts. |

Stone and Glass Processing | Cutting and shaping stone, glass, and composites with care for special shapes and looks. |

Fiberglass and Composites | Shaping and smoothing composite parts for boats, cars, and buildings, making sure they are strong and look good. |

Aerospace | Shaping and finishing important parts like turbine blades and engine pieces with care for safety. |

Automotive | Sharpening tools, smoothing engine parts, and making exact pieces for better work and longer life. |

Medical Devices | Making small surgical tools and implants with tight rules and smooth surfaces. |

The aerospace field uses these wheels for careful, fast, and steady work. The wheels keep their shape from start to end. This is very important for making plane parts. They also save money and can work with tough stuff like nickel alloys and special ceramics.

The car industry uses these wheels to sharpen tools and smooth engine parts. They also make exact pieces. This helps cars work better and last longer.

Medical device makers use these wheels for tiny, careful tools. The wheels keep their shape and cut fast. This is needed for hard-to-grind stuff. They are used to make small nickel-diamond wheels for medical tools and implants. The even spread of grit makes grinding steady and helps the wheels last. This is very important for medical work.

Electroplated grinding wheels are also used in electronics, tool making, stone and glass work, and crafts. They help cut silicon wafers, PCBs, and work with jade or ceramics. These jobs need the wheels to be exact and give the same results every time.

Electroplated grinding wheels are now must-have tools for many jobs. They are used for fine grinding in electronics and surface grinding in cars and planes. The wheels can do many things and always work well. This makes them great for any shop that needs careful and fast work.

Electroplated Grinding Wheel Benefits

No Dressing Needed

Electroplated grinding wheels are special because they do not need dressing. Regular grinding wheels must be dressed often to stay sharp and keep their shape. This takes time and stops work. Electroplated wheels use a strong bond to hold the abrasive grains tight. This keeps the wheel sharp for a long time. Workers do not have to stop to reshape or fix the wheel. The wheel stays sharp and works well, so there is less downtime and more work gets done.

Workshops save money on repairs and upkeep. The electroplated grinding wheel does not get too hot, so it does not need to cool down or be replaced often. This means workers do not have to change wheels as much, and grinding stays smooth. Shops spend less on labor and supplies because they skip extra steps needed for resin or vitrified wheels. The wheel is tough and strong, so it is great for careful grinding, dressing, and deburring, even on hard things like carbide and ceramics.

Tip: Using an electroplated grinding wheel helps shops keep tools sharp and work steady, with fewer stops.

CNC Compatibility

Electroplated grinding wheels work great with CNC machines. The wheels hold the abrasive grains tight on a metal core. This lets them cut and shape things very exactly. CNC workers can make hard shapes and designs easily. The electroplated layer fits the core well, so there is not much finishing needed after cutting. This makes making things faster and easier.

The wheels can go fast and still cut well. They can work with many hard things like carbide, composites, ceramics, and metals. They do not get too hot, so the wheel and the part stay safe. This keeps grinding safe and the finished part good. The wheels last a long time, so workers do not have to change them often. This helps work go faster and saves money.

Electroplated grinding wheels help CNC machines work faster.

They stay sharp and work the same every time.

They can be used for many CNC jobs.

Electroplated Diamond Wheels

Hard Materials

Electroplated diamond wheels are great for grinding hard and brittle things. Their design lets diamond grains stick out from the wheel. This helps the wheel cut better and keeps heat low. It stops cracks or burns on delicate things. These wheels work well with glass, ceramics, gemstones, and semiconductors. Workers use them to cut silicon wafers and shape optical lenses. They also process ferrites for electronics. These wheels can handle tungsten carbide tools, graphite, high speed steel, and fiberglass.

Electroplated diamond wheels are used for:

Shaping and edge grinding glass, ceramics, and gemstones

Cutting semiconductor wafers and printed circuit boards

Grinding carbide tools and composites

Finishing aerospace alloys and turbine blades

Electroplated diamond grinding wheels are fast and very exact. They do not need dressing, so workers save time. The strong bond keeps the diamond grains tight. This makes the wheel sharp and long-lasting. The electroplated process lets wheels be re-plated. This saves money and makes repairs easy.

Electroplated diamond wheels give a smooth finish and make less waste. They can run fast, so they are good for jobs that need quick and exact grinding.

Intricate Profiles

Electroplated diamond wheels are good at making detailed shapes. Makers can create wheels with special shapes, like small curves or tricky lines. The wheels keep their shape even after lots of use. Workers can trust the wheel to give the same results every time.

Tests show these wheels hold their shape well. Even without dressing, they make steady shapes and smooth surfaces. A new spray-mist laser method helps form exact shapes. It does not hurt the diamond grains. This keeps the wheel sharp for careful grinding.

