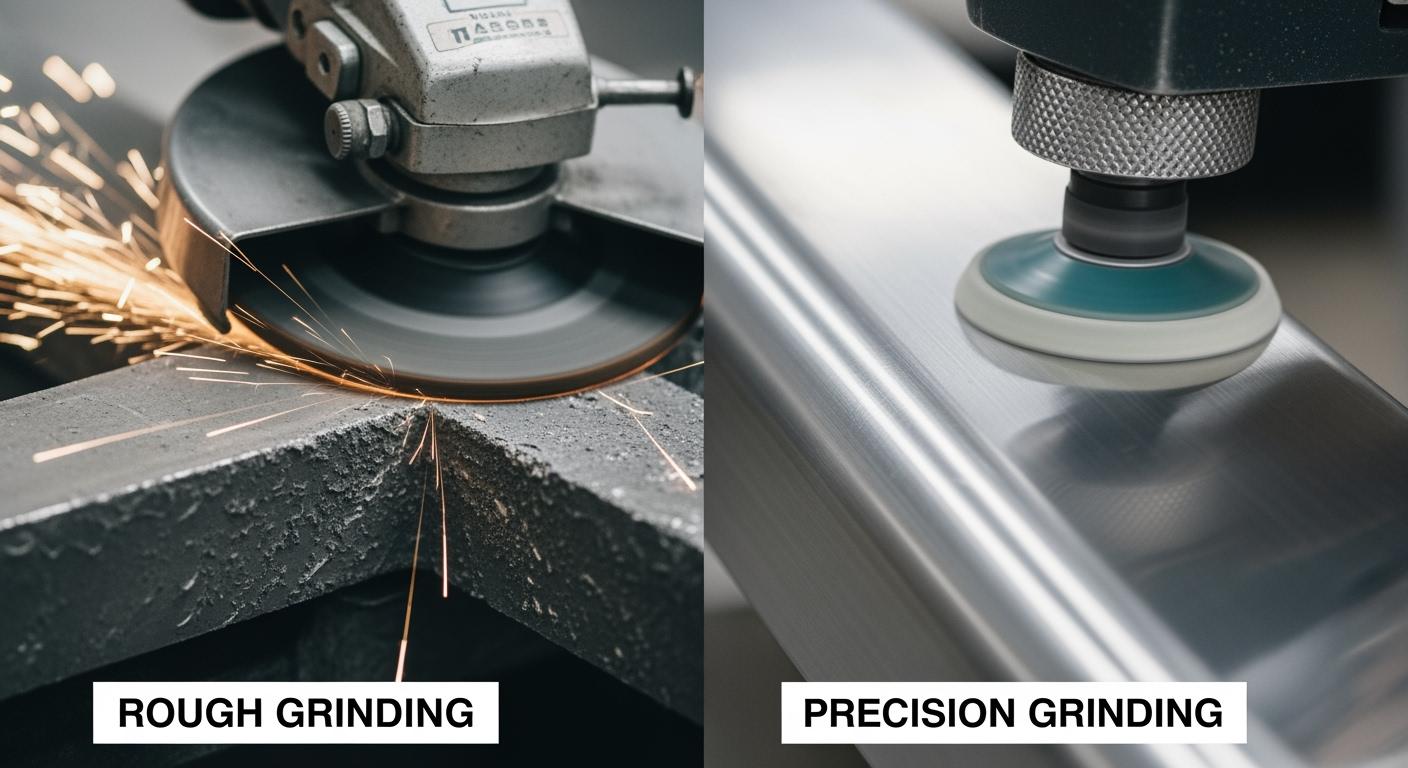

Manufacturing involves two distinct grinding methods: rough grinding and precision grinding. Rough grinding is a high-speed process focused on rapid material removal. In contrast, precision grinding is a slow and meticulous technique used to achieve a final, accurate shape and a smooth finish.

Note: The choice between these methods depends on the goal. Rough grinding prioritizes speed, while precision grinding prioritizes accuracy.

Often, these two grinding stages are sequential steps in the same workflow. A workpiece first undergoes preparation with rough grinding before moving to the final stage.

Key Takeaways

- Rough grinding quickly removes a lot of material. Precision grinding makes parts very accurate and smooth.

- Rough grinding uses strong machines and coarse tools. Precision grinding uses gentle machines and fine tools.

- Choosing the right grinding wheel is important. Different wheels work best for different jobs.

- Both grinding types are important in making things. They help create many products we use every day.

Rough Grinding vs. Precision Grinding: Key Differences

While both processes involve grinding, their core differences lie in their goals, speed, and the final quality of the workpiece. Understanding these distinctions helps manufacturers choose the right method for each stage of production.

Goal: Bulk removal vs. final accuracy

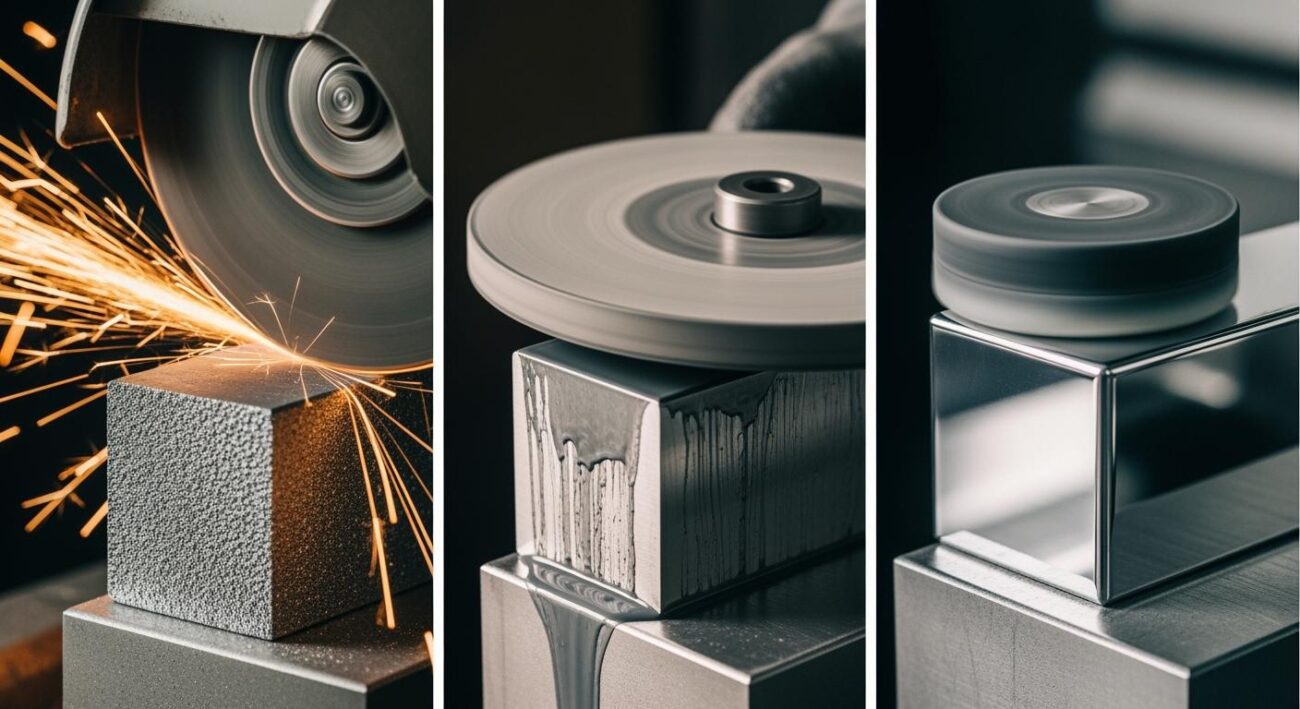

The primary objective separates rough grinding from precision grinding. Rough grinding focuses on speed and volume. Its main purpose is to remove large amounts of excess material from a workpiece as quickly as possible. This prepares the part for further finishing.

In contrast, precision grinding prioritizes accuracy and quality. This meticulous process aims to achieve exact measurements and a flawless surface. It is the final step that brings a component to its required specification.

The table below summarizes their different goals:

| Feature | Rough Grinding | Precision Grinding |

|---|---|---|

| Primary Objective | Quickly remove large amounts of excess material | Achieve exceptional accuracy and a high-quality surface finish |

| Priority | Productivity, quick stock removal | Accuracy, tight tolerances, smooth surface |

| Surface Finish | Coarse, rough | Smooth, free of defects |

| Applications | Initial shaping, preparing material for refinement | Components requiring exact dimensions (aerospace, medical) |

Material removal rate

The material removal rate (MRR) measures how quickly a grinding process removes material. Rough grinding is defined by its high MRR. Operators can remove a large material allowance, often between 0.5 mm and 2 mm, in a short time. This efficiency comes from using high-power spindles, typically ranging from 3 to 7.5 kW. A more powerful spindle allows the grinding wheel to make deeper cuts, accelerating the material removal process.

| Spindle Power Level | Impact on Material Removal Rate (MRR) |

|---|---|

| Higher Spindle Power | Enables a higher MRR by allowing larger passes, especially for hard or thick materials. |

| Lower Spindle Power | Requires lighter passes, leading to a slower MRR and longer processing times. |

Precision grinding, on the other hand, operates with a very low MRR. The focus shifts from speed to control, removing only tiny amounts of material with each pass to achieve precise dimensions.

Surface finish and tolerance

The most noticeable difference between the two methods is the final surface finish and dimensional accuracy. Rough grinding leaves a coarse, uneven surface that is not suitable for a finished product.

Precision grinding creates an exceptionally smooth and fine surface finish. This process is essential for parts that must fit together perfectly or have a specific aesthetic. The goal is a cleaner finish, free of scratches or defects.

This level of control also allows for incredible accuracy. Dimensional tolerance refers to the acceptable range of variation for a part’s size.

Precision grinding can achieve extremely tight tolerances, often within ±0.0001 inches (±0.002 mm). This level of accuracy is critical for high-tech industries where even the smallest error can cause failure. The grinding process can produce parts with an accuracy grade of IT5, ensuring components meet the most demanding specifications.

The right tools for the job

Choosing the right tools is essential for successful grinding. The machine, its settings, and the grinding wheel all play a critical role in the final outcome. A rough grinding machine is built for power and high material removal, while a precision grinding machine offers the stability and control needed for fine work.

Grinding machinery and parameters

Operators adjust machine parameters differently for each type of grinding. For rough grinding, settings are aggressive to remove material quickly. For precision grinding, settings are delicate to achieve accuracy. A rough grinding machine uses higher feed rates, while a precision grinding machine uses much finer increments.

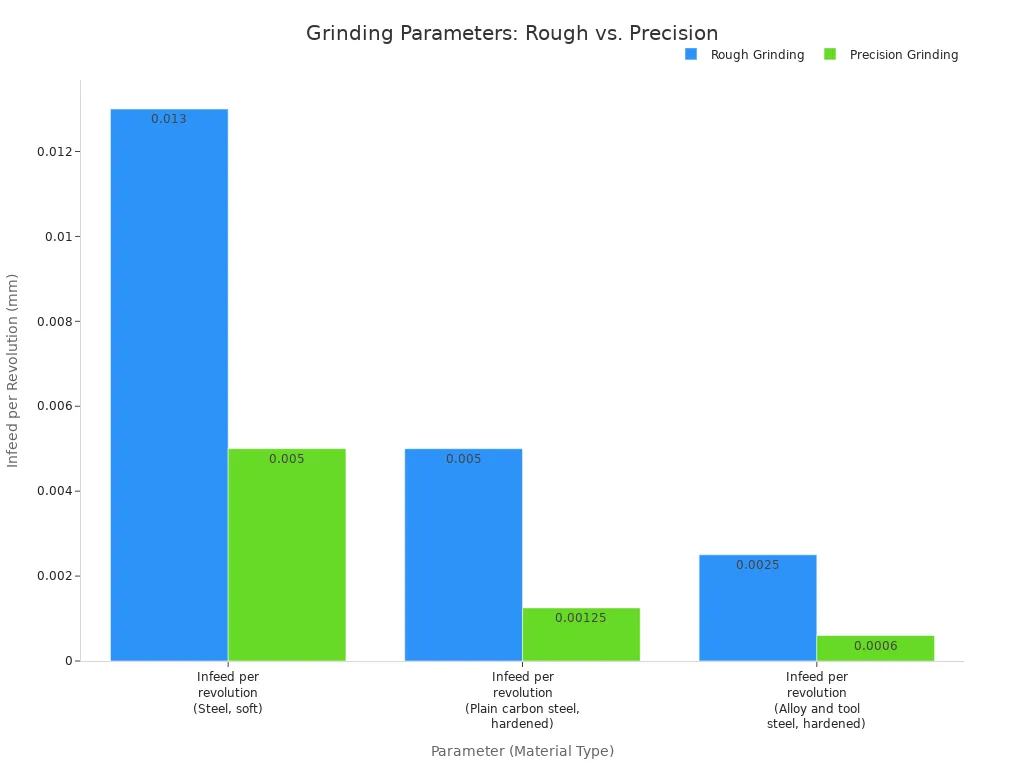

The table below shows how key parameters change between the two processes.

| Parameter | Rough Grinding | Precision Grinding |

|---|---|---|

| Downfeed per pass | 0.001 inch (0.025 mm) or more | As fine as 0.00004 inch (0.001 mm) |

| Cross-feed rate | 1/2 to 1/3 of wheel width | 1/8 to 1/12 of wheel width |

The infeed rate, or how deep the wheel cuts, also varies significantly. A rough grinding machine removes more material with each pass compared to a precision grinding machine.

Grinding wheel selection: Grit and bond

The grinding wheel is the heart of the grinding process. Its effectiveness depends on two main components: the abrasive grit and the bond that holds it.

Grit Size: Grit size determines the coarseness of the wheel. For rough grinding, operators use wheels with coarse grits (e.g., 36-46 grit). These larger particles remove material quickly but leave a rough surface. For precision grinding, finer grits (e.g., 80-600 grit) are necessary. These smaller particles remove less material, creating a smooth, polished finish.

Bond Type: The bond acts as the glue holding the abrasive grains together. The bond’s strength, or “grade,” determines how quickly the wheel wears to expose new, sharp grains. Softer bonds are often used for hard materials, while harder bonds work well on softer materials. Common bond types like vitrified and resinoid are selected based on the specific grinding task.

Choosing the right grinding wheel

Selecting the correct grinding wheel is crucial for achieving the desired results in any grinding operation. The wheel’s composition directly impacts efficiency, finish, and cost.

The role of conventional bonded abrasives

Conventional bonded abrasives are a cornerstone of the grinding industry. Materials like aluminum oxide and silicon carbide offer a fantastic balance of performance and affordability. Their primary advantages include:

- Versatility: They work effectively on a wide range of materials, including metals, wood, glass, and stone.

- Cost-Effectiveness: These abrasives are generally more affordable than other options, making them a practical choice for many jobs.

- Reliable Performance: They provide consistent and effective material removal for various grinding tasks.

Different abrasive materials excel at specific jobs. Choosing the right one ensures optimal performance for the material being worked on.

| Abrasive Type | Most Effective For |

|---|---|

| Brown Aluminum Oxide | Grinding rough iron castings |

| Green Silicon Carbide | Grinding hard materials like carbide and titanium |

| Black Silicon Carbide | Rough grinding iron castings (in resin bonds) |

| White Aluminum Oxide | Tool sharpening and heat-sensitive steels |

Aimgrind’s solutions for grinding

Finding the perfect wheel can be complex, which is why specialized brands like Aimgrind offer customized grinding wheels for different materials and processes. A versatile product like Aimgrind’s conventional bonded abrasives can be adapted for both rough grinding and precision grinding.

The key is selecting the right specification. For rapid material removal during rough grinding, operators choose wheels with coarse grits, typically between 30 and 80 mesh. These larger abrasive particles cut aggressively. For the final stages of precision grinding, a switch to wheels with much finer grits is necessary. These fine-grit wheels remove tiny amounts of material, creating a smooth surface and achieving tight dimensional tolerances. This adaptability makes conventional abrasives a valuable tool for the entire grinding workflow.

Applications of Rough Grinding and Precision Grinding

Different manufacturing stages require specific grinding methods. The application determines whether a fast, aggressive approach or a slow, careful one is better. Both processes are essential for creating finished goods across many sectors.

Common uses in manufacturing

Many manufacturing workflows begin with rough grinding. Its main purpose is rapid material removal to prepare a workpiece for later steps. The cutting tool industry, for example, uses this process to quickly shape tools before the final sharpening. A rough grinding machine is often more cost-effective than a CNC machine for removing large amounts of stock.

Precision grinding serves as the critical final step. Industries rely on it when parts need an excellent surface finish and exact dimensions.

- Aerospace and Medical: Components like turbine blades and surgical tools demand high accuracy.

- Automotive: Engine parts such as crankshafts must meet strict specifications.

- Electronics: Semiconductor wafers require a perfectly smooth surface finish.

Industry-specific examples

In the automotive industry, a rough grinding machine prepares major engine components. Technicians use grinding to shape engine blocks and camshafts. This process creates clearance for moving parts, like ensuring a crankshaft does not hit the engine block.

The aerospace industry provides a clear example of where a precision grinding machine excels.

Note: Aircraft engine turbine blades are made from advanced superalloys. A precision grinding machine is essential for finishing these parts. It creates an exceptional surface finish and holds the tight tolerances needed for safety and performance. This careful grinding prevents heat damage to the sensitive materials.

Cost and efficiency impact

Integrating both grinding processes greatly improves manufacturing efficiency. A rough grinding machine handles the heavy material removal, which reduces the workload on more delicate equipment. This separation of tasks shortens the total time needed to produce a part.

Investing in the right equipment pays off. An advanced precision grinding machine, while a significant investment, reduces waste and improves product quality. Modern grinding systems that combine rough and finish grinding in a single setup can cut processing time by up to 40%. Automating the workflow ensures a continuous flow of parts, minimizes bottlenecks, and shortens lead times from raw material to finished product.

The fundamental difference in grinding lies in the objective. Rough grinding prioritizes rapid material removal, whereas precision grinding delivers exceptional accuracy and a flawless surface finish. These two methods are complementary stages in manufacturing, where the initial grinding prepares a workpiece for the final, detailed work.

Key Takeaway: Understanding this distinction and selecting the right tools, such as those from Aimgrind, is crucial for achieving desired quality and efficiency in any grinding operation.

FAQ

What is the main difference between rough and precision grinding?

Rough grinding removes large amounts of material quickly. Its goal is speed. Precision grinding focuses on achieving an exact shape and a smooth surface. Its goal is accuracy. The choice depends on the manufacturing stage and desired outcome.

Can one machine perform both grinding types?

Some advanced CNC grinding machines can perform both rough and precision grinding in a single setup. However, many workshops use separate machines. Each machine is optimized for either high-power material removal or high-accuracy finishing to maximize efficiency.

How does grit size affect the grinding process?

Grit size directly impacts the result. The selection depends on the job’s requirements.

- Coarse Grits (e.g., 30-80 mesh) cut aggressively for fast material removal in rough grinding.

- Fine Grits (e.g., 120+ mesh) remove tiny amounts of material for a smooth finish in precision grinding.

Why choose a specialized brand like Aimgrind?

A specialized brand like Aimgrind provides expert guidance. They help manufacturers select the perfect grinding wheel for their specific material and application. This customization ensures optimal performance, better quality, and greater efficiency for both rough and precision grinding tasks.

See Also

Understanding Dry Versus Wet Grinding: Essential Knowledge for Optimal Results

Selecting the Perfect Metal Grinding Wheel for Your Specific Project Needs

Discovering the Ideal Grinding Wheel Dresser for Your Workshop Requirements

Exploring Diverse Grinding Wheel Types and Their Real-World Practical Applications

Choosing the Appropriate Grinding Wheel Specifically Designed for Stainless Steel

Contact Us

For More Grinding Solution or Customized Abrasive Tools