Choosing the right diamond cup grinding wheel can feel overwhelming. Your success with grinding projects depends on three simple things: your goal, the material’s hardness, and the finish you want.

Did you know? The global market for diamond tools is projected to reach USD 19.5 Billion by 2034, showing just how vital these tools are for modern projects.

This guide walks you through a clear process. You will learn to select the perfect diamond cup wheels, ensuring your diamond grinding work delivers professional results.

Key Takeaways

- Choose your diamond cup wheel based on your project goal, the material’s hardness, and the finish you want.

- Match the wheel type to your task: aggressive wheels for heavy removal, general-purpose for many jobs, and fine finishing wheels for smooth surfaces.

- Use a soft bond wheel for hard materials and a hard bond wheel for soft materials to ensure good grinding.

- Select grit size: low grit numbers remove material fast, and high grit numbers create a smooth finish.

- Always wear safety gear, control dust, match the wheel’s speed to your grinder, and let the tool do the work.

Key Factors for Choosing the Right Diamond Cup Wheel

Selecting the perfect tool starts with understanding your needs. There are three key factors to consider when choosing the right diamond cup wheel. These factors guide you to the best choice for your grinding application. Let’s explore these key factors to consider.

Define Your Grinding Projects

First, you must clearly define your goal. Are you removing thick coatings or just smoothing a surface? Your project’s purpose is one of the key factors to consider for your grinding application. Different projects require different diamond cup wheels. Common grinding projects include:

- Restoration: Removing rust, paint, or old finishes from metal surfaces.

- Masonry Work: Cutting bricks, concrete blocks, or pavers for landscaping.

- Sharpening: Putting a sharp edge on lawnmower blades and garden tools.

- Metalworking: Shaping and refining metal for sculptures or custom parts.

Match the Wheel to the Material

Next, you need to know the hardness of the material you are grinding. A diamond wheel for hard granite will differ from one for softer concrete. The material’s hardness directly impacts the diamond wheel’s performance. A harder material requires a softer bond diamond to expose new abrasive particles. Here is a simple hardness guide for common materials.

| Material | Mohs Hardness |

|---|---|

| Marble | 3-4 |

| Concrete | Varies (3-7) |

| Granite | 6-7 |

Knowing this helps you select the right diamond cup grinding wheel for various applications.

Determine Your Desired Finish

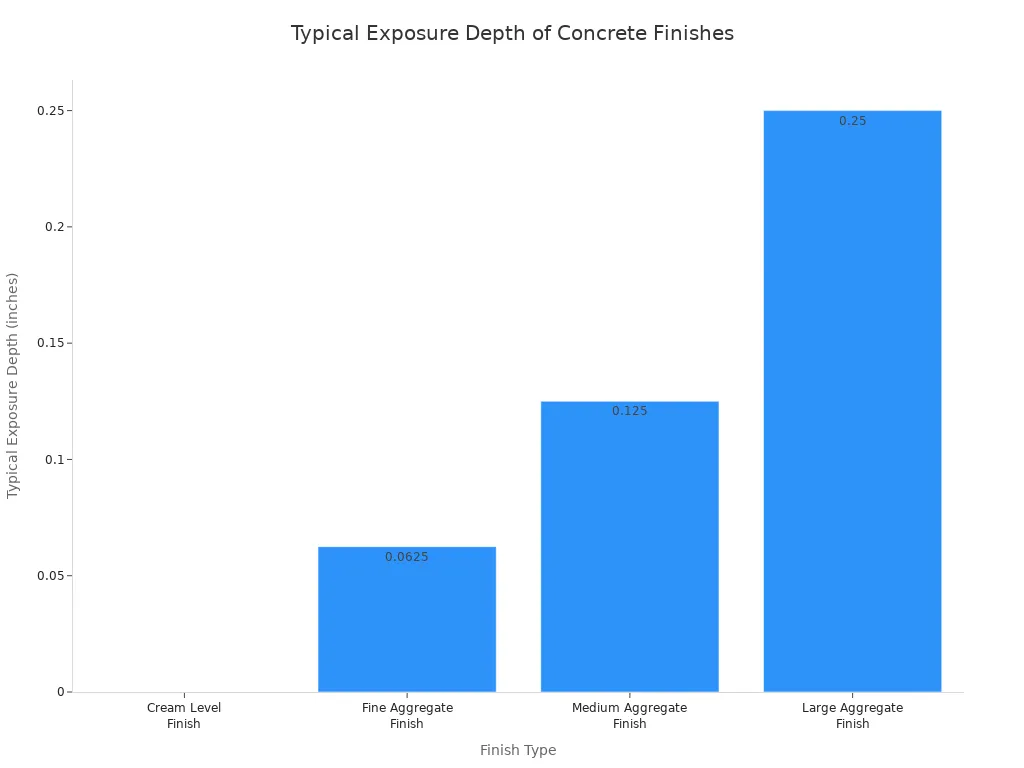

Finally, decide on the final look you want. Do you need a rough surface for a new coating or a smooth, polished finish? The desired texture determines the type of diamond and grinding process you will use. For concrete applications, professionals use the Concrete Surface Profile (CSP) scale. A lower CSP number means a smoother finish. For many applications, the amount of aggregate you expose is important.

This chart shows how different levels of grinding create different finishes. Understanding your desired outcome is crucial for your grinding application and for selecting the best diamond cup wheels for your applications.

Match Wheel Type to Your Goal

Once you know your project goal, you can match it to a specific wheel type. The design of the diamond segments on a wheel determines its grinding performance. Different designs excel at different tasks, from tearing through thick coatings to creating a glass-smooth finish. Let’s look at the main categories.

Aggressive Grinding Wheels

You need an aggressive wheel for heavy-duty jobs. These wheels are built for rapid material removal. They quickly strip away thick layers of material from surfaces. Arrow segment wheels are a top choice for this type of grinding application.

Pro Tip: For the toughest jobs, consider a PCD (Polycrystalline Diamond) wheel. These are unparalleled for removing thick mastics, glues, and heavy epoxy coatings.

Arrow segment designs are extremely effective for tough removal tasks. Use them when you need to:

- Remove epoxy, paint, glue, and other adhesives.

- Grind away thick parking deck membranes.

- Scrape and grind surfaces without the wheel gumming up.

These powerful tools are essential for demanding surface preparation and restoration projects. A good metal grinding cup wheel with an aggressive design saves you time and effort.

General-Purpose Wheels

A general-purpose wheel offers a balance of speed and finish quality. The most common type is the double-row design. These diamond cup wheels are true workhorses for a wide range of tasks. Their heat-treated steel bodies provide excellent durability and a long lifespan.

A double-row metal grinding cup wheel is a versatile choice. It gives you aggressive material removal for surface preparation. It also leaves a smoother finish than a more aggressive arrow segment wheel. This makes it ideal for many concrete and masonry grinding jobs. You can use this metal grinding cup wheel on marble, tile, and concrete. It is perfect for a grinding application that requires both removal and a decent finish.

Fine Finishing Wheels

You should choose a fine finishing wheel for projects that demand a smooth, clean surface. These wheels are designed for precision, not speed. The continuous rim is the best design for this purpose. Its solid, uninterrupted diamond edge produces a clean cut with minimal chipping. This is crucial when working with brittle materials like porcelain, glass, and granite.

For a pre-polish finish, the grit size of the diamond is also important.

- A 100-200 grit wheel removes minor imperfections.

- A 200-400 grit wheel starts refining the surface for a satin look.

Using a fine finishing metal grinding cup wheel ensures your grinding work results in a professional, high-quality appearance. The right metal grinding cup wheel improves your grinding performance and protects delicate materials from damage. This type of diamond cup grinding wheel is essential for achieving a flawless final product. The excellent grinding performance of these diamond cup wheels makes them a valuable tool for any finishing grinding application. The superior diamond quality ensures a better grinding performance.

To help you choose, here is a quick comparison of common segment designs:

| Segment Design | Primary Use | Key Feature |

|---|---|---|

| Arrow Segment | Aggressive coating removal | Scrapes and grinds tough glues and epoxies. |

| Double Row | General-purpose grinding | A durable workhorse with a long life. |

| Turbo Segment | Fast grinding, smoother finish | Cools effectively for fast work with less swirl marks. |

| Continuous Rim | Fine finishing and polishing | Provides a chip-free finish on brittle materials. |

Aimgrind Solutions for Tough Materials

Standard wheels often struggle with challenging materials. You need a high-performance solution for tough jobs. Aimgrind specializes in creating customized grinding solutions. We have nearly two decades of experience designing the best diamond cup wheels for materials like hard alloys, ceramics, and composites. Our high-quality diamond grinding wheel products deliver superior durability and precision for demanding industrial applications.

Grinding Hard Concrete

Hard concrete presents a unique grinding challenge. A standard wheel can glaze over and lose its cutting ability. For this task, you need a specific type of metal grinding cup wheel. Aimgrind provides diamond cup wheels with a softer bond. This design allows worn diamond particles to fall away, exposing fresh, sharp diamond edges. This process ensures consistent grinding performance. A proper metal grinding cup wheel makes your grinding work on hard concrete much more efficient.

The Best Metal Grinding Cup Wheel

You might be looking for the best metal grinding cup wheel. It is important to match the abrasive to the metal. Diamond is the ultimate tool for grinding hard, non-ferrous metals and alloys. However, the carbon in a diamond can react with ferrous metals like steel at high temperatures. This can affect the grinding performance. For materials like hard alloys, an Aimgrind metal grinding cup wheel provides excellent results. Our high-quality metal grinding cup wheel ensures a superior finish for many metal grinding applications. We help you choose the right metal grinding cup wheel for your specific job. This ensures the best grinding performance from your metal grinding cup wheel.

Aimgrind Expertise: We design the perfect metal grinding cup wheel for your non-ferrous metal and hard alloy applications, ensuring top-tier grinding performance.

Custom Solutions for Unique Materials

Many industries work with unique materials that require special tools. Aimgrind excels at creating custom diamond cup wheels for these specific needs. We develop high-quality solutions for various applications, from aerospace to precision tool manufacturing. Our team analyzes your material and process to design a diamond grinding wheel that delivers optimal grinding performance. Whether you are grinding tough composites or advanced ceramics, our custom metal grinding cup wheel options provide the precision you need. We offer the best diamond cup wheels for your unique grinding projects.

Select Bond Hardness and Grit Size

You have matched the wheel design to your goal. Now you must dive deeper into the wheel’s composition. The bond hardness and diamond grit size are two final, critical choices. These factors directly control the wheel’s grinding action and the quality of your final surface. Getting them right is essential for efficient work.

Understanding Bond Hardness

The bond is the glue that holds the diamond abrasive particles in the wheel. The hardness of this bond determines how the wheel performs. You must follow one fundamental rule for successful grinding.

The Golden Rule of Grinding: Use a soft bond wheel for hard materials and a hard bond wheel for soft materials.

This might seem backward, but the science is simple. It is all about how quickly the wheel exposes new, sharp diamond grit. This is called the “abrasive renewal rate.”

- Soft Bonds on Hard Materials: A soft bond wears away more easily. When grinding hard materials like granite, the diamond particles dull quickly. The soft bond releases these dull particles, exposing fresh, sharp diamond grit underneath. This allows for continuous, aggressive cutting.

- Hard Bonds on Soft Materials: A hard bond holds onto abrasive particles longer. When grinding soft materials like green concrete, the diamond grit stays sharp for a longer time. A hard bond prevents the wheel from wearing down too fast, giving you a longer tool life.

You will not usually see a “soft” or “hard” label on a diamond cup grinding wheel. Instead, manufacturers refer to the wheel’s “grade,” which describes the bond’s strength. They also specify the bond type, such as metal, resin, or vitrified. The key is to check the manufacturer’s recommendation for the material you are grinding.

Decoding Grit Size

Grit size refers to the size of the individual diamond particles on your wheel. The grit number tells you how coarse or fine the abrasive is. The numbering system is simple to understand.

- Low Grit Numbers (e.g., 30/40): These wheels have large, coarse diamond particles. They are perfect for aggressive grinding and rapid material removal. Use a low grit when you need to strip thick coatings or quickly level an uneven surface.

- High Grit Numbers (e.g., 100/120): These wheels have small, fine diamond particles. They are used for smoothing, finishing, and polishing. Use a high grit to remove swirl marks left by a coarser wheel and prepare the surface for its final finish.

Choosing the right grit is a trade-off between speed and smoothness. You can use this table as a quick guide for your grinding project.

| Grit Size Range | Particle Size | Primary Use | Result |

|---|---|---|---|

| 16-40 | Very Coarse | Aggressive material removal | Rough, textured surface |

| 50-80 | Coarse to Medium | General-purpose grinding | Lightly textured surface |

| 100-200 | Fine | Smoothing and light polishing | Smooth, semi-polished surface |

| 400+ | Very Fine | Polishing and honing | Highly refined, glossy finish |

Essential Safety for Diamond Cup Wheels

Using a diamond cup grinding wheel is powerful, but it requires your full attention to safety. Proper precautions protect you from serious injury and ensure your grinding project goes smoothly. You must follow these essential safety rules every time you work.

Wear Proper Personal Protective Equipment

You must protect yourself before you start any grinding work. Angle grinders are ranked as one of the most dangerous tools, causing thousands of injuries each year. Many accidents happen when a wheel shatters. You can prevent most injuries by wearing the right gear.

- Head and Eye Injuries: Always wear safety glasses or a full-face shield. This protects you from flying debris and diamond particles.

- Limb Injuries: Wear heavy-duty gloves and long sleeves. This can prevent deep cuts to your hands and arms if you lose control of the grinder.

Use a Dust Shroud and Vacuum

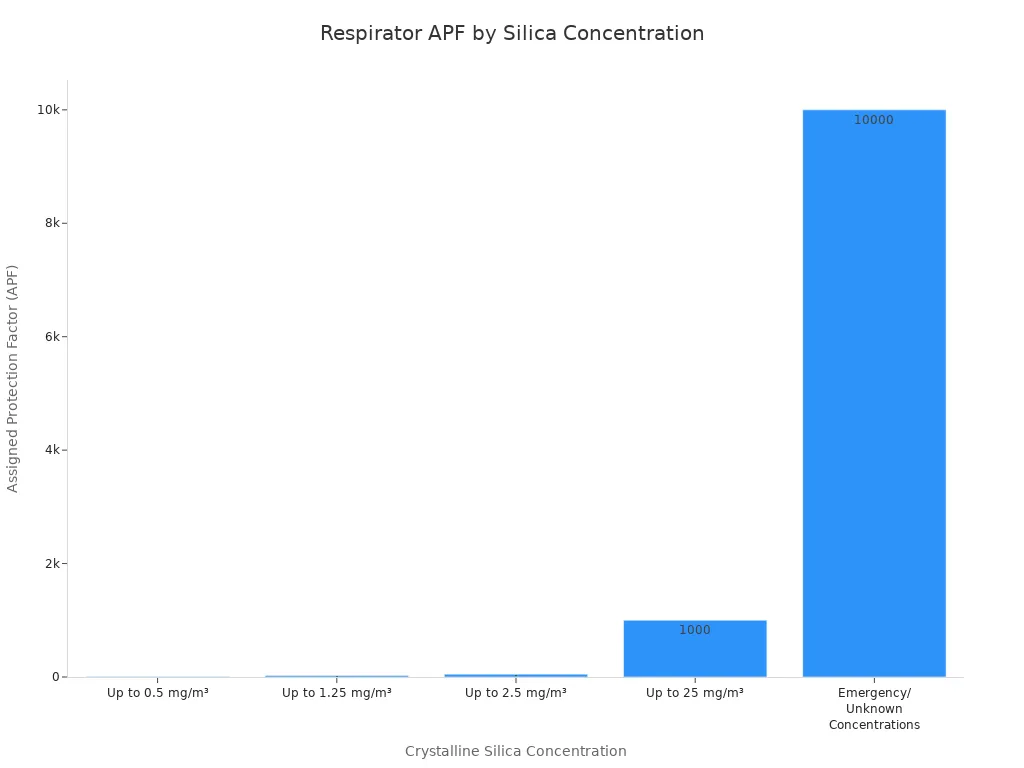

Grinding concrete and masonry creates harmful crystalline silica dust. Breathing this dust can cause serious lung disease. OSHA sets a strict Permissible Exposure Limit (PEL) of 50 micrograms per cubic meter of air. You must use engineering controls to stay below this limit. Always attach a dust shroud to your grinder and connect it to a vacuum with a high-efficiency filter. This captures the dangerous dust at the source. For extra protection, you may need a respirator.

Match Wheel RPM to Your Grinder

You must check the RPM (Revolutions Per Minute) rating on your diamond cup wheels. The wheel’s maximum RPM must be higher than your grinder’s RPM. Running a wheel too fast creates immense centrifugal force. This force can cause the diamond wheel to crack and break apart violently. For example, using a 6,600 RPM wheel on a 10,000 RPM grinder creates 2.3 times the allowed stress. This mistake can lead to catastrophic failure and severe injury.

Let the Tool Do the Work

You should not force the grinder into the material. Applying too much pressure causes uneven grinding and can leave swirl marks on your surface. It also puts extra stress on the motor and the diamond segments.

Pro Tip: Use smooth, consistent motions and let the weight of the tool and the sharpness of the diamond do the work. This improves your finish, extends the life of your diamond cup wheels, and makes the grinding process safer.

Choosing the right diamond cup wheels is simple. First, define your grinding projects. Next, match the diamond wheel type to your goal. Finally, select the correct bond and grit for your grinding needs. A high-quality diamond wheel from a specialist like Aimgrind ensures the best grinding results. This high-quality approach to your grinding work delivers a superior, high-quality diamond finish.

With this knowledge, you can confidently choose the most effective tool to grind with passion and achieve your project goals.

FAQ

What materials can I use a diamond cup wheel on?

You can use diamond cup wheels on very hard materials. They work great for grinding concrete, granite, tile, and masonry. For metals, you should use them on hard, non-ferrous alloys. Aimgrind offers wheels for tough materials like ceramics and composites for specialized industrial jobs.

Should I use my diamond cup wheel wet or dry?

You can use most diamond cup wheels for both wet and dry grinding. Using water cools the wheel and the work surface. This extends the wheel’s life and reduces harmful dust. Always check the manufacturer’s recommendation for your specific wheel.

When should I replace my diamond cup wheel?

You must replace your wheel if you see signs of damage. Look for cracks in the steel body or missing diamond segments. A worn-out wheel loses its cutting ability and becomes a safety hazard. Do not use a damaged wheel.

Safety First! ⚠️ A damaged wheel can break apart during use, causing serious injury. Inspect your wheel before every single job.

Why did my wheel stop cutting hard concrete?

Your wheel likely glazed over. This happens when the bond is too hard for the material. The diamonds become dull and cannot cut. You need a wheel with a softer bond for hard concrete. A soft bond exposes new, sharp diamonds as you work.

See Also

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Picking the Perfect Grinding Wheel for Your Circular Saw Blade

Finding the Ideal Grinding Wheel Dresser for Your Workshop

Selecting the Appropriate Metal Grinding Wheel for Specific Projects

Determining the Best Bench Grinding Wheel Material for Your Application

Contact Us

For More Grinding Solution or Customized Abrasive Tools