Choosing the right grinding wheel gives the best results for each material. CBN wheels are best for ferrous metals like steel, which is often used in car parts. Diamond grinding wheels work well on non-ferrous and hard materials, including concrete, carbide, and gemstones. Many car makers use CBN for engine parts, while the aerospace and electronics industries rely on diamond grinding wheels to carefully grind ceramics and semiconductors. Picking the right wheel helps improve grinding efficiency, provides a smoother finish, and saves money—especially important when grinding concrete.

Key Takeaways

-

Pick CBN grinding wheels for metals like steel. They do not get too hot and last longer. They also do not react with iron.

-

Use diamond grinding wheels for hard things that are not metal. These include concrete, carbide, ceramics, and glass. They give smooth finishes and are very accurate.

-

Both CBN and diamond wheels cost more at first. But they last longer and save money later. They also help you work more without stopping.

-

Choosing the right wheel is important. Cooling and cleaning the wheels often keeps them sharp. This makes grinding better and safer.

-

Listen to expert advice like checking wheels for cracks. Use the right coolant and pick the right wheel for your material. This helps you get the best results.

Key Differences

Material and Structure

Diamond grinding wheels and CBN wheels are made from different materials. Diamond is the hardest material at room temperature. But diamond reacts with iron in steel when it gets hot. This makes the diamond less sharp and the wheel wears out faster. CBN is made from boron and nitrogen. It does not react with iron, so it works well even when hot.

-

Diamond grinding wheels use diamond, which is very hard.

-

CBN wheels use cubic boron nitride, which is also hard but not as much as diamond.

-

Diamond starts to break down at about 800°C.

-

CBN stays strong up to 1,000°C.

-

Diamond grinding wheels work best on carbide, ceramics, and glass.

-

CBN wheels are best for grinding steel and other ferrous metals.

The way each wheel is built changes how it works. Diamond wheels have a crystal structure that makes them super hard. CBN wheels have a similar structure but handle heat and chemicals better. Both types use different bonds like resin, metal, or vitrified. These bonds change how long the wheels last and how well they work.

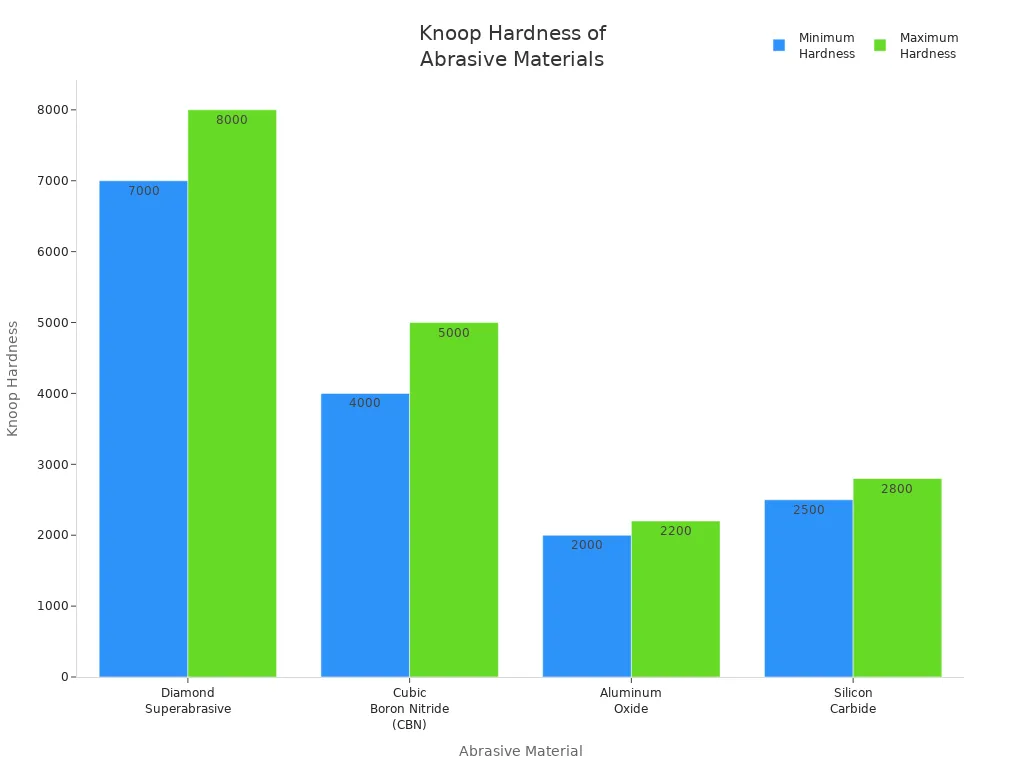

|

Abrasive Material |

Common Applications |

|

|---|---|---|

|

Diamond Superabrasive |

7000 – 8000 |

Grinding carbides, ceramics, glass, non-ferrous metals |

|

Cubic Boron Nitride (CBN) |

4000 – 5000 |

Grinding hardened steels, high-speed steels, tool steels |

|

Aluminum Oxide (Standard) |

2000 – 2200 |

Grinding ferrous metals, cast iron, non-ferrous metals |

|

Silicon Carbide (Standard) |

2500 – 2800 |

Grinding glass, ceramics, stone, non-ferrous metals |

Performance

How well a grinding wheel works depends on heat, pressure, and wear. Diamond grinding wheels are very hard and cut with great accuracy. But they do not work well on ferrous metals because of the carbon-iron reaction when hot. CBN wheels do not have this problem. They stay sharp and keep their shape even after long use on steel.

CBN wheels can remove material faster and need less pressure. This means the machine and the workpiece last longer. CBN wheels help keep the surface smooth and the size correct for a long time. Diamond grinding wheels are best for hard, non-ferrous materials. They give smooth finishes and high accuracy.

|

Aspect |

Diamond Grinding Wheels |

CBN Grinding Wheels |

|---|---|---|

|

Limited on iron-based alloys due to diamond reacting at high temperatures |

Superior heat resistance, stable under high temperatures |

|

|

Wear Rate |

Degrades faster on cobalt- and chromium-rich coatings due to chemical reaction |

Exhibits strong bond strength and uniform grit distribution, leading to better wear resistance |

|

Ideal Applications |

Tungsten carbide, ceramics, oxide-based coatings |

Cobalt- and chromium-rich coatings, superalloys, nickel- and iron-based alloys |

|

Performance in HVOF Grinding |

Effective but limited by thermal degradation on certain alloys |

Preferred for high-temperature materials, better durability and life |

|

Coolant & Heat Management |

Critical to prevent thermal damage due to diamond’s sensitivity |

Important but CBN inherently manages heat better |

CBN grinding wheels stay sharp much longer than regular abrasive wheels. They can handle high heat and keep working well. This makes them good for tough jobs where you need steady, reliable grinding.

Cost

Cost is important when picking a grinding wheel. Both diamond and CBN wheels cost a lot at first. But they last a long time and do not need to be replaced often. This can save money over time.

-

CBN grinding wheels cost more at first but last longer.

-

You do not have to replace CBN wheels as often, so work is not stopped as much.

-

CBN wheels keep their sharp edge and work well on ferrous metals.

-

Diamond grinding wheels also cost a lot at first but cut very well and last long on non-ferrous materials.

-

Using diamond wheels may need special tools and care, which can add to the cost.

-

Both types help save time because you do not need to change them often and they keep grinding well.

Tip: When buying a grinding wheel, think about how much you will save in the long run, not just the price you pay at first.

Grinding Wheel Applications

CBN Applications

CBN grinding wheels are very important in factories that work with ferrous metals. Car makers use these wheels to grind engine and transmission parts. Aerospace companies use CBN wheels for turbine blades and landing gear. These jobs need wheels that are strong and accurate. Tool makers use CBN wheels to sharpen and shape tools made from hard steel.

CBN wheels do hard jobs that regular abrasive wheels cannot do. They keep their shape and stay sharp when grinding tough metals like hardened steel and superalloys. Companies that make powertrains, bearings, and turbines like vitrified CBN wheels for grinding flat and round surfaces. These wheels give steady results and help machines run longer without stopping.

New bonding methods have made CBN wheels work even better. Metal and vitrified bonds help the wheels last longer and handle heat well. Factories with robots and fast machines need wheels that can keep up. CBN wheels are good for these jobs, especially in East Asia, where car and airplane factories are growing.

|

Industries |

Applications and Materials |

|

|---|---|---|

|

Metal Bond |

Aerospace, Automotive, Electronics |

Precision grinding of hard-to-machine materials, superalloys |

|

Vacuum Brazed |

Various industrial sectors |

Rough grinding, foundry grinding, heavy-duty removal of cast iron, high-speed steel, superalloys |

|

Resin Bond |

Tooling, Precision Grinding |

Tool and cutter grinding, cylindrical and surface grinding of carbide tools, high-speed steel, hard metals |

|

Vitrified Bond |

Powertrain, Bearing, Turbine, Cutting Tools |

Cylindrical ID/OD grinding, surface grinding of hardened steel and superalloys |

Note: CBN grinding wheels work best where heat and pressure would quickly wear out other wheels.

Diamond Grinding Wheels Applications

Diamond grinding wheels are used in jobs that need to cut or shape hard, non-ferrous materials. Construction workers use them to grind and polish concrete. Tool makers use diamond wheels to shape and sharpen carbide tools. Electronics companies use these wheels to grind ceramics and silicon wafers. Medical device makers use diamond wheels to grind implants and surgical tools.

Diamond grinding wheels are very strong and work for a long time. They last longer than regular abrasive wheels, so you do not need to replace them as often. Workers can finish grinding jobs up to 30% faster, especially with concrete, stone, or carbide. These wheels also make less dust, so the workspace is safer and cleaner.

New diamond technology, like synthetic diamonds and hybrid bonds, lets people pick the right wheel for each job. Vitrified and ceramic bonds help diamond wheels stay sharp and last longer. This makes them great for grinding concrete, gemstones, and glass. Metal bond wheels are strong for heavy jobs, while resin bonds are good for lighter work.

|

Common Applications |

Materials Used On |

|

|---|---|---|

|

Automotive |

Crankshafts, gears, cutting tools; cylindrical, surface, centerless grinding |

Carbide, hardened steel, high-strength alloys (e.g., titanium, Inconel) |

|

Aerospace |

Turbine blades, landing gear components; CNC machining |

Titanium, Inconel, high-strength alloys |

|

Tool and Cutter Manufacturing |

Grinding and sharpening drills, end mills, saw blades |

Carbide, high-speed steel |

|

Semiconductor and Electronics |

Precision grinding of silicon wafers and electronic components |

Silicon wafers, ceramics |

|

Medical Devices |

Surgical instruments, implants, prosthetics grinding |

Stainless steel, ceramics, specialized alloys |

|

Metalworking and Foundry |

Grinding hard alloys, coatings, cast iron, steel |

Hard alloys, cast iron, steel |

|

Construction and Stone Cutting |

Cutting and polishing fiberglass, stone, concrete, glass |

Fiberglass, stone, concrete, glass |

-

Diamond grinding wheels work well on concrete, carbide, and gemstones.

-

They need less care and keep their shape longer than other wheels.

-

New ideas, like UV lasers, make grinding faster and save energy.

Tip: If you need to grind concrete or other hard stuff, diamond grinding wheels are the best for speed, strength, and a smooth finish.

Diamond Grinding Wheels Features

Types and Bonds

Diamond grinding wheels have different types. Each type uses a special bond material. The bond keeps the diamond grains in place. It also changes how the wheel works when grinding. Picking the right bond helps the wheel match the job and material.

|

Bond Material |

Performance Characteristics |

Typical Applications |

|

|---|---|---|---|

|

Resin Bond |

Synthetic resin matrix (phenolic, epoxy) |

Softer bond, good cutting ability, smooth grinding, suitable for fine finish and precision work, versatile and cost-effective |

Fine grinding of carbide tools, polishing glass and ceramics, sharpening cutting tools |

|

Metal Bond |

Metal matrix (bronze, steel, iron) |

Hardest bond type, very durable, high abrasion resistance, suitable for rough grinding, high grinding forces, longer wheel life |

Grinding glass, ceramics, gemstones, concrete, stone, composites, hard coatings |

|

Vitrified Bond |

Glass-based (ceramic) bond with porosity |

Excellent rigidity and thermal stability, maintains form and size, less heat sensitive, can be dressed easily, lower grinding forces, faster cycles |

Precision grinding of diamond tools, automotive and aerospace parts, sharpening high-speed steel, double-disc grinding |

|

Electroplated Bond |

Single layer of diamond in nickel matrix |

Sharp, aggressive grinding, high precision, fine surface finish, no dressing required, suitable for intricate profiles |

Form grinding intricate parts, cutting quartz and ceramics, jewelry making |

The bond type should fit the material. Metal bonds are best for hard things like stone. Resin bonds are good for smooth finishes and polishing. Vitrified bonds give stability and are easy to dress. Electroplated bonds help with detailed shapes and high accuracy.

Note: If you use the wrong bond, the wheel may wear out fast or damage your work.

Performance Factors

Many things show how well diamond grinding wheels work. Factories check profile accuracy, grinding force, wheel wear, and how smooth the part is. They use special tools to measure these things, like force meters and 3D scanners.

-

Grinding force tells how hard the wheel must work.

-

Tool wear shows how much the wheel changes shape after use.

-

Surface roughness tells how smooth the finished part feels.

-

The wheel’s surface and holes help remove dust and keep it cool.

Special methods, like wire electrical discharge, can help the wheel last longer. These methods make the grains stay in place and lower grinding force. This makes the wheel work better and last longer. Companies also watch how much power is used to see if grinding is efficient.

Industrial Use Cases

Many industries need diamond grinding wheels for hard jobs. Car, airplane, and electronics companies use them for their strength and accuracy. These wheels grind hard materials and keep their shape even when hot.

-

Car factories use resin bond wheels for smooth engine parts.

-

Airplane companies pick metal bond wheels for tough metals and coatings.

-

Electronics makers use vitrified bond wheels for tight fits and smooth parts.

-

Medical device makers use electroplated wheels for tiny, detailed shapes.

These companies want wheels that work well, last long, and handle hard jobs. New machines and technology help these wheels last longer and make less waste. This makes them a smart choice for today’s factories.

Concrete Grinding Wheel Uses

Surface Preparation

Construction workers use a concrete grinding wheel to get surfaces ready. They need to make the floor clean before adding coatings or sealants. These wheels help take off old paint, glue, and rough spots. This makes the floor smooth and helps new layers stick better. Picking the right wheel makes sure the surface is flat and ready for the next step.

There are different concrete grinding wheels for different jobs:

-

Diamond grinding wheels are strong and level rough spots.

-

Turbo rim wheels work for wet or dry jobs, especially on edges.

-

Segmented wheels take off thick coatings or bumpy areas fast.

-

Continuous rim wheels make the surface shiny and smooth.

Note: Concrete grinding wheels work better and give a nicer finish than other tools. Quick-change systems let workers swap wheels fast and save time.

The right wheel helps workers make the floor even. Turbo diamond cup wheels cut down dust and make things smoother. Resin bond wheels polish concrete to make it shiny.

Material Removal

A concrete grinding wheel is used to take away extra material. Workers use these wheels to make floors flat and remove high spots. They also strip off thick paint or epoxy. Picking the right wheel makes the job faster and saves money.

Here is a table that shows different wheels and what they do:

|

Type of Wheel |

Key Features |

Typical Applications |

Efficiency and Finish Quality Benefits |

|---|---|---|---|

|

Single-row Diamond Cup Wheel |

Grinds hard with one row |

Prepping surfaces, taking off coatings |

Good for rough grinding and fixing uneven concrete |

|

Double-row Diamond Cup Wheel |

Two rows touch more surface |

Heavy grinding, big areas |

Removes material fast, levels big uneven spots |

|

Turbo Diamond Cup Wheel |

Turbo shape makes less dust, smooths |

Fine grinding, smoothing surfaces |

Makes smoother finishes with less dust, good balance |

|

Resin Bond Wheel |

Softer resin, not as rough |

Polishing, light grinding |

Good for fine polishing and smooth finish |

|

Vitrified Bond Wheel |

Hard bond for careful grinding |

Fine finishing, detailed polishing |

Very precise and smooth, great for good surface prep |

Workers pick diamond grinding wheels for tough jobs and leveling. For polishing or light work, they use resin or vitrified bond wheels. This means teams can do both rough and smooth work with the same kind of tool.

Tip: Using the right concrete grinding wheel makes work easier, keeps dust down, and gives a better finish on every job.

Pros and Cons

CBN Grinding Wheel

CBN grinding wheels are great for working with ferrous metals. They stay hard even when they get very hot. This means they work well on hard steels and high-speed steel. The chemical makeup of CBN stops it from reacting with iron. So, the abrasive does not wear out fast. People using these wheels see that they last longer. They do not have to change wheels as often, which saves time and money. These wheels also make less dust and waste, so the workspace stays cleaner.

Main advantages of CBN grinding wheels:

-

Keeps its hardness and works well when hot.

-

Very hard abrasive, only diamond is harder.

-

Does not react with ferrous metals, so no bad reactions.

-

Lasts longer and wears down slower than regular wheels.

-

Gives better grinding and more accurate results.

-

Makes less contamination and dangerous waste.

But, CBN grinding wheels need to be dressed and trued to keep their shape. Workers must use the right settings and coolants, usually oil-based, to stop the wheel from clogging or rusting. Setting up and taking care of these wheels takes more effort. Still, the good points are usually worth the extra work.

Diamond Grinding Wheels

Diamond grinding wheels are best for non-ferrous and hard, brittle materials. They move heat away fast, so the abrasive lasts longer when grinding things like concrete, carbide, or glass. These wheels give smooth finishes and are very accurate. They are easy to take care of, and water-based coolants work well with them.

|

Aspect |

Diamond Grinding Wheels |

CBN Grinding Wheels |

|---|---|---|

|

Lasts a long time on non-ferrous stuff, but wears out fast on ferrous metals. |

Stays sharp and keeps its shape on ferrous metals, and lasts much longer than regular wheels. |

|

|

Maintenance |

Needs less care and works with water-based coolants. |

Needs oil-based coolants and must be dressed often for best results. |

|

Application Suitability |

Best for non-ferrous, hard, and brittle materials. |

Best for ferrous metals and jobs with lots of heat. |

|

Chemical Stability |

Reacts with iron when hot, so not good for steel. |

Does not react with iron-based materials. |

|

Economic Consideration |

Costs less at first, but wears out fast on steel, so costs more over time. |

Costs more at first, but lasts longer and is easier to care for, so saves money in the long run. |

Note: Do not use diamond grinding wheels on ferrous metals. The abrasive reacts with iron and wears out fast. For steel and similar materials, CBN grinding wheels work better and last longer.

Applications and Best Practices

Selection Checklist

Picking the right grinding wheel helps you get better results and save money. The table below shows how CBN and diamond wheels work for different jobs:

|

Criterion |

CBN Grinding Wheels |

Diamond Grinding Wheels |

|---|---|---|

|

Material Compatibility |

Best for ferrous materials (e.g., hardened steel) |

Best for hard materials like ceramics, composites |

|

Wear Resistance |

Excellent wear resistance and shape retention |

Exceptional longevity and efficiency |

|

Grinding Precision |

Ideal for precision grinding (e.g., automotive parts) |

Essential for high-precision grinding tasks |

|

Cost |

Higher price, complex manufacturing |

High cost, limited to specific uses |

|

Application Examples |

Automotive crankshafts, camshafts |

Stone fabrication, electronics |

|

Thermal Stability |

Maintains shape and cutting ability at high temps |

Exceptional hardness and thermal conductivity |

|

Supplier Considerations |

Availability and import regulations vary by region |

Compliance with international quality standards |

You should also think about:

-

What kind of bond and speed rating it has.

-

Cooling choices and how much the supplier knows.

-

If you can get custom wheels and if they check for quality.

-

How much you pay compared to how good the wheel is.

Common Mistakes

People often make mistakes when picking or using a grinding wheel for concrete or other jobs. Here are the most common problems:

-

Picking the wrong wheel for the job or material.

-

Using the wrong speed, which can make the wheel too hot or break.

-

Not using coolant or oil, so the wheel wears out fast.

-

Forgetting to dress the wheel, which makes it cut worse.

-

Using the wrong pressure or feed rate.

-

Keeping wheels in wet or unsafe places.

-

Letting dirt or bad care ruin the wheel.

Tip: Always use the right wheel for the material, especially for concrete or special jobs.

Expert Tips

Experts have some easy tips to help your grinding wheel last longer and work better:

-

Check wheels for cracks or chips before you use them.

-

Clean diamond wheels after each job, especially after grinding concrete.

-

Keep wheels in a dry, cool place away from the sun.

-

Dress wheels at the right speed to keep them sharp.

-

Stay within the maker’s speed and pressure rules.

-

Use coolant to stop overheating, especially on concrete.

-

For CBN wheels, use oil-based coolant and dress with diamond rollers.

-

Pick coarse grains for rough work and fine grains for polishing.

-

Watch for heat changes and change feed rates to protect your part.

Note: If you follow these tips and best practices, your grinding wheels will work better and last longer, even on tough jobs like concrete.

Top Diamond Grinding Wheels

Selection Criteria

Professionals look for important things when picking diamond grinding wheels. The right wheel helps work go faster and makes tools last longer. It also gives a better finish. Experts say you should think about these things:

-

Bond Type: The bond keeps the diamond grit in place. Metal bonds are good for hard jobs and last a long time. Resin bonds are flexible and make smoother finishes. Vitrified and electroplated bonds are for special uses.

-

Diamond Grit Concentration: More grit means the tool lasts longer and cuts better. But it can make more heat, so cooling is needed.

-

Grit Size: Big grit takes off material fast. Small grit makes the surface smooth and shiny.

-

Material Compatibility: The wheel must fit the hardness of what you are grinding. Using the wrong wheel can hurt the tool and the material.

-

Desired Finish: Some jobs need a rough look. Others need a shiny, smooth finish. The right wheel helps you get the finish you want.

-

Wheel Design: Cup wheels are best for flat surfaces. Flat wheels are good for edges and shapes.

-

Disc Diameter and Hardness: Bigger wheels cover more space. Harder wheels keep their shape better.

Tip: Always pick the wheel that matches your job and material for the best results.

Product Overview

Many companies make strong diamond grinding wheels. The table below shows top brands known for lasting a long time and making users happy:

|

Manufacturer |

Main Products / Specialty |

Reputation / Industry Recognition |

|---|---|---|

|

3M |

Innovation-driven industrial products |

Leader in R&D, known for quality and innovation |

|

Saint-Gobain |

Construction and high-performance materials |

Strong market presence, continuous quality assurance |

|

SuperAbrasives |

Diamond and CBN grinding wheels and tools |

High-performance solutions, over 50 years of expertise |

|

Asahi Diamond Industrial |

Diamond tools and abrasives |

Leading manufacturer, focus on quality |

|

Henan Jinlun Superhard Material |

Diamond grinding wheels |

Premium diamond stone grinding wheels |

|

Klingspor |

Abrasives and grinding wheels |

Durable and reliable products |

|

EHWA Diamond Industrial |

Diamond tools for cutting, grinding, drilling |

Reliable, performance-focused manufacturer |

|

Diametal |

Cutting and precision tools |

High precision, durability, and performance |

These brands are known for making great products and helping customers. Companies like Bosch, Dewalt, and Hilti also get good reviews for being tough and working well. People like wheels that last a long time, work the same every time, and give a nice finish.

Note: Diamond grinding wheels cost more at first, but they last longer and save money in the end.

Picking the right grinding wheel depends on what you are grinding and what job you need to do. The table below shows which wheel works best for each use:

|

Abrasive Type |

Key Benefits |

Typical Applications |

|---|---|---|

|

Diamond |

Very accurate, lasts a long time |

Used for grinding hard, breakable, non-ferrous things like concrete, ceramics, and glass |

|

CBN |

Handles heat well, very strong |

Used for grinding tough steels and superalloys |

Using the right wheel for the job gives the best results, especially when working with concrete. Experts should talk to suppliers to make sure the wheel is right for concrete, check quality steps, and try the wheel on concrete before using it for big jobs. Following the checklist and good tips helps you keep doing well with concrete grinding.

FAQ

What happens if someone uses a diamond grinding wheel on steel?

Diamond wheels do not last long on steel. Heat makes diamond and iron react together. This reaction makes the abrasive break down fast. CBN wheels are better for steel and last much longer.

How often should operators dress CBN or diamond grinding wheels?

Operators should dress the wheel if it stops cutting well. Dressing keeps the wheel sharp and working right. Most people dress the wheel after using it for a few hours.

Can workers use water as a coolant with CBN wheels?

Water is not the best coolant for CBN wheels. Oil-based coolants stop rust and keep things from getting too hot. Oil helps the wheel last longer and gives better grinding results.

Are diamond grinding wheels safe for concrete grinding indoors?

Yes, diamond wheels are safe to use inside on concrete. Workers should use dust systems and wear masks. These wheels make less dust than other types, so the area stays cleaner and safer.

Contact Us

For More Grinding Solution or Customized Abrasive Tools