The centerless grinding industry is advancing with key trends for 2025. These market trends include increased automation, AI-driven precision, and sustainable technology. This innovation drives the global centerless grinding market forward, creating new opportunities for the industry.

The through-feed centerless grinder market is projected to grow at a 5.7% CAGR from 2025. This growth signals a rising centerless grinding market size and a strong industry outlook.

This positive trend shows a clear move toward greater efficiency in manufacturing. Advanced centerless grinding technology is essential for success in this competitive market.

Key Takeaways

- The centerless grinding industry is growing. It will use more automation and AI by 2025.

- New technologies make grinding more exact. They also make it work better.

- Advanced grinding wheels help make very precise parts. These parts are for cars, planes, and medical tools.

- The industry faces challenges. These include high costs and a lack of skilled workers. Technology helps solve these problems.

EMERGING CENTERLESS GRINDING TRENDS:

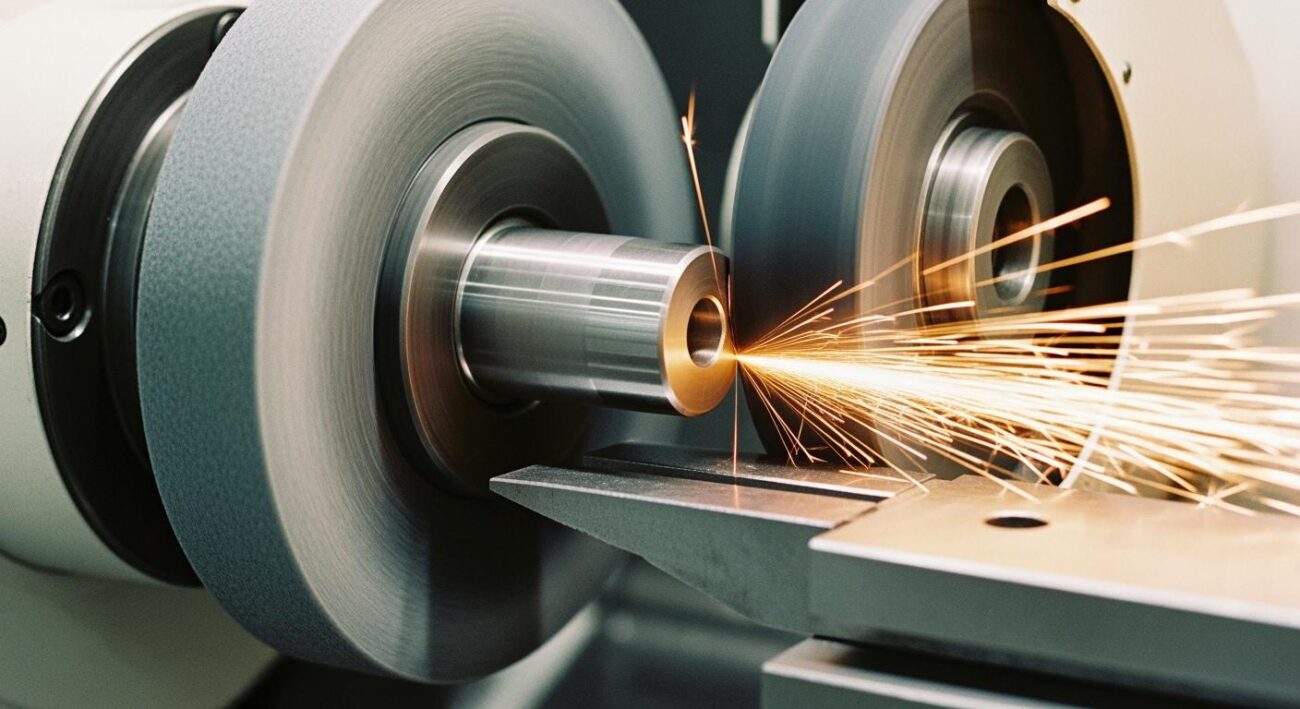

The centerless grinding market is experiencing a significant transformation. Key trends are pushing the industry toward greater precision and efficiency. This evolution is driven by three core pillars: automation, artificial intelligence, and advanced materials. These technological advancements are not just improving existing processes; they are redefining what is possible in precision manufacturing. The integration of these elements creates a new landscape for the entire manufacturing market.

AUTOMATION AND INDUSTRY 4.0:

Automation is a primary force reshaping the centerless grinding industry. The move toward Industry 4.0 and smart manufacturing involves more than just adding robots. It is a complete automation integration of systems.

- Robotics and CNC controls improve precision and boost productivity.

- Conveyor systems and overhead gantries streamline material handling.

- IoT sensors and AI-powered monitoring create smart grinding systems.

These advancements deliver tangible benefits. Automated centerless grinding systems lead to better part quality, faster cycle times, and increased machine uptime. For example, some centerless grinders can process 200–300 parts per minute. This high throughput is possible because continuous through-feed grinding eliminates time loss. The digitalization of the factory floor allows for real-time monitoring and predictive maintenance, which can reduce unplanned stoppages by up to 40%. This level of automation makes the entire manufacturing process faster and more reliable.

AI IN CENTERLESS GRINDING PROCESSES:

Artificial Intelligence (AI) is adding a layer of intelligence to the grinding process. AI algorithms analyze vast amounts of data to optimize centerless grinding operations in real time. This technology helps machines make smarter decisions without human intervention.

AI-driven software, like the DS Cloud AI Management System, provides intelligent monitoring and automated optimization. These systems track equipment status, analyze failure risks, and offer maintenance advice. This proactive approach minimizes downtime and enhances efficiency. AI also plays a crucial role in quality control. It enables in-process checks to detect minor defects, reducing scrap rates and ensuring every part meets exact specifications. This continuous innovation is pushing the market toward unparalleled accuracy.

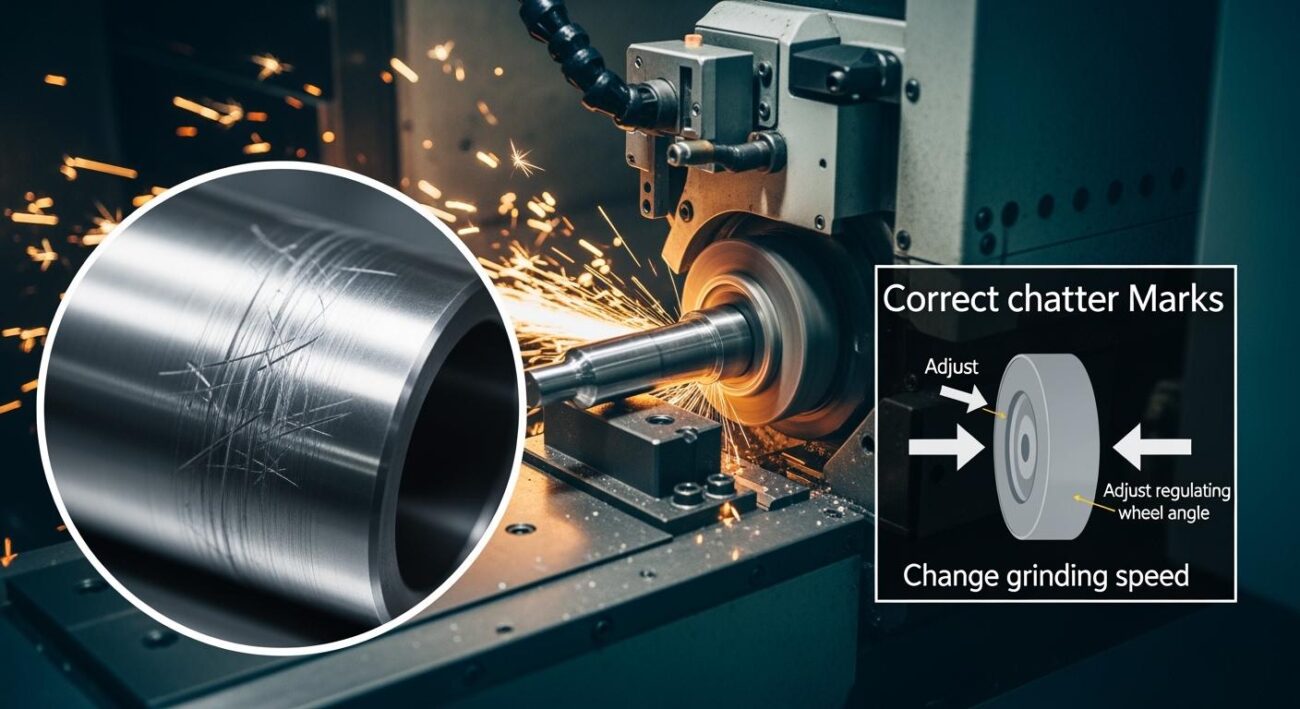

ADVANCED GRINDING WHEEL MATERIALS:

The full potential of automation and AI can only be realized with equally advanced physical tools. The grinding wheel itself is a critical component in this equation. The latest trends in the industry focus on new superabrasives and bond technologies that deliver superior performance. Materials like Cubic Boron Nitride (CBN) and diamond are setting new standards for the centerless grinding market.

| Characteristic | Conventional Abrasives | Superabrasives (cBN, Diamond) |

|---|---|---|

| Hardness | Lower | Superior; grinds hard materials efficiently |

| Wear Resistance | Lower; shorter wheel life | Significantly higher; prolonged wheel life |

| Cutting Efficiency | Requires more power | Requires less power and force |

| Dressing Efficiency | Less consistent | Up to 20x more parts per dress |

These advancements are crucial for industries that require a superior surface finish and tight tolerances, such as aerospace, medical devices, and electronics. This is where specialized abrasive solutions become essential.

Aimgrind provides the ultra-precise grinding solutions needed to leverage these new trends. High-performance tools, such as Aimgrind’s diamond grinding wheels, are engineered for the demands of modern centerless grinding. They offer the durability and precision required by automated systems to work on hard alloys, ceramics, and composites. By pairing cutting-edge technology with advanced abrasives, companies can achieve enhanced efficiency and unlock new levels of performance in their grinding operations.

CENTERLESS GRINDING MACHINE MARKET DYNAMICS:

The centerless grinding machine market shows strong growth potential. The market is estimated at $2.5 billion in 2025. Projections show the centerless grinding machinery market will grow at a Compound Annual Growth Rate (CAGR) of 6% from 2025 to 2033. This expansion is fueled by powerful industry drivers, new sustainability trends, and responses to ongoing challenges. Understanding these dynamics is key to navigating the future of the centerless grinding machinery market.

HIGH-GROWTH INDUSTRY DRIVERS:

Several key industries are pushing the centerless grinding machine market forward. The demand for high-precision components in rapidly growing sectors creates significant opportunities. The automotive, aerospace, and medical device industries are at the forefront of this growth.

The automotive industry remains a primary driver for the centerless grinding machinery market.

- High-Volume Production: Automotive manufacturing requires high-volume production of parts like crankshafts and axle shafts. Centerless grinding is the ideal technology for this scale.

- Electric Vehicle (EV) Growth: The EV sector is a major catalyst. The centerless grinding market for automotive applications is expected to hit USD 5.4 billion by 2034, largely due to EV expansion. EV manufacturing demands precision grinding for motor shafts and battery components, often requiring sub-micron accuracy. Centerless grinding machines offer the flexibility to handle diverse shaft sizes and geometries found in a single EV.

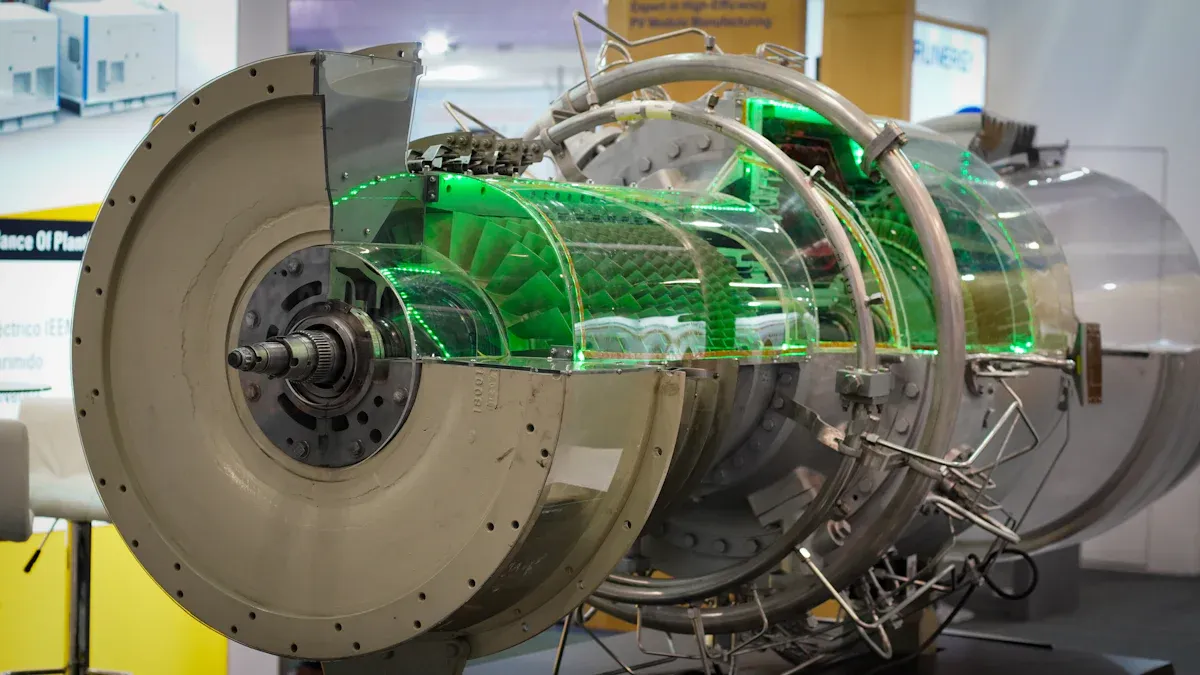

The aerospace industry also fuels demand for advanced centerless grinding. This sector requires components that can withstand extreme conditions.

The medical device industry is another high-growth driver. The global market for medical guidewires, which rely on precision grinding, is projected to reach $20.8 billion by 2035, growing at a 9.6% CAGR. Centerless grinding is a cost-effective method for producing the intricate wires used in catheters, stents, and other minimally invasive devices.

Meeting the demands of these sectors requires specialized tools. High-performance abrasives like Aimgrind’s diamond grinding wheels add critical value. They enable the high-precision grinding of hard materials used in aerospace and EV components. This innovation allows manufacturers to achieve the tight tolerances and superior finishes these advanced industries require.

THE SUSTAINABILITY TREND:

Sustainability is one of the most important trends shaping the centerless grinding machinery market. Manufacturers are adopting greener practices to meet environmental regulations and corporate goals. This shift focuses on energy efficiency, waste reduction, and the use of eco-friendly materials.

- Reduced Waste: Effective filtration systems extend the life of coolant fluids. This minimizes coolant disposal and lowers costs.

- Lower Maintenance: Clean coolant protects machine components like pumps and spindles from damage, reducing downtime.

- Energy Savings: Modern systems adapt filtration capacity to the production workload. They use less energy when machines run slower or are idle.

This focus on sustainability offers clear economic benefits. As one industry expert, Steffen Strobel of VOMAT, noted, rising energy prices and climate concerns are pushing customers to seek resource-efficient grinding solutions. This market demand makes sustainability a core component of modern manufacturing. The adoption of these green technologies helps companies reduce their environmental footprint and improve their bottom line.

COST AND SKILLED LABOR CHALLENGES:

Despite a positive outlook, the centerless grinding machinery market faces challenges. The high initial cost of advanced equipment and a persistent skilled labor shortage are two major hurdles. A recent study found 381,000 unfilled jobs in the manufacturing sector, highlighting the difficulty companies face in finding qualified machine operators.

The initial investment for state-of-the-art centerless grinding machines and superabrasive wheels can be substantial. However, the long-term value often justifies the cost. Advanced tools offer longer life, faster cycle times, and superior part quality, leading to a higher return on investment.

Technology and automation offer powerful solutions to these challenges.

AI-driven systems and robotic automation can help bridge the skilled labor gap. These technologies handle repetitive tasks, monitor machine performance, and make real-time adjustments. This reduces the need for constant human oversight and allows fewer operators to manage more machines with greater efficiency.

By embracing innovation, the industry can overcome these obstacles. Automation makes the grinding process more accessible, while the long-term efficiency of advanced systems addresses cost concerns. These trends ensure the centerless grinding machine market remains competitive and continues its growth trajectory.

REGIONAL CENTERLESS GRINDING MACHINERY MARKET:

The global centerless grinding machine market shows distinct regional dynamics. North America and Asia-Pacific lead in market size, with Europe following closely. Understanding these geographic trends is vital for navigating the competitive centerless grinding machinery market.

GEOGRAPHIC GROWTH HOTSPOTS:

The centerless grinding market share is distributed across key industrial regions. Each area contributes significantly to the overall centerless grinding machine market.

| Region | Market Size (USD Billion, 2024) | Market Share (2024) |

|---|---|---|

| North America | 2.5 | 36.2% |

| Europe | 2.0 | 29.0% |

| Asia Pacific | 2.4 | 34.8% |

The Asia-Pacific region is the fastest-growing centerless grinding machine market. This growth comes from rapid industrialization and government support.

- China is shifting to advanced manufacturing, increasing demand for high-end centerless grinding machines.

- India’s “Make in India” initiative boosts its automotive and aerospace sectors, requiring more precision grinding.

- Japan and South Korea focus on technological innovation, driving the need for advanced centerless grinding solutions in electronics and automotive manufacturing.

These factors make Asia-Pacific a key area for the future of the centerless grinding machinery market.

COMPETITIVE LANDSCAPE STRATEGIES:

Leading manufacturers in the centerless grinding machine market use strategic partnerships and acquisitions. These moves help them expand their product lines and enter new markets. This competition drives innovation across the industry. Companies focus on product differentiation to stand out. For example, some invest in advanced CNC centerless grinders with integrated automation. Others develop specialized centerless grinding machines for high-precision sectors like medical devices, which often require unique customization. This strategic focus helps them meet specific customer needs in a competitive centerless grinding machinery market.

LEADING MANUFACTURER FOCUS:

The global centerless grinding machine market is home to many influential companies. These manufacturers are at the forefront of developing new grinding technology and setting industry standards. Their work is crucial for the evolution of centerless grinding. Key players shaping the centerless grinding machinery market include:

- Schaudt Mikrosa

- JUNKER

- Danobat Group

- Koyo Machinery

- Micron Machinery

- Jainnher Machine Co., Ltd.

These companies drive the centerless grinding machinery market forward with their commitment to quality and efficiency in centerless grinding. Their efforts define the current and future state of the centerless grinding machinery market.

The future of the centerless grinding machine market is clear, shaped by key trends in automation and precision. These technological advancements define the modern centerless grinding machine market, pushing the entire market toward greater efficiency. This innovation in centerless grinding supports the growing centerless grinding machine market. The positive outlook for the centerless grinding machine market relies on these advancements and better centerless grinding machines. The centerless grinding machine market is adopting smarter centerless grinding and centerless grinding techniques. These trends show the centerless grinding machine market is creating a future of intelligent centerless grinding.

FAQ

What are the main trends in centerless grinding for 2025?

The primary trends shaping the industry are increased automation, the integration of AI for process optimization, and a strong focus on sustainable manufacturing practices. These innovations drive greater efficiency and precision.

How does automation improve centerless grinding?

Automation enhances centerless grinding by boosting productivity and consistency.

- Robotic systems handle material loading and unloading.

- Smart sensors monitor operations in real time.

- This technology reduces manual errors and allows for continuous, high-volume production with superior accuracy.

Why are advanced grinding wheels important for modern manufacturing?

Advanced grinding wheels are critical for achieving high precision on hard materials. Specialized tools, like diamond grinding wheels, enable automated systems to meet the strict tolerance demands of the aerospace, EV, and medical device industries, ensuring superior performance and part quality.

Which industries drive the growth of the centerless grinding market?

The automotive, aerospace, and medical device sectors are the main drivers of market growth. These industries require high-volume production of precise components. The expansion of electric vehicles (EVs) is a particularly strong catalyst for demand.

See Also

Exploring Grinding Wheel Varieties and Their Real-World Industrial Uses

Selecting the Optimal Crankshaft Grinding Wheel Within Your Budget

Discovering the Most Effective Grinding Wheel Dresser for Your Needs

Selecting the Ideal Metal Grinding Wheel for Your Specific Project

Contact Us

For More Grinding Solution or Customized Abrasive Tools