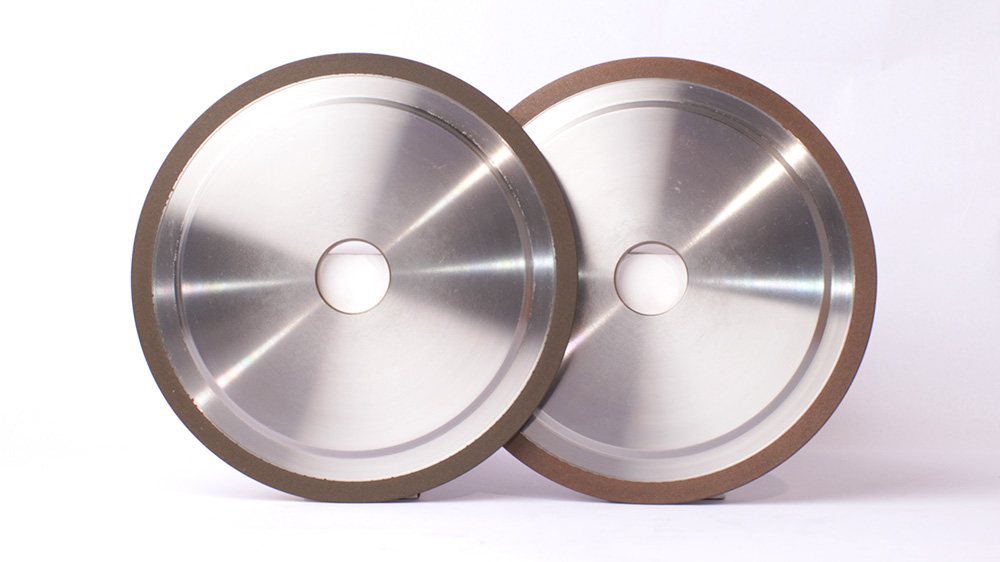

You need the right circular saw grinding wheel to get the best results from your blades. For carbide-tipped blades, resin bond diamond cut-off wheels work best. When you use steel blades, choose CBN cut-off wheels. Always match the circular saw grinding wheel to the blade material. This choice boosts performance, improves quality, and keeps you safe. Good cut-off wheels also help your blades last longer. Quality cut-off wheels support the longevity of your tools. Remember, cut-off wheels make a big difference in every project.

Key Takeaways

Pick a grinding wheel that works with your blade material. This helps it work well and keeps you safe.

Choose the abrasive type, grit size, and bond that match your cutting job. This helps you get the finish you want.

Make sure the wheel shape and size fit your saw. It should also match your blade tooth design.

Use resin bond diamond wheels for carbide blades. Use CBN or aluminum oxide wheels for steel blades.

Always follow safety rules and wear the right protection. Take care of your wheels to make them last longer and work better.

Choosing a Circular Saw Grinding Wheel

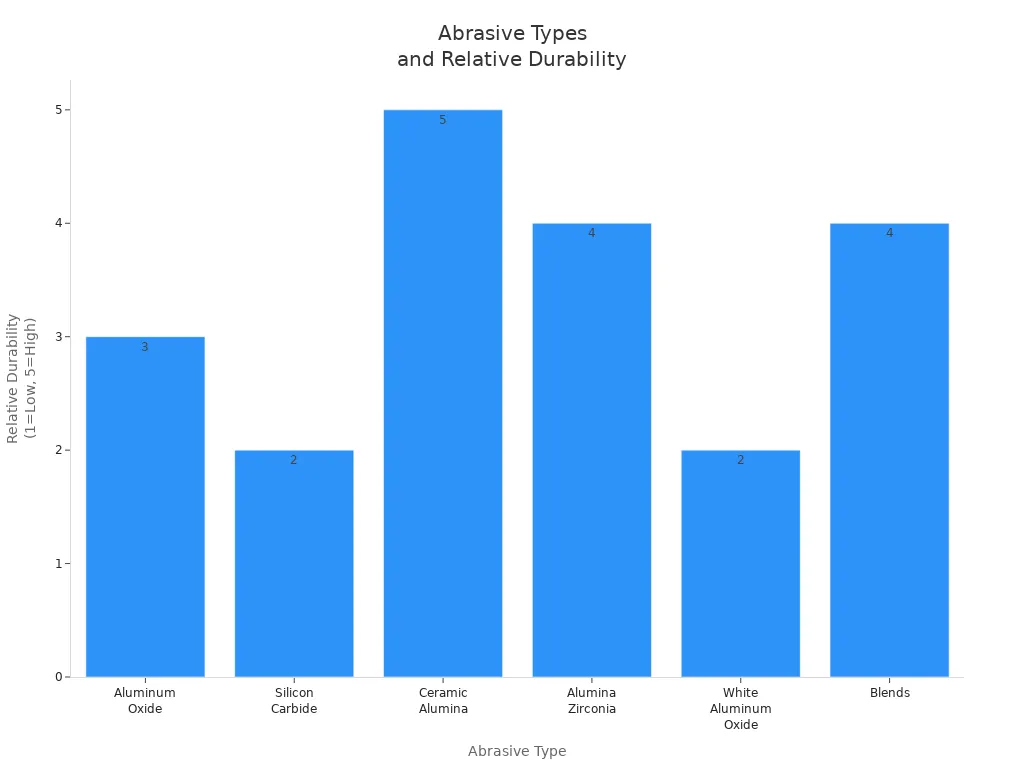

Abrasive Types

When picking a circular saw grinding wheel, start with the abrasive type. The abrasive material affects how well the wheel cuts. It also decides what materials the wheel can handle. Here is a table that compares the main abrasive types for circular saws:

Abrasive Type | Characteristics & Performance | Suitable Materials & Applications |

|---|---|---|

Aluminum Oxide | Good for many jobs, hard and tough; cuts fast at first; needs more pressure to break | Steel, ferrous metals |

Silicon Carbide | Very hard and sharp, almost as hard as diamond; not as tough; cuts fast but wears out quicker | Soft non-ferrous metals (aluminum, copper, brass), stone, concrete, PVC pipe |

Ceramic Alumina | Sharpens itself as it works; stays cool; lasts longer; does not cause much heat color | Hard-to-grind metals like tool steel, stainless steel, titanium, nickel alloys, Inconel® |

Alumina Zirconia | Tough and hard, sharpens itself; cuts fast; lasts long; handles high heat and pressure | Steel, stainless steel |

White Aluminum Oxide | Breaks easily at lower heat and pressure | Tungsten carbide, brass, non-ferrous metals |

Blends (e.g., Alumina Zirconia + Ceramic Alumina, Aluminum Oxide + Silicon Carbide) | Mixes the good parts of each grain; made for special jobs | Ductile iron, PVC pipes, mixed metal types |

Blended abrasives mix the best parts of different grains. For example, alumina zirconia and ceramic alumina together cut faster and need less effort. If you mix aluminum oxide with silicon carbide, you get a wheel that is both hard and tough. This makes your wheels last longer and work better on hard jobs.

You can see how long these abrasive types last in the chart below:

Diamond cut-off wheels are best for carbide-tipped blades. CBN grinding wheels are great for steel blades. Aluminum oxide wheels work well for most steel jobs. Each abrasive type gives different results. Always match the wheel to your blade and the material you are cutting.

Grit and Bond

Grit size and bond type are both important for how your wheels work. Grit size tells you if the wheel is rough or smooth. Coarse grits (20-40) take off material fast but leave a rough surface. Medium grits (50-80) give a balance of speed and smoothness. Fine grits (100-200+) make a smooth finish but cut slower.

Grit Size Range | Effect on Grinding Efficiency | Effect on Finish Quality | Recommended Application |

|---|---|---|---|

Coarse (20-40) | Cuts fast, removes lots of material | Rough finish, may leave marks | Demolition, rough cuts, fast removal on hard materials |

Medium (50-80) | Good balance of speed and smoothness | Medium finish quality | General purpose cutting where speed and finish are both important |

Fine (100-200+) | Cuts slower, makes more heat | Very smooth, no chips | Detailed work, tile, porcelain, ceramics, finishing cuts |

Fine grit wheels wear out slower and need water to keep cool. Coarse grit wheels wear out faster but stay sharp for tough jobs. Pick the grit size based on your material and the finish you want.

The bond holds the abrasive grains together. Resin bond wheels have weaker bonds, so they sharpen themselves and stay cool. They are good for light grinding of carbide saw blades. Vitrified bond wheels are stronger and last longer. They cut sharper and control heat better, but cost more and may leave a rougher finish. Use vitrified bonds for hard jobs or when you need high accuracy.

CBN grinding wheels last a long time and are very precise. They handle heat well and keep your saw blade sharp. The right grit and bond help you get the best results.

Wheel Shape and Size

The shape and size of your grinding wheel matter for how well and how safely you work. Common shapes are saucer, tapered, straight cup, dish cup, and cut-off wheels. Saucer wheels are often used for saw blade care. The right shape helps you match the wheel to the saw tooth shape.

You should also know about FEPA wheel types. Here are some common ones and what they do:

FEPA Wheel Type | Specific Application in Circular Saw Blade Grinding |

|---|---|

1A1 | Grinds the tooth face of carbide-tipped circular saw blades |

1V1 | Used for grinding the side of circular saw blades |

14F1 | Grinds chip breaker flutes of carbide-tipped circular saw blades |

Various others | Top grinding, hollow ground saw blades, and HSS circular saw blades grinding |

Grinding wheels for sharpening saws often have round or square profiles. A round profile matches the top and side edges of saw teeth. This helps the saw cut better and fits many saws. If you use the wrong shape, you might still cut, but the quality will be worse and you could hurt the blade.

Always check the size of your wheels. Make sure the wheel fits your saw and matches the speed rating. Using the wrong size or shape can give bad results or cause accidents. The right shape and size keep your work safe and help you do a good job.

Blades and Materials

Carbide-Tipped Blades

Carbide-tipped blades last a long time and stay sharp. You need the right grinding wheel to keep them working well. Resin bond diamond wheels are best for these blades. These wheels are not as rough as metal bonds, so they protect the carbide tips. You can pick different grades and hardness for resin bond wheels. This helps you choose the right diamond grit size for sharpening.

Resin bond diamond wheels make the blade smoother and last longer between sharpenings.

Finer grit wheels give you better cuts and use less power, but they take off material slowly.

If the wheel is too hard or you push too much, you can hurt the blade tip.

The best wheel depends on the carbide grade, cobalt amount, diamond level, speed, and how fast you move the blade.

Here is a table to compare bond types for grinding carbide-tipped blades:

Bond Type | Characteristics and Performance for Carbide Grinding |

|---|---|

Resin Bond | Most common for carbide; customizable grades and hardness; suitable for wet/dry grinding; phenolic and polyimide types; polyimide offers higher temperature tolerance and form holding. |

Metal Bond | Too aggressive for carbide; better for non-metallic surfaces like glass and ceramics. |

Hybrid Bond | Removes material 10x faster than resin bonds; higher thermal stability; lower spindle loads. |

Electroplated | Strong nickel coating; holds profile for life; good for intricate profile grinding. |

Vitrified Bond | Rigid, strong, porous; allows coolant penetration; good heat removal; extends wheel life. |

Polyimide Bond | Harder resin than phenolic; withstands higher temperatures; better form holding; lower power requirement; ideal for CNC operations. |

Tip: Always match the resin bond diamond wheel to your blade’s carbide type and your grinding machine’s speed. This helps you get the best results and keeps your blades sharp for longer.

Steel Blades

Steel blades need a different grinding wheel. Use aluminum oxide or zirconia alumina wheels for steel blades. These abrasives are tough and can handle strong forces. Aluminum oxide wheels are cheap and work well for soft steel. Zirconia alumina wheels cost more, but last longer and work better on hard steel like stainless steel.

Aluminum oxide wheels are good for sharpening and cutting soft steel.

Zirconia alumina wheels are best for harder metals and last longer.

Resinoid bonds in cut-off wheels help absorb shock and let you work fast.

Type 1 (flat) wheels are good for general cutting. Type 27 (depressed center) wheels help you reach tight spots.

Thin wheels cut faster and more accurately, but thick wheels last longer and are better for tough jobs.

You can also use cbn grinding wheels for steel blades. CBN is almost as hard as diamond and works well for hard steel. These wheels take off material quickly and keep their shape longer. They also make the blade smoother and you do not have to change wheels often.

CBN wheels let you grind faster without making the blade too hot.

You get less shaking and better control, so your hand stays steady.

CBN wheels cost more at first, but save money later because they last longer and need less fixing.

You can use them for dry grinding, so you do not always need water.

Note: Picking the right grinding wheel for your steel blade helps you cut faster, keeps your blades sharp, and makes grinding safer.

Specialty Blades

Some blades are made for special jobs or use special materials. For these blades, you need grinding wheels made for the task. For example, cubic boron nitride (cBN) wheels with vitrified bonds work well for technical blades made from high-carbon martensitic stainless steel. These wheels come in different grain sizes and shapes to fit the blade’s design. They help you grind hard materials with less heat and lower force.

Diamond abrasive blades are good for cutting very hard things like concrete, stone, ceramics, marble, granite, and fiberglass. These blades use different bond types and segment designs for each material. You can find turbo, segmented, or continuous rim designs for different cutting jobs. Some are made for wet cutting, while others work dry.

Specialty grinding wheels help you sharpen blades with tricky shapes or made from tough materials.

Using the right wheel lowers heat, keeps the blade sharp, and makes the blade last longer.

Always check if the wheel works with your blade and the material you want to cut.

Remember: When you match the grinding wheel to your blade’s material, you get better cutting and longer blade life. You also make your work safer and easier.

Saw Blade Grinding Applications

Wood Cutting Saw Blade Grinding Tips

When you work with wood cutting blades, you want clean, smooth cuts every time. Diamond cut-off wheels are the top choice for saw blade grinding in woodworking. These wheels use diamond particles, which last a long time and keep your blades sharp. You can choose from different shapes and sizes to match your saw blade and the job you need to do.

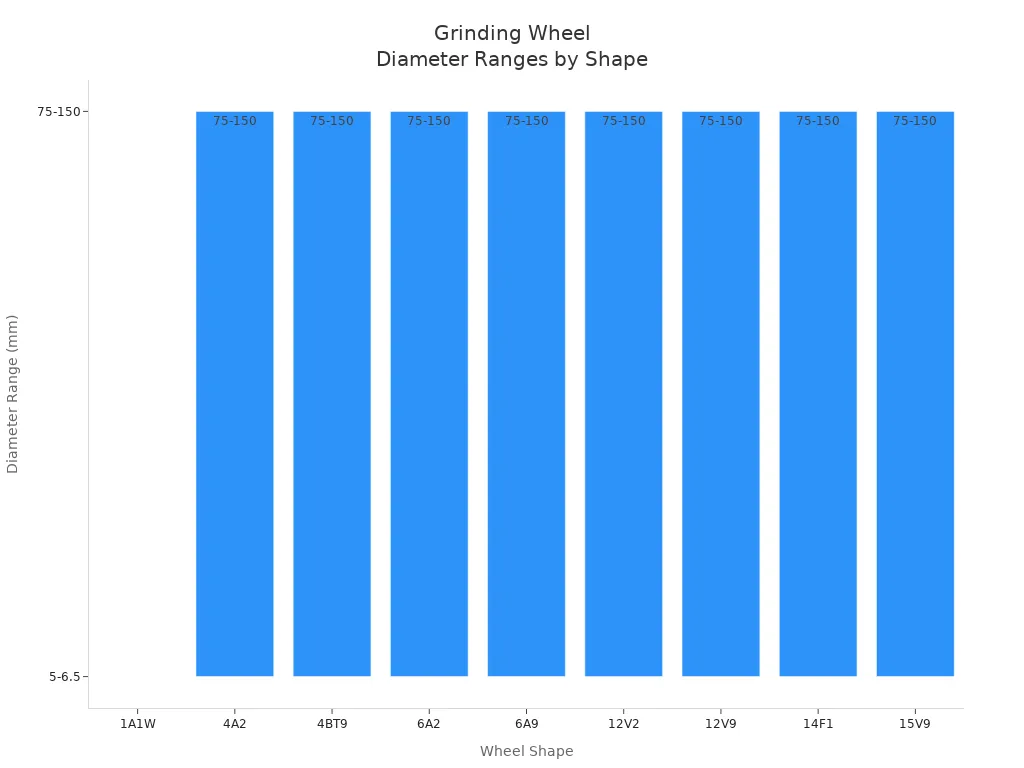

Here is a table showing common diamond cut-off wheel shapes and their sizes for wood cutting:

Shape | Diameter (mm) | Layer Width (mm) | Layer Thickness (mm) | Inner Hole (mm) |

|---|---|---|---|---|

1A1W | 5 / 5.5 / 6.0 / 6.5 | 1.5 | 3.0 | On request |

4A2 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

4BT9 | 75 / 100 / 125 / 150 | N/A | N/A | N/A |

6A2 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

6A9 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

12V2 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

12V9 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

14F1 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

15V9 | 75 / 100 / 125 / 150 | 5 / 6 / 10 | 2 / 3 / 5 / 10 | N/A |

You should always match the cut-off wheel to your blade’s diameter and tooth shape. Straight wheels work well for sharpening the face of the teeth, while cup wheels help grind the sides. Pick the right grit for your job—coarse for fast material removal, fine for a smooth finish. This helps you get a burr-free finish and keeps your saw blade grinding safe and effective.

Metal Cutting Saw Blade Grinding Tips

Metal cutting blades need strong cut-off wheels that can handle tough jobs. For steel and other metals, use cut-off wheels made from CBN or aluminum oxide. These wheels give you enhanced precision and help you achieve a burr-free finish. Always check the wheel’s RPM rating to match your saw’s speed.

Use thin cut-off wheels for fast, accurate cuts.

Choose thicker wheels for heavy-duty grinding and longer life.

For precision metal cutting, select wheels with a triple chip grind tooth design.

Make sure your cut-off wheel fits the blade and arbor size.

Cut-off wheels for metal cutting are designed for high RPM and efficient material removal. This keeps your blade sharpening process smooth and your blades ready for the next job.

Face and Tooth Grinding Tips

You need the right cut-off wheel shape for each part of the blade. Here are some tips:

Dish-shaped cut-off wheels work best for grinding the tooth back face and front face. They match the bevel angles of the teeth and help you sharpen with accuracy.

Disc-shaped cut-off wheels are great for top grinding. They help keep the blade round and set the wedge and clearance angles.

Use thin cut-off wheels for narrow tooth gaps. This prevents damage to nearby teeth.

Bowl-shaped and disc-shaped cut-off wheels with diameters around 150mm are common for these tasks.

Always pick a cut-off wheel that matches the tooth geometry and grinding area. This gives you sharp, accurate blades and safe saw blade grinding.

Tip: Matching the cut-off wheel shape and size to your grinding task helps you get the best results and keeps your blades in top shape.

Safety and Best Practices

Installation and Handling

You need to install grinding wheels with care to keep your work safe and your results high in quality. Always use the correct guard for your cut-off wheel. The guard should cover at least 180 degrees to protect you from flying fragments. Before you start, check the wheel and tool for cracks or damage. Mount the wheel with the stamped metal ring facing the spindle. This helps the wheel fit flush and run true.

Follow these steps for safe installation:

Inspect the wheel for cracks or chips.

Make sure the wheel matches your saw’s speed rating and size.

Use a torque wrench to tighten bolts evenly. Tighten bolts in a diagonal pattern.

Replace damaged or missing paper pads.

Secure the workpiece so it does not move.

Never flex or bend the wheel.

Only use grinding wheels for grinding, not for cutting.

If you see any signs of slippage or uneven wear, stop and check the wheel and chuck. Always follow the manufacturer’s instructions for the best quality and safety.

PPE and Operation

You must wear the right personal protective equipment (PPE) every time you use a grinding wheel. Put on safety goggles or a face shield to protect your eyes and face. Use hearing protection if the saw is loud. Avoid loose clothing and gloves that could get caught in the wheel.

For safe operation:

Stand to the side when starting the saw.

Let the wheel run at full speed for one minute before you begin.

Hold the tool with both hands for control.

Do not force the wheel; let the tool do the work.

Grind only on the correct part of the wheel—face for straight wheels, side for cup wheels.

Always unplug the saw before changing wheels or making adjustments.

These habits help you avoid injury and keep your work at a high level of quality.

Maintenance

Good maintenance keeps your grinding wheels and saw blades working at their best. Clean the machine and wheels after each use to remove dust and debris. Lubricate moving parts like gears and bearings to prevent wear. Check bolts and screws often and tighten them if needed.

You should also dress the grinding wheel regularly. Dressing exposes fresh abrasive grains and keeps the wheel’s shape. This step improves cutting quality and extends the wheel’s life. Store grinding wheels in a dry place, away from sunlight and heat. Lay them flat or use racks to prevent damage. Always perform a ring test before mounting a wheel to check for cracks.

Keep a maintenance log to track your work. Follow the manufacturer’s schedule for cleaning and inspections. These steps support the maintenance of saw blades and help you achieve the best quality in every project.

Choosing the right cut-off wheels for your circular saw means better results and safer work. You must match cut-off wheels to your blade’s material and application. Always check abrasive type, grit size, bond, and wheel shape. Cut-off wheels that fit your saw’s speed and job give you the best durability and longevity. Safety matters—use proper cut-off wheels, follow guidelines, and wear protection. Avoid mistakes like using the wrong cut-off wheels or skipping coolant. Here’s a quick checklist for selecting cut-off wheels:

Identify blade material and application.

Choose cut-off wheels with the right abrasive and grit.

Match cut-off wheels to saw speed and size.

Use coolant and follow safety steps.

Inspect and maintain cut-off wheels for top performance.

Using the correct cut-off wheels boosts your blade’s longevity and keeps every cut safe and smooth.

FAQ

What grinding wheel should you use for carbide-tipped blades?

You should use a resin bond diamond wheel. This type keeps carbide tips sharp and smooth. It helps your blade last longer and cut better.

How do you know if a grinding wheel fits your circular saw?

Check the wheel’s diameter and arbor hole size. Look at your saw’s speed rating. Match these numbers before you install the wheel.

Can you use the same grinding wheel for steel and carbide blades?

No, you should not. Use CBN wheels for steel blades. Use diamond wheels for carbide blades. Each wheel works best with its own material.

How often should you replace your grinding wheel?

Replace your wheel when you see cracks, chips, or uneven wear. If the wheel cuts slower or makes rough edges, you need a new one.

What safety gear do you need when using a grinding wheel?

Always wear safety goggles, a face shield, and hearing protection. Use gloves that fit well. Stand to the side when you start the saw.

Contact Us

For More Grinding Solution or Customized Abrasive Tools