The centreless grinding process delivers three primary advantages: high efficiency, superior precision, and operational flexibility. This machining process is a cornerstone technology for modern manufacturing. It enables high-volume production of quality cylindrical parts for the automotive and aerospace industries. This advanced grinding process translates into major benefits. Companies using centerless grinding can achieve total cost reductions of up to 30%. The advantages of centerless grinding ultimately improve component reliability while boosting productivity. The use of centerless grinding is a strategic choice for competitive manufacturing.

Key Takeaways

- Centerless grinding makes manufacturing faster and more productive.

- This process creates very accurate parts with smooth surfaces.

- It can work with many different materials and part sizes.

- Centerless grinding is good for making fragile parts without damage.

Key Advantages of Centerless Grinding: Efficiency

Efficiency is a defining characteristic of the centerless grinding process. This method streamlines manufacturing by minimizing non-productive time and maximizing output. The design of centerless grinding machines inherently supports rapid part handling and continuous operation. These factors combine to deliver significant gains in productivity, making centerless grinding a superior choice for demanding production environments. The entire grinding process is optimized for speed and consistency from start to finish.

Faster Setup and Loading

Centerless grinding dramatically reduces setup and loading times compared to traditional methods. Modern machines incorporate features that simplify initial configuration. For example, a height-adjustable work rest blade with specialized control software can automatically calculate the optimal blade position. This automation eliminates manual trial-and-error adjustments.

Automation is a key driver of efficiency in centerless grinding. It allows skilled labor to focus on more strategic tasks by reducing operator intervention and minimizing human error in setups.

This leads to several advantages:

- Faster turnaround times

- More precise control over the setup

- Reduced operational expenses

These automated features ensure the machine is ready for production much faster, boosting overall operational efficiency.

Continuous High-Volume Production

The design of centerless grinding is ideal for continuous high-volume production. Using the through-feed method, parts are fed through the machine one after another without stopping. The regulating wheel applies a gentle axial force, moving the workpiece continuously past the grinding wheel. This eliminates the separate loading and unloading steps common in other grinding methods.

This continuous cycle enables incredible production rates for components like bearings and shafts. Some applications achieve cycle times as low as 21 seconds per part. The ability to perform multiple grinding operations in a single pass further accelerates high-volume production. This makes centerless grinding an essential technology for industries requiring large quantities of precision cylindrical parts with consistent quality.

Precision in Centerless Grinding

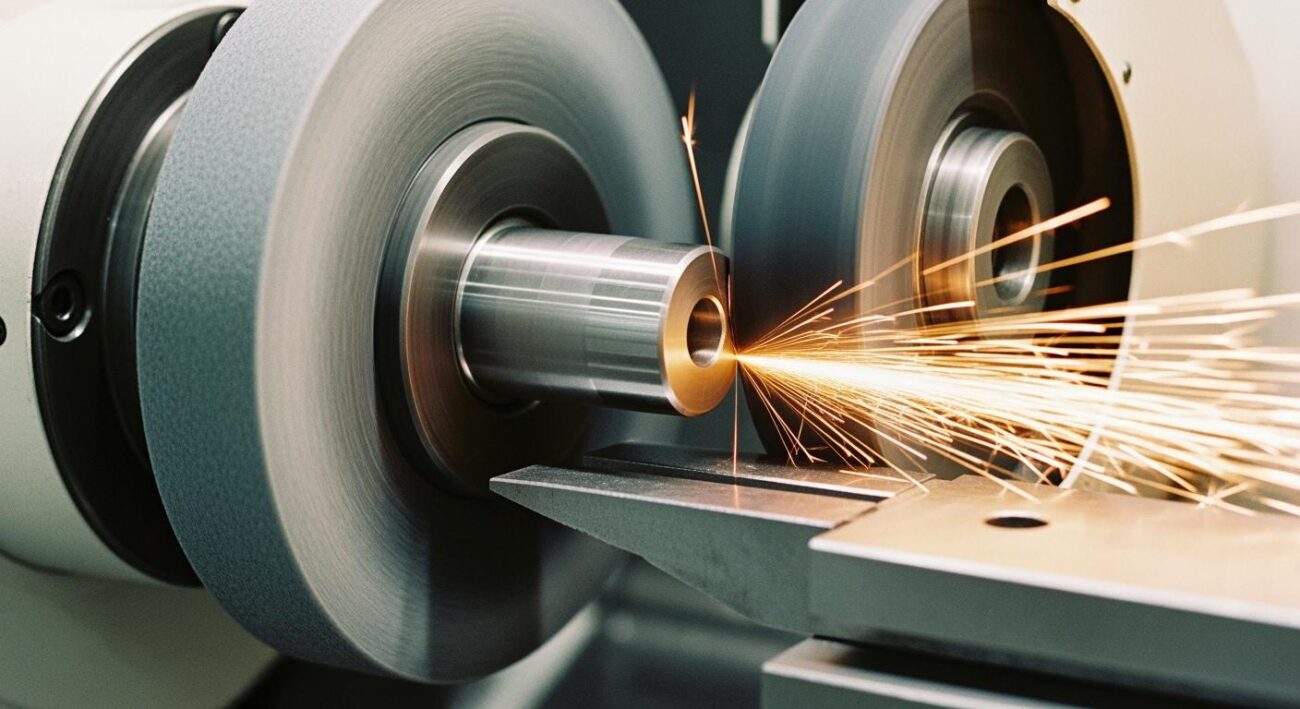

Precision is a major strength of the centerless grinding process. The unique geometric arrangement of the grinding wheel, regulating wheel, and work rest blade delivers exceptional accuracy. This setup supports the workpiece along its entire length, which is fundamental to achieving superior results. The process inherently corrects imperfections, making centerless grinding a top choice for manufacturing components that demand tight tolerances.

Exceptional Roundness and Concentricity

Centerless grinding excels at producing parts with outstanding roundness and concentricity. The workpiece rotates between three contact points, allowing it to find its natural center. This method references only the diameter being ground, which promotes both roundness and straightness. This self-correcting action is a key factor in the process’s overall precision.

The regulating wheel plays a vital role in this system. Its angle of inclination generates the axial force needed to guide the workpiece, ensuring stable and consistent rotation for uniform material removal.

This level of control makes centerless grinding ideal for critical components like engine valve stems, where perfect concentricity is non-negotiable. Modern CNC machines can achieve extremely tight tolerances, often in the range of 1-5 microns. This capability ensures that every part meets exact specifications, contributing to significant error reduction in high-volume production.

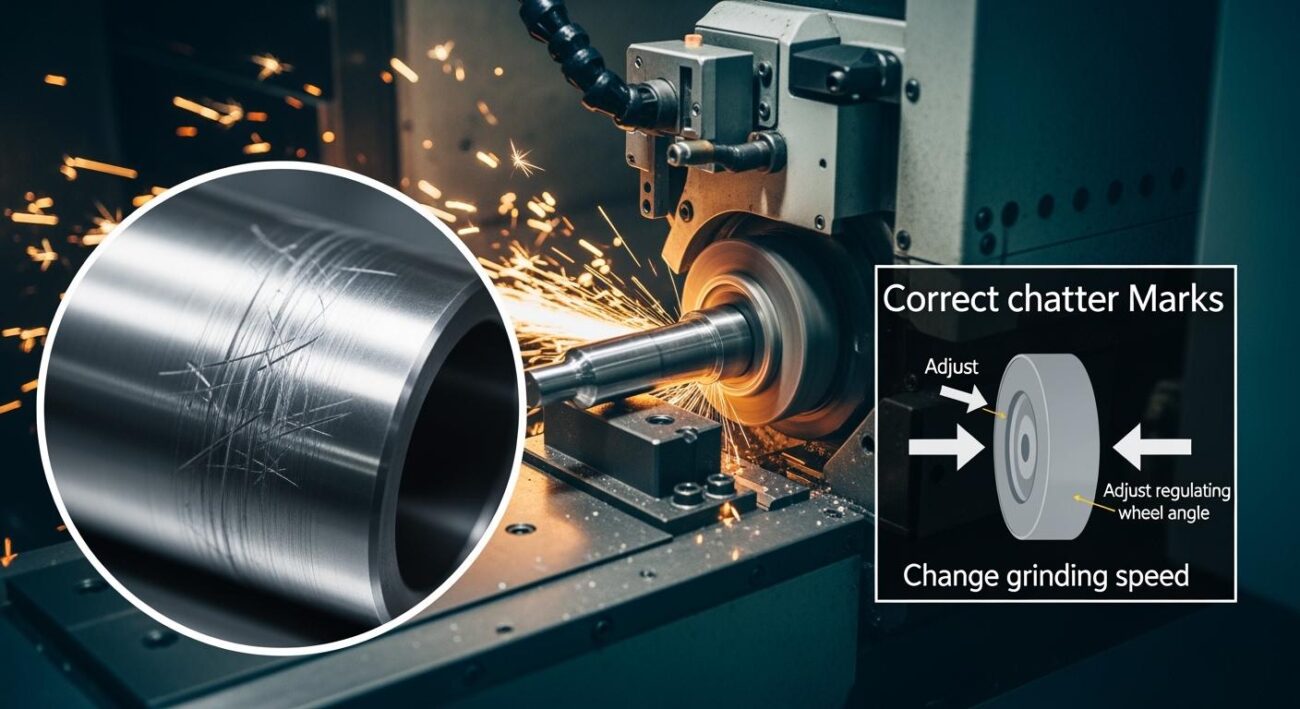

Consistent High-Quality Finishes

The centerless grinding method consistently produces smooth surface finishes. The work rest blade provides continuous support, which minimizes vibration and prevents workpiece deflection during the operation. This stability is crucial for avoiding chatter marks and achieving a flawless surface. The result is a superior finish that other grinding methods struggle to match.

Achieving these finishes on hard materials like ceramics or hard alloys, however, requires specialized abrasive tools. The properties of these materials demand a more robust solution.

- Standard abrasives may wear quickly or fail to produce the desired finish.

- Specialized wheels are designed to handle the hardness and thermal sensitivity of these advanced materials.

High-performance diamond grinding wheels, like those offered by Aimgrind, are engineered to deliver exceptional surface quality and precision in these demanding applications. The use of advanced abrasives with centerless grinding makes it possible to achieve mirror finishes and tight tolerances even on the most challenging materials. This makes centerless grinding a versatile and highly effective process.

Versatility and Flexibility

The centreless grinding process offers remarkable versatility. It adapts to a wide array of manufacturing needs. This flexibility makes centerless grinding a valuable asset for industries producing diverse components. The process handles different part sizes, shapes, and materials with ease. This adaptability is a key reason for its widespread adoption in modern production environments.

The Centreless Grinding Process for Diverse Parts

Centerless grinding accommodates an impressive range of part dimensions and materials. The process is not limited to simple metal cylinders. It effectively grinds various materials, including:

- Glass

- Plastic

- Rubber

- Fiberglass

This capability expands the applications of centerless grinding beyond traditional metalworking. The process also handles a wide spectrum of part diameters. Some systems can grind miniature pins as small as 0.04 inches, while others manage large bars up to 6 inches in diameter.

Ideal for Fragile Components

The centreless grinding process is uniquely suited for delicate or thin-walled parts. The workpiece receives continuous support from the work rest blade and regulating wheel along its entire length. This full-length support distributes grinding forces evenly and prevents the part from bending or distorting under pressure.

This stability is crucial when working with fragile components like thin tubes or hollow shafts. Traditional grinding methods that clamp the part at its ends can introduce stress and cause damage. Centerless grinding eliminates this risk. It ensures that even the most delicate parts maintain their structural integrity and dimensional accuracy throughout the grinding operation. This makes centerless grinding an indispensable solution for high-precision manufacturing of fragile items.

The centreless grinding process delivers three core advantages: enhanced efficiency, superior precision, and unmatched versatility. These benefits make centerless grinding an indispensable method for manufacturers aiming to gain a competitive edge.

Adopting centerless grinding, supported by quality abrasives from specialists like Aimgrind, is a strategic decision for improving both quality and productivity. ✅

This powerful combination ensures companies can meet the highest standards of modern production.

FAQ

What is the main difference between centerless and cylindrical grinding?

Centerless grinding supports the workpiece on a work rest blade between two wheels. Traditional cylindrical grinding secures the workpiece between centers. This key difference allows for continuous feeding and faster production in the centerless process.

Can centerless grinding handle non-metal materials?

Yes, the process is highly versatile. It effectively grinds various materials beyond metals. Common applications include parts made from:

- Ceramics

- Plastics

- Glass

- Rubber

This adaptability makes it a valuable manufacturing solution for many industries.

What makes centerless grinding so precise?

The process uses a unique three-point contact system. The grinding wheel, regulating wheel, and work rest blade work together. This setup naturally corrects roundness errors and supports the part along its entire length, ensuring exceptional precision.

How do I choose the right grinding wheel?

Selecting the correct wheel depends on the workpiece material, required surface finish, and machine parameters. For hard materials like ceramics, specialized diamond wheels are necessary. Consulting with experts like Aimgrind ensures you get a customized wheel for optimal performance. ✅

See Also

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Dry Versus Wet Grinding: Essential Insights for Your Workshop

Picking the Perfect Metal Grinding Wheel for Your Specific Project

Understanding CBN Grinding Wheels: Their Function and Operational Principles

Discovering the Ideal Grinding Wheel Dresser for Your Application

Contact Us

For More Grinding Solution or Customized Abrasive Tools