You can prevent chatter and vibration in crankshaft grinding by focusing on machine setup, choosing the right grinding wheel, and keeping your equipment well-maintained. Chatter leads to poor surface finish and reduces tool life. Quality and efficiency improve when you address these problems early. Aimgrind CBN grinding wheels help you achieve smoother results and longer-lasting performance. Take action now to create a stable grinding process and boost your productivity.

Key Takeaways

- Prevent chatter by ensuring strong machine rigidity. Check for loose parts and worn bearings to maintain stability during grinding.

- Choose Aimgrind CBN grinding wheels for better performance. These wheels provide high efficiency and reduce the risk of chatter.

- Adjust grinding parameters like feed rate and depth of cut. Small changes can stabilize the process and improve surface finish.

- Regular maintenance is crucial. Inspect and clean your machine, and replace worn parts to keep operations smooth and efficient.

- Use diagnostic tools to identify vibration sources. Early detection helps you address issues before they affect grinding quality.

Understanding Chatter and Vibration

What Is Chatter?

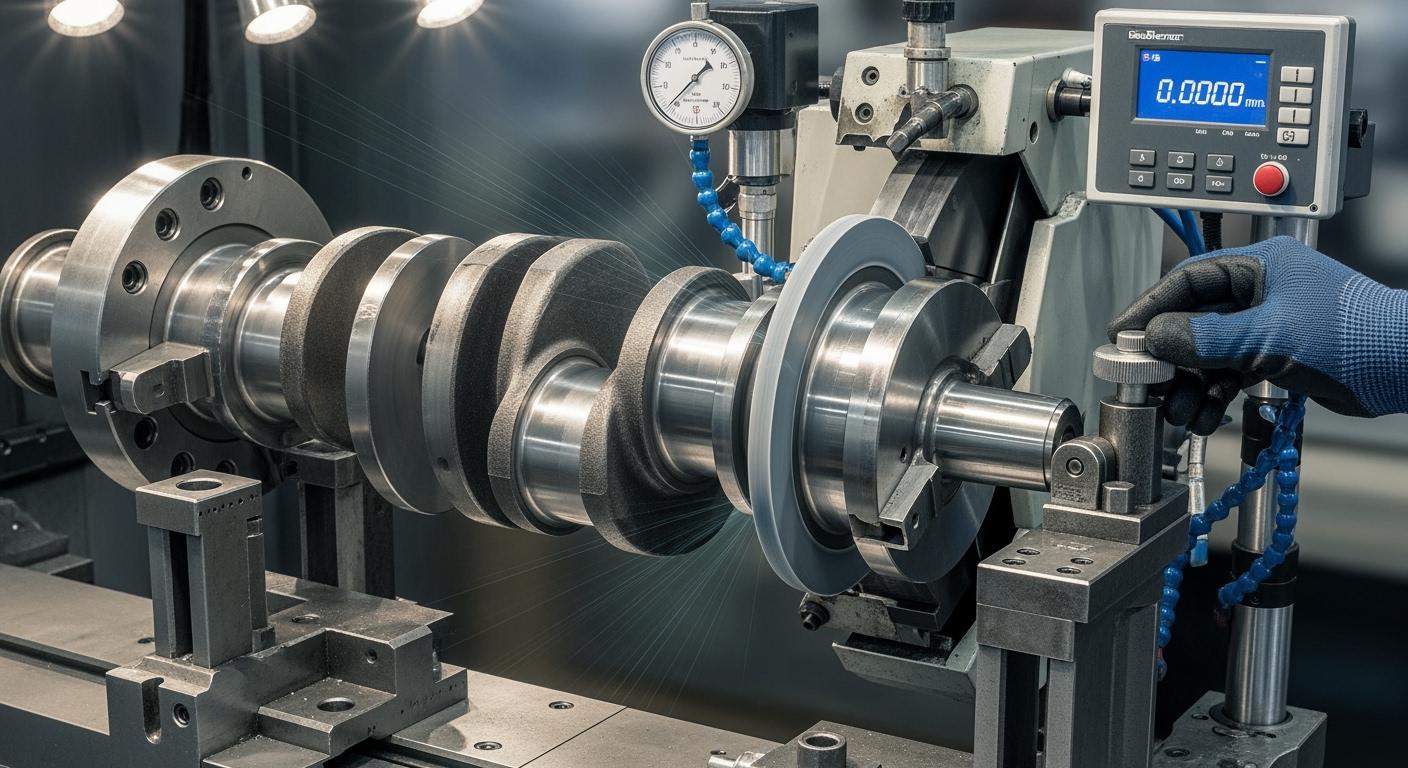

Chatter is a type of unwanted movement that happens during crankshaft grinding. You notice it as a repeating pattern or wave on the surface of the crankshaft. Chatter comes from unstable interactions between the grinding wheel and the workpiece. It affects both the surface quality and production efficiency. Engineers use dynamic models and formulas to predict and control chatter in grinding operations.

- Chatter causes visible marks and roughness on the crankshaft.

- It can slow down your grinding process and make it less stable.

- You may see a flutter or vibration that repeats at certain speeds.

What Is Vibration?

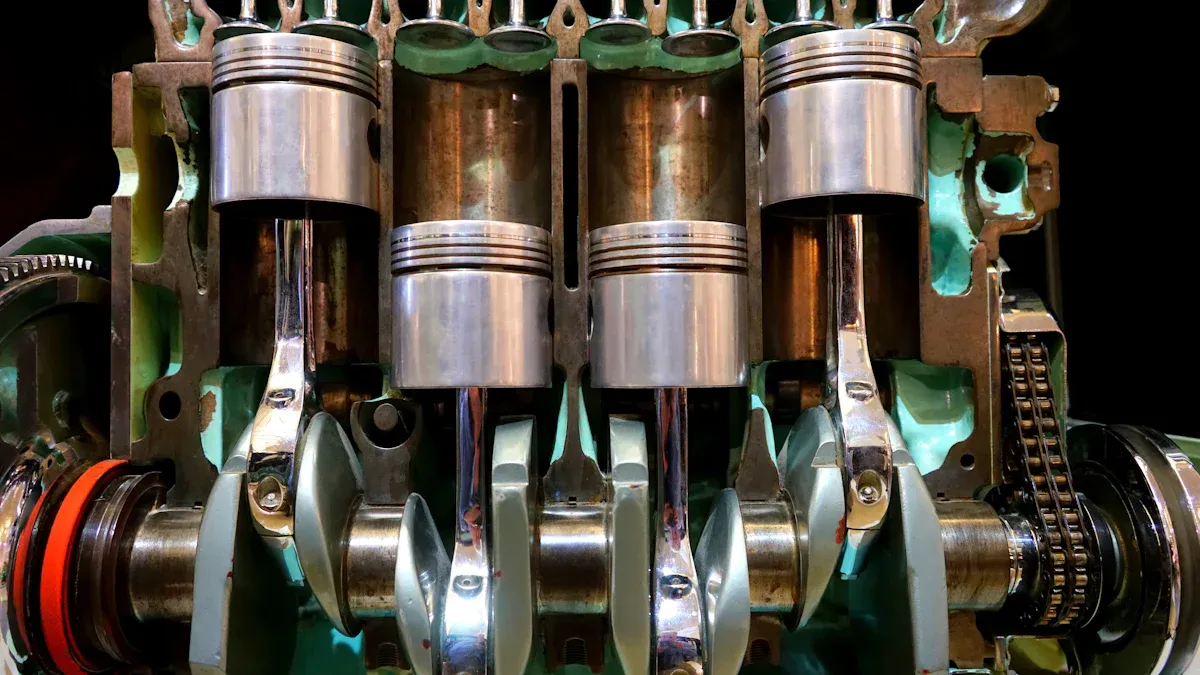

Vibration is another form of movement that affects crankshaft grinding. It can come from the machine, the spindle, or the workpiece itself. Vibration impacts machining accuracy and surface quality.

- In a 4-cylinder 4-stroke engine, you get 4 power strokes every 2 revolutions.

- At 3000 rpm, the engine produces 6000 vibration cycles per minute, which equals 100 cycles per second (100 Hz).

- This vibration is mostly torsional, meaning it twists the crankshaft, but does not move it side to side.

Tip: You can use diagnostic tools to measure vibration and find its source. This helps you fix problems before they affect your grinding results.

Why Chatter Matters

Chatter matters because it changes the thickness and quality of the hardened layers on the crankshaft. When chatter increases, the grinding hardening layers become thicker, but their quality drops. This can hurt the mechanical properties of the crankshaft. You may see poor surface finish and lose dimensional accuracy. If you control chatter, you get better results and longer-lasting crankshafts.