Electroplated diamond wheels are used for:

Shaping optical lenses and prisms

Polishing jewelry with fine details

Creating dental and medical implants with exact profiles

Cleaning the wheel and using coolant helps it stay exact. Workers check the wheel for wear and change feed rates to stop damage. These steps help the wheel keep its shape and do careful grinding for every job.

Diamond Grinding Wheel Versatility

Ferrous and Non-Ferrous

A diamond grinding wheel can work with many materials. These wheels are made to handle both ferrous and non-ferrous things. They can grind hardened steels, carbide, glass, ceramics, composites, and super-hard alloys. The wheel works best on non-ferrous metals like aluminum and copper alloys. Diamond grinding wheels cut faster and leave a smoother finish than regular abrasive wheels. Their sharp crystals help remove material quickly and keep the surface smooth. The wheel also spreads heat well, so the workpiece does not get damaged.

Diamond grinding wheels last longer than normal abrasive wheels. They stay exact and do not need much extra polishing. Even though diamond wheels cost more at first, they last longer and help workers get more done. For ferrous metals, CBN wheels are often better because diamond can wear out faster from chemical reactions. Still, diamond grinding wheels are the best for non-ferrous metals and hard alloys.

Tip: Shops that use diamond grinding wheels on non-ferrous metals get better finishes, faster work, and longer tool life.

Diamond grinding wheels work well on:

Aluminum and copper alloys

Carbide and composites

Glass and ceramics

Hardened steels (if the right bond is used)

Abrasive Materials

Diamond grinding wheels can easily grind tough materials. Their hardness makes them great for stone, ceramics, glass, quartz, silicon, crystal, titanium alloys, cemented carbide, fireproof materials, and semiconductor electronics. The bond type—resin, metal, vitrified, or electroplated—depends on what you are grinding and the finish you want. Resin bonds are good for ceramics and glass. Metal bonds work well for sapphire and quartz. Electroplated bonds are best for heat-resistant and low abrasive grinding.

How much diamond is in the wheel changes how it grinds. Lower amounts help with dry grinding and heat control. Medium amounts balance grinding power and heat. High amounts are good for heavy grinding and big jobs.

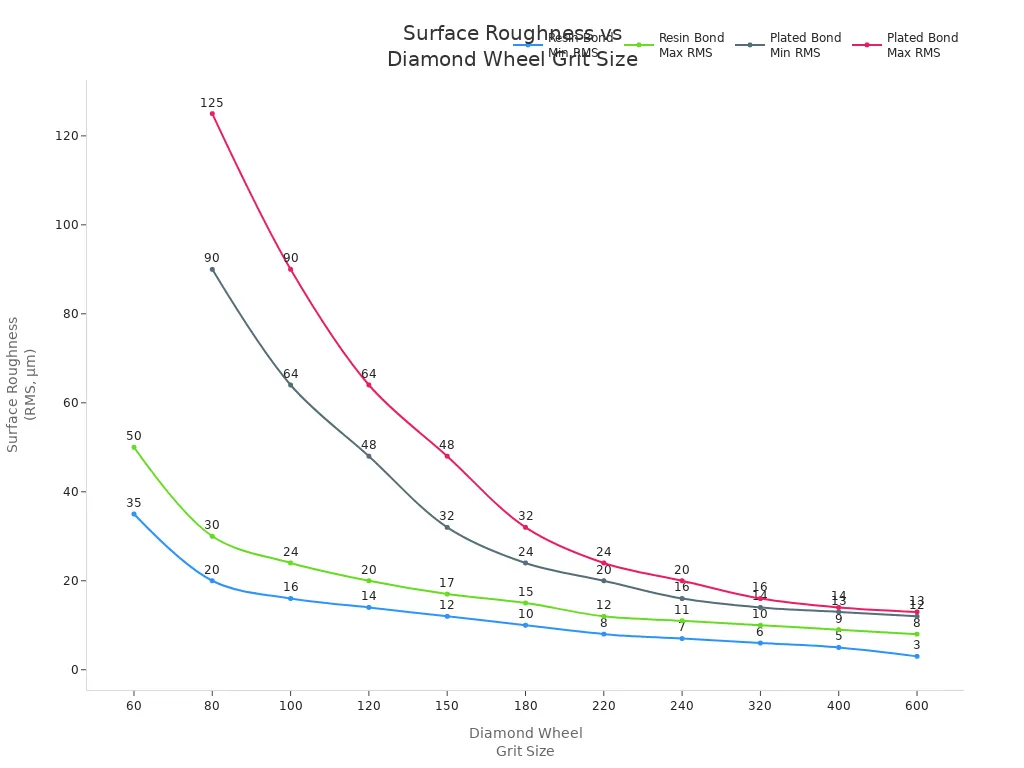

The grit size of the diamond wheel changes how smooth the finish is. Smaller grits make smoother finishes. Bigger grits make rougher surfaces. The table below shows how grit size changes surface roughness for resin and plated bonds:

Diamond Wheel Grit Size | Expected Surface Roughness (RMS) Range (Resin Bond) | Expected Surface Roughness (RMS) Range (Plated Bond) |

|---|---|---|

60 | 35 – 50 | N/A |

80 | 20 – 30 | 90 – 125 |

100 | 16 – 24 | 64 – 90 |

120 | 14 – 20 | 48 – 64 |

150 | 12 – 17 | 32 – 48 |

180 | 10 – 15 | 24 – 32 |

220 | 8 – 12 | 20 – 24 |

240 | 7 – 11 | 16 – 20 |

320 | 6 – 10 | 14 – 16 |

400 | 5 – 9 | 13 – 14 |

600 | 3 – 8 | 12 – 13 |

Diamond grinding wheels give high accuracy and a steady finish on tough materials. The tiny shape of the wheel, changed by how it is prepared, also affects the final surface. Shops can change grit size and diamond amount to get the finish they want for each job.

Maintenance and Longevity

Service Life

Electroplated grinding wheels last a long time and work well. Their metal-bonded design helps them keep their shape. Workers see that these wheels do not need to be changed often. This means less downtime and more work gets done. Electroplated wheels have one layer of abrasive held by nickel. This makes them good for fast grinding and careful work. But, they do not last as long as wheels with more layers, like vitrified or resin-bond wheels. Those wheels can be dressed to show new abrasive grains. This helps them last longer.

Electroplated wheels are best for jobs that need exact shapes and smooth surfaces. They stay strong and work the same each time. When they wear out, workers must get a new wheel.

The table below shows how long different grinding wheels last and how they wear:

Wheel Type | Service Life / Wear Behavior | Key Notes |

|---|---|---|

Electroplated Diamond | Dulls quickly, about 20% faster than 180-grit wheels | One abrasive layer, no re-dressing, works best at first, does not last as long |

Vitrified Wheels | Many abrasive layers, lasts longer with dressing | Dressing shows new abrasive, lasts longer |

Resin-Bond Wheels | Wears evenly, keeps corners well | Many layers, keeps its shape |

Metal Bond Wheels | Lasts a long time, keeps shape | Very tough, can handle strong grinding |

CBN Wheels | Lasts almost forever, stronger than diamond wheels | Handles heat well, sharpens itself, great for hard metals |

Cost Savings

Electroplated grinding wheels help shops save money over time. They do not need much fixing or changing. Their strength means fewer stops and lower tool costs, especially when making lots of things. Unlike resin or vitrified wheels, electroplated wheels cannot be dressed. Workers must get a new wheel when it wears out. This can cost more to run. But, less downtime and steady work often make up for these costs.

Grinding Wheel Type | Maintenance Characteristics | Cost Implications |

|---|---|---|

Electroplated (EP) | One abrasive layer; must be replaced when worn | |

Vitrified | Can be dressed to keep working well | Costs less to fix because it can be dressed |

Resin | Cheaper at first; needs dressing often | Costs less but needs more fixing |

Shops like electroplated wheels because they work well and last. They help get a smooth finish on hard things. Less fixing and fewer changes save money in the long run. By picking electroplated wheels, workers keep high performance and get the finish they want with less stopping.

Electroplated grinding wheels help shops work with metals, ceramics, and composites. They are very exact and can do many jobs. The single layer of abrasive lets workers grind small shapes well. The strong bond means the wheel lasts longer and needs fewer changes. Shops can finish jobs faster and get smoother parts. This also helps save money on each part.

The wheels are tough and stop heat from hurting the work.

More shops use these wheels because of automation and caring for the environment.

Shops that want better tools can get ahead by using these new grinding wheels.

FAQ

What materials can electroplated grinding wheels process?

Electroplated grinding wheels can work on metals, ceramics, glass, composites, and gemstones. They are good for hard and breakable materials. Many jobs use them for shaping, cutting, and finishing.

How often should a workshop replace electroplated grinding wheels?

How often you change the wheel depends on how much you use it and how hard the material is. Most shops see the wheel work less well after lots of use. You cannot dress electroplated wheels, so you must get a new one when the abrasive layer is gone.

Do electroplated grinding wheels require special maintenance?

Electroplated grinding wheels do not need much care. Workers should clean them after using and look for wear. Storing them right stops damage. You do not need to dress or reshape them.

Are electroplated grinding wheels safe for CNC machines?

Yes. Electroplated grinding wheels work well with CNC machines. The strong bond keeps the abrasive grains in place. CNC workers can make exact cuts and shapes with less stopping.

Can electroplated wheels improve workshop efficiency?

Electroplated wheels help lower downtime.

They keep their shape and stay sharp.

Workers spend less time fixing them.

Shops finish jobs faster and save money.

Contact Us

For More Grinding Solution or Customized Abrasive Tools