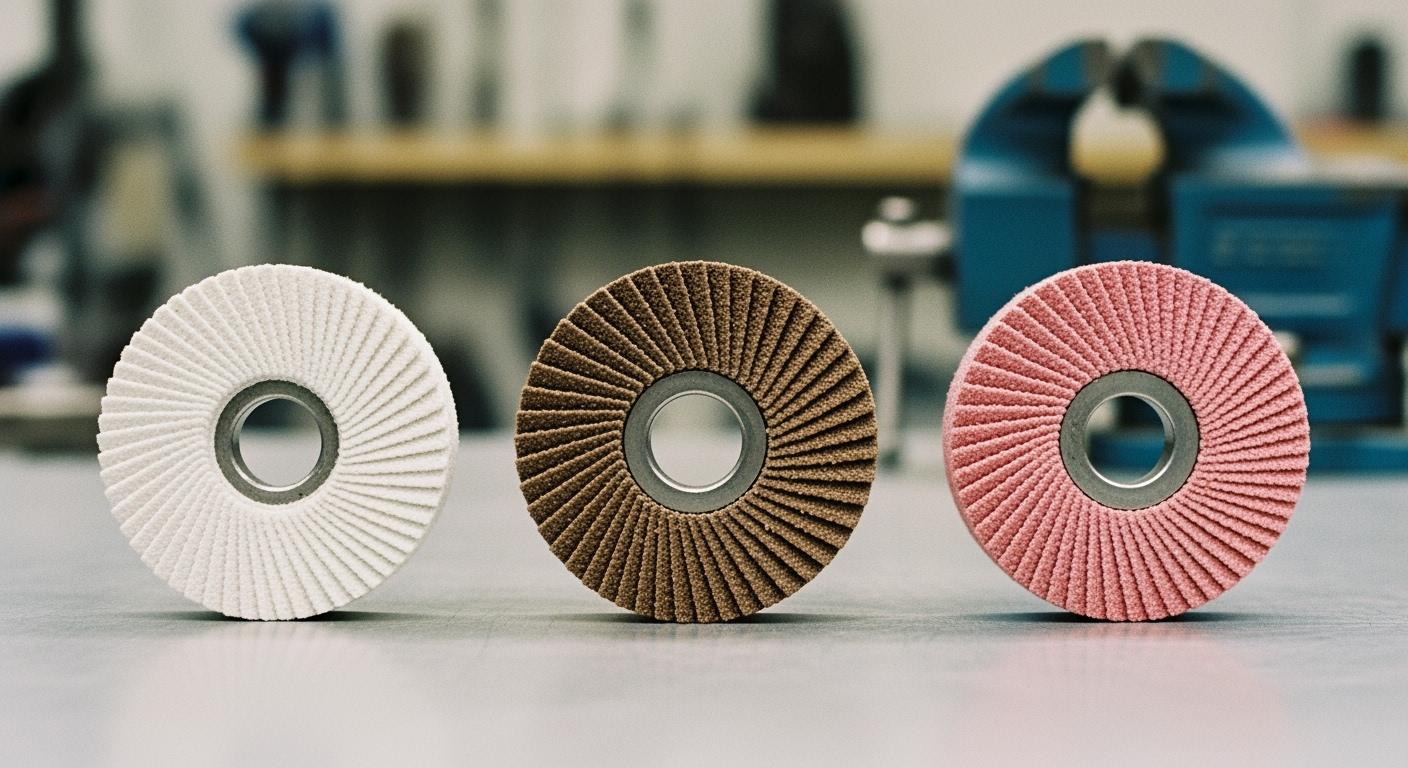

Choosing the correct type of aluminum oxide wheel isn’t a one-size-fits-all decision. Your choice hinges on the material you’re grinding, the desired finish, and your budget. This straightforward guide will help you in choosing the correct type by explaining the key differences between these common aluminum abrasives.

- Brown: Use brown aluminum oxide for tough, general-purpose work.

- White: Select white aluminum oxide for cool, precise grinding on heat-sensitive metals.

- Pink: Choose pink aluminum oxide as a durable upgrade for hard tool steels.

Key Takeaways

- Brown aluminum oxide is best for tough, general grinding jobs. It removes a lot of material and costs less.

- White aluminum oxide works well for heat-sensitive metals. It grinds cool and gives a smooth finish.

- Pink aluminum oxide is good for hard tool steels. It lasts longer and is tougher than white aluminum oxide.

- Choose the right wheel based on your material and job. This helps you get the best results.

Brown Aluminum Oxide: The All-Purpose Workhorse

When you need a reliable and tough abrasive, brown aluminum oxide is your go-to choice. It is the most common and cost-effective type of aluminium oxide, making it a staple for a wide range of grinding applications.

What It Is: The Cost-Effective Standard

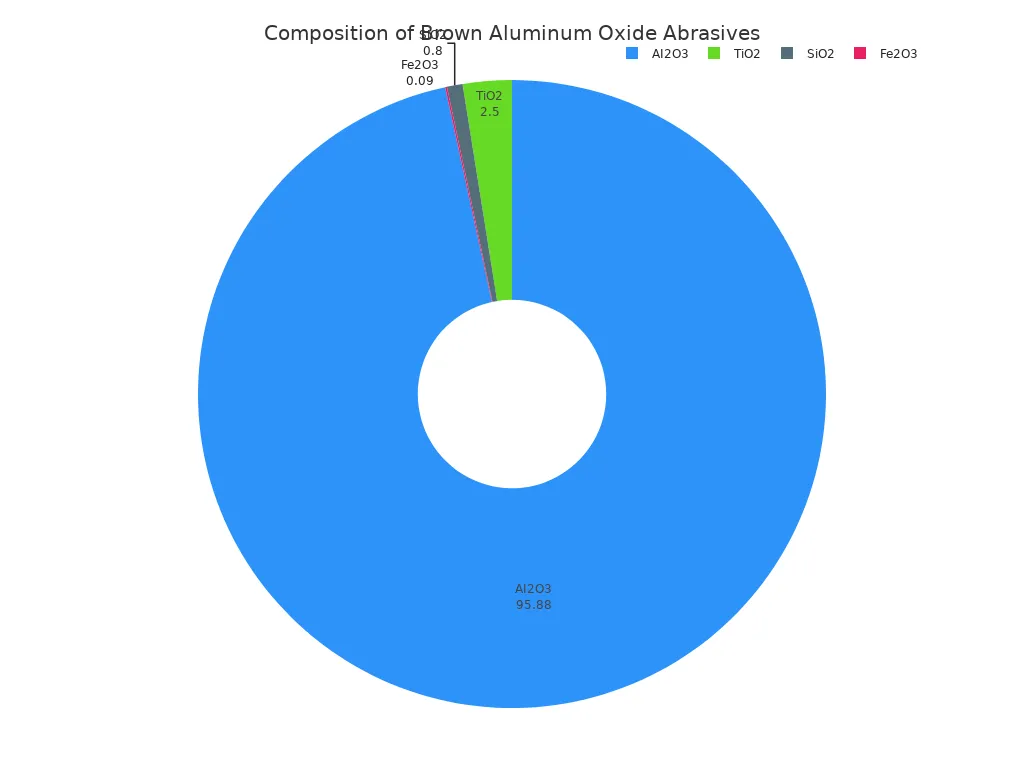

Manufacturers create brown fused aluminum oxide by melting raw materials like bauxite in an electric arc furnace. This process happens at extremely high temperatures, over 2000°C. The result is a tough, blocky abrasive grit that is crushed and sorted for use. The typical chemical makeup of this material shows its high purity and strength.

| Component | Typical Value |

|---|---|

| AI₂O₃ | 95.88% |

| TiO₂ | 2.50% |

| SiO₂ | 0.80% |

| Fe₂O₃ | 0.09% |

Key Characteristics: High Durability and Aggressiveness

The defining features of brown aluminium oxide are its toughness and durability. It has a Mohs hardness rating of 9, making it one of the hardest materials available for abrasives. This hardness allows the wheel to cut aggressively and last a long time, even under heavy pressure. The small amount of titanium oxide in its composition, as shown below, adds to its overall toughness.

This durability means you spend less time changing wheels and more time working.

Best For: Heavy Stock Removal and General Grinding

You should choose a brown wheel for demanding jobs that require fast material removal. It excels at general-purpose grinding on less heat-sensitive metals.

Common Uses for Brown Wheels:

- Heavy stock removal on ferrous metals like steel and iron.

- Removing rust, paint, and scale from surfaces.

- Deburring and cleaning welds.

- Sharpening common carbon-steel tools.

The coarse grit sizes of brown wheels are perfect for aggressive cutting, while finer grits can handle smoother finishing tasks. This versatility makes it an essential tool for metalworking and fabrication shops.

White Aluminum Oxide: The Precision Specialist

When your project demands precision and a delicate touch, you should turn to white aluminum oxide. This abrasive is the top choice for tasks where heat generation is a major concern. It offers a cooler, cleaner cut compared to its brown counterpart.

What It Is: The High-Purity Abrasive

Manufacturers create white aluminum oxide by fusing high-purity alumina in an electric arc furnace. This process results in a material with exceptional purity. This high-purity aluminum oxide, also known as white fused alumina, typically contains over 99% aluminium oxide (Al₂O₃). The lack of impurities makes the white abrasive grains more brittle, or friable, which is a key advantage for specific grinding applications. The higher purity gives the white wheel its distinct characteristics.

Key Characteristics: Friability and Cool Cutting

The most important feature of white aluminum oxide is its high friability. This means the abrasive grains fracture easily under pressure. This breakdown exposes new, sharp cutting edges continuously during grinding. This self-sharpening action prevents the wheel from loading up with material and reduces heat buildup. The result is a cool, fast cutting action that protects your workpiece from heat damage and discoloration. These white abrasives are perfect for precision work.

Best For: Heat-Sensitive Metals and Fine Finishes

You should use a white aluminium oxide wheel when working with hard, heat-sensitive materials. Its cool cutting ability makes it ideal for tool and cutter grinding. The fine grains of white aluminium oxide can also produce an excellent surface finish. On some metals, it can reduce surface roughness to above 0.2 micrometers Ra, creating a high-gloss look.

Choose a white wheel for these tasks:

- Sharpening and grinding heat-treated materials.

- Light grinding on all types of tool steels.

- Working with heat-sensitive alloys like high-speed steel (HSS).

- Achieving fine, smooth surface finishes.

This makes the white wheel an essential tool for any precision metalworking.

Pink Aluminum Oxide: The Durable Edge-Holder

When you need a wheel that balances the cool cutting of white aluminium oxide with enhanced durability, you should consider pink aluminum oxide. This abrasive offers a significant upgrade in toughness, making it perfect for more demanding grinding applications.

What It Is: The Chromium-Doped Upgrade

You can think of pink fused alumina as an enhanced version of white aluminium oxide. Manufacturers create it by adding a small amount of chromium oxide during the fusion process. This addition gives the abrasive its characteristic pink color and superior properties.

The typical amount of chromium oxide added is very small, often around 0.7%. However, the exact percentage can vary to create abrasives with different properties.

The chromium content level determines the final characteristics of the pink abrasive.

| Chromium Content | Cr₂O₃ (%) for F90-F150 Grit |

|---|---|

| Low | 0.2-0.45 |

| Medium | >0.45-1.00 |

| High | 1.00-2.00 |

Key Characteristics: Enhanced Toughness and Edge Retention

The addition of chromium oxide makes the pink aluminium oxide grain tougher than the white variety. This increased toughness means the abrasive grains resist fracturing. The wheel maintains its sharp cutting performance for a longer time, giving it excellent edge retention. This durability allows you to apply higher pressure during grinding without the wheel breaking down too quickly. The result is a wheel that lasts longer and performs consistently on hard materials.

Best For: Hardened Tool Steels and Demanding Applications

You should choose a pink wheel for grinding hard, tough, and heat-sensitive materials. It excels at working with hardened tool steels like D2 and A2. The enhanced toughness of the pink abrasive makes it ideal for applications where wheel life and edge stability are critical.

Use a pink wheel for these demanding applications:

- Precision grinding of tools, instruments, and threading workpieces.

- Sharpening high-speed steel cutters, reamers, and end mills.

- Flute and tooth grinding on cutting tools.

- Working with hardened steels and alloys with high tensile strength.

These specialized applications benefit greatly from the unique balance of hardness and toughness that pink wheels provide.

Aimgrind’s Conventional Bonded Aluminium Oxide Abrasives

Now that you understand the differences between brown, white, and pink aluminium oxide, you need a reliable source for your tools. Aimgrind specializes in providing high-quality conventional bonded abrasives, including the exact types discussed in this guide.

Your Source for Quality Grinding Wheels

With nearly two decades of experience, Aimgrind is dedicated to delivering exceptional quality and reliability. You can trust that our grinding wheels are manufactured to high standards. We focus on providing durable and cost-effective abrasives that help you achieve your goals. Our commitment to quality ensures you get consistent results for all your grinding projects. We understand that the right tool is essential for a job well done.

Customized Solutions for Every Application

Aimgrind offers more than just products; we provide complete solutions. Our process includes problem diagnosis and parameter matching to ensure the abrasives you choose are perfect for your equipment. We create customized solutions that balance cost, durability, and performance for a wide range of applications. Our products serve many demanding industries.

Industries We Serve:

- You can find our grinding wheels in the tool and cutter industry.

- We provide solutions for the woodworking industry.

- Our abrasives are used in the glass industry for grinding and polishing.

We help you find the perfect wheel for your specific needs, whether you are working with metal, wood, or glass. Explore our range of conventional bonded abrasives to find the ideal, high-quality solution for your applications.

Choosing the Correct Type: A Direct Comparison

Making the right choice becomes easier when you compare the abrasives side-by-side. This direct comparison will help you in choosing the correct type of wheel for your specific job by looking at hardness, cutting action, primary uses, and cost.