Causes of Chatter and Vibration

Machine Rigidity

You need strong machine rigidity to keep grinding operations stable. When your machine lacks rigidity, it can deform and vibrate during cutting. This movement causes fluctuations in cutting forces and triggers chatter. If any part of your system is not stiff enough, it will deflect and lose dynamic stability. Mechanical resonance can happen when cutting forces match the machine’s natural frequencies. You can improve rigidity by checking for loose parts and worn spindle bearings. The table below shows how insufficient rigidity affects grinding:

| Evidence Description | Key Points |

|---|---|

| Insufficient rigidity leads to machine deformation and vibration during cutting. | This deformation causes fluctuations in cutting forces, triggering vibrations and chatter. |

| Lack of stiffness in any part of the system results in deflection. | Deflection decreases dynamic stiffness, exacerbating vibrations during the cut. |

| Mechanical resonance occurs when cutting forces align with natural frequencies. | Improving rigidity shifts these frequencies away from common cutting frequencies, reducing chatter. |

Workpiece Support

You must support the crankshaft properly to maintain stability. Poor support lets the workpiece vibrate, which leads to chatter marks. Some machines use air suspension systems in the tailstock, allowing smooth movement without contact. Others, like the Landis LT2HHe, use hydrostatic slideways to boost stiffness and repeatability. These features help dampen vibration and improve grinding stability.

- Air suspension systems allow smooth movement and reduce contact.

- Hydrostatic slideways increase stiffness and repeatability.

- Good support prevents vibration and keeps grinding stable.

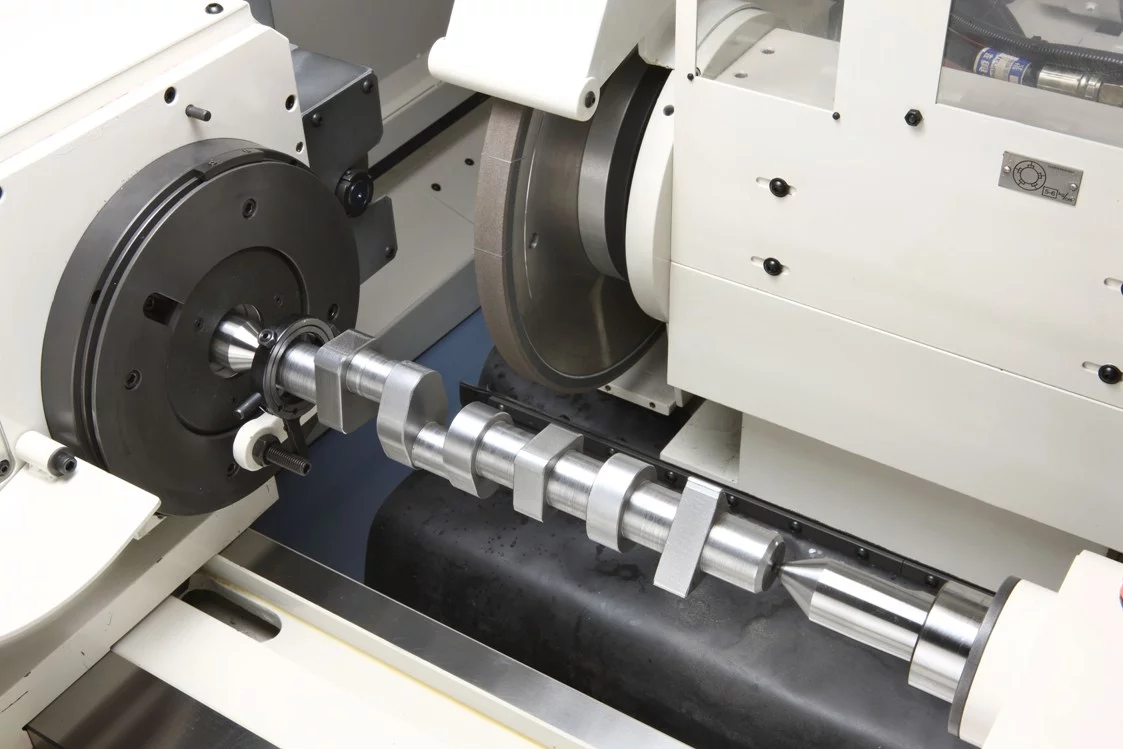

Grinding Wheel Condition

You should check your grinding wheel for wear, imbalance, and proper dressing. A wheel with imbalance creates vibrations and disrupts smooth contact. If your wheel is worn, it slips instead of cutting, which promotes chatter. Inadequate dressing makes the wheel dull and prevents synchronized motion. Mechanical wear introduces irregularities and amplifies vibration. The table below explains how wheel condition affects stability:

| Factor | Impact on Chatter |

|---|---|

| Wheel Imbalance | Creates vibrations disrupting smooth contact, leading to chatter marks. |

| Worn Grinding Wheel | Causes slippage instead of cutting, promoting chatter. |

| Inadequate Dressing | Dull wheel surface leads to slippage, preventing synchronized motion. |

| Mechanical Wear | Introduces imbalances and irregularities, amplifying vibrations. |

Process Parameters

You control grinding process parameters to maintain stability. High feed rates or deep cuts can cause vibration. Incorrect grinding fluid application also affects stability. You should adjust these parameters to match your machine and workpiece. Proper settings help you avoid excessive vibration and keep your grinding process stable.

Tip: Always monitor your grinding parameters and make small adjustments to improve stability and surface finish.

Identifying Chatter in Grinding

Surface Finish Signs

You can spot early signs of grinding problems by looking at the surface finish of the crankshaft. When you see unusual patterns or waves, you know something is wrong. These marks often appear as repeating lines or rough patches. You should pay attention to the texture and shine of the surface. If the finish looks uneven or has visible ridges, you may have a vibration issue.

Undesirable vibration of machine tool, workpiece, or toolholder during the cutting process forms characteristic chatter patterns in front of the surface, which vastly accentuates the roughness.

You can use a magnifying glass or a surface roughness tester to check for these patterns. If you find roughness or waves, you need to investigate further.

Sound and Vibration Clues

You can listen for unusual sounds during grinding. A steady grinding process produces a smooth, consistent noise. When you hear a high-pitched squeal or rhythmic thumping, you should check for vibration. These sounds often signal a problem with the grinding wheel or workpiece.

The vibration signal in grinding includes three main parts. Harmonic vibrations come from the unbalance of the grinding wheel or workpiece axis. Chatter vibrations result from regenerative effects. Stochastic disturbances arise from measurement system noise and uneven workpieces.

| Type of Signal | Description |

|---|---|

| Force Signal | Measures the force during grinding |

| Acceleration Signal | Captures acceleration changes |

| Motor Current | Monitors motor current |

| Sound Signal | Records grinding sounds |

| Torque Signal | Measures torque applied |

| Displacement Signal | Tracks grinding wheel movement |

You can use vibration sensors or microphones to detect these signals. If you notice spikes or irregular patterns, you should take action.

Diagnostic Tools

You can use advanced tools to analyze grinding signals and detect problems. These tools help you find the source of vibration and improve your process.

- BEMD (Bivariate Empirical Mode Decomposition) helps detect the start of vibration in grinding.

- LSSVM (Least Squares Support Vector Machine) uses time series modeling for detection.

- S-transformation extracts the damping index for inspection.

- Wavelet Transforms create feature vectors for fast identification.

- Coarse-Grained Entropy Rate acts as a vibration index and drops when problems begin.

You can combine these tools with your experience to keep your grinding process stable and efficient.

How to Prevent Chatter

Machine Setup Tips

You can prevent chatter by setting up your grinding machine with care. Start by checking the tool geometry. The right edge radius and rake angle help control vibration and clear chips. Use balanced tool holders for long shafts. These holders keep cuts smooth and improve performance. Hydraulic and shrink-fit holders grip tools tightly. They minimize tool runout and help you machine journals accurately. Live centers and steady rests support the crankshaft during turning. They stop bending from tool pressure. Modular fixtures work well for multi-axis CNC machines. They hold the workpiece firmly and allow accurate repositioning.

| Practice | Description |

|---|---|

| Tool Geometry | Correct edge radius and rake angle help control vibration and clear chips efficiently. |

| Balanced Tool Holders | Prevent chatter for long shafts, ensuring smooth cuts and optimal performance. |

| Hydraulic and Shrink-fit Holders | Minimize tool runout and grip tools tightly for accurate machining of journals. |

| Live Centers & Steady Rests | Support the crankshaft during turning, preventing bending from tool pressure. |

| Modular Fixtures | Ideal for multi-axis CNC machines, holding the workpiece firmly and allowing accurate repositioning. |

Tip: Always check your setup before you start. A stable setup helps you prevent chatter and keeps your grinding process smooth.

Aimgrind CBN Grinding Wheels for Reducing Chatter

You can achieve better results by choosing Aimgrind CBN grinding wheels. These wheels work well on hardened steels and superalloys. Their hardness and thermal stability help you grind at high speeds. You get faster cutting and cooler operation. This reduces the risk of thermal damage and helps you prevent chatter. Aimgrind CBN wheels keep their shape and sharpness. You spend less time dressing the wheel and more time grinding. The wheels come in different bond types, such as vitrified, resin, and electroplated. You can match the wheel to your grinding machine and material.

Aimgrind offers personalized selection and formula design. You get a wheel that fits your process and equipment. The service includes problem diagnosis and parameter matching. Aimgrind CBN wheels help you with precision grinding and reducing chatter. You can use them for both wet and dry grinding. They work well with coolant, which keeps the grinding area cool and clean. This helps you prevent chatter and improve surface finish.

Note: Aimgrind CBN grinding wheels are a smart choice for hard materials. They help you prevent chatter and boost productivity.

Adjusting Parameters

You can prevent chatter by adjusting your grinding parameters. Start with the feed rate. Lower feed rates help you keep the process stable. Adjust the depth of cut to avoid overloading the wheel. Use the right speed for your grinding machine. If you see vibration, change the speed slightly. This can move away from the natural frequency and prevent chatter. Apply coolant generously. Coolant keeps the grinding area cool and flushes away chips. It also reduces friction and helps you prevent chatter. Make sure the coolant flows directly to the contact point. You can use different types of coolant, such as oil-based or water-based. Choose the one that fits your material and process.

Callout: Adjusting parameters and using coolant are key steps to prevent chatter. Small changes can make a big difference in grinding quality.

Maintenance Practices

You can prevent chatter by keeping your grinding machine in good shape. Set up a regular maintenance schedule. Inspect and replace worn spindle bearings, drive belts, and other parts. Tighten all fasteners and mounting points. This keeps the machine rigid and stable. Use vibration-dampening mounts or pads. These help isolate the machine from external vibrations. Clean the machine often. Remove dust and debris that can cause imbalance. Check the coolant system. Make sure it works well and delivers enough coolant to the grinding area.

| Maintenance Action | Purpose |

|---|---|

| Implement a regular preventive maintenance schedule | To inspect and replace worn spindle bearings, drive belts, and other mechanical parts, ensuring proper function and stability. |

| Tighten all fasteners and mounting points | To ensure structural rigidity, minimizing the risk of vibrations that lead to chatter. |

| Use vibration-dampening mounts or pads | To isolate the machine from external vibrations, further reducing the potential for chatter. |

Tip: Good maintenance helps you prevent chatter and keeps your grinding machine running smoothly. Always check the coolant system for leaks or blockages.

Parts and Accessories for Reducing Chatter

Vibration Dampers

You can use vibration dampers to make your crankshaft grinding process more stable. Torsional vibration dampers absorb rotational vibrations in engines. These dampers help control the movement of the crankshaft and protect the belt drive and other parts. When you install a damper, you reduce the impact of crankshaft irregularities. This improves the durability of your engine and grinding machine. Modern engines need vibration dampers because smaller designs create more vibration. Manufacturers rely on these dampers to meet fuel efficiency and emissions goals. You get smoother grinding and less risk of chatter when you use the right damper.

Tip: Always check the damper for wear or damage. A good damper keeps your grinding operation stable and safe.

Balancing Systems

You can use balancing systems to keep your grinding wheel running smoothly. Balancing happens before grinding and after you dress the wheel. You can balance the wheel manually or automatically. Automatic systems use movable weights in the wheel flange or cup. These systems help you control vibration and improve precision. You must pay close attention to balancing in high-speed grinding. The table below shows how balancing systems work:

| Step | Description |

|---|---|

| Manual Balancing | You adjust weights by hand before grinding. |

| Automatic Balancing | The system moves weights in the wheel flange or cup. |

| Timing | Balance before grinding and after wheel dressing. |

| Importance | Balancing is key for reducing vibration and improving accuracy. |

Callout: Proper balancing keeps your grinding wheel steady and helps you achieve a better surface finish.

Fixturing Solutions

You can use fixturing solutions to hold the crankshaft firmly during grinding. Steady rests and live centers support the workpiece and prevent movement. Modular fixtures let you reposition the crankshaft for multi-axis grinding. Good fixturing stops the crankshaft from bending or vibrating. You get more accurate results and less risk of chatter. Choose fixtures that match your machine and crankshaft size. Secure fixturing is important for reducing vibration and improving grinding quality.

Note: Always check your fixtures before you start grinding. Tight fixtures help you avoid chatter and keep your process stable.

Best Practices and Troubleshooting

Troubleshooting Guide

You can solve persistent chatter and vibration by following a step-by-step approach. Start by looking for long, regular-spaced marks on the crankshaft. These marks often mean the grinding wheel is unbalanced. Use a balancing stand to fix this. If the wheel is out of round, true the sides and rebalance it. Check for loose motor mounting bolts or a loose spindle pulley. Tighten them to stop extra vibration. Make sure the motor itself is balanced. Use a sharp diamond tool for dressing the wheel. A dull tool can cause faulty dressing and lead to more chatter.

- Look for regular-spaced chatter marks. Re-balance the wheel if you see them.

- True the wheel sides and rebalance if the wheel is out of round.

- Check and tighten motor mounting bolts and spindle pulleys.

- Verify the motor balance.

- Dress the wheel with a sharp diamond tool.

Tip: Always address the most obvious issues first. Small adjustments can make a big difference.

Maintenance Checklist

You can prevent vibration and chatter by keeping up with regular maintenance. Watch for unusual vibrations or noises. These signs may point to misalignments or worn-out parts. Inspect your grinding wheels often. Dress them regularly to keep them sharp and effective. Clean the machine and check for dust or debris. Make sure all fasteners are tight. Lubricate moving parts as needed.

- Monitor for unusual vibration and noise.

- Inspect and dress grinding wheels regularly.

- Clean the machine and remove debris.

- Tighten all fasteners.

- Lubricate moving parts.

| Maintenance Task | Why It Matters |

|---|---|

| Monitor vibration/noise | Detects early warning signs |

| Dress wheels | Maintains grinding quality |

| Clean machine | Prevents imbalance |

| Tighten fasteners | Ensures machine stability |

| Lubricate parts | Reduces wear and friction |

Operator Training

You play a key role in preventing chatter and vibration. Learn how to set up the machine correctly. Understand how to balance and dress grinding wheels. Practice listening for unusual sounds during grinding. Use diagnostic tools to spot problems early. Stay updated on new grinding techniques and equipment. Good training helps you spot issues before they become serious.

Note: Well-trained operators keep the grinding process smooth and efficient. Your skills make a big difference in quality and productivity.

You can prevent chatter and vibration in crankshaft grinding by following industry best practices:

- Choose the right grinding wheel for your job.

- Dress the wheel properly.

- Use enough coolant.

- Adjust grinding parameters as needed.

- Inspect your machine and accessories.

Aimgrind CBN grinding wheels help you achieve high efficiency and quality. You can grind up to 800 crankshafts with one dressing, reach speeds of 140 m/s, and keep surface roughness as low as 0.5 μm. Proactive strategies reduce scrap, extend tool life, and save costs. Stay updated on new technologies like active tailstocks and adaptive clamping systems for even better results.

FAQ

What causes chatter in crankshaft grinding?

Chatter often comes from machine vibration, poor workpiece support, or an unbalanced grinding wheel. You can also see chatter if you use the wrong grinding parameters or a worn wheel.

How do Aimgrind CBN grinding wheels help reduce vibration?

Aimgrind CBN wheels stay sharp and balanced. You get smoother grinding and less vibration. Their hardness and thermal stability let you grind hard materials with less risk of chatter.

How often should you dress a grinding wheel?

You should dress your grinding wheel when you see surface marks or feel roughness. Regular dressing keeps the wheel sharp and helps you avoid vibration and poor finishes.

What is the best way to check for machine vibration?

You can use vibration sensors or listen for unusual sounds. A steady, smooth noise means your machine runs well. If you hear thumping or squealing, check your setup and balance.

Contact Us

For More Grinding Solution or Customized Abrasive Tools