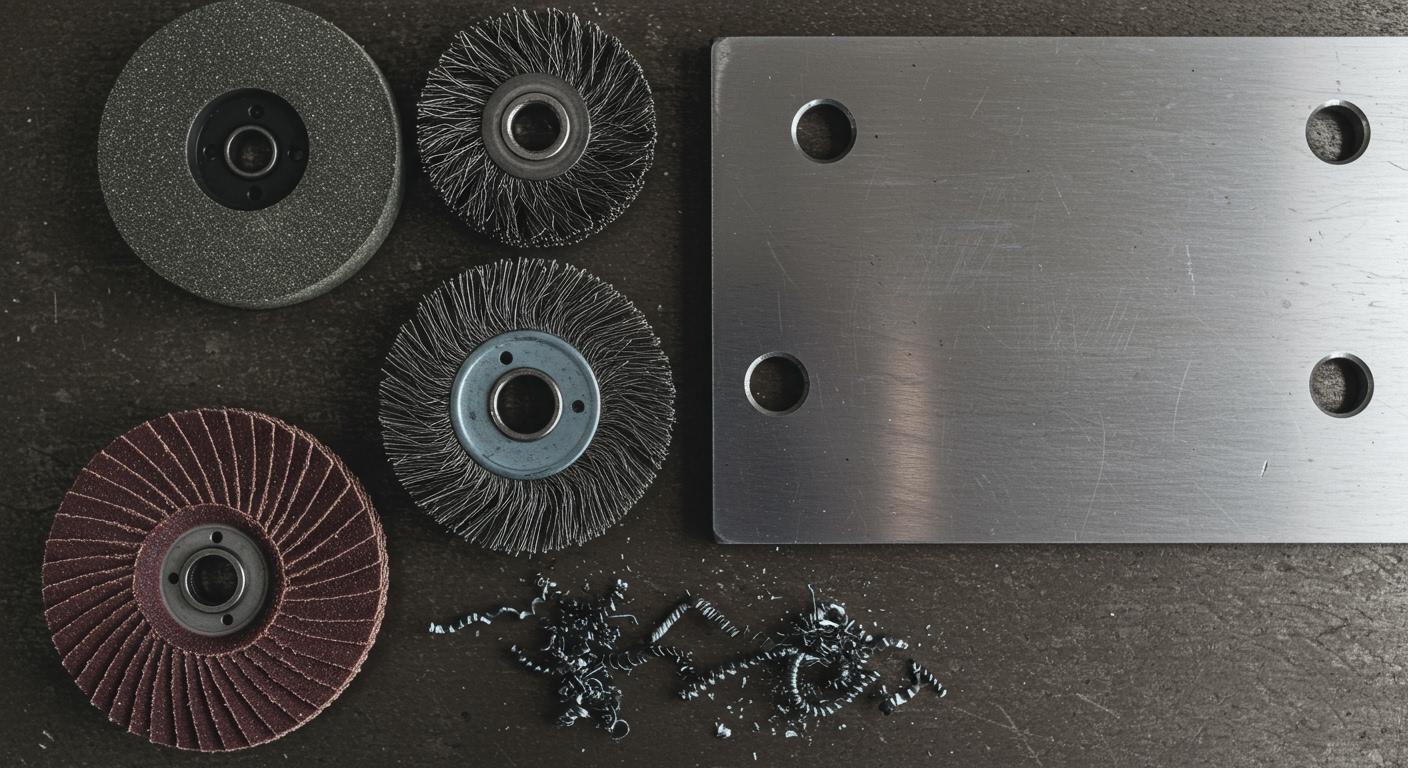

Your grinding wheel selection is a straightforward process. You can choose the correct deburring wheel by focusing on four essential factors for your specific task. This guide will help you make a confident decision.

You need to consider these four elements:

- Wheel Type

- Abrasive Material

- Grade and Density

- Workpiece Material

We will walk through each step. You will learn to select the perfect deburring wheel for any project you tackle.

Key Takeaways

- Choose between convolute or unitized wheels based on your project needs. Convolute wheels work best on flat surfaces, while unitized wheels are good for edges and curves.

- Match the abrasive material to your workpiece. Use aluminum oxide for steel, silicon carbide for non-ferrous metals like aluminum, and ceramic alumina for tough jobs.

- Select the right density and grade for your wheel. Soft, fine wheels are for polishing, while hard, coarse wheels are for removing a lot of material.

- Operate your deburring wheel at the correct speed and use coolants. This prevents burning your workpiece and makes the wheel last longer.

Step 1: Select Your Deburring Wheel Type

Your first decision involves choosing between two main grinding wheel types. Each type has a unique construction for different jobs. You will select either a convolute wheel or a unitized wheel.

Understanding the Convolute Wheel

A convolute wheel is made from non-woven abrasives wrapped around a central core. This construction makes the convolute wheel very durable for tough grinding jobs. You must run a convolute wheel in the direction shown by the arrow on its side. This unidirectional use is important for safety and performance. The convolute wheel works best on stationary machines for consistent grinding on flat surfaces.

You can find a convolute wheel in soft, medium, or hard densities. This variety helps with many tasks.

- Light Deburring: A soft convolute wheel is great for applying decorative finishes.

- Blending: A medium-density convolute wheel can blend scratch patterns from previous grinding steps.

- Heavy Grinding: A hard convolute wheel is a general purpose wheel for removing heavy burrs.

This general purpose wheel excels at edge grinding and finishing. The convolute wheel is a powerful tool for many grinding needs. A convolute wheel is a reliable choice for your grinding project.

Unitized Wheels

Unitized wheels have a different design. Manufacturers press layers of non-woven abrasives together to form a solid wheel without a core. This layered construction makes them excellent for working on edges and contours. Their soft fibers conform to irregular surfaces for smooth grinding.

These wheels are bidirectional. You can run them in either direction. This feature makes them a versatile deburring wheel for hand tools and automated robotic systems. Their flexibility allows you to access awkward angles during grinding. A unitized wheel is a great general purpose wheel.

Quick Comparison: Convolute vs. Unitized

| Feature | Convolute Wheel | Unitized Wheel |

|—|—|—|

| Construction | Wrapped on a core | Layered, no core |

| Direction | Unidirectional | Bidirectional |

| Best Use | Flat surface grinding | Contour and edge work |

Step 2: Match Abrasive to Workpiece

After you select the wheel type, your next step is choosing the right abrasive grain. This part of your grinding wheel selection is critical. The correct grain optimizes your workflow and boosts productivity. An incorrect choice can lead to rapid wheel wear or damage to your parts. Let’s look at the three most common abrasives to improve your grinding performance.

Aluminum Oxide

Aluminum Oxide is a tough and durable abrasive. You will find it is an excellent choice for grinding most steels and other ferrous alloys. Its exceptional hardness allows it to withstand the high pressures of grinding without dulling quickly.

Key Benefit: Aluminum oxide has a low-iron content. This feature is vital because it prevents rust from depositing on your workpiece surface, saving you from costly repairs later.

This abrasive is a versatile workhorse for many general-purpose grinding applications.

Silicon Carbide

You should choose silicon carbide for non-ferrous metals. It works perfectly on materials like aluminum, brass, and titanium. Silicon carbide is sharper and more friable than aluminum oxide. This means the grain fractures during grinding, constantly exposing new, sharp edges. This action provides a fast cut and prevents surface burn, which is especially useful when grinding hard materials. While it excels at grinding many metals, you should avoid using it for grinding steel.

Ceramic Alumina

When you need aggressive material removal, you should turn to ceramic alumina. This premium abrasive is ideal for grinding hard-to-grind alloys and for demanding jobs like heavy deburring or descaling.

- It offers a faster cut and longer life than aluminum oxide.

- It excels at high-pressure grinding applications.

- It is the top choice for tough grinding tasks that require both speed and durability.

Choosing ceramic alumina ensures you can power through the most challenging grinding projects efficiently.

Step 3: Choose Density and Grade

Your grinding wheel selection continues with density and grade. These two factors work together to control your grinding process. Density is how compact the wheel is, while grade is the size of the abrasive grit. Understanding them helps you master your grinding results.

Soft vs. Hard Density

Density determines the wheel’s hardness. A wheel’s density affects how it performs during grinding.

- Soft Density Wheels: You should use a soft density convolute wheel for finishing and polishing. These wheels conform to the shape of your workpiece. This flexibility prevents you from accidentally changing the part’s dimensions. They are great for decorative finishes.

- Hard Density Wheels: You need a hard density wheel for tougher jobs. These are excellent for heavy grinding, blending, and cleaning. A hard convolute wheel is a great general purpose wheel for removing sharp edges.

