You achieve optical clarity and precision edges in glass grinding by choosing specialized tools like Aimgrind diamond grinding wheels. These wheels remove tiny parts from glass edges, improving both surface quality and edge precision. Smaller grain sizes and wear-resistant materials help you get better results. The right equipment and careful preparation affect how clear and durable your glass edges turn out. Steady movements and controlled grinding processes make your edges uniform and high quality.

| Findings | Description |

|---|---|

| Surface Roughness | Laser fine-tuning on diamond particles lowers surface roughness in glass grinding. |

| Wear Resistance | Diamond grinding wheels last longer and show less wear. |

| Grinding Performance | Optimized diamond particles increase grinding performance. |

Key Takeaways

- Choose Aimgrind diamond grinding wheels for optimal glass grinding. These wheels enhance surface quality and edge precision.

- Always inspect and clean glass before machining. This prevents scratches and ensures a flawless finish.

- Use the correct grinding technique, starting with coarse grits and moving to finer ones. This method improves optical clarity.

- Maintain a clean and organized workspace. This reduces mistakes and enhances the efficiency of your glass machining process.

- Regularly calibrate your CNC machine and check your tools. This ensures straight edges and high-quality results.

Essential Tools for Glass Grinding

Aimgrind Diamond Grinding Wheels Overview

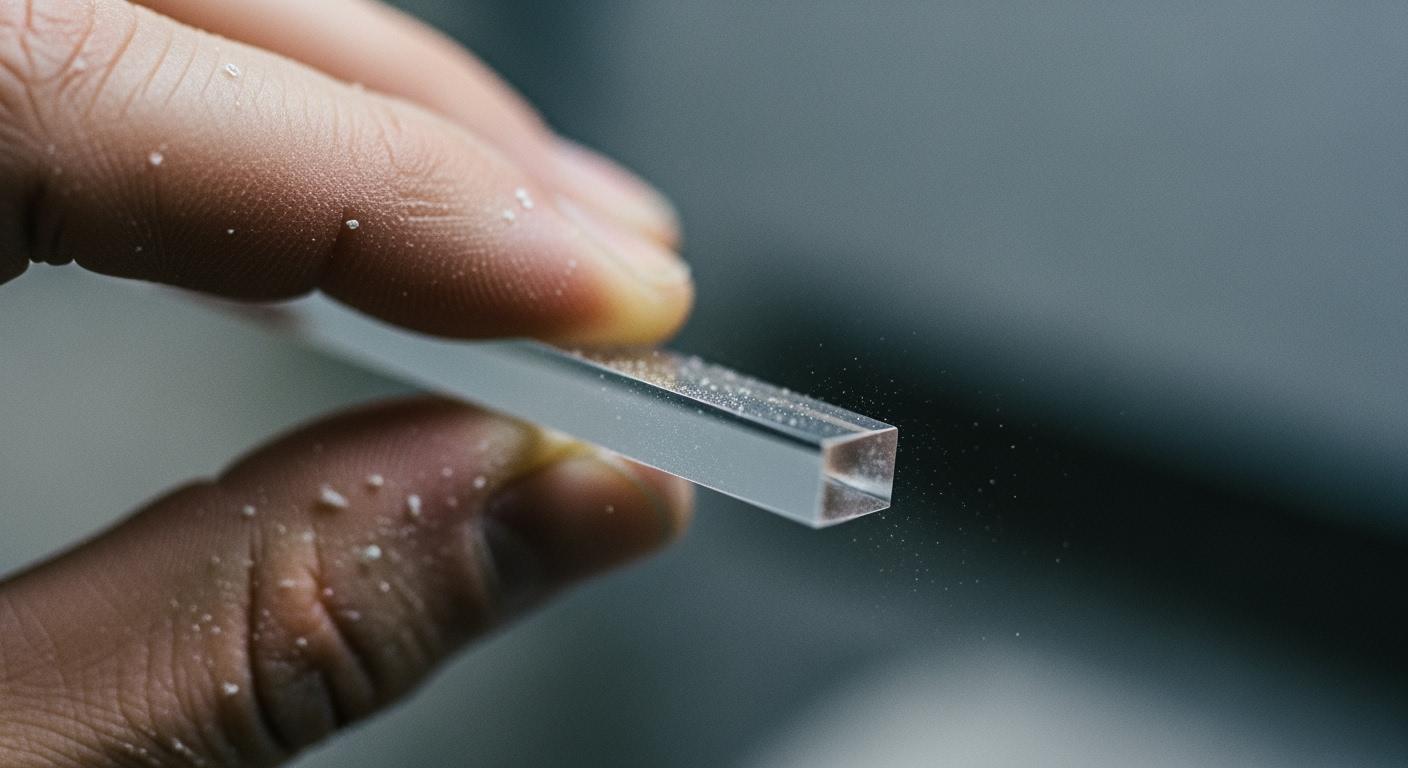

You need the right tools to achieve clear and precise edges in glass cnc machining. Aimgrind diamond grinding wheels stand out for their durability and high performance. These wheels use a strong diamond abrasive layer. This layer helps you grind glass with less effort and more accuracy. You can use them for both wet and dry machining. They keep their shape and sharpness, so you get consistent results every time. Aimgrind offers different bond types, such as resin, metal, and vitrified, to match your cnc machining needs. You can also choose custom sizes for your glass projects. These wheels help you remove rough spots and polish glass edges until they shine.

| Functionality/Application | Description |

|---|---|

| Grinding and Polishing | Essential for transforming rough glass into smooth, finished edges, enhancing aesthetic appeal and safety. |

| Mass Production | Used in factories for systematic edging, polishing, and preparing glass for further processing. |

| Versatility | Capable of creating various edge types (flat, pencil, beveled, OG) and adapting to different glass thicknesses. |

Choosing the Right Edge Grinding Machine

You should select a machine that matches your glass cnc machining goals. Wet grinders work well because they prevent overheating and protect the glass. Dry grinders help with shaping and polishing. Machines with adjustable speed and pressure let you control the grinding process for better precision. Cooling systems, like water or air jets, keep the glass from cracking. Precision measurement tools, such as calipers and micrometers, help you check the edges during cnc machining.

| Feature | Description |

|---|---|

| Type of Grinder | Wet grinders prevent overheating, while dry grinders are suitable for shaping and polishing. |

| Abrasive Material | Diamond abrasives offer exceptional hardness; silicon carbide is used for finer finishing. |

| Adjustable Speed and Pressure | Allows fine-tuning of the grinding process for desired precision. |

| Cooling Systems | Water or air jets prevent overheating, ensuring a uniform edge finish. |

| Precision Measurement Tools | Calipers and micrometers ensure accuracy in dimensions and tolerances of glass edges. |

Safety and Cleaning Supplies

You must always protect yourself during glass cnc machining. Wear safety glasses and gloves to shield your eyes and hands from sharp glass pieces. Clean your workspace and tools before and after machining. This keeps the glass free from dust and helps you achieve optical clarity. Good cleaning supplies, like soft cloths and gentle cleaners, prevent scratches on the glass surface.

Tip: Always wear appropriate safety gear when working with grinding wheels, including safety glasses and gloves.

Preparing Glass for CNC Machining

Cleaning and Inspection Steps

You must start every glass cnc machining project with clean and flawless glass. Dirt, oil, or dust can cause scratches and ruin the final result. Use a soft cloth and gentle cleaner to wipe the glass surface. Inspect the glass for chips, cracks, or bubbles. Hold the glass up to the light to spot any hidden flaws. If you find defects, replace the glass before you begin cnc machining. This step helps you avoid wasting time and materials.

Professional glass manufacturers always check the Coefficient of Expansion (COE) to prevent cracking or breaking during machining. You should also pay attention to the type of glass you use.

Aimgrind diamond grinding wheels make the cleaning and inspection process easier. Their precision helps you spot and remove rough spots before you start cnc machining.

Marking for Precision Edges

You need to mark the glass before you begin glass cnc machining. Accurate marking ensures you get straight and smooth edges. Use a fine-tip marker or scribe to outline the cutting path. For complex shapes, create a CAD drawing and transfer the design to the glass.

| Technique | Description | Benefits |

|---|---|---|

| Mechanical Scribing | Draws lines for simple shapes. | Easy and cost-effective. |

| CNC Edging | Uses computer control for high accuracy. | Custom designs and tight tolerances. |

| Laser Cutting | Cuts with a focused laser beam. | Minimal chipping and high-quality edges. |

| Waterjet Cutting | Uses water and abrasives for thick glass. | Accurate cuts for complex shapes. |

| Diamond Saw Cutting | Cuts with diamond-tipped blades. | High precision for many glass types. |

You can use Aimgrind diamond tools for scribing and cutting. These tools help you achieve clean lines and reduce the risk of chipping during cnc machining.

Workspace Setup

A well-organized workspace leads to better results in glass cnc machining. Make sure all mounting hardware is tight. Loose parts can cause the glass to shift during machining. Lubricate the motion systems to keep everything moving smoothly. Check pneumatic systems for leaks. Stable air pressure helps you get consistent cuts. Verify the power supply to avoid electrical problems.

- Tighten all clamps and mounts before starting.

- Lubricate moving parts to prevent binding.

- Inspect air lines for leaks.

- Check power quality for steady operation.

A clean and safe workspace reduces mistakes and keeps your glass cnc machining process efficient. Aimgrind grinding wheels fit most cnc machines and help you prepare your glass for flawless edges.

Grinding Process for Optical Clarity

Coarse to Fine Grinding Techniques

You start the grinding process by checking the glass for scratches and defects. This step helps you choose the right starting grit for your grinding wheel. Clean the glass and protect the work area. Use Aimgrind diamond grinding wheels for the best results in glass cnc machining. These wheels help you remove rough spots and prepare the surface for further steps.

Follow these steps for a smooth surface finish and optical clarity:

- Inspect the glass for scratches and decide on the starting grit.

- Clean the glass and protect the surrounding area.

- Begin with a coarse grit wheel to remove deep scratches and shape the glass. Keep the glass cool to prevent cracks.

- Move to finer grits step by step. Feather the edges as you grind to avoid distortion.

- Check the surface after each grit change. Make sure you see fewer scratches and a smoother finish.

You should always keep the glass wet during grinding. This prevents overheating and helps you achieve a better surface finish. If you rush or skip grits, you may leave marks that affect optical clarity. Take your time and check your progress often.

Tip: Use Aimgrind diamond grinding wheels in the correct order, from coarse to fine, for the best surface enhancement and optical clarity.

Polishing with Diamond Wheels

Polishing is the key to getting a clear and shiny surface. After you finish grinding, switch to a polishing wheel. Aimgrind diamond wheels work well for this step in glass cnc machining. Start with a medium grit and move to a fine grit for the final polish.

You can use cerium oxide as a polishing compound. Apply it to the surface and keep the area wet. Move the wheel slowly and evenly across the glass. This method removes tiny scratches and brings out the optical clarity you want.

Here are some tips for polishing:

- Use light pressure to avoid creating new scratches.

- Keep the surface wet to prevent heat buildup.

- Check the finish often. Stop when you see a clear and smooth surface.

- Clean the glass after polishing to remove any leftover compound.

If you notice dull spots or streaks, go back to a finer grit and repeat the polishing step. Aimgrind diamond wheels help you get a perfect finish every time.

Machine Parameter Adjustments

You must adjust your cnc machine settings to get the best results in glass cnc machining. The right parameters help you achieve a smooth surface and high optical clarity. Use the table below to understand how each setting affects the process:

| Machine Parameter | Effect on Optical Clarity |

|---|---|

| Grinding Wheel Speed | Higher speeds reduce subsurface damage and improve surface quality. |

| Strain Rate | Increased strain rate makes the glass tougher but can lower microhardness. |

| Temperature | Local temperature changes the glass properties and affects grinding performance. |

| Tool Design | Good tool design improves grinding and reduces surface roughness. |

You should also pay attention to these points:

- Cutting speed affects both productivity and the quality of the cut. Adjust the speed based on the type and thickness of the glass.

- Cutting pressure is important. Too much pressure can crack the glass, while too little may not cut well.

- Scoring depth must be just right. This helps you break the glass cleanly without chipping.

- Choose the right Aimgrind diamond grinding wheel for your glass type.

Note: Overheating and vibration can cause poor surface finish and reduce tool life. Always monitor your machine and adjust settings as needed.

Common Mistakes to Avoid

Mistakes during grinding can ruin the surface finish and optical clarity. Watch out for these common errors:

| Mistake | Explanation |

|---|---|

| Selecting the wrong bond for the glass | The wrong bond can cause poor cutting or fast wear. |

| Running the grinder too fast | High speed can overheat the glass and glaze the diamonds. |

| Using the wrong pressure | Not enough pressure slows grinding. Too much can damage the glass. |

| Skipping inspection | Missed defects can lead to poor results and machine damage. |

- Overheating can make the surface cloudy and reduce clarity.

- Excessive vibration can cause scratches and wear out your tools.

You can avoid these problems by using Aimgrind diamond grinding wheels, adjusting your cnc machine settings, and checking your work often. This process gives you a perfect surface finish and the optical clarity you need for any glass cnc machining project.

Achieving Precision Edges

Maintaining Edge Straightness

You need straight edges for high-quality glass cnc machining. Straight edges help you meet tight tolerances and improve the look of your glass. You can follow these steps to keep your edges straight:

- Calibrate your cnc machine often. Check the guides and fixtures to make sure they move in a straight line.

- Choose Aimgrind diamond grinding wheels with sharp and even edges. These wheels help you grind glass with high accuracy.

- Set the right cutting speed, feed rate, and depth. These settings help you avoid wavy or uneven edges.

- Keep your workspace at a steady temperature and humidity. Changes in the environment can cause the glass to shift during machining.

- Train yourself or your team to use the cnc machine well. Skilled operators can spot problems and fix them quickly.

- Use advanced cnc technology and vision systems. These tools help you watch the process and make changes for better straightness.

You should always check the surface after each pass. If you see any bends or waves, adjust your settings before you continue. This process helps you create precision components with perfect edges.

Using Clamping Devices and Jigs

You must hold the glass firmly during cnc machining. Clamping devices and jigs keep the glass from moving. This step is important for keeping tolerances tight and edges straight.

- Use soft clamps that do not scratch the glass surface.

- Place the glass on a flat, clean base. This support helps you avoid chips and cracks.

- Adjust the clamps so they hold the glass evenly. Uneven pressure can cause the glass to break or shift.

- For complex shapes, use custom jigs. These jigs match the shape of your glass and help you keep accuracy high.

Aimgrind diamond grinding wheels work well with many types of clamping systems. You can use them for both simple and complex glass cnc machining projects. Good clamping helps you get smooth edges and a flawless surface.

Tip: Always check your clamps and jigs before you start machining. Loose parts can ruin your work and waste materials.

Measurement and Quality Checks

You need to measure your glass edges to make sure they meet your tolerances. Quality control starts with the right tools and ends with a final inspection.

- Use calipers and micrometers to check the width and straightness of the glass edge.

- Try metal-bonded diamond grinding wheels for coarse, medium, and fine grit steps. These wheels help you get a smooth surface.

- Use resin bonded diamond grinding wheels if you want a frosted surface.

- Finish with polishing wheels and low-hardness abrasives like cerium oxide for a clear, shiny surface.

You should use in-process monitoring to check your work as you go. This method helps you catch mistakes early and fix them before the final inspection.

| Inspection Technique | Description |

|---|---|

| Machine Vision | Detects edge defects in real-time, ensuring immediate quality control. |

| Load-Testing Simulations | Validates edge strength before installation, ensuring safety and durability. |

| Multi-Axis Precision | Allows for complex shapes, enhancing the accuracy of edge grinding. |

| Adaptive Grinding Heads | Adjusts pressure dynamically to prevent over-grinding, maintaining edge quality. |

You should always do a final inspection before you finish your glass cnc machining project. This step helps you make sure your glass meets all tolerances and looks perfect. Good measurement and quality control give you the best results for any glass machining job.

Common Mistakes in Glass Grinding

Over-Grinding and Chipping

You can easily make mistakes during glass cnc machining if you grind too much or use the wrong tools. Over-grinding removes more material than needed and causes chipping along the edge. You might choose the wrong grinding wheel or apply too much pressure. This leads to cracks and weak spots. Aimgrind diamond grinding wheels help you avoid these issues because they match the material and keep the surface strong. You should always check your wheel selection and adjust the feed rate. Regular maintenance and proper coolant use prevent overheating and protect the glass.

Tip: Use the correct wheel speed and pressure to keep the surface smooth and reduce chipping.

Uneven Edges and Scratches

Uneven edges and scratches often appear when you do not align the glass properly or use inconsistent pressure during cnc machining. You may see edge breakage if you press too hard or forget to lubricate. Scratches happen when debris collects on the grinding wheel. Clean the wheel often and use smooth, overlapping motions. Aimgrind diamond wheels provide uniform grinding and help you achieve a flawless surface. You should calibrate your cnc machine and measure the glass before each step. Accurate alignment and steady pressure keep the edges straight.

| Cause | Solution |

|---|---|

| Excessive Pressure | Use moderate, even pressure |

| Faulty Alignment | Calibrate cnc machine regularly |

| Debris on Wheel | Clean wheel between steps |

Improper Polishing and Cleaning

Improper polishing and cleaning can ruin the surface after cnc machining. If you skip abrasive steps or use uneven pressure, you leave scratches and dull spots. You should polish in a logical order and clean between each step. Use distilled water and alcohol for the final rinse. Aimgrind diamond wheels help you polish evenly and achieve optical clarity. For deep cleaning, try an ultrasonic cleaner with the right surfactant. Smooth motions and moderate pressure give you the best surface finish.

Note: Careful polishing and cleaning keep your glass clear and free from defects.

You achieve the best glass edges by using Aimgrind diamond grinding wheels and following careful CNC machining steps. Start with the right discs and polish with advanced compounds for a flawless finish. Pay close attention to detail during each stage. Practice regularly to improve your posture, tool handling, and sensitivity to feedback.

- Regular training helps you master pressure and movement.

- Careful inspection and cleaning ensure professional results.

- Consistent effort leads to optical clarity and precision every time.

FAQ

What makes Aimgrind diamond grinding wheels ideal for glass edge precision?

You get consistent results because Aimgrind diamond grinding wheels use high-quality diamond abrasives. These wheels keep their shape and sharpness. You achieve smooth, clear edges with less effort.

Can I use Aimgrind diamond grinding wheels for both wet and dry grinding?

You can use Aimgrind diamond grinding wheels for wet and dry grinding. Wet grinding helps prevent overheating and improves surface clarity. Dry grinding works well for shaping and quick material removal.

How do I choose the right grit size for glass grinding?

You start with a coarse grit to remove scratches and shape the glass. You switch to finer grits for polishing and achieving optical clarity. Aimgrind offers many grit sizes for different glass types.

What safety steps should I follow when grinding glass?

You wear safety glasses and gloves to protect your eyes and hands. You clean your workspace before and after grinding. You check your tools and machines for damage before you start.

Contact Us

For More Grinding Solution or Customized Abrasive Tools