Choosing the right glass grinding wheel for your shape edging machine plays a key role in getting smooth, safe edges on glass. The correct wheel helps you save time and lower costs by making the process faster and more efficient. Diamond wheels work well for thick glass, while finer wheels suit thin glass. Using water-based coolant systems reduces heat and dust, keeping you safe during operation. Regular checks and careful handling of the glass grinding wheel keep your work safe and your results consistent.

Key Takeaways

Always pick a grinding wheel that fits your machine’s size. Make sure it matches the mounting too. This helps the machine work safely and smoothly.

Diamond wheels, like metal bond types, last a long time. They work well for grinding glass edges.

Pick the right grit size for your job. Coarse grits shape glass fast. Fine grits make the edges smooth and shiny.

Use water-based coolant to lower heat and dust. This keeps the glass and the worker safe while grinding.

Clean and check your grinding wheels often. Handle them with care to keep good results and stay safe.

Compatibility

When you pick a grinding wheel, first check if it fits your machine. The wheel must match your machine and what you need to make. Using the wrong wheel can cause chips or scratches. It might even break your machine. Keeping your machine clean and learning how to use it helps stop these problems. Dust and wet air can also change how your machine and wheel work together.

Size & Mounting

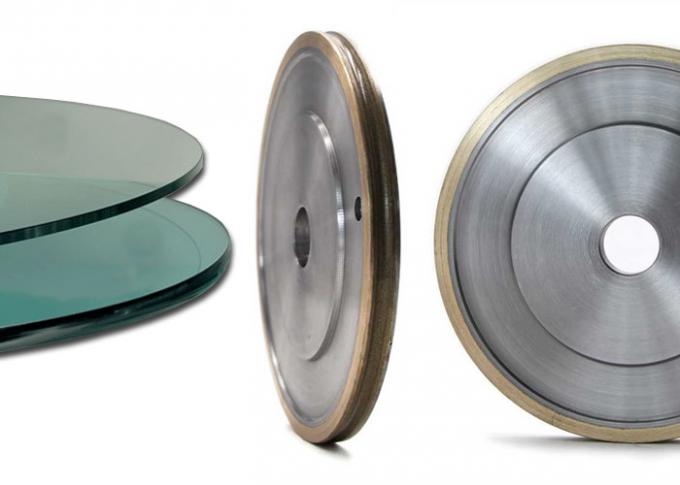

Pick a grinding wheel that is the right size for your machine. Look at the numbers from the maker, like 150x22mm. These numbers help you find a wheel that fits tight on the shaft. A good fit keeps the wheel steady when you use it. Many machines use clamps to hold the wheel in place. You can move the wheel a little to line it up right. This helps the wheel cut well and makes the glass edge smooth. Pencil edge and trapezoidal wheels are used a lot. They work for glass that is 3mm to 8mm thick. These wheels last a long time, even if you use them a lot.

Tip: Always check the wheel size and how to put it on in your machine’s manual before you start.

Speed & Power

Your machine’s speed and power must match the grinding wheel. Most shape edging machines spin up to 25 times each minute. They use about 3 kW of power. If you set the speed or power too high, the wheel can get too hot. The glass might break. If the speed is too low, the glass edge will not be smooth. The right settings help stop chips, scratches, or motor problems. Change the speed and pressure for the glass and wheel you use. Check your machine often and keep it oiled so it works well and stays safe.

Glass Grinding Wheel Materials

Diamond Wheels

You will find that diamond wheels are the top choice for grinding glass. These wheels use diamond as the abrasive, which is the hardest material on earth. This makes them perfect for shaping and smoothing glass edges. When you use a diamond glass wheel, you get a tool that lasts longer than regular abrasive wheels. You can grind hard glass without the wheel wearing down quickly.

Note: Diamond wheels work well for both rough grinding and fine finishing. You can pick different grit sizes to match your needs. Coarse grits remove material fast, while fine grits give a smooth finish.

Here are some reasons why diamond wheels stand out:

They have exceptional hardness and wear resistance. You can use them for a long time before needing a replacement.

They offer high grinding performance. You can remove a lot of glass quickly or achieve a precise finish, depending on the grit.

They generate less heat, especially when you use water as a coolant. This keeps the glass from cracking.

They come in different bond types, so you can choose the right one for your job.

They keep a sharp cutting surface, which means you get steady results every time.

Type of Diamond Wheel | Best Use Cases | Durability and Performance |

|---|---|---|

Fine finishing, delicate glass, wet grinding | Softer, good for precision, wears faster | |

Metal Bond Diamond Wheels | Heavy-duty grinding, thick glass, long runs | Hard, heat-resistant, lasts longer |

You will see metal bond glass grinding wheels used most often in shape edging machines. These wheels handle tough jobs and keep their shape even after many uses.

Bond Types

The bond in a glass grinding wheel holds the diamond particles in place. The type of bond changes how the wheel works and how long it lasts. You need to pick the right bond for your glass and your machine.

Vitrified Bond: This bond uses glass or ceramic materials. It gives the wheel strength and lets water flow through, which helps cool the glass. Vitrified bonds last a long time but can break if you drop them.

Resin Bond: This bond uses plastic resins. It is softer and more flexible. You get a smoother finish, but the wheel wears out faster if you use it for heavy grinding.

Metal Bond: This bond uses metals like brass or bronze. It is very strong and resists heat. Metal bond wheels are best for tough jobs and thick glass. They last longer and keep their shape, but they may dull faster if you use them for fine work.

Tip: Harder bonds make the wheel last longer, but softer bonds give you a smoother grind and expose new diamond grains faster.

You should always match the bond type to your application. For most shape edging jobs, metal bond glass grinding wheels give you the best mix of durability and performance.

Grit Selection

Choosing the right grit size for your glass grinding wheel shapes the quality of your work. Grit size tells you how rough or smooth the wheel feels. You can see grit numbers on the wheel or in the product details. Higher numbers mean finer grit, while lower numbers mean coarser grit.

Coarse vs. Fine

You need to know the difference between coarse and fine grit wheels. Coarse grit wheels have larger abrasive particles. They remove glass quickly but leave a rough surface. Fine grit wheels have smaller particles. They work slower but give you a smooth, chip-free finish.

Here is a table to help you compare:

Aspect | Coarse Grit Grinding Wheels | Fine Grit Grinding Wheels |

|---|---|---|

Grit Size | 10 to 70 | 70 to 1000+ |

Material Removal | Fast | Slow |

Surface Finish | Rough | Smooth |

Best Use | Shaping, heavy removal | Finishing, polishing glass |

Glass Suitability | Large, thick pieces | Thin, brittle, or decorative glass |

You often start with a coarse grit, such as 400, to flatten the glass. Then, you move to finer grits like 600 or 800 for a better finish. Using only coarse grit can leave scratches. Fine grit wheels are best for polishing glass and reducing chips.

Application Match

You should match the grit to your job. If you want to shape glass quickly, use a coarse grit. For smoothing and polishing glass, choose a fine grit. Fine grits, such as 600 or 800, help you get a clear, even edge. Some people use 3-micron aluminum oxide for the final step. This gives the glass a very smooth surface.

When you polish glass, start with a coarse grit for fast shaping. Move to finer grits for a smooth finish. For small pieces, you can begin with 600 or 800 grit to save time. Always check the quality of your grit powder. Different brands can give different results when polishing.

Tip: Progress from coarse to fine grit for the best balance of speed and finish. This method helps you avoid scratches and get a perfect result when polishing glass.

Applications

Edge Quality

You want your glass edges to be smooth and safe. The right glass grinding wheel helps you get polished, chip-free edges. For pencil edge grinding, you use metal bond diamond wheels. These wheels make strong, rounded edges that last a long time. If you want a perfect finish, use finer grit wheels for polishing. This step takes away small scratches and makes the glass shiny and clear. When working with optical glass, you use superabrasive diamond tools. These tools help you get a very smooth and exact finish. Always use water coolant to keep the glass cool and stop cracks.

Industry rules say how straight and smooth glass edges must be. You can use optical tools to check if your work meets these rules.

Grinding Wheel Type | Edge Quality Impact | Best Use Case |

|---|---|---|

Chip-free, smooth, durable edges | Pencil edge, high production | |

Resin Bond Diamond Wheels | Smooth finish, wears faster | Fine finishing, polishing |

Thin Diamond Wheels | Clean, precise cuts | Cutoff grinding |

Glass Types

Different glass types need different grinding wheels. Float glass, laminated glass, and stratified glass each need special care. For float glass, you often use diamond wheels to shape and polish the edges. Laminated glass needs wheels that can work on layers without causing chips. Stratified glass has many layers, so you need wheels for carving glass. These wheels help you shape and smooth the edges without breaking the layers. For carving and engraving glass, you need wheels that can make fine details and smooth lines.

Float glass: Use diamond wheels to shape and polish.

Laminated glass: Pick wheels that stop chipping between layers.

Stratified glass: Use carving wheels to keep layers safe.

Carving and engraving glass: Use fine wheels for detailed work.

Production Needs

Your work needs decide which glass grinding wheel to use. In the car industry, you use grinding wheels to polish windshields and smooth edges for safety. For building glass, you need wheels that can handle big panels and give a nice look. If you do art or DIY, you want wheels that are easy to use and can make custom shapes. Big factories use diamond wheels with CNC machines for fast, exact work. Art studios use flexible wheels for carving and engraving glass to make special designs.

Factories and builders use automated wheels for lots of work and high quality.

Art and DIY need wheels that work for custom and small jobs.

CNC machines let you switch between glass types and shapes fast.

Glass grinding wheels help you smooth, shape, and polish glass in many jobs. You can use them for cars, buildings, and art glass. This makes them important for both big factories and small studios.

Grinding Wheels for Glass Lathe

Lathe Compatibility

When you choose grinding wheels for glass lathe work, you need to match the wheel to your machine and the type of glass you want to shape. Each lathe has its own speed, power, and mounting system. You must check the wheel’s size, speed rating, and bond type. For example, vitrified bonds work well at lower speeds, while organic bonds handle higher speeds. The type of abrasive matters too. Many people use silicon carbide for glass because it cuts hard materials without causing cracks.

You should also think about the machine’s horsepower. If your lathe has more power, you can use a harder wheel grade. If you use coolant, remember that it can change how the wheel behaves. Vitrified wheels get softer with coolant, but organic wheels get harder. Always balance these factors to keep your work safe and get the finish you want.

Tip: Always check the wheel’s label for speed and bond information before you start.

Here is a quick checklist for compatibility:

Match wheel size and mounting to your lathe.

Choose the right abrasive and bond for glass.

Check speed rating and machine horsepower.

Adjust for coolant use and grinding pressure.

Specialized Uses

Grinding wheels for glass lathe let you do more than just shape edges. You can use them for carving and engraving glass, making detailed patterns and textures. These wheels come in many shapes, such as V-wheels, olive wheels, and spherical wheels. Each shape helps you create different effects on the glass surface.

You might use sintered or electroplated diamond wheels for deep carving and engraving glass. For polishing, felt or cork wheels give a smooth, shiny finish. Artists and craftspeople often use these wheels to make custom designs, logos, or artwork on glass. Factories use them to add textures or patterns to glass panels.

Wheel Type | Best Use | Typical Profile |

|---|---|---|

Sintered Diamond | Deep carving | V, olive, spherical |

Electroplated | Fine engraving | Flat, strap |

Felt/Cork | Polishing | Flat, soft |

You can see how grinding wheels for glass lathe open up many creative options. They help you move from simple edge work to advanced carving and engraving glass, making each piece unique.

Maintenance & Safety

Wheel Care

Taking care of your glass grinding wheel keeps your work safe and your results sharp. You should always start by cleaning the wheel and machine after each use. Use a soft brush or compressed air to remove glass particles and dust. This step prevents clogging and damage. Check the wheel for chips, cracks, or signs of wear before you begin grinding. If you see any damage, replace the wheel right away.

Store your wheels in a dry place. Stand them on edge with dividers so they do not touch each other. This helps prevent cracks and chips. Handle each wheel gently, like you would with fine china. Dress the wheel regularly to keep its shape and cutting ability. This practice helps you maintain grinding wheel consistency and ensures smooth edges on your glass.

Follow these steps for daily care:

Remove debris from the wheel and machine surfaces.

Inspect the wheel for damage or wear.

Check the coolant system for leaks or blockages.

Lubricate moving parts as recommended.

Adjust machine calibration for accurate grinding.

Tip: Replace any wheel that looks glazed, clogged, or makes unusual noises. These are signs the wheel needs attention.

Safety Tips

You must always put safety first when using a glass grinding wheel. Wear safety glasses with side shields to protect your eyes from flying shards. Use a dust mask to keep glass dust out of your lungs. Stand to the side of the wheel when you turn on the machine. This keeps you safe if the wheel breaks.

Keep the workspace clean and dry. Use water cooling to reduce heat and control dust. Make sure the coolant system works well before you start. Operate dust collectors or exhaust systems to keep the air clean. Never wear gloves while grinding, but use them when handling wheels or glass pieces.

Here is a quick safety checklist:

Wear personal protective equipment (PPE).

Keep wheel guards in place.

Apply gentle, steady pressure during grinding.

Turn off the machine when not in use.

Remember: Replace any wheel that shows cracks, glazing, or uneven wear. Regular checks and safe habits protect you and your equipment.

Glass Grinding Wheel types

When you choose a glass grinding wheel for your shape edging machine, you will see many types. Each type has a special design for different jobs. Here are the main types you will find:

Diamond Pencil Edge Glass Grinding Wheel

You use this wheel when you want smooth, rounded edges on glass. The wheel has synthetic diamond grains and a strong steel base. You can pick from sizes like 100mm, 150mm, or 200mm. Grit options include 120#, 150#, and 180#. This wheel gives you sharp grinding, low noise, and no vibration. You get a high-quality edge with no chips. You can use it for safety glass, automotive glass, and even stone or ceramics. It works well for shaping straight lines, curves, and special shapes.

Feature | Description |

|---|---|

Abrasive Material | Synthetic diamond |

Edge Design | Round or concave |

Performance | Sharp, quiet, long life, no broken edges |

Applications | Glass, stone, ceramics, optical lenses |

Tip: This wheel helps you remove uneven edges quickly and leaves a smooth finish.

Trapezoidal Edge Glass Grinding Wheel

You pick this wheel for special shapes and high-precision work. The trapezoidal design fits vertical grinding machines. It reduces vibration and adapts to glass warping. You get a smooth, even edge every time. The wheel works well for both rough and fine grinding. You can use it for optical glass and other hard materials. The special shape lets you grind complex profiles with high accuracy.

1A1 Flat Edge Glass Grinding Wheel

You use the 1A1 flat edge wheel for straight, flat edges. This wheel is common in many glass factories. It gives you a clean, flat surface, perfect for windows or tabletops. You can use it for both rough grinding and fine finishing. The wheel fits most shape edging machines and works well with water cooling.

Continuous Rim Diamond Cup Grinding Wheel

You choose a continuous rim wheel when you want a smooth finish. The rim has no gaps, so you get less cleanup and no wobble. You can grind right up to the core. This wheel comes in coarse, medium, and fine grits. It is best for fine grinding and polishing. You use it when you need precise, gentle grinding.

Smoother grinding

Precise control

Less dust and cleanup

Full Segmented Diamond Cup Grinding Wheel

You use a full segmented wheel for fast, rough grinding. The segments help cool the wheel and remove glass chips quickly. This wheel works on all types of glass. You get a good flat edge, ready for polishing. The design prevents overheating and protects the glass from burns. You will find this wheel in edging machines and double edgers.

High speed and flexibility

Long service life

Prevents edge breakage

Half Segmented Glass Grinding Wheel

You pick a half segmented wheel for aggressive cutting and fast material removal. The open structure means you finish the job faster and use less abrasive. You need to check the coolant often because it mists more. The wheel costs less and is easy to adjust on the machine. You get a rougher finish, so you may need to polish after.

Aspect | Half Segmented Wheel | Flat Ring Wheel |

|---|---|---|

Cutting Action | Aggressive, interrupted | Smooth, continuous |

Efficiency | Fast, less abrasive used | Slower, more abrasive used |

Finish | Rougher, needs polishing | Smoother |

Diamond OG Wheel

You use the diamond OG wheel for decorative edges. The OG shape gives you a classic, curved profile. This wheel is great for mirrors, furniture glass, and art pieces. You get a high-performance glass grinding wheel that shapes and polishes in one step. The wheel fits most shape edging machines and gives you a smooth, chip-free edge.

Note: Each wheel type helps you match your machine and your job for the best results.

Choosing the right glass grinding wheel helps you get the best results on your shape edging machine. You should check these key points before you buy:

Match the wheel size and mounting to your machine.

Choose the right grit for your finish.

Make sure your machine has enough spindle power and no vibration.

Use water-based coolant to keep things cool and safe.

Ask your supplier about technical support and guaranteed run time.

If you have special needs, talk with a trusted glass grinding wheel manufacturer. You can always ask for expert advice to get the best performance for your project.

FAQ

What is the best way to store glass grinding wheels?

Store your wheels upright on a flat surface. Keep them dry and away from direct sunlight. Use dividers so the wheels do not touch each other. This helps prevent cracks and chips.

How often should I replace my glass grinding wheel?

Check your wheel before each use. Replace it if you see cracks, chips, or if it feels dull. Most wheels last several months with regular use, but always follow the manufacturer’s advice.

Can I use one grinding wheel for all types of glass?

You should match the wheel to the glass type. For example, use a diamond wheel for float glass and a special wheel for laminated glass. This gives you the best results and keeps your glass safe.

Why is water cooling important during grinding?

Water cooling keeps the wheel and glass cool. It reduces dust and prevents cracks. You also get a smoother edge. Always check that your coolant system works before you start grinding.

Contact Us

For More Grinding Solution or Customized Abrasive Tools