Hardness and Toughness

You should understand the difference between hardness and toughness. Hardness measures an abrasive’s ability to resist scratching, while toughness measures its ability to resist fracturing under pressure. All aluminum oxide types are very hard. However, their toughness varies significantly.

- Brown Aluminum Oxide is the toughest of the three. Its grains can withstand heavy pressure, making it great for aggressive grinding.

- White Aluminum Oxide is less tough but has a very high hardness. Its grains are more brittle.

- Pink Aluminum Oxide gets a toughness boost from chromium oxide. This makes it tougher than white aluminum oxide, so it holds its shape longer.

The Knoop scale measures the hardness of materials. You can see how white and pink abrasives compare below.

| Aluminum Oxide Type | Knoop Hardness |

|---|---|

| White | 20500 N/MM² |

| Pink | 2050 (Knoop Scale) |

Note: The values above use different units but show that both materials have a very high hardness rating, close to each other on the scale. The main difference is their toughness.

Friability and Cutting Action

Friability is a key factor in choosing the correct type of wheel. It describes how easily abrasive grains break down to expose new, sharp edges. This self-sharpening action keeps the wheel cutting cool and clean.

- White: This is the most friable abrasive. The grains fracture easily, providing a very cool, fast cut. This action prevents heat damage on sensitive metals.

- Pink: This wheel is less friable than white. The added chromium makes it tougher, so it holds its edges longer. This gives you a balance between a cool cut and longer wheel life.

- Brown: This is the least friable. Its toughness means it lasts a long time under heavy pressure, but it generates more heat during grinding.

Primary Use and Materials

Your material and application will guide your choice. Each wheel excels in different areas. Choosing the correct type of wheel for your material ensures the best results and protects your workpiece.

| Wheel Type | Key Property | Best For These Materials | Common Applications |

|---|---|---|---|

| Brown | Toughest, most durable | Ferrous metals (iron, non-hardened steel) | Heavy stock removal, weld cleaning, deburring, general-purpose grinding. |

| White | Most friable, coolest cut | Hardened and heat-sensitive steels (HSS), lacquers | Precision grinding, tool sharpening, creating fine surface finishes. |

| Pink | Tougher than white, holds edge | Hardened tool steels (D2, A2), hard alloys | Sharpening cutters and reamers, high-performance precision grinding. |

These grinding wheels are versatile. For example, you can often find white aluminium oxide blended with other grains to improve the performance of vitrified wheels. Pink abrasives are also excellent for achieving a high polish on hard metals like chrome and nickel.

Cost vs. Performance

Your budget plays a role in choosing the correct type of wheel. You must balance cost with the performance you need.

- Brown: This is your most budget-friendly option. It offers great performance for general-purpose jobs where cost is a primary concern.

- White: This wheel costs slightly more than brown. However, its superior performance on heat-sensitive metals makes it a worthwhile investment for precision work.

- Pink: This is the premium choice. It has the highest initial cost, but its extended life and excellent performance on tough tool steels can save you money over time by reducing wheel changes.

Ultimately, the best wheel delivers the performance you need for your specific applications at a price that makes sense for your operation.

Choosing the correct wheel ensures you get the best results on ferrous metals. You can make the right decision by remembering these key points:

- Brown: This is your go-to for general-purpose, heavy-duty grinding where cost-effectiveness is key.

- White: You should select this for precision work on hard, heat-sensitive steels.

- Pink: This is the premium option for applications demanding superior wheel life and edge stability.

Ready to find the perfect tool? Explore Aimgrind’s range of conventional bonded abrasives to find the high-quality wheel for your specific project needs.

FAQ

Can I use a brown wheel for finishing work?

You can use a brown wheel with a fine grit for some finishing. However, a white aluminum oxide wheel will give you a much better and smoother surface. You should choose the white wheel for tasks that require a high-quality, fine finish.

Which wheel is best for sharpening a lawnmower blade?

For a standard lawnmower blade made of carbon steel, a brown aluminum oxide wheel is your best choice. It is tough, removes material effectively, and is very cost-effective for this type of general-purpose sharpening task.

Do I need to use coolant with these wheels?

You can use all three wheels for dry grinding. However, using a coolant is always a good practice, especially with brown wheels, to prevent overheating. White and pink wheels run cooler, but coolant helps extend wheel life and improves the surface finish on sensitive metals.

What is the main reason to choose pink over white aluminum oxide? 🤔

You should choose a pink wheel when you need more durability. The added chromium makes it tougher than a white wheel. This means the pink wheel lasts longer and holds its shape better when grinding hard tool steels, saving you time and money on demanding jobs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools