Out-of-tolerance parts are among the most common quality problems in grinding processes. Achieving dimensional accuracy is a fundamental objective of the grinding process, as this precision ensures component functionality and helps control manufacturing costs. Meeting tighter tolerances is essential for modern production. This guide provides a systematic approach to identifying the root causes of dimensional inaccuracy. Understanding these factors is crucial for operators to hit dimensional targets and maintain consistent precision and accuracy, ensuring final dimensions are correct after grinding.

Key Takeaways

- A grinding machine must be in good condition. Problems like spindle vibration or loose parts cause errors in the final product.

- How you hold the workpiece matters. If the part is not held correctly or has internal stress, it will not be ground accurately.

- The grinding wheel is very important. Using the wrong wheel or a worn-out wheel leads to mistakes in size and finish.

- Setting up the grinding process correctly is key. Things like how deep the cut is or how fast the wheel moves affect the final part’s accuracy.

Machine-Related Dimensional Inaccuracy:

The grinding machine is the foundation of any precision operation. Its condition directly influences the final quality of a workpiece. Even with a perfect setup, a machine with underlying issues will consistently produce parts that fail to meet tighter tolerances. Identifying these machine-related problems is the first step toward achieving reliable precision and accuracy.

Spindle Runout and Vibration:

The spindle holds and rotates the grinding wheel. Any deviation in its rotation, known as runout, or any vibration transfers directly to the workpiece. These movements can cause significant dimensional inaccuracy.

- Low-frequency vibrations often create wavy patterns on the part.

- Pulse-like movements, sometimes from the machine’s thermal compensation systems, can leave step-shaped marks.

- High-frequency vibrations may degrade the overall surface finish and prevent the part from achieving the required precision.

Poor Machine Rigidity and Stiffness:

A grinding machine must be extremely rigid to withstand the forces generated during the grinding process. The stability of the machine tool is a crucial factor influencing machining accuracy. A machine that lacks stiffness will flex or deflect under load. This movement, however small, causes the grinding wheel to remove material inconsistently, making it impossible to hold close tolerances.

Slide and Guideway Inaccuracies:

Slides and guideways direct the machine’s moving components. Wear on these surfaces from friction or contamination introduces errors in positioning. This wear prevents smooth, predictable motion.

Signs of guideway wear include jerky or uneven movement, visible scratches or grooves on the tracks, and a noticeable delay between a command and the machine’s response. These issues directly lead to dimensional errors and poor surface quality.

Thermal Deformation of the Machine:

Grinding generates significant heat, which affects not only the workpiece but the machine itself. Temperature changes from startup to full operation cause machine components to expand and contract. This thermal growth alters the machine’s geometry. During long grinding cycles, this constant change can cause dimensional drift, where the final dimensions of parts slowly change over the production run.

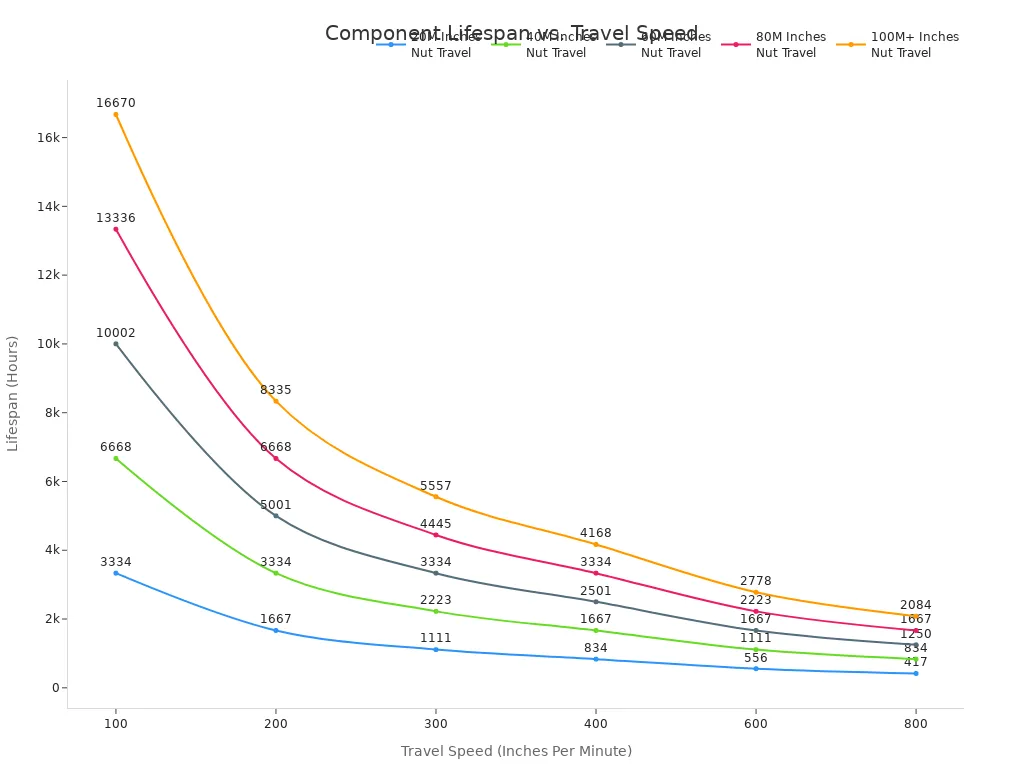

Worn Machine Components:

Critical components like ball screws and bearings have a finite lifespan. As they wear, they lose their ability to position machine elements with precision. The lifespan of a ball screw, for example, is often measured by an L-10 rating, which estimates its operational life in inches of travel. As the chart below shows, this lifespan decreases significantly as travel speed increases. Worn components introduce backlash and play, destroying the machine’s ability to maintain precision and accuracy.

Ineffective Coolant Delivery:

Proper coolant delivery is essential for managing heat during grinding. If nozzles are clogged, misaligned, or provide insufficient flow, localized hot spots can develop on the machine or workpiece. This uneven heating causes thermal expansion, which can spoil the part’s final dimensions.

Workpiece and Fixturing Issues:

Beyond the machine itself, the workpiece and how it is held are critical sources of error. A flawless machine cannot compensate for a poorly prepared or improperly secured part. These issues directly undermine the precision of the grinding operation.

Improper Workpiece Fixturing:

The method used to hold a workpiece is fundamental to achieving accuracy. Excessive or uneven clamping force can bend or deform a part before the grinding even begins. To prevent this, operators must calculate the necessary clamping force and distribute it evenly.

Best Practices for Fixturing:

- Position clamps opposite bearing points to prevent the part from springing.

- Use fixtures like bridge clamps to spread force over a larger area.

- Ensure the clamping design provides stability without causing part distortion.

Workpiece Distortion and Instability:

An unstable workpiece cannot be ground accurately. If the part moves or vibrates in the fixture, it becomes impossible to maintain consistent contact with the grinding wheel. This instability often leads to specific geometric errors. For example, unstable clamping or misaligned work centers can cause unwanted taper. Similarly, if the centers holding the part are not perfectly round, the workpiece will not rotate on a true axis, resulting in out-of-roundness errors.

Internal Material Stress:

Many workpieces undergo heat treatment processes like hardening before grinding. These processes, especially those involving rapid cooling or quenching, can lock significant stress inside the material. During grinding, the removal of surface material releases these internal stresses. This release causes the part to warp or change shape, leading to dimensional inaccuracy and making it difficult to hold tight tolerances.

Inconsistent Material Hardness:

Variations in hardness across a single workpiece can also cause problems. The grinding wheel will remove material at different rates from softer and harder areas. This uneven material removal makes it challenging to achieve uniform dimensions and a consistent surface finish, compromising the final precision of the component.

Thermal Expansion of the Workpiece:

The heat generated during grinding causes the workpiece to expand. Different materials expand at different rates, a property measured by the coefficient of thermal expansion. For example, aluminum expands nearly twice as much as steel for the same temperature change.

| Material | Coefficient of Thermal Expansion (10⁻⁶/°C) |

|---|---|

| Steel | 12.0 |

| Aluminum | 21 – 24 |

| Titanium | 8.5 – 9.0 |

This expansion can cause the final dimensions to be incorrect once the part cools. Operators must account for this effect to meet tighter tolerances.

Grinding Wheel Impact on Precision and Accuracy:

The grinding wheel is where the machine’s precision meets the workpiece. Its condition and specification are paramount for achieving tight tolerances. An incorrect or poorly maintained wheel will undermine even the most capable machine, leading to dimensional inaccuracy and scrapped parts. True precision and accuracy depend heavily on the wheel itself.

Incorrect Wheel Specification:

Selecting the correct grinding wheel is a critical first step. Parameters like abrasive type, grit size, hardness, and bond directly affect the final precision and surface finish. Finer grit sizes generally produce smoother surfaces, while the bond type determines the wheel’s structural integrity.

| Grit Size | Grinding Wheel Grades | Suitable Materials | Typical Application |

|---|---|---|---|

| 30-60 | Medium-Hard | Mild steel, aluminum | General purpose, shaping |

| 70-220 | Medium-Hard | Carbide, high-speed steel | Precision grinding, finishing |

Navigating these options can be complex. Specialists like Aimgrind provide customized grinding solutions to address these challenges. For example, high-performance tools like Aimgrind’s diamond grinding wheels are engineered for specific materials like hard alloys and ceramics. This ensures consistent performance and reduces wear-related inaccuracies.

Grinding Wheel Imbalance:

An imbalanced grinding wheel creates significant vibration during rotation. This vibration transfers directly to the workpiece, making it impossible to hold close tolerances. Industry standards like ISO 1940-1 define balance quality requirements for rotating components. For high-precision grinding, spindles and wheels must meet very strict balance grades, such as G0.4, to minimize vibration.

Excessive or Uneven Wheel Wear:

As a grinding wheel wears, it loses its original shape and cutting efficiency. Uneven wear causes the wheel to become out-of-round, which directly translates into geometric errors on the part. This gradual loss of form makes it difficult to maintain consistent precision and accuracy throughout a production run.

