Choosing the right diamond dresser for your job is a critical step. A logical selection process ensures optimal grinding performance. You must evaluate key factors like the dressing type, wheel characteristics, and the final finish you need.

Tip: Making an informed choice improves your machine’s performance and helps you select the appropriate tool for the application.

Key Takeaways

- Choose the right diamond dresser for your job. This helps your grinding machine work better and gives you good results.

- Diamond dressers clean and sharpen grinding wheels. This makes the wheel cut well and gives you a smooth finish.

- Different jobs need different dressers. Use a single point dresser for very exact work. Use multi-point dressers for fast, big jobs.

- Match the diamond size to your grinding wheel. A bigger wheel needs a bigger diamond to last longer and work well.

- Always check the dresser’s shank size. It must fit your machine to work correctly and avoid damage.

Understanding the Diamond Dresser and Its Use

A diamond dresser is a vital tool for maintaining your grinding wheels. Over time, your wheel can become clogged with material or its abrasive grains can become dull. Dressing restores the wheel’s cutting ability, which is essential for high-precision results and top performance. Think of it like sharpening a knife; a dull wheel will rub and create heat instead of cutting effectively.

The process uses a diamond grinding wheel dresser, which is harder than the grinding wheel itself. This allows the tool to remove a tiny amount of bond material and any embedded metal chips. This action exposes fresh, sharp abrasive grains, restoring the wheel’s free-cutting performance. Choosing the right type of dresser and method is key to your success.

Straight Dressing for Flatness

You use straight dressing to create a perfectly flat and true surface on your grinding wheel. This method is fundamental for applications like surface grinding. Using the proper dressing tools correctly ensures the wheel has the right geometric form for the job.

Pro Tip: Always apply grinding fluid from the start of the dressing operation. This simple step prevents heat damage to your diamond dresser and the grinding wheel.

For a superior finish, you should apply small amounts of infeed, typically between 0.002 to 0.03 mm per pass. You can also achieve a smoother wheel surface by reducing the cross-feed speed of your dressing tool.

Form Dressing for Profiles

Form dressing is the technique you use to transfer a specific profile or contour onto a grinding wheel. This is necessary when you need to grind parts with complex shapes. The process often uses a rotary form dresser that has a single row of diamonds with a precisely shaped radius.

This is how it works:

- You input the diamond’s exact radius into the machine’s control system.

- The CNC control then generates a precise path for the dresser.

- As the dresser moves along this path, it creates the desired profile on the grinding wheel.

This flexible method allows you to create intricate shapes on your workpieces with high accuracy.

Matching Dressers to Application Specific Needs

Selecting the right tool is the most important step in achieving your desired grinding results. Each type of diamond dresser is designed for specific tasks, so understanding their differences is key to matching them to your application specific needs. From achieving superior precision on a single part to dressing wheels for high-volume production, the right choice impacts efficiency, finish quality, and tool life. At Aimgrind, we provide a comprehensive range of high-quality Diamond Tools, including various diamond dressers designed for excellent performance and durability.

The Single Point Diamond Dresser for Precision

You should choose a single point diamond dresser when your work demands the highest level of accuracy. This tool uses a single, high-quality diamond to true and dress the grinding wheel. The single point diamond dresser is the go-to choice for precision grinding because it gives you complete control over the wheel’s surface. A single point diamond dresser creates a more “open” or free-cutting wheel surface. This helps reduce heat and improve cutting action.

The versatility of the single point diamond dresser makes it essential across many industries. You will find it used for:

- Automotive Manufacturing: Grinding components like camshafts and crankshafts to exact tolerances.

- Aerospace Industry: Achieving perfect finishes on critical parts such as turbine blades.

- Medical Equipment: Creating the smooth, detailed shapes needed for surgical tools and implants.

- Tool and Die Making: Ensuring grinding wheels can produce precise molds with fine finishes.

A single point diamond dresser is a fundamental dressing tool for any precision operation. The performance of a single point diamond dresser is unmatched for fine, detailed work.

Multi-Point and Cluster Dressers

You might consider multi-point or cluster dressers for high-volume production environments. These tools feature multiple diamond points arranged in a specific pattern. This design distributes the workload across several diamonds, which increases the tool’s lifespan and allows for much faster dressing speeds.

Note: A multi-point dresser is a robust solution for frequent and heavy use. You can use it for both rough and fine dressing until the last diamond is consumed, without needing to reset the tool.

The primary advantage is efficiency. You can dress wheels significantly faster with a multi-point tool compared to a single point diamond dresser.

| Dresser Type | Dressing Speed (Normal Grinding) | Dressing Speed (Roughing) |

|---|---|---|

| Single Point | ~5 mm/s (12 ipm) | 11 mm/s (26 ipm) |

| Multipoint | ~25 mm/s (60 ipm) | 50 mm/s (120 ipm) |

While a single point diamond dresser is known for creating an open wheel face, you can achieve a similar result with a multi-point tool by adjusting the dressing speed.

Blade and Chisel Dressers for Forms

When you need to create a specific profile on your grinding wheel, you should use a blade or chisel dresser. These stationary diamond dressers are designed for shaping wheels with high accuracy. A chisel-type or coned single point diamond dresser is perfect for forming intricate shapes.

You can use these tools to create various profiles, including:

- Arcs and angles

- Grooves and radii

- Complex step or thread forms

These capabilities make them vital in industries that require precise part geometries. For example, you will see them used in the manufacturing of bearings, crankshafts, piston rings, and electronic components. A single point diamond dresser with a chisel tip is a specialized tool for these demanding jobs.

Impregnated Dressers for Superabrasives

You need a special type of diamond grinding wheel dresser for superabrasive wheels like CBN and diamond. Impregnated diamond dressers are the right choice for this task. These tools contain diamond grit embedded within a metal or resin matrix.

The mechanism is straightforward. The hard diamond grit in the dresser cuts through the extremely hard abrasive grains and strong bond material of the superabrasive wheel. This action effectively exposes fresh cutting edges. Using an impregnated diamond dresser offers several benefits:

- Extended tool life

- Faster dressing rates

- Improved tolerance to vibration

While a single point diamond dresser is not suitable for these wheels, an impregnated dresser has the necessary composition to condition them effectively, ensuring top performance.

Key Specifications for Your Dresser

After you choose the right type of diamond dresser, you must select the correct technical specifications. This step is crucial for getting the best results. You need to think about several factors to ensure optimal performance. These include:

- The tolerance you need to hold

- The required surface finish

- The grinding machine type you are using

- The grinding wheel’s own specifications

Getting these details right ensures your tool works perfectly for your job.

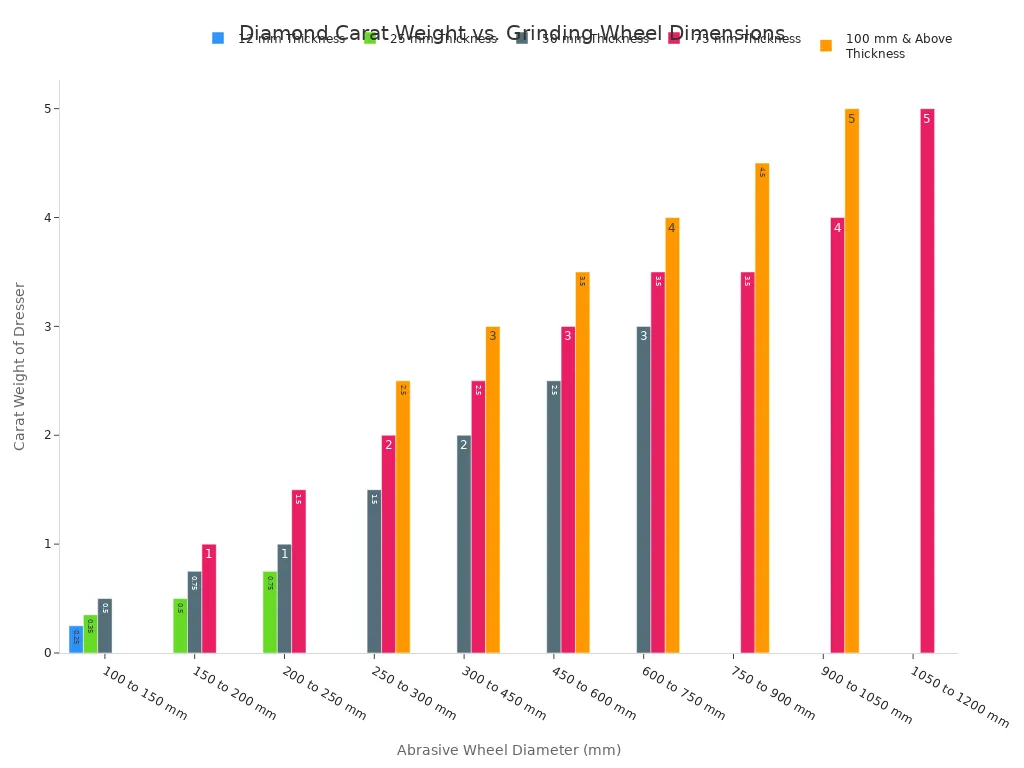

Selecting Diamond Carat Weight

You must choose the correct diamond size, or carat weight, for your grinding wheel. A larger, wider wheel needs a larger diamond to dress it effectively. Using a diamond that is too small will cause it to wear out quickly. A general guideline is to match the carat weight to the wheel’s diameter and width.

Tip: A larger diamond provides greater durability and can handle more heat during the dressing process.

The chart below gives you a standard guide for selecting the right carat weight for your single point diamond dresser.

Shank Design and Compatibility

The shank is the part of the dresser that you insert into the machine’s holder. You must ensure the shank’s size and shape match your grinder. An incorrect fit can lead to poor dressing and potential damage.

To guarantee grinding wheel compatibility, you should verify the shank diameter of the diamond grinding wheel dresser against your machine’s specifications. For example, some grinders use a common shank diameter of 0.437 inches. Always check your machine’s manual or measure the holder to confirm the correct size before ordering.

Aimgrind’s Focus on Diamond Quality

The quality of the diamond in your tool directly impacts its performance and lifespan. High-quality diamonds, whether natural or synthetic, have better clarity and structure with fewer internal cracks or impurities. This makes the tool durable and long lasting. Synthetic diamonds often provide more consistent and predictable results, which is vital for precision applications like a single point diamond dresser.

At Aimgrind, we prioritize diamond quality. We understand that a superior diamond ensures your tool delivers consistent accuracy and excellent durability. By using high-grade diamonds, our tools provide the reliable performance you need to achieve a perfect finish every time.

Quick Selection Guide by Grinding Type

Choosing the right tool often depends on your specific grinding operation. Different methods have unique requirements for achieving the best results. This guide will help you select the appropriate dresser for your application.

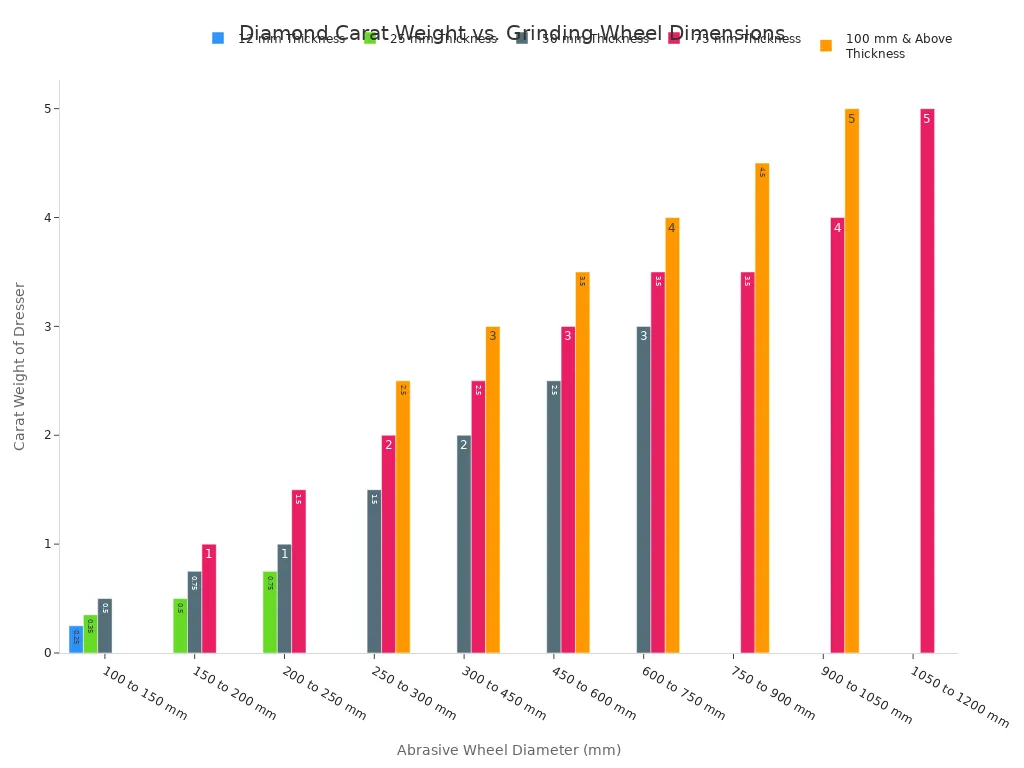

Surface Grinding

For surface grinding, your main goals are flatness and a consistent surface finish. Accurate dressing is essential to achieve these results. You will often use a single-point diamond dresser for this task because it offers excellent precision. The carat size of the diamond should match the size of your grinding wheel to ensure proper performance and tool life.

Tip: For high-volume production, you can use a multi-point dresser. It provides consistent results and helps stabilize the grinding process by minimizing uneven wheel wear.

The following chart offers a helpful starting point for selecting the right carat weight for your single-point tool based on wheel diameter.

Cylindrical Grinding

In cylindrical grinding, maintaining the wheel’s roundness and achieving a fine finish are critical. Dressing the wheel restores its cutting efficiency and ensures the geometric accuracy of your parts.

- Grit Impregnated Dressers: These are excellent for applications that require a long tool life and consistent surface finishing.

- Multi-Point Indexable Dressers: These are highly recommended for cylindrical grinders. They feature sharp, natural diamonds that you can re-adjust as they wear, extending their use.

Centerless Grinding

Centerless grinding involves dressing two different wheels: the grinding wheel and the regulating wheel.

- Grinding Wheel: Because these wheels are often wide, a single-point tool is not suitable. You should use multi-point diamonds, blade dressers, or rotary dressers to recondition the wheel face.

- Regulating Wheel: You can typically use a single-point diamond dresser for the regulating wheel. This dressing action usually happens at the back of the wheel.

For automated, high-production environments, rotary dressers are a great choice due to their efficiency and ability to produce a uniform finish.

Internal Grinding

Internal grinding presents the unique challenge of working with small-diameter wheels. You need specialized tools that can fit inside the workpiece and accurately dress the small wheel surface.

- Electroplated Diamond Mounted Points are made for grinding small, precise holes.

- Diamond Rat Tail Radius Dressers are available with very small radii, making them perfect for detailed internal work.

These tools offer the precision needed for the tight spaces common in internal grinding.

Thread Grinding

Thread grinding requires creating very precise profiles on the grinding wheel. The right tool must be able to form these intricate shapes accurately. While a single-point diamond dresser can handle simple profiles, you will need a more specialized tool for complex forms.

Blade and chisel dressers are ideal for this task. They are engineered to trace steep angles and sharp internal corners with high precision. Their design ensures they maintain the correct form throughout their lifespan, demonstrating excellent versatility across applications.

You can achieve successful grinding wheel dressing by following a few key steps. This ensures you select the right tool for your job.

- Understand your grinding wheel’s bond type.

- Match the dresser to your machine and application.

- Select the correct specifications for your desired outcome.

A well-chosen tool is essential for efficiency, superior surface finishes, and long-term durability. It helps you maximize your grinding wheel’s life and performance.

Grind with Passion, Achieve with Aim.

FAQ

How often should you dress a grinding wheel?

You should dress your wheel whenever you notice a drop in cutting performance, see glazing on the wheel face, or need to restore its profile. The frequency depends on your material, grinding parameters, and desired finish. Regular dressing ensures consistent results and prevents part damage.

What is the difference between truing and dressing?

Truing makes the grinding wheel concentric and geometrically true to the machine’s axis. Dressing cleans the wheel’s surface and exposes sharp abrasive grains. You often perform both actions at the same time, but they have different primary goals for wheel maintenance.

How do you know when to replace a diamond dresser?

You should replace your single-point dresser when the diamond becomes flat, dull, or chipped. For multi-point or impregnated dressers, replacement is needed when they no longer effectively sharpen the wheel. A worn-out dresser will produce a poor surface finish and can damage your wheel.

Why is the quality of the diamond important?

A high-quality diamond ensures your dresser lasts longer and performs consistently. Better diamonds have fewer flaws, providing greater durability and precision. This leads to more accurate dressing, better surface finishes on your parts, and a more reliable grinding process overall.

See Also

Selecting the Ideal Grinding Wheel Dresser for Your Specific Needs

Optimal Grinding Wheel Selection for Sharpening Your Carbide Tools

Picking the Perfect Grinding Wheel for Your Circular Saw Blade

Selecting the Appropriate Metal Grinding Wheel for Your Project

Finding the Best Bench Grinding Wheel Material for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools