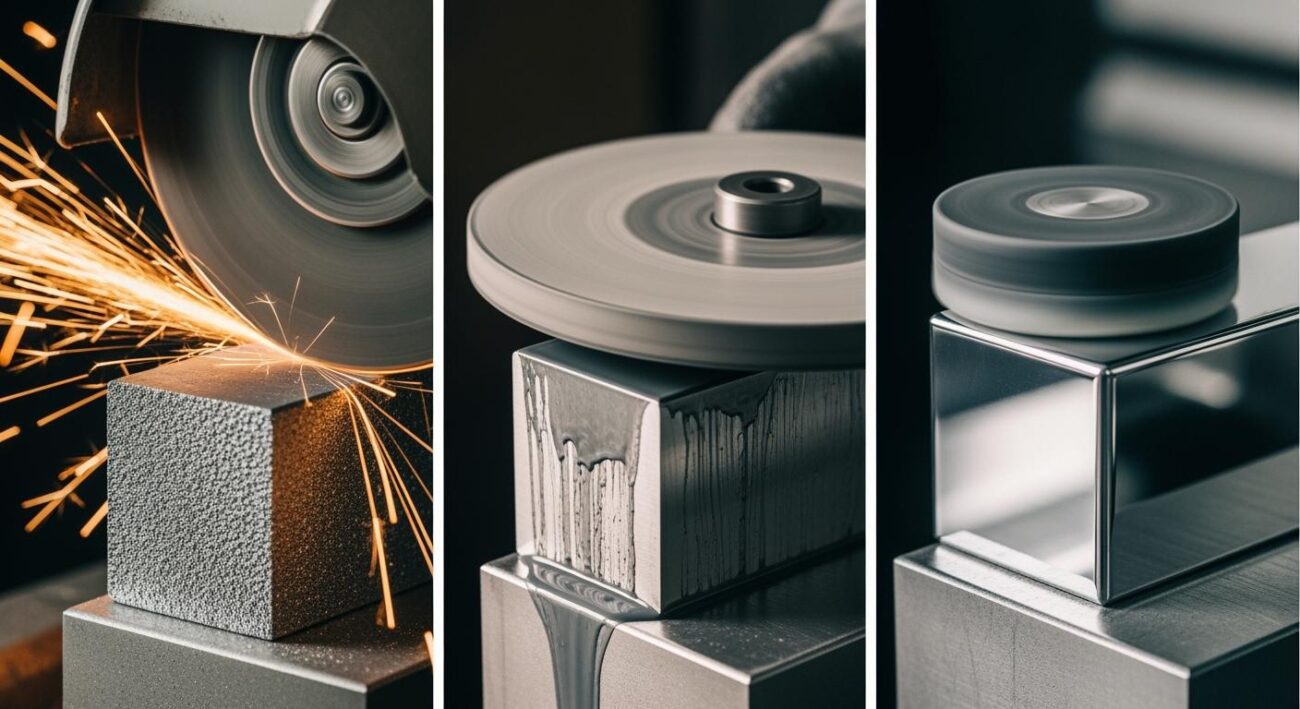

You face unique challenges when working with thin-wall aluminum parts. Precision grinding demands careful attention because these parts can deform easily and react to heat quickly. You often see issues like warping, vibration, tool deflection, and heat buildup. The right grinding wheel and setup help you avoid these problems. Aimgrind’s diamond grinding wheels give you the reliability you need for precision grinding. You achieve better finishes and keep your parts stable. Precision grinding lets you produce parts with tight tolerances and smooth surfaces. You improve your results by using the best tools and techniques for precision grinding.

| Challenge | Description |

|---|---|

| Deformation | Thin-wall aluminum parts are prone to warping due to low stiffness. |

| Vibration | Lack of rigidity causes vibrations that affect surface quality. |

| Tool Deflection | Aggressive cutting leads to tool deflection and loss of precision. |

| Heat Buildup | High thermal expansion can change dimensions and cause warping. |

Key Takeaways

- Choose the right diamond grinding wheel to prevent warping and achieve smooth finishes. Aimgrind’s wheels offer high precision and long life.

- Use low grinding pressure and effective clamping methods to minimize distortion. Soft jaws and vacuum chucks help keep parts stable.

- Control heat during grinding with proper coolant application. Synthetic coolants work best for maintaining temperature and preventing corrosion.

- Monitor tolerances closely to ensure accuracy. Regularly check measurements and adjust your process to maintain high standards.

- Prepare your workspace and tools thoroughly before grinding. A clean setup leads to better quality and fewer issues during the grinding process.

Preparation for Precision Grinding

Choosing Diamond Grinding Wheels from Aimgrind

You need the right grinding wheel for thin-wall aluminum parts. The wrong wheel can cause warping or poor finishes. Aimgrind offers diamond grinding wheels that match your needs. These wheels give you high cutting efficiency and long service life. You can choose from resin, metal, or vitrified bonds. Aimgrind helps you select the best wheel for your process. You get support for custom sizes and formulas. This ensures your grinding wheel fits your machine and your part.

When you prepare to grind machined aluminum components, you must consider the technical factors that affect accuracy and quality. The table below shows important factors to review before you start:

| Technical Factor | Description |

|---|---|

| Clamping Methods | Choosing the correct clamping method is essential to improve the accuracy of the CNC operation process. |

| Cutting Angles | The front and back angles of the tool significantly influence deformation; optimal angles reduce friction damage. |

| Cutting Paths | Unreasonable cutting methods can lead to deformation; efficient paths improve accuracy and reduce wear. |

| Processing Route | The overall processing route must be carefully planned to maintain the integrity of thin-walled components. |

You should also match the grinding wheel to the aluminum alloy group. For some alloys, silicon carbide wheels work best. For others, aluminum oxide wheels are better. Aimgrind’s diamond wheels provide a universal solution for many alloys, especially when you need high precision and a smooth finish.

Tip: Use low grinding pressure and keep the workpiece in a stress-equalized state. This helps prevent warping and keeps your machined aluminum components accurate.

Machine Setup for Aluminum

You must set up your machine carefully to avoid distortion. High-speed milling reduces cutting forces. This is important for thin-wall parts. Use a smaller tool draft to limit vibration. Always check your cooling system. Good cooling stops heat from building up and flexing the workpiece.

Here are some best practices for machine setup:

- Symmetrical machining spreads heat evenly and prevents thermal deformation.

- Stratified multiple machining processes all holes at once. This reduces unbalanced stress.

- Select the right cutting parameters. Lower cutting force and heat help prevent distortion.

- Optimize your cutting tool. The right tool material and shape reduce force and heat.

- Use effective clamping. Soft jaws and process tabs keep your part stable.

You can also follow these steps for better results:

- Use soft jaws for clamping. This prevents dimensional changes.

- Reduce residual stress. An aging process can help release internal stresses.

- Choose suitable process parameters. A modest axial depth of cut lowers cutting force.

- Control cooling and tool path. This keeps deformation to a minimum.

Note: Short length tools reduce cutting forces and increase rigidity. Necked tools reach deep into thin-walled structures and improve precision.

| Tool Type | Benefits |

|---|---|

| Short Length Tools | Reduces cutting forces, enhances rigidity |

| Necked Tools | Reaches deep into thin-walled structures, improves precision |

Workpiece Preparation

You must prepare your workspace and workpiece before grinding. Follow these steps for the best results:

- Clear your workspace. Remove flammable materials.

- Put on safety gear. Wear goggles, gloves, and a dust mask.

- Select the right grinding wheel for aluminum.

- Inspect the grinding wheel. Make sure it is not damaged and is mounted securely.

- Set the grinder speed. Follow the manufacturer’s instructions.

- Apply coolant or lubricant. This reduces heat and friction.

- Position the aluminum workpiece. Secure it to prevent movement.

- Start grinding. Use light, even pressure.

- Monitor the process. Watch for overheating or damage.

- Check your results. Look at the surface finish often.

You should always plan your process route. This keeps your thin-wall parts safe from damage. Good preparation leads to better quality and fewer problems during grinding.

Fixturing and Handling Thin Walls

Minimizing Distortion

You must pay close attention to distortion when grinding thin walls. These parts can bend or warp if you do not use the right techniques. Always control residual stresses in the material. You can do this by using stress-relieving processes like annealing before you start grinding. Try to perform all machining steps in one setup. This keeps the part stable and reduces the chance of movement. Distribute heat-generating operations around the part to avoid hot spots.

To prevent part distortion, it is crucial to control residual stresses in high-performance aluminum alloys. Techniques such as using a versatile machine to perform all operations in the same setup, distributing heat-generating operations around the part, and applying balanced machining operations after heat treatment can significantly minimize distortion.

A study on the ice fixation method shows that cooling the workpiece can improve flatness by up to 60% compared to traditional methods. This method helps you keep thin walls straight and true, especially in aerospace applications.

Support and Clamping Methods

You need the right support and clamping methods to keep thin walls from moving. Secure fixturing stops vibration and holds the part steady. Some of the best methods include:

- Vacuum chuck systems grip thin, flat parts with suction and reduce distortion.

- Custom soft jaws match the shape of your part and spread pressure evenly.

- Adhesive workholding secures very thin parts without clamps.

- Expanding mandrels hold parts from the inside, applying even pressure.

- Vacuum pods help with complex shapes and keep thin walls stable.

Leaving extra material on thin walls during grinding gives you more support. You can remove this material at the final stage for a better finish at every Z-level.

Stability During Grinding

Stability is key when you work with thin walls. Always check that your fixture holds the part tightly but does not crush it. Use vacuum suction cups for even clamping force. You can also fill the workpiece with a liquid medium to boost rigidity and reduce bending. When you grind thin parts, keep the grinding pressure low and use light passes. This helps you avoid flexing the thin walls.

| Fixturing Method | Benefit |

|---|---|

| Vacuum Chuck | Even grip, less distortion |

| Soft Jaws | Gentle, custom fit for thin walls |

| Adhesive Workholding | No clamp marks, good for thin parts |

| Expanding Mandrel | Internal support, keeps shape |

Tip: Always plan to finish thin walls at every Z-level. This approach gives you better control and a smoother surface.

You can achieve high precision and protect thin walls by following these fixturing and handling tips.

Grinding Techniques for Thin Walls

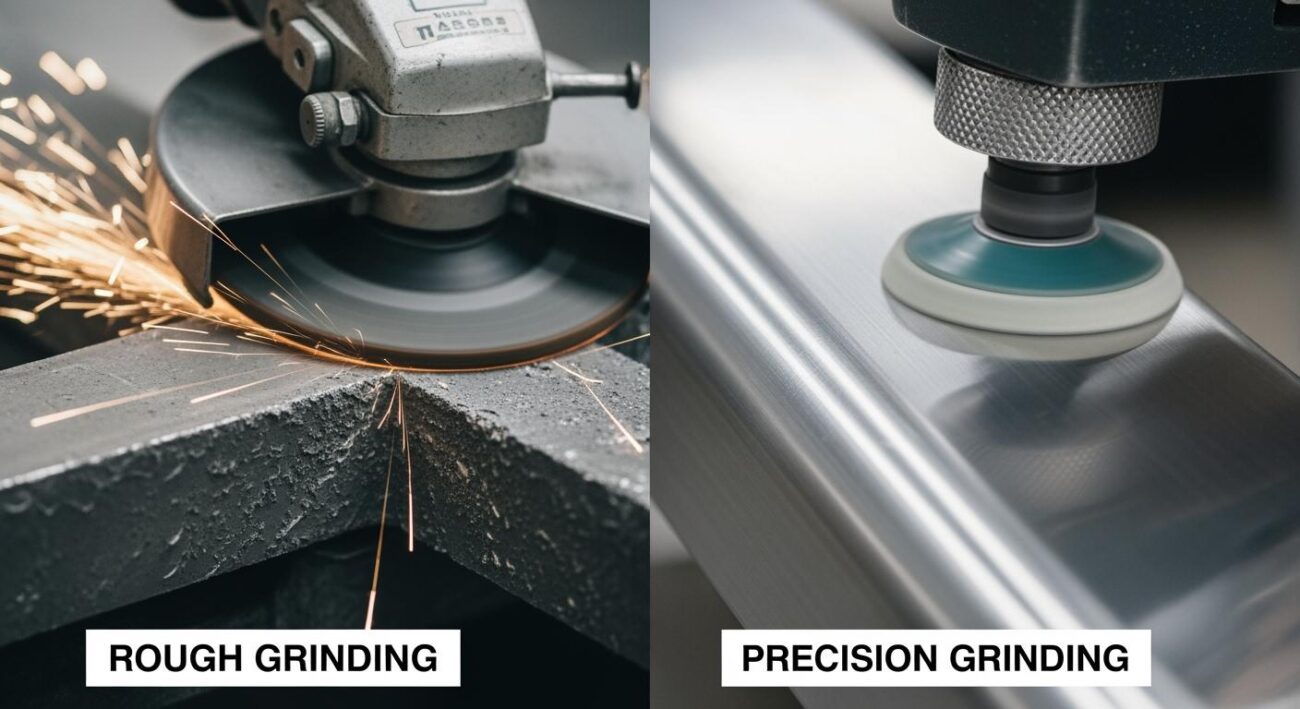

Optimizing Parameters for Precision

You must set the right parameters to achieve precision when grinding thin-wall aluminum parts. Thin walls can flex or distort if you use too much force or the wrong speed. You should always start with a low depth of cut. This keeps the grinding force low and helps you avoid bending the wall. Use a high spindle speed to reduce the contact time between the grinding wheel and the part. This method works well in cnc machining because it keeps the temperature down and improves the finish.

You should also choose the right feed rate. A steady feed rate gives you a uniform surface. If you go too fast, you may see chatter or vibration. If you go too slow, you may burn the surface. In cnc machining, you can set these values in your program for each pass. Always check your part after each pass. Look for signs of heat or warping.

Aimgrind’s diamond grinding wheels help you keep these parameters stable. The wheels stay sharp and cool, even during long cnc jobs. You get a smooth finish and less risk of distortion. You can trust these wheels for both roughing and finishing passes in cnc machining.

Tip: Use a staged roughing approach. Start with a short, strong tool for the top section. Switch to a longer, anti-vibration tool for deeper sections. This method keeps your thin walls safe and improves your results.

Climb Milling and Pass Strategy

You can improve your grinding results by using climb milling. In climb milling, the grinding wheel moves in the same direction as the feed. This method gives you a better surface finish and reduces distortion. You can see the differences in the table below:

| Aspect | Climb Milling | Conventional Milling |

|---|---|---|

| Surface Finish | Significantly improved, mirror effects below Ra 0.4 μm | More streaks and tears on the surface |

| Distortion | Reduced distortion | Higher distortion |

| Processing Time | Reduced due to lower cutting thickness | Longer due to higher cutting thickness |

| Production Efficiency | 10-20% increase in batch CNC tasks | N/A |

You should always match your pass strategy to the wall thickness and height. Here are some best practices for cnc machining:

- For a low height to thickness ratio (less than 15:1), use separate milling of each wall side in non-overlapping passes.

- For a moderate ratio (less than 30:1), alternate machining at a constant depth of cut on both side walls, also in non-overlapping passes.

- For a high ratio (greater than 30:1), use the ‘christmas tree’ routine. This means you reach the wall thickness setpoint in stages.

You can also:

- Use a staged roughing approach instead of machining a deep cavity in one go.

- Start with a short, strong tool for the top section to remove most material quickly.

- Switch to a longer, anti-vibration tool for deeper sections, slowing down the process.

- Optimize feed rates for consistent profiles.

- Decrease the duration of cutting edge contact with the workpiece by increasing cutting speed and using a low depth of cut to width ratio.

Aimgrind’s diamond grinding wheels support these strategies. The wheels cut smoothly and resist loading, which helps you keep a uniform finish. You can rely on them for both climb milling and conventional passes in cnc machining.

Note: Always check your cnc program for pass overlap. Non-overlapping passes help you avoid thin wall vibration and improve surface quality.

Avoiding Thermal Damage

You must control heat when grinding thin-wall aluminum parts. Too much heat can cause warping, softening, or even cracks. You can use several techniques to avoid thermal damage in cnc machining:

- Vibrational Stress Release (VSR): This method bends the metal at its resonance frequency. It helps release tension and keeps your part stable.

- Cryogenics: You can use liquid nitrogen to cool the part. This reduces residual tension and makes your part stronger and more resistant to wear.

- Symmetric Processing: Spread heat evenly by machining both sides of the part in turn. This prevents hot spots and keeps your part flat.