Wheel Glazing and Loading:

Two common wheel-face issues directly impact grinding performance:

- Glazing: The abrasive grits on the wheel become dull and flat. This increases friction and heat instead of cutting material efficiently.

- Loading: Pores on the wheel face become clogged with grinding debris. This prevents the sharp grits from engaging with the workpiece.

Both conditions lead to poor cutting action and excessive heat, causing dimensional errors.

Improper Wheel Dressing:

Dressing is the process of sharpening a wheel and restoring its geometry. An improper dressing technique can introduce runout or create an incorrect profile on the wheel face. This error is then copied directly onto every part, making it a primary cause of dimensional problems.

Defective Wheel Mounting or Flanges:

A grinding wheel must be mounted securely and concentrically on the spindle. Loose or improperly torqued flange bolts can cause the wheel to wobble or shift during operation. Operators should always use a torque wrench and follow a sequential tightening pattern to ensure the wheel is stable and runs true.

Optimizing the Grinding Process:

Even with a perfect machine and setup, incorrect process parameters will consistently produce out-of-tolerance parts. Optimizing the grinding process itself is the final, critical step to achieving consistent precision and accuracy. Each parameter must be carefully controlled to meet tight tolerances.

Incorrect Depth of Cut:

An excessive depth of cut increases the grinding forces, which can cause the workpiece to deflect. While a deeper cut removes material faster, it often compromises the final dimensions and surface finish. The precision grinding process relies on very shallow depths, typically from 0.01 mm to 0.1 mm, to manage these forces and maintain stability.

Improper Traverse and Feed Rates:

Traverse and feed rates control how quickly the wheel moves across the workpiece. If the rate is too fast, the wheel may not have enough time to cut cleanly, leading to a poor finish. A rate that is too slow can generate excessive heat, causing thermal expansion and dimensional errors. Finding the optimal balance is essential for efficient and accurate grinding.

Unsuitable Grinding Speed:

The rotational speed of the grinding wheel must match the material being processed. Different materials require different speeds to avoid heat damage and achieve precision.

- Hardened Tool Steel: A speed of 4500 to 6500 SFPM is often effective.

- Heat-Sensitive Materials: Very low speeds, around 3,000 to 4,000 fpm, are necessary to minimize heat generation.

Insufficient Spark-Out Time:

Spark-out is a crucial final stage in many grinding processes. It involves letting the wheel pass over the workpiece without any additional infeed. This allows the machine and workpiece to relax from grinding pressures. Skipping this step can leave residual stress and prevent the part from reaching its final size, undermining precision and accuracy.

Inconsistent Coolant Application:

Consistent coolant flow is vital for thermal stability. Fluctuations in pressure or volume can cause thermal shock or allow hot spots to form on the workpiece.

Without adequate cooling, this concentrated heat leads to thermal expansion, which directly harms dimensional accuracy. This is especially critical when grinding materials like titanium that are prone to work hardening from heat buildup.

Operator-Induced Errors:

Operators play a direct role in the outcome of the grinding operation. Manual measurement errors are a common source of inaccuracy. These mistakes often stem from:

- Improper methodology or inconsistent techniques.

- Rough handling of measurement instruments.

- Recording values before the instrument reading has stabilized.

Such errors can lead to incorrect process adjustments, making it impossible to achieve the required precision.

Dimensional inaccuracy in the grinding process stems from four areas: the machine, workpiece setup, the grinding wheel, and process parameters. A systematic troubleshooting approach is crucial for diagnosing grinding issues, enabling teams to move from symptoms to root causes efficiently. This method prevents recurring problems and ensures consistent precision and accuracy.

The formula for achieving reliable precision and accuracy in grinding combines a well-maintained machine, proper setup, optimized parameters, and a correctly specified wheel from specialists like Aimgrind.

FAQ

What is the first step to fix dimensional errors?

Operators should first inspect the machine and the grinding wheel. Issues like spindle vibration, poor machine rigidity, and incorrect wheel dressing are common root causes. A stable foundation is essential before adjusting process parameters. A systematic check prevents wasted time and materials.

How does the grinding wheel choice impact accuracy?

The grinding wheel directly transfers precision to the part. Its specification, balance, and condition are critical. An incorrect wheel causes poor surface finish and dimensional errors.

Specialists like Aimgrind help select the right wheel, such as their diamond grinding wheels, to match specific materials and ensure consistent, accurate results.

Why do parts sometimes change size after cooling?

This happens due to two main factors:

- Thermal Expansion: The workpiece expands from grinding heat and shrinks as it cools.

- Internal Stress: Grinding can release internal material stress, causing the part to warp.

Both effects alter the final dimensions after the part reaches room temperature.

Can correct process parameters fix a bad setup?

No. Optimized process parameters cannot compensate for fundamental problems. A worn machine, an imbalanced wheel, or improper fixturing will always undermine accuracy. A correct setup provides the necessary foundation for precision, which optimized parameters then refine.

Contact Us

For More Grinding Solution or Customized Abrasive Tools