Choosing the right cylindrical grinding wheel can feel hard. You need to match abrasive type, grit, bond, and shape. These must fit your workpiece and grinding needs. Picking the wrong wheel can cause a bad surface finish. It can also make the wheel wear out fast. Sometimes, it can even be unsafe. Studies show the right wheel controls heat well. It stops microcracks and gives a smooth finish. Think about the material, finish, and if it fits your machine. This helps you save time and money. Always look at both technical and practical things. This keeps grinding safe and efficient.

Key Takeaways

-

Pick the abrasive type that matches your workpiece material. This helps you get better grinding and makes the wheel last longer. – Choose the grit size for your goal. Use coarse grits to remove material fast. Use fine grits for a smooth finish. – Select the bond type and wheel grade that match your grinding pressure. Make sure they fit your machine power and the finish you want. This gives you the best results. – Pick a wheel shape and size that fit your machine and workpiece. This helps control heat and stops damage. – Use coolant the right way and follow safety rules. This keeps you safe, protects your machine, and helps you grind better.

Workpiece Material

Material Properties

When you pick a cylindrical grinding wheel, look at the workpiece material first. Every material acts in its own way during grinding. Some common materials you might see are:

-

Steel

-

Aluminum

-

Titanium

-

Ceramics

-

Carbides

-

Softer metals

Steel and aluminum are used a lot in cars and planes. Each material changes how grinding works. Steel is strong and tough. You need abrasives like aluminum oxide or cubic boron nitride (CBN) for steel. These abrasives can handle the heat and strength of steel. Aluminum is softer and can block the wheel. For aluminum, use a wheel with a softer bond and open spaces. This helps chips move away and stops the wheel from glazing. Carbide and ceramics are hard but break easily. You need diamond or green silicon carbide wheels for these. These abrasives are sharp and hard, so grinding works well.

Tip: Always pick the abrasive type that matches your workpiece material. This makes grinding better and helps the wheel last longer.

Hardness and Wheel Choice

How hard your workpiece is matters a lot when picking a grinding wheel. Harder materials like steel or carbide need a softer wheel grade. A softer wheel lets new sharp grains show up. This keeps grinding working well and stops too much heat. Softer materials need a harder wheel grade. A harder wheel holds grains longer, which is good for gentle grinding. Always think about both hardness and what your workpiece is made of. This helps you pick the right wheel grade, abrasive type, and bond for your grinding job.

Types of Abrasive Wheels

Abrasive Materials

When you pick a grinding wheel, you should know the main types. Each type works best for a certain job. The table below lists common wheel types and what they are used for:

|

Abrasive Wheel Type |

Type Number |

Typical Applications in Cylindrical Grinding |

|---|---|---|

|

Straight Grinding Wheel |

Type 1 |

Centerless and cylindrical surface grinding; bench grinders |

|

Cylinder (Wheel Ring) |

Type 2 |

Horizontal or vertical spindle grinders for smooth, flat surfaces |

|

Tapered Grinding Wheel |

Type 4 |

Gear teeth and thread grinding |

|

Straight Cup Wheel |

Type 6 |

Cutter and gear grinding; extra grinding surface |

|

Dish Cup Wheel |

Type 12 |

Jug grinding and cutter grinding; slots and crevices |

|

Saucer Grinding Wheel |

Type 13 |

Twist drills, milling cutters, saw blade maintenance |

You also need to pick the right abrasive material. Aluminum oxide and silicon carbide are the most used. Aluminum oxide is good for metals like steel. It lasts longer and keeps its edge. Silicon carbide is sharper and harder. It cuts faster but wears out quicker. Use it for hard and brittle things like ceramics or glass. The table below shows how these two abrasives compare:

|

Property |

Aluminum Oxide Abrasive |

Silicon Carbide Abrasive |

|---|---|---|

|

Hardness |

Mohs ~9.0 |

Mohs ~9.5 |

|

Toughness |

High; self-sharpening |

Brittle; wears faster |

|

Durability |

2-3 times longer than SiC |

Less durable |

|

Cutting Efficiency |

Stable; best for metals and wood |

Higher at first; best for ceramics and glass |

|

Suitable Materials |

Metals, wood, composites |

Ceramics, glass, carbide |

|

Surface Finish |

Good for metal finishing |

Good for mirror finishes |

|

Cost |

More economical |

Higher cost |

|

Application Examples |

Metalworking, wood processing |

Precision machining, glass, ceramics |

Tip: For tough materials, use a softer wheel. This lets new grains show as old ones wear out. For gentle grinding, pick a harder wheel. This keeps the abrasive grains longer.

Diamond and CBN Wheels

Diamond and cubic boron nitride wheels are called superabrasives. You use diamond wheels for non-ferrous and brittle things like ceramics and carbides. These wheels cut very well and last a long time. They give a smooth finish and help reduce waste. But diamond wheels do not work well with ferrous metals. This is because of heat and chemical reactions.

Cubic boron nitride wheels are best for ferrous things like hardened steel and cast iron. They keep cutting even at high heat, up to 1000°C. These wheels last much longer than regular abrasives. CBN wheels help you get tight sizes and smooth finishes. Even though they cost more at first, you save money later. You spend less time changing wheels and get more work done.

-

Use diamond wheels for ceramics, glass, and carbide.

-

Use CBN wheels for steel, cast iron, and other ferrous metals.

Modern grinding wheels use new abrasive materials for hard jobs. You can now grind superalloys and composites better. New wheel designs help control heat and wear. This gives you a better finish and longer tool life.

Grit and Bond Selection

Grit Size Guide

Choosing the right grit size is key for successful grinding. Grit size tells you how coarse or fine the abrasive grains are on your wheel. Coarser grits, like 36 or 46, remove material quickly. You use these for roughing or when you need to shape a part fast. Finer grits, such as 80 or 120, give you a smoother finish. These work best for finishing steps.

-

Coarse grits (36–46): Fast material removal, rough grinding, soft materials.

-

Medium grits (60): General-purpose grinding, balance between speed and finish.

-

Fine grits (80–120+): Smoother finishes, tight tolerances, final passes.

Walter Graf notes that finer grits increase the number of cutting edges on the wheel. This leads to a better surface finish but also raises grinding forces. For example, switching from grit 60 to 80 can quadruple the number of active grits, improving finish but increasing pressure. Scientific studies show that finer grains lower surface roughness but may slow down material removal. You must balance your need for speed with your need for a smooth surface.

When you choose a grit size, think about your grinding goals. If you want to remove a lot of material, pick a coarse grit. If you need a fine finish, go with a finer grit. Most cylindrical grinding uses grits from 60 to 120. For very fine work, you may use even higher numbers.

Bond Types

The bond holds the abrasive grains together in your grinding wheel. The type of bond affects how the wheel cuts, how long it lasts, and how it handles heat.

|

Characteristics |

Performance and Longevity |

|

|---|---|---|

|

Vitrified |

Strong, ceramic-like, porous |

Long life, good chip removal, brittle under impact |

|

Resin |

Flexible, synthetic resin |

Good for fine finishes, wears faster at high temperatures |

|

Metal |

Made from metals like brass or bronze |

Handles high heat, very durable, can dull abrasive grains |

Vitrified bonds create a porous structure. This helps with chip removal and cooling during grinding. You get better performance and longer wheel life, but the wheel can be brittle. Resin bonds are more flexible. They work well for lighter grinding and fine finishes, but they wear out faster if you use them at high temperatures. Metal bonds are very strong and resist heat. You use them for tough grinding jobs, but they can dull the abrasive grains faster.

Tip: Always match the bond type to your grinding needs. Vitrified wheels work well for most jobs. Use resin bonds for fine work and metal bonds for high-heat or heavy-duty grinding.

Choosing the Right Grinding Wheel

Picking the best cylindrical grinding wheel takes careful steps. You need to think about the workpiece material and how hard you will grind. The area where the wheel touches the workpiece matters too. You should also know what kind of finish you want. Knowing how to choose grinder wheels for each job helps you avoid mistakes. It also helps you get good results every time.

Wheel Grade

Wheel grade means how hard the bond is that holds the abrasive grains. You must balance how fast the wheel wears out with how smooth the finish is. A harder grade keeps grains longer, so the wheel lasts more. But it can make the grinding hotter and the finish rougher. A softer grade lets grains go sooner. This helps keep things cool and makes a smoother finish. But the wheel will wear out faster.

If you grind with high pressure or fast speeds, use a harder wheel grade. This helps the wheel keep its shape and not break down. For gentle or careful grinding, a softer grade is better. It stops the grains from breaking and keeps the finish nice.

The size of the contact area changes what grade you need. If the contact area is big, the force spreads out. You can use a softer wheel grade. If the contact area is small, each grain gets more force. Then, a harder grade works better. For easy materials, harder grades make the wheel last longer. For tough materials, softer grades help control heat and stop damage.

Tip: Always pick the wheel grade that fits your grinding job. Think about how hard you will grind, the contact area, and the finish you want.

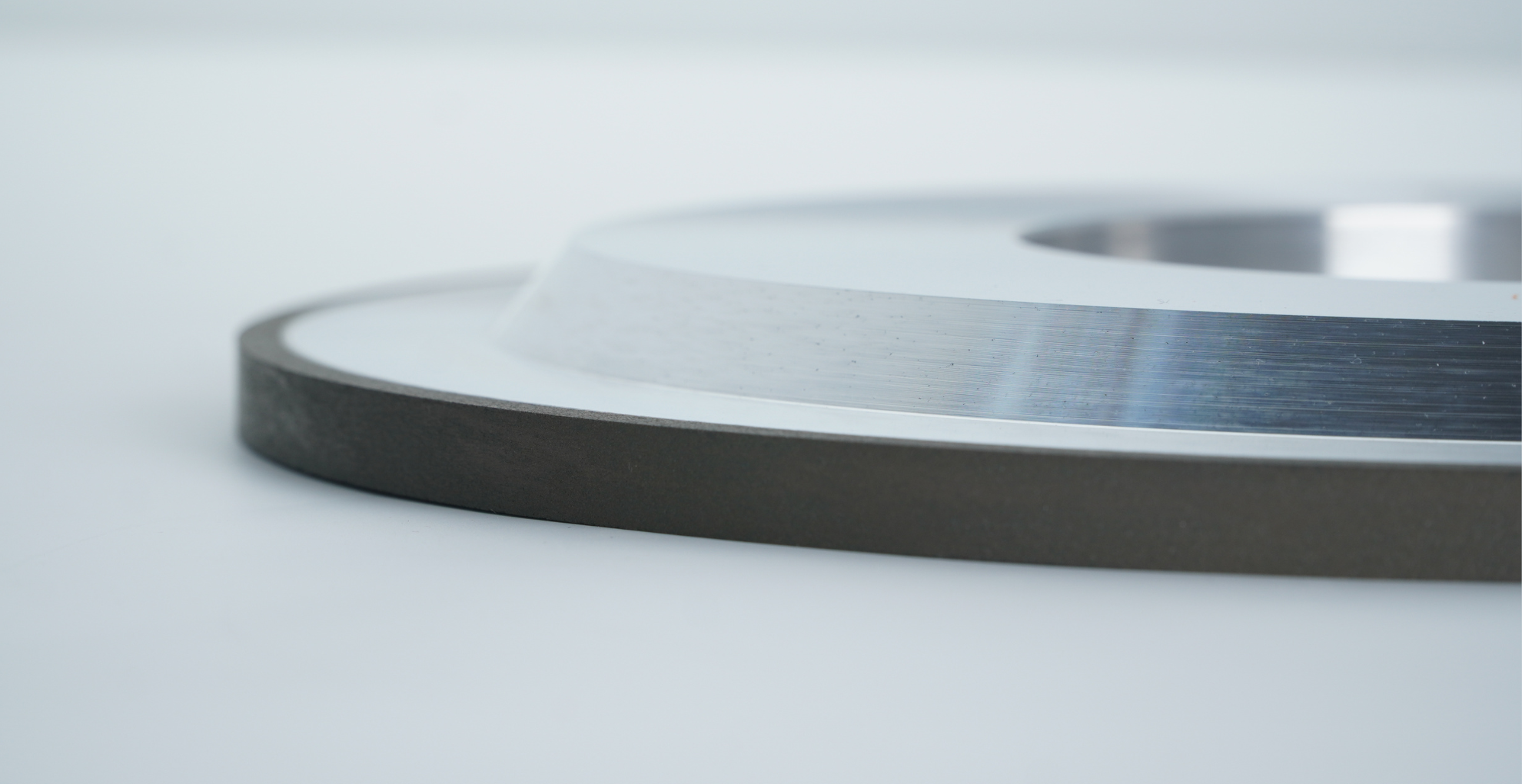

Wheel Shape and Size

The shape and size of your cylindrical grinding wheel must fit your machine and your workpiece. Common shapes are straight, cylinder, cup, and dish wheels. Each shape is good for different jobs. Cylindrical wheels are best for round parts. Cup wheels work well for inside grinding or step holes.

Pick the wheel diameter and width based on your workpiece size. The diameter should be close to the bore diameter. A good ratio is between 0.5 and 0.9. This helps control speed and heat. The wheel width should match the workpiece length. If the wheel is too narrow, it wears out fast. If it is too wide, it can cause too much force and bend the part.

Here is a quick table to help you match wheel size to your workpiece:

|

Recommended Wheel Diameter (mm) |

|

|---|---|

|

12 – 17 |

10 |

|

17 – 22 |

15 |

|

22 – 27 |

20 |

|

Workpiece Length (mm) |

Recommended Wheel Width (mm) |

|---|---|

|

14 |

10 |

|

30 |

25 |

You also need to know about grinding wheel markings. Each wheel has markings for diameter, thickness, and hole size. These markings help you pick a wheel that fits your machine and your grinding job.

|

Parameter |

Meaning/Interpretation |

Significance |

|---|---|---|

|

Diameter |

Size of the grinding wheel (mm) |

Affects if it fits, how much area it grinds, and speed |

|

Thickness |

Width of abrasive material (mm) |

Changes how deep you can grind and how strong the wheel is |

|

Hole Size |

Diameter of mounting hole (mm) |

Makes sure the wheel fits safely on the spindle |

Note: Always check the wheel markings before you put it on your machine. This keeps you safe and helps you get the grinding results you want.

Step-by-Step Guide: How to Choose Grinder Wheels for Different Applications

-

Pick the abrasive type that matches your workpiece.

-

Choose the wheel shape for your grinding job.

-

Pick the grit size for the finish and material hardness.

-

Decide on the bond type and hardness for your grinding and machine.

-

Think about the contact area: use coarser grit and softer bond for big areas; finer grit and harder bond for small areas.

-

Look at how hard you will grind to pick the right abrasive and bond.

-

Match the wheel hardness to your machine’s horsepower.

-

Test and change grinding settings to get the best results.

📝 Checklist: Always go over these steps before you start grinding. This helps you pick the right cylindrical grinding wheel and get better results.

Remember, picking the right grinding wheel is not just one choice. You may need to change your pick after testing and learning. If you follow these steps, you can get smoother finishes, longer wheel life, and safer grinding.

Operational Factors

Machine Power and Speed

You must match your grinding wheel to your machine’s power and speed. Machine horsepower changes how your wheel performs. If you use a high-horsepower machine, choose a harder wheel grade and strong abrasive grains. This setup lets the wheel hold its shape and self-sharpen under heavy force. For low-horsepower machines, pick a softer wheel grade with more friable grains. This helps the grains break away and keeps the wheel from dulling or burning your workpiece.

|

Machine Horsepower Level |

Effect on Grinding Wheel Hardness and Bond Type |

Explanation |

|---|---|---|

|

High horsepower |

Use harder wheel grades and durable grains |

Higher forces allow the wheel to hold form longer; grains fracture properly enabling self-sharpening |

|

Low horsepower |

Use softer wheel grades and more friable grains |

Insufficient force to break down grains leads to dullness and surface damage; softer grades help grain release and prevent burning |

Wheel speed also matters for safety and performance. Most cylindrical grinding runs best between 4500 and 6500 surface feet per minute (SFM). Ceramic wheels on hard tool steels work well at about 4600 SFM. You can go up to 10,000 SFM, but higher speeds increase the risk of wheel breakage, especially with small wheels. Always check your wheel’s markings and follow safety standards.

Tip: Keep your machine rigid and powerful enough for the job. This helps you grind harder steels and get a better finish.

Coolant and Safety

Coolant plays a big role in grinding. It cools your workpiece, flushes away chips, and keeps the wheel clean. Coolant also reduces heat, which protects both your wheel and your part. Using coolant helps you avoid wheel loading and burning. High-pressure, high-velocity coolant systems work best for modern grinders. Aim the nozzle right at the hot point where the wheel meets the material.

-

Coolant extends wheel life by lowering heat and stopping clogging.

-

It improves workpiece quality by controlling temperature and preventing oxidation.

-

Clean coolant tanks and filters keep your system working well.

-

Pick the right coolant type and keep it at the right concentration.

Safety is always important when you use a cylindrical grinding wheel. Here are some quick tips for better grinder wheel performance and safety:

-

Inspect the wheel for cracks or damage before use.

-

Mount the wheel correctly and check that the machine speed matches the wheel rating.

-

Stand to the side when starting the grinder.

-

Let the wheel run for a minute before grinding.

-

Keep the work rest close to the wheel (no more than 1/8 inch).

-

Use both hands and apply gentle, steady pressure.

-

Only grind on the wheel face unless the wheel is made for side grinding.

-

Turn off the machine when not in use.

-

Store wheels in a dry, safe place.

Regular maintenance keeps your grinding setup safe and effective. Dress your wheel often to remove dull grains. Lubricate moving parts and keep your coolant system clean. Avoid overloading your machine and balance your wheel to reduce vibration. Clean your grinder daily and schedule professional checks every year.

When you pick a grinding wheel, match its features to your needs. Make a checklist to help you choose the right material and pressure. Think about the finish you want and if the wheel fits your machine. Always check wheels for cracks or damage before using them. Follow the maker’s rules for picking abrasive, bond, and grit. Pick wheels with ANSI certification for safety. Take care of your wheels and use coolant the right way. This helps grinding work well and keeps you safe.

Remember, picking the right wheel helps you avoid mistakes. It also makes grinding work better and safer.

-

Pick wheels that fit your grinding job.

-

Help the environment by choosing wheels that last and can be recycled.

FAQ

What happens if you use the wrong grinding wheel?

If you use the wrong wheel, you risk poor surface finish, fast wheel wear, or even machine damage. You may also face safety hazards. Always match the wheel to your workpiece and machine.

How do you know when to replace a cylindrical grinding wheel?

You should replace the wheel if you see cracks, chips, or uneven wear. If the wheel vibrates or does not cut well, change it. Always inspect before each use.

Can you use one grinding wheel for all materials?

No, you cannot. Each material needs a specific abrasive type and bond. Using the wrong wheel can cause poor results or damage. Always check the manufacturer’s guide for the best match.

Why does coolant matter in cylindrical grinding?

Coolant keeps your workpiece and wheel cool. It removes chips and prevents burning. Using coolant helps you get a better finish and extends wheel life.

How do you read grinding wheel markings?

Look for numbers showing diameter, thickness, and hole size. You will also see codes for abrasive type, grit, grade, and bond. Always match these to your machine and job needs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools