You need to spot and fix Common Defects in crankshaft grinding to keep engines running smoothly. Proper grinding protects engine parts from damage and keeps performance high. When you use customized grinding solutions like Aimgrind diamond grinding wheels, you can lower defect rates by choosing the right wheel hardness and structure. This helps prevent thermal damage and grinding burns. Paying attention to work speed and wheel speed also makes a big difference in defect prevention.

Key Takeaways

- Proper crankshaft grinding enhances engine performance by improving fuel efficiency and reducing wear.

- Regular inspections and maintenance prevent common defects like out-of-round journals and surface cracks.

- Choosing the right grinding wheel, such as Aimgrind diamond wheels, minimizes defects and improves grinding quality.

- Always monitor grinding parameters like speed and coolant flow to avoid overheating and burn marks.

- Invest in operator training to ensure safe handling and effective defect detection during the grinding process.

Why Proper Crankshaft Grinding Matters

Engine Performance Impact

You play a key role in keeping engines running at their best. When you use crankshaft grinding, you restore the shape and surface of the crankshaft. This process helps the engine work smoothly and reduces friction. A well-ground crankshaft improves fuel efficiency and power output. You see measurable gains in engine performance after proper grinding. The table below shows how much improvement you can expect:

| Improvement Type | Percentage Improvement |

|---|---|

| Fuel Efficiency | 2-5% |

| Thermal Efficiency | Direct correlation with reduced fuel consumption and emissions output |

You also extend the life of engine parts. Optimized geometry and surface finish lead to better power and less wear. You notice fewer mechanical issues and more reliable operation. Precision machining makes the engine run quietly and reduces energy loss.

- Enhanced performance comes from a smooth surface and correct shape.

- Extended lifespan results from eliminating defects and wear.

- Improved reliability means fewer breakdowns and repairs.

Risks of Grinding Defects

Grinding defects can cause serious problems for your engine. If you miss defects during crankshaft grinding, you risk damaging the crankshaft and other parts. The table below lists common risks and their effects:

| Risk Type | Description |

|---|---|

| Stress Points | Stress concentrations can initiate cracks that propagate due to cyclic loading. |

| Corrosion and Residual Stresses | Corrosion and residual stresses can weaken the crankshaft, making it more susceptible to failure. |

| Vibration | Torsional vibrations can cause cracks and lead to fatigue failure, especially in high-performance engines. |

| Insufficient Lubrication | Inadequate lubrication can lead to bearing failure, directly affecting the crankshaft. |

| Over-Pressurized Cylinder | Excessive pressure can cause the crankshaft to bend or slip out of alignment, leading to failure. |

| Cracks | Cracks can form in high-stress areas and propagate over time, leading to total failure. |

| Bearing Issues | Improper installation or worn-out bearings can lead to uneven loading and premature fatigue. |

| Axial Clearance | Excessive axial clearance can increase stress concentrations, causing fractures and failure. |

| Dynamic Imbalance | Imbalance can generate strong vibrations, increasing bearing load and leading to fatigue. |

| Improper Grinding or Straightening | Improper techniques can introduce harmful residual stresses, making the crankshaft vulnerable to failure. |

Tip: Always check for defects after grinding. Early detection prevents costly repairs and keeps your engine safe.

You protect your engine by paying attention to every step in crankshaft grinding. This care ensures smooth operation and long-lasting performance.

Pre-Grinding Checks and Preparation

Crankshaft Inspection Steps

You need to inspect the crankshaft carefully before you start grinding. This helps you find any problems early and avoid wasting time or damaging equipment. Follow these steps:

- Remove the crankshaft from the engine block. Look for obvious damage, like broken keyways or worn thrust surfaces. Discard any crankshaft that shows severe wear.

- Use magnetic particle inspection to check for cracks or hidden flaws in the metal. This method helps you spot issues that you cannot see with your eyes.

- Complete a failure assessment. Find out which part failed and caused the damage. This step helps you prevent the same problem in the future.

Tip: Always inspect the crankshaft in a clean, well-lit area. This makes it easier to spot small defects.

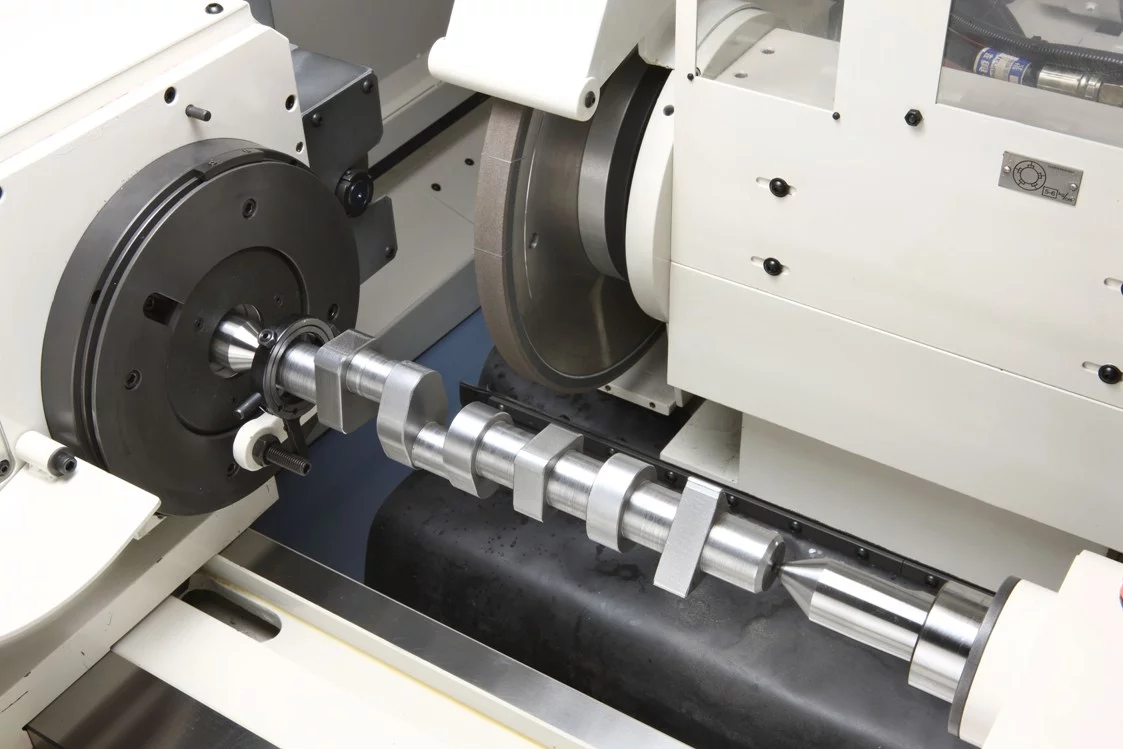

Machine Setup and Calibration

You must set up your grinding machine correctly to get the best results. Start by cleaning the machine and checking all moving parts. Make sure the workpiece is secure and aligned. Calibrate the machine to match the size and shape of the crankshaft. Double-check the settings for speed and feed rate. Proper setup helps you avoid common grinding defects and keeps your work accurate.

Choosing the Right Grinding Wheel

Selecting the right grinding wheel is important for a smooth finish and long tool life. Look at these factors:

- Grit size affects how smooth the surface will be. For most crankshaft grinding jobs, a grit size between 60 and 120 works well.

- Wheel hardness matters. Softer wheels cut cooler but may not hold their shape as long. Find the right balance for your job.

- Porosity helps with cooling and chip removal. A more porous wheel can make grinding more efficient.

Aimgrind Diamond Grinding Wheels Overview

Aimgrind diamond grinding wheels help you prevent defects and improve grinding quality. These wheels offer several features that make them ideal for crankshaft grinding:

| Feature | Benefit |

|---|---|

| Ultra-hard abrasive | Grinds tough materials with ease |

| Long service life | Reduces how often you need to change wheels |

| High grinding efficiency | Lowers the chance of defects |

| Eco-friendly | Produces less dust and waste |

| Ideal for high-speed use | Keeps precision high during fast grinding |

You can trust Aimgrind wheels to deliver consistent results and help you maintain high standards in your work.

Common Defects in Crankshaft Grinding

When you work with crankshafts, you need to watch for common defects that can affect performance and reliability. These issues often appear during or after grinding, so knowing what to look for helps you prevent bigger problems.

Out-of-Round Journals

You may notice out-of-round journals if the grinding process is not controlled. This defect often happens because of excessive steady rest pressure, spindle run-out, or poor wheel dressing. Problems with workdrive components, like loose belts or bearings, can also cause this issue.

Tapered Journals

Tapered journals appear when the grinding wheel or workpiece is not aligned correctly. You might see one end of the journal larger than the other, which can lead to uneven wear and poor engine performance.

Surface Cracks

Cracks are one of the most common defects in crankshaft grinding. You can detect these using Magnetic Particle Inspection (MPI), a non-destructive method that finds surface and near-surface cracks in ferromagnetic materials. This inspection is important for keeping your crankshaft safe and reliable.

Chatter Marks

Chatter marks are wavy lines or patterns on the surface. Chatter often comes from grinding wheel issues, such as imbalance or runout. Machine problems, like worn spindle bearings or loose parts, can also cause chatter. Poor fixture design or high feed rates may make chatter worse.

Burn Marks and Overheating

Burn marks show up when the temperature during grinding gets too high. If the core temperature rises above 220 °C, you risk grain boundary liquation, which makes the crankshaft brittle and more likely to develop cracks.

Excessive Material Removal

Removing too much material is a common defect. This weakens the shaft, removes the hardened surface, and increases the risk of fatigue failure.

| Consequence | Explanation |

|---|---|

| Reduced shaft strength | Excessive regrinding reduces the overall strength of the crankshaft. |

| Loss of surface hardening | Regrinding can remove the hardened layer, lowering fatigue resistance. |

| Increased risk of fatigue failure | Without proper hardening, the crankshaft becomes a weak point. |

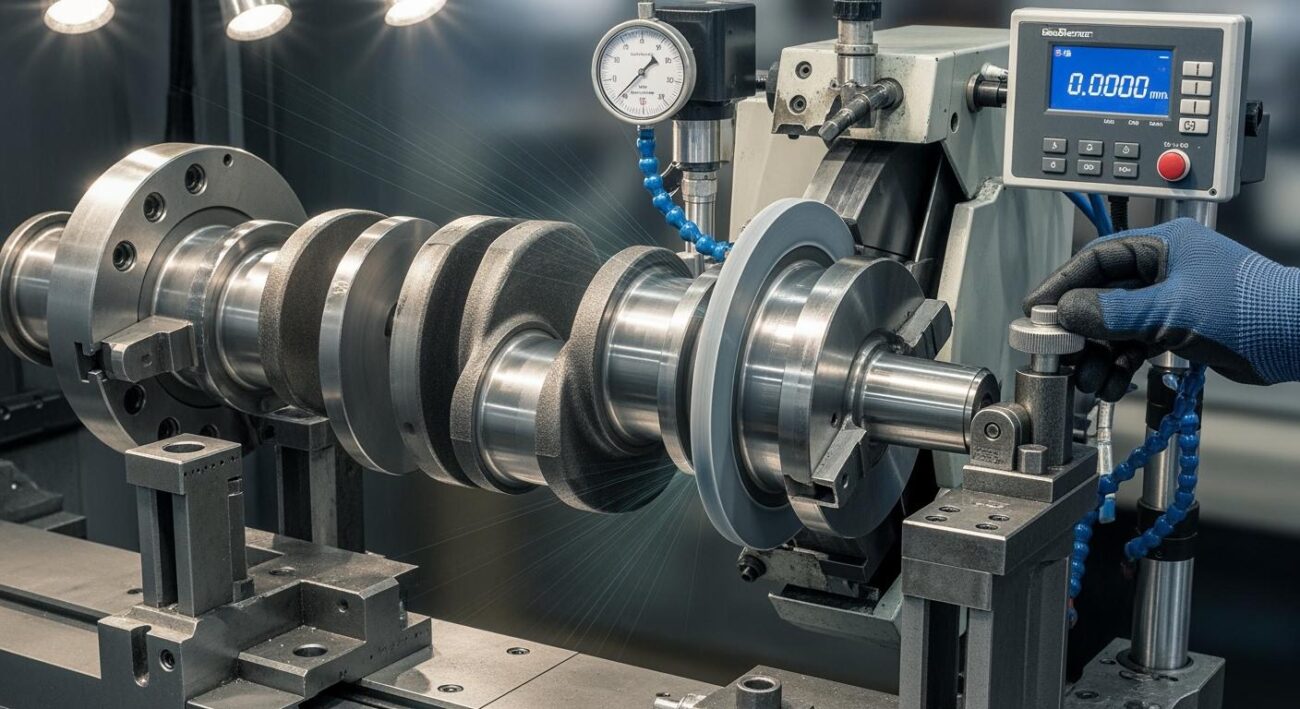

Incorrect Journal Size

You need to measure carefully to avoid this defect. Techniques like laser diffraction and microscopy help ensure the journal size is correct after grinding.

Poor Surface Finish

A poor surface finish is another common defect. Acceptable roughness values for crankshaft journals fall between Ra 0.33-0.63 μm. If the finish is rougher, the crankshaft may not work well after repairs.

Misalignment Issues

Misalignment during grinding affects oil-film thickness and journal center paths. This can cause metal-to-metal contact in bearings, leading to more wear and possible cracks.

Wheel Loading and Glazing

Wheel loading and glazing are common defects you might see. When metal particles clog the wheel, it loads up. If the wheel looks shiny and feels slick, it is glazing. You can fix these by using a coarser grit, more coolant, and proper dressing.

Tip: Industry surveys show that thermal fatigue cracks, misalignment, and lubrication issues are the most frequently reported common defects in crankshaft grinding.

Causes and Corrective Actions for Common Defects

Out-of-Round Journals – Causes & Solutions

Out-of-round journals happen when the grinding wheel or crankshaft does not move evenly. You might see this if the steady rest pressure is too high or if the spindle has runout. Poor wheel dressing or loose workdrive parts can also cause this problem.

How to fix it:

- Check and adjust steady rest pressure.

- Inspect the spindle for runout and fix any issues.

- Dress the wheel properly by bringing the diamond into contact with the center, feeding in a maximum of .002″, and traversing left and right off the edge.

- Tighten all belts and bearings in the workdrive.

Tip: Always measure journals after grinding to catch this defect early.

Tapered Journals – Causes & Solutions

Tapered journals show up when one end of the journal is larger than the other. This often happens because of poor alignment or uneven pressure during grinding.

| Process Adjustment | Solution Description |

|---|---|

| Precise Measurements | Use accurate tools to check journal size during grinding. |

| Tight Tolerances | Keep strict tolerances to avoid imbalances. |

| Advanced Techniques | Use modern machines and precision tools. |

You should also:

- Dress the wheel from the center outward to minimize spiral marks.

- Make sure the grinding wheel and crankshaft are aligned before starting.

Surface Cracks – Causes & Solutions

Surface cracks form when the crankshaft faces too much heat or stress during grinding. High grinding temperatures and mechanical stresses can tear the surface. Surface imperfections and tensile residual stresses make cracks more likely.

To prevent cracks:

- Keep grinding temperatures low by using enough coolant.

- Use smooth, even passes to avoid high mechanical stress.

- Make sure the surface is smooth to reduce stress risers.

- Try to create compressive residual stresses, which help resist cracks.

Note: Surface cracks often start at microscopic peaks and valleys. Smoother surfaces help prevent them.

Chatter Marks – Causes & Solutions

Chatter marks look like wavy lines on the crankshaft. They come from machine vibration, loose parts, or poor workholding.

You can stop chatter marks by:

- Checking and maintaining the spindle, bearings, and belts.

- Making sure the machine is stable and balanced. Use vibration-dampening pads if needed.

- Listening for unusual sounds from the motor.

- Using strong clamping devices and steady rests for support.

- Reducing feed rate and depth of cut.

- Applying coolant to lower friction and cool the workpiece.

- Adjusting wheel speed to change vibration frequency.

Tip: Secure all loose parts to reduce general vibration.

Burn Marks – Causes & Solutions

Burn marks appear when grinding generates too much heat. If the temperature gets too high, the crankshaft can become brittle and crack.

To avoid burn marks:

- Use plenty of coolant to keep the temperature down.

- Reduce grinding pressure and speed if you see signs of overheating.

- Dress the wheel regularly to keep it sharp and cool-cutting.

Excessive Material Removal – Causes & Solutions

Removing too much material weakens the crankshaft and removes the hardened surface. This makes the crankshaft more likely to fail.

| Best Practice | Description |

|---|---|

| Grinding Parameter Setting | Adjust wheel speed, feed speed, and cutting depth for the material and hardness. |

| Cooling and Lubrication | Use enough coolant to lower temperature and improve grinding efficiency. |

| Tool Geometry | Use the correct edge radius and rake angle to control vibration and chip clearance. |

Always measure material removal carefully and stop grinding once you reach the correct size.

Incorrect Journal Size – Causes & Solutions

Incorrect journal size happens when you do not measure carefully or set the machine wrong. This can cause engine problems later.

How to fix it:

- Use precise measuring tools like micrometers or laser devices.

- Double-check machine settings before grinding.

- Measure journals after each pass to stay within limits.

Poor Surface Finish – Causes & Solutions

A poor surface finish can cause oil problems and early wear. The right grinding wheel and process help you get a smooth finish.

| Grit Size | FEPA Designation | Expected RMS Finish (Resin) | Estimated Ra Value (μin) |

|---|---|---|---|

| 60 | D251 / B251 | 35 – 50 | 87 |

| 80 | D181 / B181 | 20 – 30 | 71 |

| 100 | D151 / B151 | 16 – 24 | 58 |

| 120 | D126 / B126 | 14 – 20 | 52 |

| 150 | D107 / B107 | 12 – 17 | 42 |

| 180 | D91 / B91 | 10 – 15 | 30 |

| 220 | D76 / B76 | 8 – 12 | 19 |

| 320 | D54 / B54 | 6 – 10 | 12 |

| 400 | D46 / B46 | 5 – 9 | 9 |

| 600 | D30 / B30 | 3 – 8 | 5 |

You should:

- Choose the right grit size for your finish needs.

- Use wet grinding with coolant for a better finish.

- Pick the right bond type and wheel speed.

Misalignment – Causes & Solutions

Misalignment causes uneven wear and can lead to cracks. You can fix misalignment by:

- Using peen straightening to reduce stress and straighten the crankshaft.

- Applying heat treatment to lower hardness and keep strength.

- Following precision straightening procedures to restore correct rotation.

Always check alignment before and after grinding.

Wheel Loading & Glazing – Causes & Solutions

Wheel loading happens when metal fills the spaces in the wheel. Glazing makes the wheel shiny and slick, which lowers grinding efficiency.

To fix these issues:

- Dress the wheel often to keep it sharp.

- Use a coarser grit if the wheel loads up.

- Increase coolant flow to wash away chips and keep the wheel cool.

Note: Proper coolant use helps prevent both loading and glazing.

Using Aimgrind Diamond Grinding Wheels for Correction

Aimgrind diamond grinding wheels help you solve many crankshaft grinding defects. These wheels keep their shape and sharpness, so you get consistent results. The diamond abrasive layer cuts hard materials easily and resists loading and glazing. You can use these wheels for both wet and dry grinding, but wet grinding with coolant gives the best finish and prevents overheating.

Aimgrind wheels also help reduce vibration and general vibration, which lowers the risk of chatter marks and misalignment. Their long service life means you spend less time changing wheels and more time getting quality results. When you use Aimgrind diamond grinding wheels, you improve grinding efficiency and prevent common defects in crankshaft work.

Preventive Measures and Best Practices

Routine Maintenance

You keep your equipment in top shape by following a regular maintenance schedule. Clean the grinding machine after each use. Check for worn parts and replace them before they fail. Lubricate moving parts to reduce friction. Inspect the coolant system to make sure it works well. A well-maintained machine helps you avoid unexpected breakdowns and keeps your work accurate.

Operator Training

You improve results when you invest in training. Learn how to set up the machine and select the right tools. Practice safe handling of crankshafts and grinding wheels. Understand how to spot early signs of defects. Training helps you work faster and reduces mistakes. Many shops use checklists or short quizzes to keep skills sharp.

Tip: Attend workshops or online courses to stay updated on new grinding techniques.

Quality Control Procedures

You ensure high standards by using quality control steps. Measure crankshaft journals before and after grinding. Use tools like micrometers and surface testers. Record your results in a logbook or digital system. Compare your work to industry standards. If you find a defect, fix it right away. Consistent checks help you catch problems early.

| Step | Tool Used | Frequency |

|---|---|---|

| Journal Measurement | Micrometer | Every pass |

| Surface Finish | Surface Tester | After grinding |

| Crack Inspection | Magnetic Particle | After grinding |

Optimizing Grinding Parameters with Aimgrind Solutions

You get better results when you match grinding parameters to your job. Adjust wheel speed, feed rate, and coolant flow for each crankshaft. Aimgrind diamond grinding wheels help you achieve a smooth finish and reduce defects. You can contact Aimgrind for advice on parameter selection. Their team helps you choose the best wheel and settings for your needs.

You protect your engine when you spot and fix grinding defects early. High-quality tools like Aimgrind diamond grinding wheels help you prevent many common problems. Regular checks, good maintenance, and strong training keep your work reliable.

- Use the right tools for every job.

- Check your work often.

- Keep learning new skills.

Remember: Careful grinding leads to better engine performance and longer part life.

FAQ

What is the most common defect in crankshaft grinding?

You often see out-of-round journals as the most common defect. This happens when the grinding wheel or crankshaft does not move evenly. You can prevent it by checking machine alignment and steady rest pressure.

How do you prevent burn marks during grinding?

You should use enough coolant to keep the crankshaft cool. Lower grinding pressure and dress the wheel often. These steps help you avoid overheating and burn marks.

Why should you choose Aimgrind diamond grinding wheels?

Aimgrind diamond grinding wheels give you a longer service life and high grinding efficiency. You get a smooth finish and fewer defects. You can use them for both wet and dry grinding.

How do you check for cracks after grinding?

Use magnetic particle inspection to find cracks. This method helps you see hidden flaws that you cannot spot with your eyes. Always inspect the crankshaft in a clean, bright area.

What is the best way to improve surface finish?

- Choose the right grit size for your grinding wheel.

- Use wet grinding with coolant.

- Adjust wheel speed for a smoother finish.

These steps help you get a better surface finish on crankshaft journals.

Contact Us

For More Grinding Solution or Customized Abrasive Tools