Centerless grinding can produce common defects like out-of-roundness, taper, and poor surface finish. These centerless grinding defects are common grinding defects. The problems often trace back to an incorrect machine setup, a faulty grinding wheel, or operational parameters. Solving these defects is crucial. Effective correction of centerless grinding problems leads to significant financial benefits.

- Minimizes material waste and associated costs.

- Improves efficiency by streamlining the grinding process.

- Reduces part defects and scrap rates for a better surface.

This guide provides clear solutions for these centerless grinding issues, helping you master the centerless grinding machine and its grinding wheel for higher precision.

Key Takeaways

- Out-of-roundness, or lobing, happens when parts are not perfectly round. Adjust the work-rest blade height and regulating wheel speed to fix this problem.

- Taper means a part is wider at one end. This problem comes from machine alignment issues. Adjust the regulating wheel and re-dress the grinding wheel to correct it.

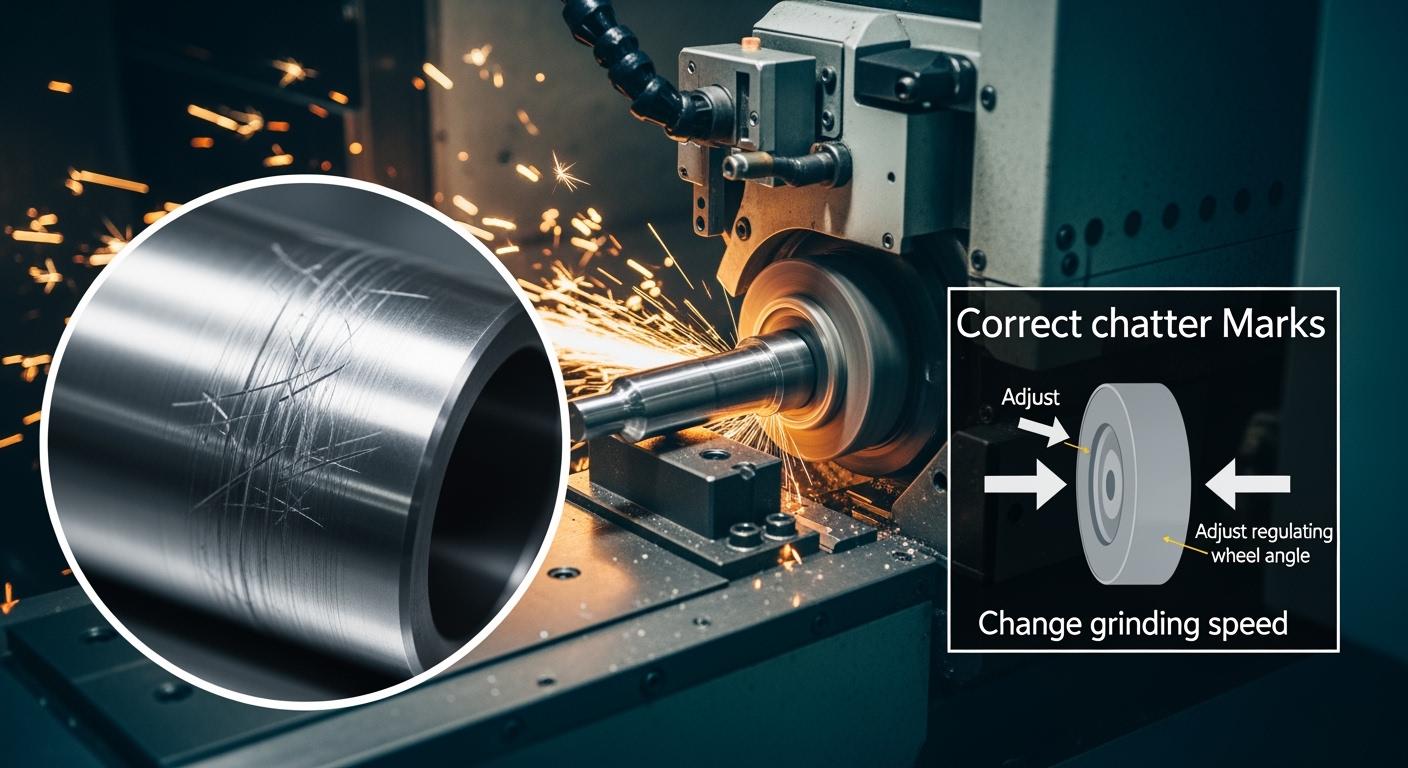

- Chatter marks are wavy lines from vibrations. An unbalanced grinding wheel often causes chatter. Balance the wheel and adjust its speed to stop vibrations.

- Spiral lines are helical marks on the part. An uneven grinding wheel surface causes these lines. Dress the wheels properly and adjust speeds to prevent them.

- Poor surface finish means the part looks rough. Dirty coolant or the wrong grinding wheel can cause this. Use a finer grit wheel and keep the coolant clean for a smooth finish.

Diagnosing Out-of-Roundness (Lobing)

Out-of-roundness, or lobing, is one of the most common defects in centerless grinding. This issue results in parts not being round, even if they measure correctly with a two-point micrometer. Understanding the root causes is the first step toward fixing these grinding problems.

Causes of Lobing

Lobing primarily occurs due to the geometric instability of the grinding setup. In this process, the workpiece is not held by fixed centers. This “centerless” nature means any surface irregularity on the workpiece can cause it to shift as it contacts the work blade and regulating wheel. This movement produces a lobed, out-of-round surface. The geometry of the setup also contributes to these defects. For example, odd-numbered lobes (like 3, 5, or 7) often appear when tangent angles are below four degrees.

Key Mechanical Causes:

- Incorrect Blade Height: A major cause of lobing is an improperly set work-rest blade. Placing the blade directly on the centerline of the grinding wheel and regulating wheel creates a two-point contact that promotes lobing.

- Uneven Blade Wear: A worn or damaged blade surface prevents the workpiece from rotating uniformly, leading to roundness defects.

Corrections for Roundness

Correcting roundness involves adjusting the machine’s geometry and operational parameters. A stable grinding process is essential for producing perfectly round parts.

- Adjust the Work-Rest Blade: The most effective correction is to adjust the blade height. The centerline of the workpiece should be positioned slightly above or below the centerline of the grinding wheel and regulating wheel. This change creates a rounding action that eliminates lobing.

- Optimize Regulating Wheel Speed: The speed of the regulating wheel directly impacts stability. If the speed is too fast, the grinding wheel cannot cut the material smoothly. Reducing the regulating wheel speed stabilizes the workpiece during the grinding cycle. Slower speeds are especially useful for in-feed grinding, as they improve roundness during the spark-out phase.

- Inspect and Dress the Grinding Wheel: Ensure the grinding wheel is properly dressed and balanced. An out-of-balance or poorly dressed wheel can transfer vibrations to the workpiece, causing roundness issues.

By addressing these core causes, you can significantly reduce lobing defects and improve the precision of your components.

Solving Taper and Other Centerless Grinding Defects

A taper is a common issue where a workpiece is ground to different diameters at each end. This is one of the most frustrating centerless grinding defects because it directly impacts part tolerance. Understanding the root causes is essential for solving these grinding problems.

Causes of Taper

Taper defects almost always point to an alignment problem within the centerless grinding setup. The geometry between the workpiece, grinding wheel, and regulating wheel must be perfect. If not, uneven material removal occurs.

The primary machine setup causes for taper include:

- Angular misalignment between the grinding wheel and the workpiece centerline.

- Incorrect positioning of the work rest blade.

These alignment errors create uneven pressure. For example, a taper can occur if the part is grinding too hard on either the entrance or exit end of the wheel. This imbalance directly produces a tapered workpiece. Identifying these specific causes is the first step toward correction.

Corrections for Taper

Correcting a taper requires careful adjustments to the machine’s alignment. The goal is to ensure the workpiece travels on a perfectly straight path through the grinding zone.

Key corrections involve realigning the guides and conditioning the grinding wheel.

- Adjust the position of the regulating wheel in relation to the workblade.

- Check that the grinding wheel cuts evenly across its entire width.

- Re-dress the regulating wheel to ensure it is perfectly cylindrical.

Dressing the grinding wheel face is another critical step. For cylindricity defects like taper, you must adjust the dresser’s position based on the workpiece’s taper direction and then re-dress the grinding wheel. Timely dressing prevents other defects, such as trumpet-shaped parts that result from a dull wheel. Using a multi-point diamond dresser can effectively create a straight or tapered surface on the grinding wheel, fixing the source of the taper.

Eliminating Chatter and Vibration Defects

Chatter marks are wavy patterns on a workpiece surface caused by vibration during the grinding process. These defects seriously compromise the part’s quality and finish. Understanding the sources of vibration is the first step to solving these problems.

Causes of Chatter

Chatter defects almost always originate from vibration. An unbalanced grinding wheel is a primary cause. Even a slight imbalance creates significant vibrations at high rotational speeds. The centerless grinding machine then transfers these vibrations to the workpiece, resulting in chatter marks across its surface.

Mechanical Causes of Vibration ⚙️

Besides the grinding wheel, other mechanical issues can be causes of vibration:

- Worn or poorly designed spindles.

- Issues with the spindle drive motor or belts.

- Incorrect motor parameter settings.

- Vibrations from other machines in the shop.

Identifying the specific source of vibration is crucial for effective correction. These causes lead to poor part quality and other grinding defects.

Centerless Grinding Wheel Corrections

Correcting chatter often involves addressing the grinding wheel itself. Dynamic wheel balancing is a critical tool for vibration control in precision grinding. This process is more accurate than static balancing for high-speed applications. Experts recommend re-balancing the grinding wheel after every dressing, as removing material alters its weight distribution.

Another effective technique involves adjusting rotational speeds. The RPM ratio between the grinding wheel and the dressing tool can create or eliminate chatter. Certain non-integer ratios can reduce the pattern’s amplitude as the wheel rotates. For example, a dresser-to-wheel RPM ratio of an integer plus 0.125 to 0.25 is recommended to minimize chatter on the workpiece. Proper setup in centerless grinding is essential for preventing these defects.

Preventing Spiral Lines in Centerless Operations

Spiral lines, or feed lines, are helical marks that appear on the surface of a workpiece after grinding. These defects are unacceptable for high-precision components. Understanding the root causes of these lines is essential for preventing them and solving related grinding problems.

Causes of Spiral Lines

The primary cause of spiral lines is an improperly prepared grinding wheel. An uneven or excessively straight surface on the grinding wheel leads to partial contact with the workpiece. As the part moves through the centerless grinder, this inconsistent contact creates a spiral pattern. These defects often point to issues with the dressing process. Other causes can include incorrect machine settings or hydraulic system issues that affect the stability of the grinding operation. Identifying these specific causes is the first step toward a solution.

Corrections for Feed Lines

Correcting spiral line defects requires careful adjustments to both the machine setup and the grinding wheel itself. The goal is to ensure smooth, full contact between the workpiece and the wheel.

Key Adjustments for a Flawless Finish 📝

- Properly Dress the Wheels: The most effective correction is to re-dress the grinding wheel. Ensure the dresser creates a perfectly straight surface. You can also dress the edge of the grinding wheel to a slight radius or taper to improve the entry and exit of the part.

- Optimize Speeds and Feeds: Reduce the worktable and workpiece rotational speeds. A good rule of thumb is to set the workpiece’s linear speed to be 1/60th to 1/100th of the grinding wheel’s speed.

- Adjust the Regulating Wheel: Swiveling the regulating wheel slightly can change the contact geometry and help eliminate feed lines. The dress angle on the regulating wheel should typically be about 0.5 to 0.75 degrees less than its inclination angle.

By implementing these corrections, you can prevent spiral lines and achieve a smooth, defect-free surface on every part.

Achieving a Perfect Surface Finish

A perfect surface finish is the ultimate goal of any precision grinding operation. However, various defects can compromise the final quality of the workpiece. Achieving a smooth, flawless surface requires understanding the common causes of these issues and how to correct them effectively.

Causes of Poor Finish

Poor surface finish can appear as roughness, scratches, or grinding burn. These surface finish problems often stem from a few key areas in the grinding process. Identifying the source is the first step to fixing these defects.

Common Causes of a Rough Surface ⚙️

- Dirty Coolant: Contaminated fluid can carry metal fines and loose abrasives back to the workpiece, causing scratches and pitting. It also reduces cooling, which can lead to thermal damage.

- Dresser Issues: A worn or improperly used dressing tool will create a rough, uneven surface on the grinding wheel, which then transfers to the workpiece.

- Incorrect Grinding Wheel: Using a grinding wheel with a grit size that is too coarse for the desired finish is a primary cause of roughness.

- Loose Abrasive Grains: Grains that break free from the grinding wheel bond can get trapped between the wheel and the workpiece, creating drag lines.

Corrections for Surface Finish

Correcting surface finish defects often comes down to the grinding wheel itself. The wheel’s specification and condition are the most significant factors influencing the final surface quality. Using a grinding wheel with the wrong grit or a low-quality bond will cause persistent problems. A coarse grit removes material quickly but leaves a rougher surface.

A proven solution is to use a high-quality, finer grit wheel. For example, Aimgrind‘s conventional bonded abrasives are designed for consistent performance and superior finishes. These grinding wheels provide the reliability needed for precision grinding. Aimgrind also has deep expertise in providing customized grinding solutions to perfectly match your material and process requirements.

For a flawless finish, consider these key corrections:

- Select the Right Grinding Wheel: Choose a finer grit size (500# to 800#) for finishing passes. This reduces the size of each cut, creating a smoother surface.

- Refine the Dressing Process: Use a slower traverse speed when dressing. This creates a less aggressive, smoother face on the grinding wheel.

- Maintain Clean Coolant: Ensure your coolant system is clean and properly filtered to prevent contaminants from scratching the workpiece.

By optimizing your grinding wheels and process parameters, you can eliminate surface defects and consistently produce high-quality parts.

Successfully troubleshooting centerless grinding issues requires a systematic process. You must identify the defect, find its root cause, and apply a precise correction. However, prevention is always better than taking corrective actions. A consistent maintenance schedule, proper machine setup, and using a high-quality grinding wheel are essential. Mastering these grinding techniques helps control the centerless process. This leads to higher part quality, less scrap, and improved efficiency.

Grind with Passion, Achieve with Aim

FAQ

What is the most common defect in centerless grinding?

Out-of-roundness, or lobing, is one of the most common defects. This issue happens when the workpiece geometry is unstable during the grinding process. Incorrect work-rest blade height is a primary cause of these particular defects.

Can a single adjustment fix all centerless grinding defects?

No, a single adjustment rarely fixes all centerless grinding defects. Each problem, like taper or chatter, has a specific cause. You must identify the root of the issue to apply the correct solution for these common defects.

How does wheel dressing prevent grinding defects?

Proper wheel dressing creates a clean and true cutting surface on the grinding wheel. This action prevents many defects. It removes dull grains and corrects the wheel’s shape, which stops issues like spiral lines and poor surface finish from developing.

Why is my part quality still poor after fixing common defects?

Your grinding wheel choice might be the problem. Even with a perfect setup, a low-quality or incorrect wheel can cause issues. Using a high-quality wheel designed for your specific grinding application is essential for achieving a great finish.

Contact Us

For More Grinding Solution or Customized Abrasive Tools