No, not all grinding wheels can be dressed. Many wheels, however, require regular dressing for the best grinding performance. The ability to perform dressing depends on the wheel’s abrasive material and its bond type.

Note: Some bond types make dressing a wheel very difficult.

- Metal-bonded wheels are highly wear-resistant, making them hard to dress.

- Electroplated wheels have a single abrasive layer, so dressing is not practical.

Operators dress conventional wheels to restore sharpness. In contrast, they “condition” or “clean” superabrasive wheels to expose new grinding particles.

Key Takeaways

- Not all grinding wheels can be dressed; some need “conditioning” or “cleaning” instead.

- Dressing makes a grinding wheel sharp again and fixes its shape.

- Look for signs like a shiny surface or poor performance to know when to dress a wheel.

- Always use the right tools and follow safety rules when dressing a wheel.

- Some wheels, like cut-off wheels, cannot be dressed and must be replaced when worn.

Dressable Grinding Wheels

Certain grinding wheels are designed for dressing. This maintenance is essential for wheels made with conventional abrasives and specific bond types. Operators perform dressing to keep these tools in top condition for any grinding task.

Conventional Abrasives: Aluminum Oxide and Silicon Carbide

Most dressable wheels use conventional abrasives like aluminum oxide or silicon carbide. These materials are tough but wear down over time. Dressing is the process that restores their cutting ability. Aluminum oxide is a versatile abrasive, often chosen for its durability and cost-effectiveness in many applications. It excels when working with high-strength metals.

Operators often choose aluminum oxide for specific tasks. Its toughness makes it ideal for demanding jobs.

| Task / Material | Recommended Abrasive | Why |

|---|---|---|

| Carbon steel heavy grinding | Aluminum Oxide | Toughness & life under high pressure |

| General fabrication on mixed steels | Aluminum Oxide | Cost-effective, durable, predictable wear |

| High-volume belt sanding | Aluminum Oxide (coated) | Long belt life, consistent finish |

Silicon carbide is harder and sharper than aluminum oxide. It is better for grinding non-ferrous metals, cast iron, and very hard materials. However, it is more brittle, so it may not be the best choice for high-pressure grinding on steel.

Vitrified and Ceramic Wheels

The bond holds the abrasive grains together in a wheel. Vitrified and ceramic bonds are very common in dressable wheels. These bonds create a strong, rigid, and porous structure, much like glass. This structure contains the abrasive particles, which can be conventional types or superabrasives like diamond.

The porosity of vitrified wheels is a key feature.

- Open pores create space for chips and allow coolant to flow freely. This prevents the wheel from overheating during grinding.

- Closed pores affect the wheel’s self-sharpening ability and how easily an operator can perform dressing.

Because of this porous nature, vitrified wheels respond very well to dressing. The process removes worn grains and material buildup, exposing fresh, sharp abrasive particles underneath. This reconditioning is crucial for achieving consistent results over the wheel’s long life.

Signs Your Wheel Needs Dressing

Knowing when to perform dressing is vital for safety and performance. An operator should look for several clear indicators. Ignoring these signs can lead to poor surface finishes, inaccurate parts, and potential safety hazards.

You should check your wheel if you notice these signs:

- Glazing: The wheel’s surface looks shiny or smooth. This means the abrasive grains are dull and are rubbing instead of cutting.

- Loading: The wheel is clogged with material from the workpiece. This often happens when grinding soft metals.

- Poor Performance: The grinding process takes longer than usual, or you see burn marks on the workpiece.

- Vibration: The grinding machine starts to vibrate more than normal. This can mean the wheel is out of round or unbalanced.

- Inaccurate Shape: The wheel’s face is no longer flat or has lost its intended profile.

Regularly checking for these signs ensures your grinding operations remain efficient and precise.

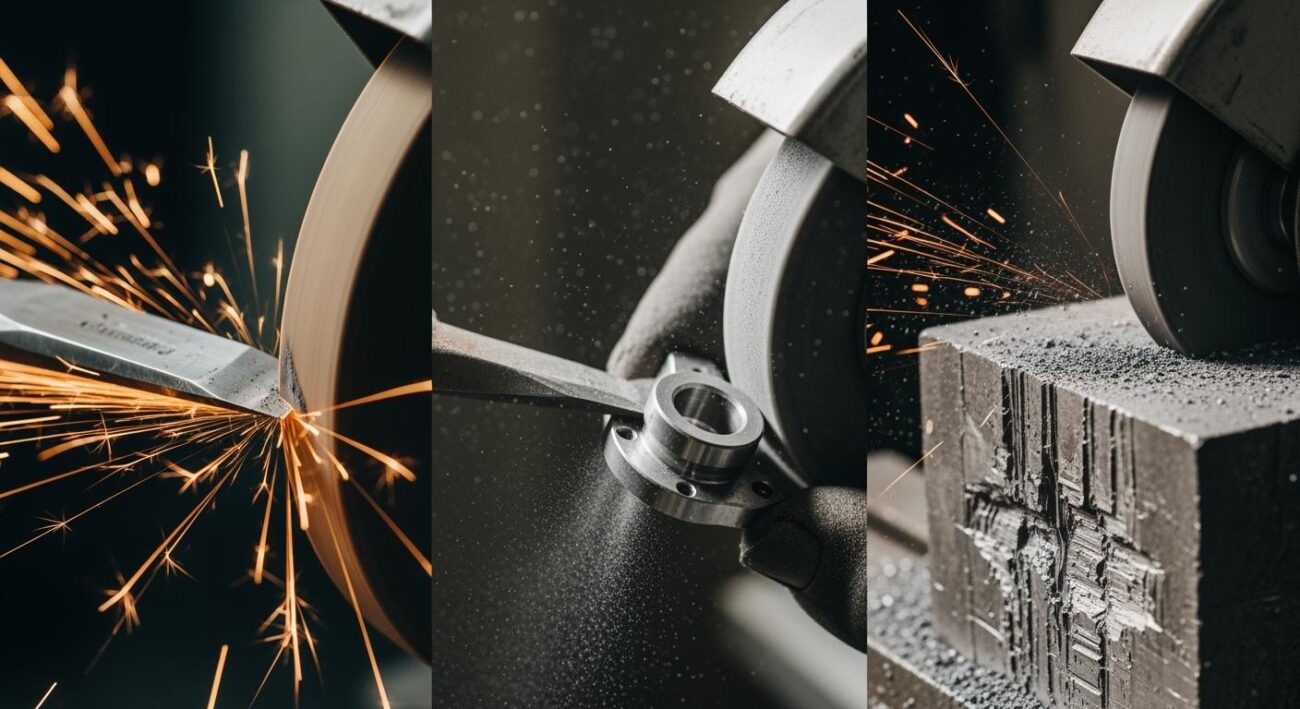

How to Dress a Grinding Wheel

Operators perform dressing and truing to maintain conventional grinding wheels. Dressing sharpens the wheel’s surface, while truing corrects its shape. This maintenance ensures the wheel performs correctly and safely. Following the right dressing procedure is essential for quality grinding work.

The Right Tools for the Job

Choosing the correct tool is the first step to properly dress a grinding wheel. Operators have several options available.

- Dressing Sticks: These are simple, handheld tools. They are often made from aluminum oxide with a 70 grit. An operator uses them to clean the wheel’s surface.

- Diamond Dressing Tools: These tools use industrial diamonds for precision work. They come in many forms, including single-point, multi-point, and impregnated types for different grinding applications.

The choice of tool depends on the wheel size and the specific dressing task.

The Dressing Process Step-by-Step

An operator must follow specific steps for dressing a wheel to achieve the best results. This process involves both dressing and truing for complete wheel restoration.

- Secure the Tool: The operator must firmly mount the dressing tool to the machine. The tool should be angled slightly toward the wheel.

- Set the Speed: The machine should run at its normal operating speed for grinding.

- Begin Dressing: The operator slowly moves the tool across the wheel’s face. The depth of cut should be very small, around 0.00005″ to 0.0001″ per pass. This light touch is key for effective truing.

- Repeat Passes: The operator makes several passes. This action accomplishes both truing the shape and exposing fresh abrasive.

- Inspect the Wheel: After the final pass, the operator checks the wheel. It should have a flat, sharp surface ready for use.

Safety Precautions

Safety is the top priority when dressing a grinding wheel. An operator must always protect themselves from debris and potential hazards.

Safety First! 🛡️

- Always wear safety glasses or a face shield.

- Ensure all machine guards are in place.

- Secure the dressing tool properly before starting.

- Never stand directly in line with the rotating wheel.

Following these rules helps prevent accidents during the dressing process.

Non-Dressable and Specialized Wheels

The term “non-dressable” can be misleading. For many advanced grinding wheels, it does not mean they require no maintenance. Instead, it signifies that they undergo a different process called “conditioning” or “cleaning” rather than the material-removal dressing seen with conventional wheels. This maintenance is crucial for specialized tools like superabrasive and consumable wheels.

Superabrasive Wheels: Diamond and CBN

Superabrasive wheels use materials like diamond or Cubic Boron Nitride (CBN). These materials are exceptionally hard and wear-resistant. Operators do not perform dressing on these wheels to remove large amounts of material. Instead, they condition them to expose new abrasive particles and clean away buildup. This process restores the wheel’s cutting ability without significantly altering its size.

Diamond and CBN each have unique properties suited for specific grinding tasks.

| Feature | Diamond Wheels | CBN Wheels |

|---|---|---|

| Material Suitability | Excels on ceramics, glass, and non-ferrous materials. | Ideal for hardened steels and ferrous alloys. |

| Hardness | The hardest known material, offering excellent wear resistance. | The second hardest material with superior chemical stability. |

| Thermal Stability | Degrades around 700-800°C when used with ferrous metals. | Maintains integrity above 1200°C, making it great for steel. |

| Surface Finish | Capable of creating exceptionally smooth, mirror-like finishes. | Achieves very high-quality finishes on hardened steels. |

Conditioning a superabrasive wheel involves two key actions:

- Truing: This step ensures the wheel is perfectly round and concentric with the spindle. It also shapes the wheel to the correct profile for precision grinding.

- Dressing: This action follows truing. It sharpens the wheel by removing clogged material and exposing fresh, sharp abrasive edges for efficient cutting.

Aimgrind Diamond Grinding Wheels

High-performance wheels, such as Aimgrind diamond grinding wheels, are engineered for longevity and precision. These wheels are not dressed to remove material. Instead, operators condition them with a dressing stick. This maintenance cleans the wheel face, removes clogs from “loading,” and breaks away the smeared bond from “glazing.” This simple action exposes new diamond particles, which maintains the wheel’s sharpness and ensures a long service life.

Pro Tip 💡

When conditioning diamond grinding wheels, use a dressing stick made of a softer abrasive, like aluminum oxide or silicon carbide. The stick wears away, cleaning the diamond wheel without damaging it.

A user can follow these steps to properly condition a wheel:

- Start the Machine: Turn on the grinder and let it reach its full operating speed.

- Position the Stick: Firmly hold a dressing stick on a secure tool rest.

- Apply Gentle Pressure: Carefully bring the stick into contact with the rotating wheel face.

- Move Smoothly: Traverse the stick across the entire wheel surface to ensure even cleaning.

- Inspect the Surface: Withdraw the stick and stop the machine. The wheel face should have a uniform, open texture, ready for high-performance grinding.

Consumable Wheels: Cut-Offs and Flap Discs

Some wheels are truly non-dressable because they are consumable. Cut-off wheels and flap discs fall into this category. These tools are designed to wear away as they cut or finish a workpiece. Their structure is not intended for reshaping or sharpening.

Attempting to perform dressing on a consumable wheel is both ineffective and unsafe. The process would remove too much material, compromising the wheel’s integrity and creating a significant safety hazard. Once these wheels wear down, users must replace them.

The Purpose of Wheel Dressing

Proper wheel maintenance is essential for effective grinding operations. The processes of dressing and truing serve specific purposes that restore a wheel’s performance. Operators perform dressing to sharpen the wheel, while truing corrects its physical shape. Understanding the goals of dressing and truing helps operators achieve precision and efficiency.

Restoring Sharpness and Shape

The primary goal of dressing and truing is to restore a wheel’s cutting ability. Over time, abrasive grains become dull and rounded. This condition, known as glazing, causes the wheel to rub instead of cut. The role of truing is to make the wheel perfectly round again. Proper truing ensures the wheel makes even contact with the workpiece.

Key Actions of Truing ⚙️

- Removes dull, clogged abrasive grains.

- Exposes a new layer of sharp cutting points.

- Restores the wheel’s original profile or shape.

Effective truing makes the grinding process faster and reduces heat generation. A sharp, correctly shaped wheel requires less pressure, which improves cutting performance and reduces wear on the machine.

Removing Clogs and Buildup

Another critical purpose of truing is to clean the wheel. During grinding, small particles of the workpiece can get stuck in the wheel’s pores. This issue, called “loading,” is common when working with soft metals. A loaded wheel cannot cut efficiently.

The process of truing clears away this embedded material. It also removes excess bond material, which restores the wheel’s porosity. This action achieves two important things:

- It creates space for chips to clear away from the cutting zone.

- It allows coolant to reach the grinding surface, preventing overheating.

Ensuring a Consistent Surface Finish

Consistent results depend on regular maintenance. The frequency of dressing and truing directly impacts the final surface finish. An operator must perform truing whenever the wheel’s performance declines to maintain quality. Issues like an out-of-round condition can develop from improper truing, leading to a rougher finish.

Achieving a smooth surface requires careful truing. The parameters used during the process, such as the dresser’s grain size, influence the workpiece’s final roughness. A well-maintained wheel produces a uniform finish on every part. For this reason, operators must master both dressing and truing to ensure all wheels deliver consistent, high-quality results.

Operators must perform dressing on conventional grinding wheels, while superabrasive wheels like Aimgrind‘s diamond wheels are conditioned. Proper maintenance is essential for safe and efficient grinding. Case studies show that consistent maintenance programs prevent catastrophic failures and improve operational efficiency.

Final Advice ✍️

Always follow the manufacturer’s guidelines for your specific wheels. This ensures longevity and peak performance. Aimgrind’s commitment to quality includes providing the right tool and guidance for every grinding task, including regularly dressing and truing. This maintenance is key to success.

FAQ

How often should an operator perform dressing on a wheel?

Operators should perform dressing when they see signs of wear. These signs include a glazed surface, material loading, or poor grinding performance. The frequency depends on the job and the material. Regular checks ensure optimal performance.

Can dressing fix a cracked grinding wheel?

No. An operator must never use a cracked wheel. Dressing cannot repair structural damage. A cracked wheel is a major safety hazard and requires immediate replacement to prevent it from breaking apart during use.

What is the main difference between dressing and truing?

Dressing sharpens the wheel’s surface by exposing new abrasive grains. Truing corrects the wheel’s shape, making it perfectly round and concentric. Both actions are vital for maintaining high-quality grinding wheels.

Why can’t an operator dress a cut-off wheel?

Cut-off wheels are consumable tools. They are designed to wear away during use. Attempting to dress them is unsafe because it compromises their structural integrity. Users must replace these wheels once they are worn down.

Contact Us

For More Grinding Solution or Customized Abrasive Tools