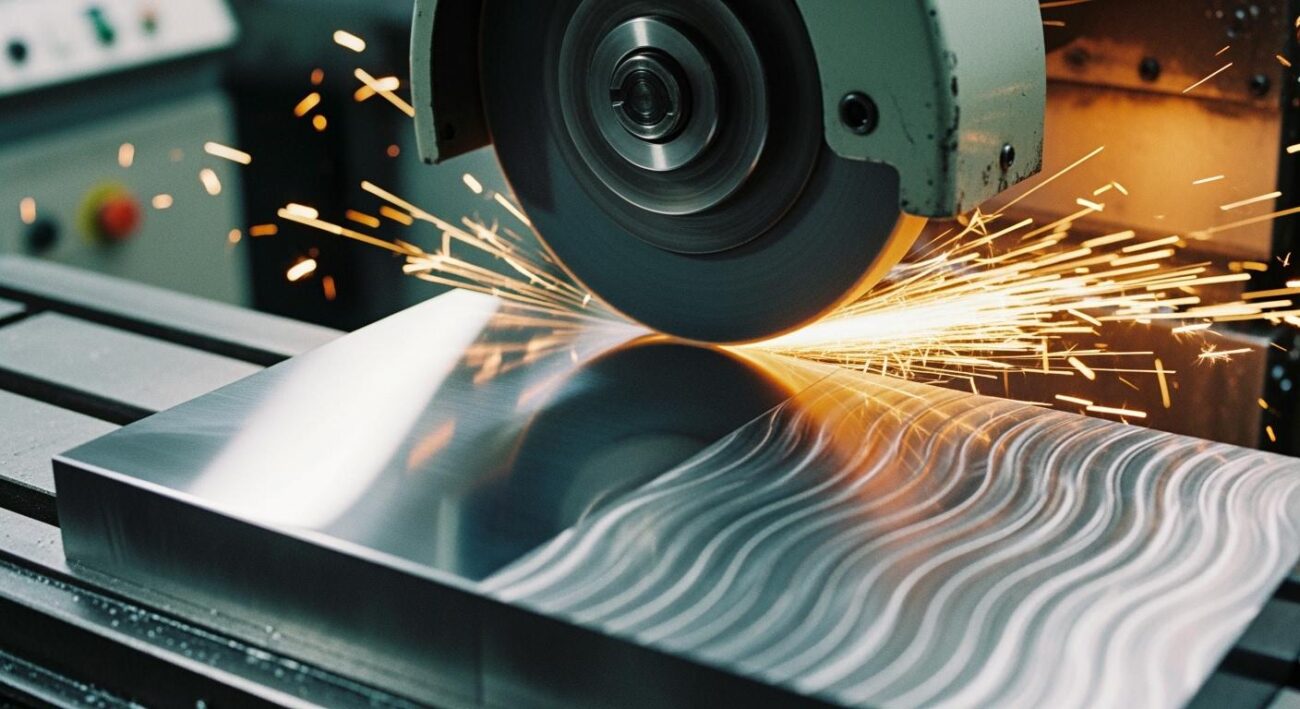

Surface grinding is a precision process. You may still face common problems like burning or a poor finish. These typical grinding errors are frustrating. This troubleshooting guide offers clear solutions. Most common grinding problems originate from three areas. You should check the grinding wheel, the machine setup, or the wheel dressing process. Understanding these sources is the first step to fixing the problems.

Key Takeaways

- Check your grinding wheel, machine setup, and wheel dressing first. These are the main causes of grinding problems.

- A poor surface finish often comes from the wrong wheel, dirty coolant, or bad machine settings. Use the right wheel and clean your coolant.

- Workpiece burning happens from too much heat. Reduce your depth of cut and use enough coolant to prevent this.

- Vibration and taper issues come from an unbalanced wheel or a loose machine. Balance your wheel and make sure your machine is stable.

- A grinding wheel can get clogged or dull. Dress your wheel often to keep it sharp and cutting well.

Common Grinding Problems with Surface Finish

A faulty grinding result often appears as a poor surface finish. This is one of the most frequent common problems operators face. Achieving a smooth, precise surface is the goal of grinding, but several factors can prevent you from getting the quality you need.

Causes of Poor Surface Finish

You may see a rough surface finish for many reasons. The issue often traces back to the grinding process itself. Understanding these causes is the first step toward a solution.

- Incorrect Wheel Specification: A grinding wheel with a large grit size (like 60#) will produce a rougher surface than a wheel with a finer grit (like 80#).

- Improper Wheel Dressing: A dull or loaded wheel will not cut efficiently. It can burnish or smear the material instead of shearing it, leading to a poor finish.

- Contaminated Coolant: Dirty coolant contains small metal particles. These particles get trapped between the wheel and the workpiece, causing random scratches and imperfections on the surface.

- Incorrect Machine Parameters: Using the wrong feed rate or grinding pressure can cause chatter marks, gouging, or burn marks on your workpiece.

Solutions for a Better Surface

You can fix these problems with a systematic approach. The right solutions will help you achieve a high-quality surface finish consistently.

Tip: Start by checking your grinding wheel. The correct wheel selection is the primary fix for many surface finish issues.

For hard or brittle materials like ceramics, composites, or hard alloys, you need a high-performance wheel. Specialized wheels, such as Aimgrind‘s diamond grinding wheels, are engineered for these demanding applications. They provide a superior finish and prevent defects.

Next, examine your coolant system. Proper coolant filtration is critical. Fine particles suspended in the fluid can ruin your workpiece surface. Ensure your filtration system removes contaminants effectively. Also, check that you are using correct oscillation strokes during the grinding cycle. A smooth, consistent motion helps prevent uneven wear and improves the final finish.

Thermal Damage and Workpiece Burning

Seeing burn marks on your workpiece is one of the most serious common problems in grinding. This thermal damage indicates that the workpiece is burnt, which can alter its hardness and compromise its integrity. You can prevent this issue by understanding its root causes.

Causes of Grinding Burn

Grinding generates intense heat in a very small contact zone. This heat can quickly damage your material. Several factors contribute to this problem.

- Excessive Heat Generation: Friction between the wheel and the workpiece creates high temperatures. Hard materials especially increase this friction.

- Aggressive Machine Settings: A depth of cut that is too deep removes too much material at once. This action builds up heat faster than it can dissipate.

- Ineffective Coolant: Your coolant can boil if the surface temperature gets too high. This creates a vapor barrier, preventing the fluid from cooling the part effectively.

Solutions to Prevent Burning

You can implement several effective solutions to manage heat and avoid burning. A systematic check of your process will lead to better results.

Tip: Start by adjusting your machine parameters. Reducing the depth of cut is a simple first step to lower heat generation. You can also increase the work speed to reduce the contact time between the wheel and the part.

Proper coolant application is also essential. Your coolant stream must have enough pressure and flow to break through the air barrier created by the spinning wheel. This ensures the fluid reaches the grinding zone to cool and lubricate. Using an open-structure grinding wheel can also help. These wheels have more space for chip removal and coolant flow, which significantly lowers grinding temperatures and prevents thermal damage.

Chatter, Vibration, and Taper Issues

Vibration, wheel chatter, and taper are common problems that can ruin your workpiece. These issues prevent you from achieving the precision required for parts with tight tolerances. They often result in poor roundness and an unacceptable finish. Understanding the source of these errors is key to fixing them.

Causes of Chatter and Taper

You will find that most vibrations come from an imbalance in the grinding system. A wheel out of balance is a primary cause. The uneven mass distribution in a spinning wheel creates forces that cause the machine to vibrate. This vibration transfers to your workpiece, creating a chattery surface. Other causes include:

- Worn spindle bearings or a bent spindle

- Loose machine parts or an unstable foundation

- An improperly dressed or loaded grinding wheel

- Aggressive grinding parameters like high feed rates

Taper, or a non-parallel surface, usually points to a machine alignment problem. If your machine’s ways are not true or the chuck is not parallel to the table’s movement, the wheel will not grind evenly. This misalignment results in a tapered part and affects the final roundness.

Effective Solutions for Chatter and Taper

You can find effective solutions by systematically checking your machine and setup. Correcting these issues will improve part geometry and surface finish.

Tip: Always start by balancing your grinding wheel. This is the most effective way to reduce vibration and eliminate wheel chatter. Use a proper balancing stand to ensure the wheel has an even mass distribution.

After balancing the wheel, you should check your machine’s stability. Ensure the machine is perfectly level on a solid foundation. Tighten any loose components that could contribute to vibration. For taper issues, you must precisely align your machine. Use a dial indicator to check that the work head and table are parallel to the grinding head’s axis. Relying on scribed lines is not accurate enough for high-precision work. A proper alignment is essential for achieving good roundness.

Common Grinding Wheel Problems

Your grinding wheel is the heart of the operation, but it can also be the source of frustrating problems. When your wheel stops cutting effectively, you lose time and produce scrap parts. Understanding these common grinding wheel problems is the first step toward finding the right solutions.

Causes of Wheel Loading and Glazing

Two main issues prevent your grinding wheel from performing its job: loading and glazing. You can identify these problems by inspecting the wheel’s surface.

- Loading: This happens when particles of the material you are grinding clog the pores of the wheel. Ductile or soft materials often cause this issue. The clogged wheel loses its cutting ability and generates excess heat.

- Glazing: This occurs when the abrasive grains on the wheel become dull and smooth. The wheel face will look shiny. This is a sign that the bond is too hard for your material, preventing dull grains from breaking away to expose fresh, sharp cutting edges.

In both cases, you will find the wheel not cutting efficiently. This leads to poor surface finish, thermal damage, and a wheel life too short for your needs.

Solutions for Wheel Performance

You can restore your wheel’s cutting performance with the right approach. The first and most immediate solution is proper dressing.

Tip: A correct dressing process is essential for good grinding. Use a sharp, high-quality dressing tool to open the wheel face. This action removes loaded material and dull grains, restoring the wheel’s cutting ability.

Regular dressing keeps your grinding wheel in optimal condition for cutting. However, if loading or glazing returns quickly after dressing, you have a bigger issue. Persistent problems indicate your wheel specification is wrong for the material. A wheel not cutting properly is often a mismatch between the wheel’s bond or grit and the workpiece.

This is where a custom solution becomes valuable. If you face ongoing issues, a provider like Aimgrind can analyze your process. They can design a grinding wheel with the correct formula to match your specific material and application, ensuring efficient cutting and eliminating these persistent problems.

This troubleshooting guide shows a clear path to success. You can solve most common problems by checking your grinding wheel, machine settings, and dressing process. Applying these logical steps improves your outcomes and efficiency. A proper dressing routine keeps your wheel sharp. However, some jobs require more than a standard wheel.

For persistent issues or a better surface on tough materials, consult an expert. A custom solution from Aimgrind saves time and material by optimizing your grinding wheel and dressing strategy, reducing scrap and rework.

FAQ

What should I check first when I have a grinding problem?

You should always start with the three main areas. Check your grinding wheel for damage or wear. Inspect your machine setup for stability and alignment. Finally, review your wheel dressing process to ensure the wheel face is sharp and clean.

How do I know if my grinding wheel is loaded or glazed?

You can inspect the wheel’s surface. A loaded wheel has metal particles stuck in its pores, making it feel clogged. A glazed wheel looks shiny and smooth because the abrasive grains are dull. Both conditions prevent the wheel from cutting properly.

When should I consider using a diamond grinding wheel?

You should use a diamond grinding wheel for hard or brittle materials. These include ceramics, hard alloys, and composites. For these demanding jobs, a specialized wheel from an expert like Aimgrind provides a superior finish and prevents defects.

Why is wheel dressing so important?

Wheel dressing is crucial for maintaining performance. It removes clogged material and dull abrasive grains from the wheel’s surface. This process restores the wheel’s cutting ability, which helps you achieve a better surface finish and prevent workpiece burning.

Contact Us

For More Grinding Solution or Customized Abrasive Tools