Coarse vs. Fine Grade

Grade refers to the abrasive particle size, often called grit. A grinding wheel grit chart helps you visualize this. Coarse grits have lower numbers, and fine grits have higher numbers.

Pro Tip 💡

Coarse grits remove material faster because each particle is larger. Fine grits have more cutting particles, which creates a smoother surface finish. Your choice affects both the speed of the grinding and the final look. A grinding wheel grit chart can guide this decision.

Choosing Your Combination

The right mix of density and grade is key to successful grinding. You must match them to your project’s goal. Think of a grinding wheel grit chart for density and grade.

| Goal | Density | Grade | Result |

|---|---|---|---|

| Aggressive Deburring | Hard | Coarse | Fast material removal |

| Blending Surfaces | Medium | Medium | Smooths scratches |

| Final Polishing | Soft | Fine | Mirror-like finish |

For example, a hard convolute wheel with coarse grit is a powerful general purpose wheel for heavy grinding. For delicate work, a soft deburring wheel with fine grit is best. Using a mental grinding wheel grit chart helps you pick the right combination. This makes your general purpose wheel perform perfectly. Your grinding wheel grit chart is a key tool for any grinding task.

Step 4: Achieve the Perfect Finish

You have selected your wheel, abrasive, and density. Now you can focus on the final step: achieving a perfect finish. Your technique during the grinding process is just as important as your tool selection. Proper speed and lubrication will elevate your results.

Optimizing Operating Speed

You must operate your deburring wheel at the correct speed. This speed is measured in Surface Feet Per Minute (SFPM). Running the wheel outside its recommended SFPM range leads to poor grinding results. You can experience several problems.

- You might burn your workpiece.

- The wheel’s surface can become loaded or glazed.

- You will notice poor wheel life.

- A wheel turning too fast can even cause fires during grinding.

Following the manufacturer’s speed recommendations ensures safe and effective grinding.

Using Coolants and Lubricants

You can improve your grinding performance with coolants and lubricants. These fluids offer significant benefits during the grinding process. They reduce heat buildup, which protects both the workpiece and the wheel from damage. Lubricants also prevent the wheel from loading with material. This keeps the abrasive sharp and extends the wheel’s life. Using a coolant makes your grinding smoother and more efficient.

From Deburring to Polishing with Aimgrind

Your project may require more than just removing burrs. You might need a flawless, mirror-like finish. This is where you transition from grinding to polishing. As experts in customized abrasive solutions, we at Aimgrind understand this final step is crucial. For the ultimate surface finish, you need a specialized tool.

Aimgrind offers a range of high-quality Polishing Wheels. Our wheels are designed for materials like glass and metal. They deliver superior, reflective finishes that elevate the quality of your final product. When your goal is perfection, trust Aimgrind to provide the right polishing solution for your needs.

You now have the knowledge to choose the right deburring wheel. Your selection process involves four key steps:

- Picking the wheel type

- Matching the abrasive

- Choosing density and grade

- Perfecting your grinding technique

A great finish starts with proper grinding. You can perfect your grinding results with the right tools. Apply this guide to your next grinding project. Explore Aimgrind’s solutions to master your grinding and achieve superior results from your grinding process.

FAQ

Can I use one deburring wheel for all my projects?

You should select a specific wheel for each job. A single wheel will not give you the best results across different materials and finish requirements. Matching the wheel to your project ensures better performance, safety, and a higher quality finish.

What happens if I run a convolute wheel backward?

You must never run a convolute wheel against its directional arrow. Running it backward can cause the abrasive material to unravel from the core. This will destroy the wheel and create a serious safety risk for you and others nearby.

How do I know when to replace my deburring wheel?

You should replace your wheel when you notice a significant drop in performance. Look for signs like slow cutting, visible damage, or if the wheel has worn down to a much smaller diameter. A worn wheel is less effective and can be unsafe.

Why is my workpiece getting burned during grinding? 🔥

Burning often happens when your wheel speed is too high or you apply too much pressure. You should check the manufacturer’s recommended SFPM for your wheel. Using a coolant or lubricant also helps reduce heat and prevent burning your part.

See Also

Selecting the Perfect Metal Grinding Wheel for Your Specific Project

Picking the Optimal Bench Grinding Wheel Material for Your Requirements

Identifying the Ideal Grinding Wheel for Your Carbide Tool Sharpening

Selecting the Appropriate Grinding Wheel for Your Circular Saw Blade

Discovering the Most Effective Grinding Wheel Dresser for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools