The best grinding wheel for your project depends on both your material and your specific application. For example, aluminum oxide wheels work best for steel, while silicon carbide suits aluminum and non-ferrous metals. Diamond wheels handle ceramics and composites with high precision. Key factors—abrasive type, grit size, bond, hardness, and structure—affect your results when you choose grinding wheel options. Aimgrind delivers expertise in superhard and conventional wheels, offering custom solutions for every challenge. Identify your needs to achieve the best performance.

Material

Common Wheel Type

Aluminum Oxide

Aluminum

Silicon Carbide

Ceramics/Composites

Diamond

Key Takeaways

-

Choose a grinding wheel that matches your material’s hardness and type for the best results and longer wheel life.

-

Select the right abrasive type—aluminum oxide for steel, silicon carbide for aluminum, and diamond or CBN for very hard materials like ceramics.

-

Pick the correct grit size based on your goal: coarse for fast material removal, fine for smooth finishes.

-

Match the bond type and wheel structure to your material and grinding task to improve performance and prevent wheel clogging.

-

Always follow safety rules: wear proper protective gear, inspect wheels before use, and replace wheels when damaged or worn.

Materials

Hardness

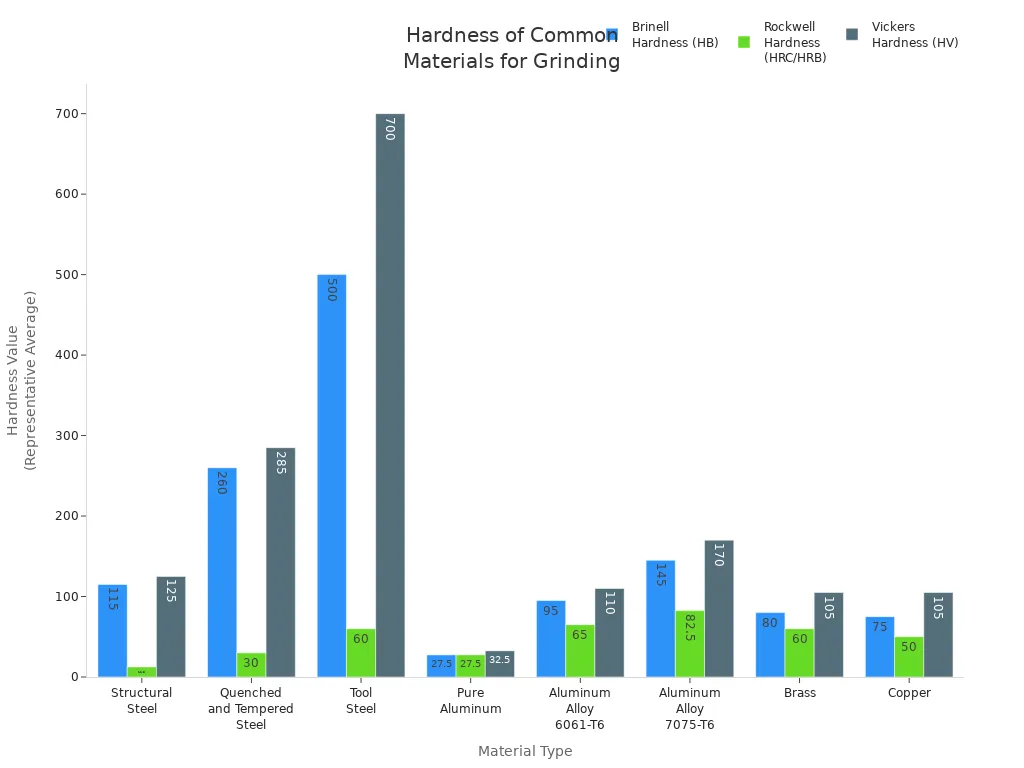

When you choose a grinding wheel, you must consider the hardness of your material. Hardness measures how well a material resists scratching or indentation. Materials like steel, aluminum, ceramics, and composites all have different hardness levels. This difference affects which abrasive and wheel hardness grade you should use.

Here is a table that compares the hardness characteristics and typical grinding wheel choices for common material types:

|

Material Type |

Hardness Characteristics |

Typical Abrasive Used |

Grinding Wheel Hardness Grade Selection |

|---|---|---|---|

|

Ferrous Metals |

Generally higher hardness; includes steels, cast iron |

Aluminum oxide (balance of toughness and cutting speed) |

Softer wheels to allow quick grain shedding and maintain sharpness |

|

Non-Ferrous Metals |

Generally softer than ferrous metals (e.g., aluminum) |

Silicon carbide (harder, sharper but brittle) |

Harder wheels to maintain wheel shape longer |

|

Ceramics & Composites |

Very hard and brittle |

Superabrasives (cubic boron nitride, diamond) |

Specialized wheel hardness and bond types for effective grinding |

You can also compare the actual hardness values for these materials using different scales. The chart below shows Brinell, Rockwell, and Vickers hardness values for common metals:

Tip: Always match the wheel type and hardness grade to your material. This step helps you achieve better results and longer wheel life.

Grindability

Grindability describes how easily you can grind a material while keeping wheel wear low and the surface finish high. Steel is versatile and works well with conventional abrasives like aluminum oxide. Aluminum, being softer, can clog wheels quickly. You need a wheel that resists loading to keep grinding efficient. Ceramics and composites are very hard and brittle. You should use superabrasive wheels, such as diamond or cubic boron nitride, for these materials.

Composite materials, like carbon fiber reinforced plastics or metal matrix composites, present unique challenges. Their mixed structure can cause both wheel loading and rapid abrasive wear. Specialized wheels with the right grit and bond help you manage these issues.

-

Materials with high grindability let you remove more material with less wheel wear.

-

Harder materials with low grindability cause faster wheel wear and need more frequent dressing.

-

The G-ratio (material removed vs. wheel lost) helps you measure grindability. A higher G-ratio means better grindability and longer wheel life.

Choosing the right grinding wheel for your material’s hardness and grindability ensures efficient, safe, and cost-effective grinding.

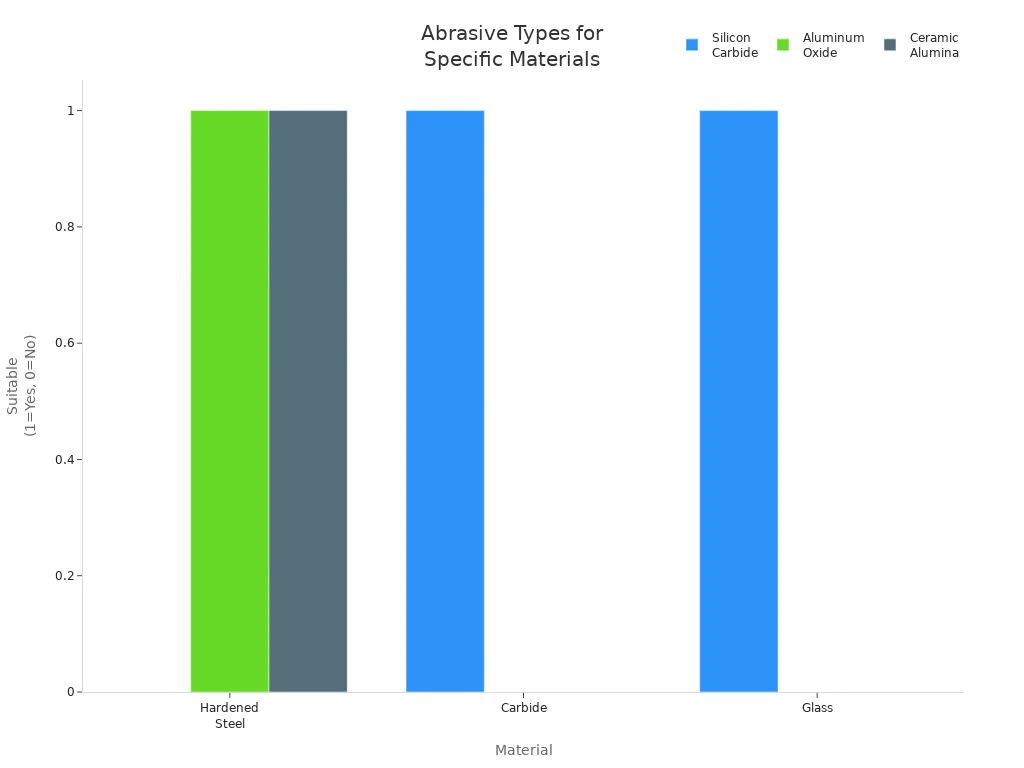

Abrasive Types

Choosing the right abrasive type is key to getting the best results from your grinding wheel. Each abrasive has unique properties that make it suitable for certain materials and tasks. You can see the main differences in the table below:

|

Abrasive Type |

Hardness & Toughness |

Heat Resistance & Stability |

Cutting Characteristics & Applications |

|---|---|---|---|

|

Diamond |

Hardest known material |

Limited by graphitization above 660°C; reacts with carbon steels |

Best for grinding tungsten carbide, glass, ceramics; used in precision grinding; available in resin, vitrified, and metal bonds |

|

Cubic Boron Nitride (CBN) |

Second hardest; very tough grains |

Excellent thermal stability up to 2000°C |

Ideal for grinding hard ferrous metals, cast iron, nickel, cobalt alloys; used in automotive parts grinding; needs strong bonds |

|

Aluminum Oxide |

Varies by type; generally tough |

Good heat resistance; ceramic type especially durable |

Widely used; ceramic aluminum oxide good for high stock removal and precision grinding; brown fused for rough grinding; white fused for heat-sensitive alloys |

|

Zirconia Alumina |

Toughest alumina-based abrasive |

Good heat resistance; can overheat under pressure |

Aggressive, self-sharpening; excellent for high-pressure, high stock removal; less suitable for fine finishes; used in steel fabrication |

|

Silicon Carbide |

Very sharp but brittle |

Lower heat resistance; breaks down faster under heavy loads |

Best for grinding hard or brittle materials and soft metals; not suited for high-pressure grinding; used in automotive sanding, stone polishing |

Superhard Abrasives

Superhard abrasives include diamond and cubic boron nitride (CBN). You should use diamond wheels for the hardest materials, such as tungsten carbide, ceramics, and glass. Diamond wheels deliver unmatched precision and durability, but they do not work well on steel because of chemical reactions at high temperatures. CBN wheels are perfect for hard ferrous metals like hardened steel, cast iron, and nickel alloys. They handle high heat and keep their shape longer than conventional wheels.

Note: Superhard wheels cost more at first, but they last much longer and reduce downtime. You save money over time because you change wheels less often.

Aimgrind offers a full range of superhard wheels. You can also request custom solutions for unique grinding challenges.

Conventional Abrasives

Conventional abrasives include aluminum oxide, silicon carbide, and zirconia alumina. Aluminum oxide wheels are the most common choice for grinding steel and strong metals. They are tough, affordable, and work well for both rough and fine grinding. Silicon carbide wheels are sharper but more brittle. You should use them for hard, brittle materials like glass, stone, and ceramics, or for soft metals such as aluminum.

Zirconia alumina wheels are very tough and self-sharpening. They work best for heavy stock removal on steel and high-pressure applications, but they do not give the finest finish.

|

Abrasive Type |

Notes |

|

|---|---|---|

|

Aluminum Oxide |

Steel, Strong Metals |

Hard-cutting, aggressive abrasion; less dust; suitable for steel and other strong metals. |

|

Silicon Carbide |

Hard Metals, Glass, Stone |

Fast cutting speed; ideal for glass and carbide; breaks down quickly under heavy load. |

|

Ceramic Alumina |

Hardened Steel, Stainless Steel |

Long-lasting synthetic grain; good for metal finishing, especially stainless steel. |

Tip: If you want a balance between cost and performance, choose a conventional abrasive. For the longest life and best results on hard or brittle materials, select a superhard abrasive.

Aimgrind supplies both superhard and conventional wheels. You can get expert advice and custom options to fit your exact needs.

Choose Grinding Wheel

Selecting the right grinding wheel involves more than just picking an abrasive. You need to consider grit size, bond type, and wheel structure. Each factor affects how the wheel performs and how well it matches your material and machine.

Grit Size

Grit size refers to the size of the abrasive particles in the wheel. This choice directly impacts both the surface finish and the rate at which you remove material. When you choose grinding wheel options, think about your goal—do you want a smooth finish or fast material removal?

-

Coarse grits (lower numbers, such as 80-180) remove material quickly and are best for rough grinding or shaping.

-

Medium grits (180-240) balance removal rate and surface finish, often used for general-purpose grinding.

-

Fine grits (240-600) produce smooth, high-quality finishes and are ideal for final passes or precision work.

For example:

-

Start with a coarse grit for heavy stock removal.

-

Move to finer grits for each step to improve the surface finish.

-

For very hard materials, diamond wheels with fine grits (240 and up) give the best results.

Lower grit numbers mean faster cutting but rougher surfaces. Higher grit numbers mean slower cutting but smoother finishes. Always match the grit size to your material and the finish you need.

Bond Type

The bond holds the abrasive grains together and affects how the wheel wears and performs. When you choose grinding wheel types, you must match the bond to your material and application. Here is a table summarizing common bond types and their uses:

|

Bond Type |

Properties & Composition |

Typical Applications & Advantages |

|---|---|---|

|

Vitrified |

Glass or ceramic-based, porous, allows dressing/coolant |

High-production, precise grinding, automotive parts, low grinding force |

|

Resin |

Synthetic resin (phenolic/epoxy), tough and versatile |

Cutoff wheels, centerless wheels, superabrasives, general applications |

|

Metal |

Bronze, iron, or alloys, hardest and most durable |

Hard materials (glass, ceramics, carbides), aerospace, long wheel life |

|

Electroplated |

Single abrasive layer on metal core, no dressing needed |

Complex shapes, high removal rates, reconditioning possible |

Different bonds suit different needs:

-

Vitrified bonds work well for precise, high-volume jobs and allow easy dressing.

-

Resin bonds offer versatility and cost-effectiveness for many materials.

-

Metal bonds provide durability for grinding very hard materials.

-

Electroplated bonds handle complex shapes and high removal rates.

Tip: If you grind heat-sensitive materials, use a soft bond and open structure to reduce heat buildup. For hard materials or precision work, a hard bond and fine grit will give you a better finish and longer wheel life.

Structure

Structure describes how tightly the abrasive grains are packed in the wheel. This affects heat dissipation, chip clearance, and overall performance. When you choose grinding wheel structure, consider your material and the type of grinding operation.

|

Structure Type |

Heat Dissipation |

Chip Clearance |

Best For |

|---|---|---|---|

|

Open Structure |

Excellent (more voids) |

High (less clogging) |

Soft, ductile materials; heavy stock removal |

|

Dense Structure |

Limited (fewer voids) |

Low (more clogging) |

Hard, brittle materials; fine surface finish |

-

Open structures allow better cooling and chip removal, which extends wheel life and prevents loading, especially when grinding soft or sticky materials.

-

Dense structures hold grains tightly, making them stronger and better for achieving fine finishes on hard materials.

Note: Always match the wheel structure to your grinding operation. For rough grinding or when working with soft metals, open structures help prevent clogging. For precision finishing on hard materials, dense structures provide the best results.

Matching Wheel Hardness, Size, and Machine Compatibility

Wheel hardness, or grade, ranges from A (softest) to Z (hardest). Softer grades release worn grains quickly, which is ideal for hard materials. Harder grades hold grains longer, making them better for softer materials and heavy-duty grinding. Always check your machine’s specifications for wheel diameter, thickness, and arbor size. For example, a 4.5-inch wheel with a 1/8-inch thickness fits a right angle grinder with a 7/8-inch arbor. Using the correct size ensures safe operation and optimal performance.

-

Use softer wheels for hard materials and high-precision work.

-

Use harder wheels for soft materials and high stock removal.

-

Make sure the wheel’s speed rating matches your machine.

Safety Reminder: Never use a wheel that does not fit your machine’s size or speed requirements. Always inspect wheels for damage before use.

When you choose grinding wheel features like grit size, bond, and structure, you optimize both performance and safety. Matching these factors to your material, operation, and machine helps you achieve the best results every time.

Performance and Safety

Efficiency Tips

You can extend the life of your grinding wheel and improve your results by following a few key strategies:

-

Hold the correct grinding angle, usually around 15 degrees, to reduce wear and avoid gouging your material.

-

Use smooth, long strokes instead of short, repetitive ones. This helps keep the wheel cool and prevents uneven wear.

-

Apply only light pressure. Forcing the wheel does not speed up the process and can cause damage.

-

Keep your wheel sharp by dressing it regularly. This removes loaded material and exposes fresh abrasive grains.

-

Use plenty of coolant or a high-volume coolant system. This reduces heat, protects your workpiece, and extends wheel life.

-

Choose the right wheel for your material and application. The correct abrasive and bond type make a big difference.

Tip: Advanced machines with CNC control and automation can help you achieve more precise results and reduce human error.

Safety Guidelines

Grinding wheels can be dangerous if you do not follow safety rules. Always wear the right personal protective equipment (PPE):

-

Safety glasses with side shields and a full face shield protect your eyes and face from flying debris.

-

Use earplugs or earmuffs to guard against loud noise.

-

Wear dust masks or respirators if you work in dusty conditions.

-

Choose gloves that protect against cuts, heat, and vibration.

-

Wear sturdy, non-flammable clothing and steel-toe boots.

Before you start, inspect your wheel for cracks or damage. Perform a ring test on ceramic wheels to check for hidden cracks. Make sure the wheel is mounted correctly and never exceed the maximum speed marked on the wheel. Stand to the side during the first minute of operation, as wheels are most likely to break at startup.

Note: Adjust work-rests and tongue-guards close to the wheel to prevent jamming and contain sparks.

Replacement Signs

You should replace your grinding wheel when you notice these signs:

-

The wheel has a visual wear indicator that shows it is worn out.

-

You see edge chipping or cracks on the wheel.

-

The wheel feels out of balance or vibrates during use.

-

The wheel no longer cuts efficiently, even after dressing.

-

You notice glazing or loading that does not go away with cleaning.

Using a worn or damaged wheel can lead to poor results and serious safety risks. Always follow manufacturer guidelines for replacement and disposal.

To choose grinding wheel options that fit your needs, follow these steps:

-

Identify your material and its hardness.

-

Select the right abrasive type, grit size, bond, and structure.

-

Balance removal rate, wheel speed, and coolant for efficiency.

-

Consult with grinding experts for specialized or challenging jobs.

Custom solutions from Aimgrind help you achieve the best results, especially for unique materials or tight tolerances. Expert advice prevents common mistakes and ensures safe, cost-effective grinding.

FAQ

How do you know which grinding wheel to choose for your project?

You should match the wheel to your material and task. Check the abrasive type, grit size, bond, and structure. If you work with steel, use aluminum oxide. For ceramics, pick diamond. Always review your machine’s requirements.

What safety gear should you wear when using a grinding wheel?

Always wear safety glasses, a face shield, gloves, and hearing protection. Use a dust mask if you grind in dusty areas. Choose sturdy clothing and closed-toe shoes for extra protection.

How often should you replace your grinding wheel?

Replace your wheel if you see cracks, chips, or heavy wear. If the wheel vibrates or cuts poorly after dressing, it is time for a new one. Always follow the manufacturer’s guidelines.

Why does your grinding wheel load up or clog?

Soft metals like aluminum can clog your wheel. Use a wheel with an open structure or a coarser grit. Dress the wheel often to remove buildup and keep it sharp.

Can you use one grinding wheel for different materials?

You should not use the same wheel for all materials. Each material needs a specific abrasive and bond. Using the wrong wheel can cause poor results or damage. Always select the right wheel for each job.

Contact Us

For More Grinding Solution or Customized Abrasive Tools