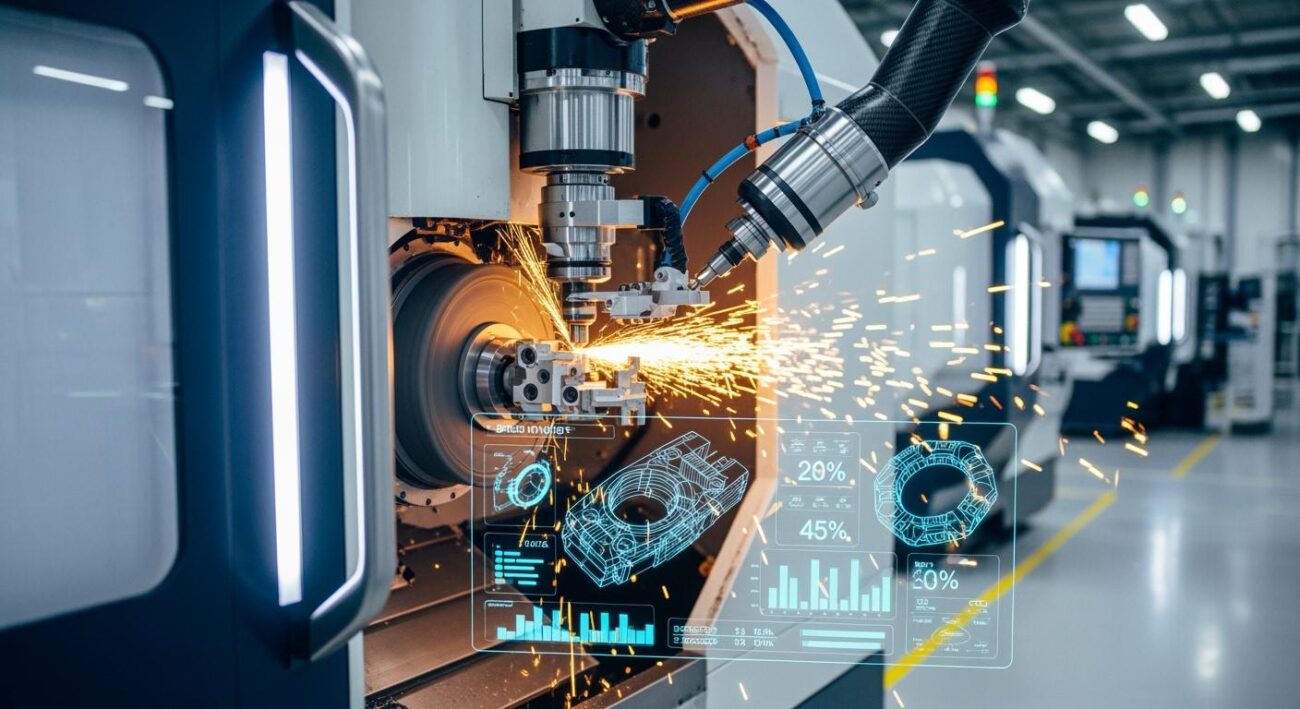

The global market for 5-axis CNC machines is projected to grow at a compound annual growth rate of up to 8.7% through 2028. This highlights the shift towards advanced precision manufacturing. 5-axis CNC grinding offers unique benefits over traditional 3-axis methods. It allows for the grinding of complex parts in a single setup, boosting efficiency. This process enhances precision for demanding applications. Unlike older techniques that require multiple setups and risk errors, 5 axis cnc machining delivers superior results consistently.

Key Takeaways

- 5-axis CNC grinding makes complex parts with high precision. It finishes parts in one setup, which reduces errors.

- This method improves how fast parts are made. It combines many steps into one process, saving time and effort.

- Special grinding wheels are important for 5-axis machines. They help achieve the best results for different materials.

- Industries like aerospace and medical use 5-axis grinding. It helps them make very important and precise parts.

Unmatched Precision with 5-Axis CNC Grinding

The core advantage of 5-axis CNC grinding is its ability to deliver flawless precision. This capability stems from a combination of advanced mechanics and consolidated processes. The result is a higher quality part produced with greater accuracy and consistency.

Single Setup Machining

Traditional machining requires multiple setups to access different faces of a part. Each time a part is re-clamped, a small positioning error of around 0.01 mm is introduced. These errors accumulate, reducing final part precision. 5 axis cnc machining solves this problem by completing complex geometries in a single setup. This method keeps all features referenced to a single datum.

Did You Know? Simultaneous 5-axis processing can reduce workpiece handling errors by approximately 68% compared to traditional methods. This enhanced precision is vital for parts with stringent specifications.

Superior Surface Finish

The continuous toolpath of a 5-axis machine allows the grinding wheel to maintain optimal contact with the workpiece. This smooth, uninterrupted motion eliminates the stop-start marks common in 3-axis operations. The result is an exceptional surface finish.

- Standard grinding can achieve surface roughness (Ra) values from 0.2 to 0.8 μm.

- Advanced 5 axis cnc machining can consistently produce finishes as fine as Ra 0.2 μm, a critical requirement for medical implants and aerospace components.

Tighter Tolerance Achievement

Single-setup machining and superior finishes directly contribute to tighter dimensional tolerances. The 5-axis cnc grinding process minimizes the variables that cause deviation. Premium systems can achieve a positioning accuracy of 0.005mm. This allows manufacturers to consistently hold tolerances as tight as ±2 microns (±0.002 mm) on complex parts. This level of precision is essential for high-performance industries where even microscopic errors can lead to failure.

Efficiency Gains in 5 Axis CNC Machining

Beyond precision, 5 axis cnc machining introduces significant gains in operational efficiency. These improvements streamline the entire manufacturing workflow. The result is faster turnaround and higher throughput. This technology transforms a complex series of tasks into a single, optimized process.

Consolidated Operations

A key benefit is the ability to consolidate multiple machining processes. A single 5-axis center can perform complex milling, drilling, and grinding operations without moving the workpiece. This integration offers several advantages:

- Eliminates the need for multiple specialized machines.

- Reduces capital investment in equipment.

- Simplifies production scheduling and workflow management.

This consolidation is a major factor in achieving reduced production time.

Faster Material Removal

5 axis cnc machining enables the use of shorter, more rigid cutting tools. The machine can orient the part to maintain an optimal cutting position. This allows for more aggressive, high-speed toolpaths.

Pro Tip: Shorter tools are less prone to vibration. This stability permits higher feed rates and deeper cuts, removing material faster than traditional 3-axis methods without sacrificing accuracy.

This capability significantly shortens cycle times for each part.

Reduced Part Handling and Setup

Every time an operator moves a part to a new machine, time is lost. Manual handling, inspection, and re-fixturing add significant delays to the production process. 5 axis cnc machining minimizes these non-value-added activities. Completing a part in one setup drastically cuts down on labor costs and the potential for human error. This streamlined approach boosts overall productivity and accelerates the journey from raw material to finished component.

The Role of Advanced Grinding Wheels

The incredible precision of a 5-axis machine is only half the story. To unlock its full potential, the system requires equally advanced tooling. The grinding wheel is where the machine meets the material, making its quality paramount for success in high-stakes applications.

Choosing the Right Abrasive

Selecting the correct abrasive is the first step toward optimal performance. The choice depends entirely on the workpiece material. Using the wrong abrasive can lead to rapid tool wear and poor results. Superhard abrasives like Diamond and Cubic Boron Nitride (CBN) are essential for difficult-to-process materials.

Key Selection Criteria:

- Workpiece Hardness: The abrasive must be significantly harder than the material it is grinding.

- Material Composition: Abrasives can react chemically with certain metals at high temperatures.

A simple guide helps in making the right choice:

| Abrasive Type | Best For |

|---|---|

| Diamond | Tungsten carbide, ceramics, glass, and other non-ferrous materials. |

| CBN | High-speed steel, tool steel, stainless steel, and other ferrous materials. |

Extending Tool Life

Even the best wheels experience wear. Over time, abrasive grains can become dull, reducing cutting ability and increasing friction. This dulling converts more energy into heat, which can damage the part and shorten the wheel’s life. Proper maintenance, including processes like dressing, is crucial. Dressing resets the wheel’s surface, exposes fresh cutting edges, and ensures consistent grinding performance. This extends tool life and maintains part quality.

Achieving a Flawless Finish

A flawless finish starts with a superior tool. The geometry of the grinding wheel, including the profile formed by its abrasive grains, directly impacts the final surface roughness. The full capability of 5 axis cnc machining is only realized when the machine is paired with a tool designed for the task. For the most demanding jobs, specialized tools are not just an option—they are a necessity.

This is why Aimgrind‘s specialized diamond grinding wheels are engineered to maximize the performance of 5-axis CNC grinding systems. They ensure optimal surface finish and tool life, delivering the flawless results modern manufacturing demands.

Applications and Benefits of 5 Axis CNC Machining

The theoretical advantages of precision and efficiency become tangible in real-world applications. The applications and benefits of 5 axis cnc machining are most visible in industries where failure is not an option. This technology enables the production of parts with complex designs that were previously impossible or too costly to manufacture.

Aerospace and Defense Components

The aerospace industry relies on 5 axis cnc machining for manufacturing critical aerospace parts. Components must withstand extreme conditions and meet strict safety standards.

- Turbine Blades and Turbine Airfoils: These parts require complex contours and flawless surfaces for optimal aerodynamic performance. Single-setup machining eliminates cumulative errors, ensuring the highest level of accuracy.

- Fuel Injection Systems: The intricate internal channels of these parts are machined with exceptional precision to guarantee efficient fuel flow and engine reliability.

Medical Device Manufacturing

In medical device manufacturing, precision directly impacts patient outcomes. 5 axis cnc machining is essential for creating custom orthopedic implants and surgical tools. The process is vital for shaping and finishing parts to enhance their fit and function.

- Orthopedic Implants: Femoral knees, tibial trays, and hip stems are ground to achieve perfect geometries and ultra-smooth surfaces, which are crucial for biocompatibility and long-term performance.

- Surgical Instruments: The technology enables the creation of intricate components for next-generation surgical devices, improving their effectiveness in the operating room.

Precision Tool and Die Making

The quality of a final product often depends on the quality of the tool used to make it. This technology excels at creating high-precision cutting tools, molds, and dies from hardened materials. The ability to machine complex negative spaces and sharp cutting edges in a single operation streamlines the production of tooling for various manufacturing applications.

High-Performance Automotive Parts

The automotive industry uses 5 axis cnc machining to produce high-performance engine and transmission parts. The benefits of enhanced efficiency and precision are key to building powerful and reliable vehicles. This grinding method helps achieve the tight tolerances needed for modern engines.

- Camshafts: Lobes are ground with an accuracy of ±5 μm for precise valve timing.

- Hardened Steel Gears: Precision grinding delivers a fine surface finish (Ra ≤ 0.4 μm), which is essential for high-load transmissions.

These diverse applications demonstrate the clear applications and benefits of 5 axis cnc machining in modern manufacturing.

5 axis cnc machining delivers clear benefits. It provides unmatched precision and operational efficiency. The full potential of this technology is realized when paired with advanced tooling. Aimgrind’s specialized diamond grinding wheels are engineered for this purpose. This combination makes 5-axis cnc grinding an essential solution for modern manufacturing.

The future of high-value applications depends on this powerful grinding method to drive innovation and redefine what is possible.

FAQ

What is the main difference between 3-axis and 5-axis grinding?

3-axis machines move a tool along the X, Y, and Z axes. 5-axis machines add two rotational axes. This allows the machine to grind complex shapes from multiple angles in a single setup, improving precision and efficiency.

Is 5-axis CNC grinding cost-effective?

Yes, it is highly cost-effective for complex parts. It reduces setup time, minimizes manual labor, and consolidates operations. These efficiencies lower the overall cost per part, especially in high-volume or high-value production runs.

What materials are best for 5-axis CNC grinding?

This process excels with hard and difficult-to-machine materials. It is ideal for grinding tungsten carbide, ceramics, hardened steels, and superalloys. The right grinding wheel is critical for success with these materials.

Expert Tip 💡

The performance of 5-axis grinding depends heavily on the tool. Using a specialized wheel, like Aimgrind’s diamond grinding wheels, ensures you achieve the best possible precision and surface finish on hard materials.

How does 5-axis grinding improve part quality?

It improves quality by machining a part in one clamping. This single-setup process eliminates the risk of errors from moving the part. It also allows for smoother toolpaths, resulting in superior surface finishes and tighter dimensional tolerances.

Contact Us

For More Grinding Solution or Customized Abrasive Tools