- CNC High-Speed Machining: Use high speeds and low depths of cut. This reduces the time the tool touches the part and keeps the temperature low.

Aimgrind’s diamond grinding wheels help you avoid thermal damage. The wheels stay cool and cut efficiently, even during long cnc jobs. You get less heat buildup and a better finish. You can trust these wheels for all your cnc machining needs.

Tip: Always use coolant or lubricant during cnc machining. This keeps the temperature down and protects your thin walls.

You can achieve precise, high-quality results by following these grinding techniques. You keep your thin-wall aluminum parts safe and improve your cnc machining process.

Coolant and Lubrication

Selecting the Right Coolant

You must choose the right coolant for precision grinding of thin-wall aluminum parts. The coolant you use affects heat control, surface finish, and part quality. Each coolant type has different properties. You can compare them in the table below:

| Type of Coolant | Key Properties | Suitability for Aluminum Parts |

|---|---|---|

| Water-Based Coolants | Excellent cooling, low cost, environmentally friendly | Good for easy materials, not ideal for precision aluminum |

| Oil-Based Coolants | Better lubrication, low-cost, versatile | Works well for hard materials, including aerospace aluminum |

| Synthetic Coolants | Outstanding cooling, low residue, antibacterial | Best for high-end machines and tough aluminum alloys |

| Semi-Synthetic Coolants | Combines soluble and synthetic benefits, better lubrication | Excellent corrosion resistance, great for precision aluminum |

Synthetic and semi-synthetic coolants work best for thin-wall aluminum. They keep your parts cool and clean. You get better finishes and less risk of corrosion.

Application Methods

You must apply coolant the right way to protect thin walls. Flood coolant covers the grinding area and keeps the temperature even. Minimum quantity lubrication (MQL) uses a small amount of lubricant to reduce heat and friction. For high-speed grinding, mist cooling with alcohol-based lubricants works well. It helps you keep the surface smooth and stops chips from sticking.

Coolant does more than cool your part. It also reduces friction, flushes away chips, and protects against rust. You should always match the coolant and method to your grinding process and material. This gives you the best results and keeps your parts safe.

Tip: Always check your coolant system for clean flow. Dirty or blocked coolant can cause heat buildup and damage your part.

Preventing Surface Issues

Proper coolant and lubrication prevent many surface problems. You can see common issues and how to stop them in this table:

| Surface Issue | Prevention Method |

|---|---|

| Heat Buildup | Use the right coolant mix for cooling |

| Poor Surface Finish | Keep coolant clean to avoid stains |

| Burr Formation | Use chip breakers to control chip size |

You can also:

- Switch to emulsified coolant to reduce friction and prevent scratches.

- Avoid mineral oil-based coolants if you want a clean finish, as they can leave residue.

A sharp grinding wheel is important. Dull tools can cause burrs and rough surfaces. You should always check your wheel and replace it when needed. Good coolant and sharp tools help you get the best finish on thin-wall aluminum parts.

Quality Control in Precision Grinding

Measuring Thin-Wall Parts

You need accurate measurement tools to check thin-wall aluminum parts after grinding. Ultrasonic thickness measurement gives you high precision and works well for closed structures. You can use handheld devices for flexibility. The surface must be flat and smooth for the best results. Calibration for different alloys is important. The table below shows the advantages and disadvantages of ultrasonic thickness measurement:

| Measurement Technique | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| Ultrasonic Thickness Measurement | High accuracy (±0.01 mm ~ ±0.1 mm) | Needs couplant for sound wave transmission | Quality inspection, equipment monitoring |

| Flexible and portable | Surface must be flat and smooth | Raw material evaluation | |

| Single-sided access | Requires sound velocity calibration | ||

| Measures total and coating thickness |

Tip: Always calibrate your device for the specific aluminum alloy before measuring.

Monitoring Tolerances

You must monitor tolerances closely during grinding. Industries like aerospace and automotive require tight tolerances for safety and performance. Designers set strict standards to ensure quality. You face several challenges:

- Tool deflection causes inaccuracies if you use too much force.

- Thermal expansion changes part dimensions during grinding.

- Tool wear reduces precision as you work.

- Material selection affects how well you achieve tight tolerances.

- Thin walls vibrate easily, making precision harder.

- Warping happens from heat and stress, so you need careful strategies.

You improve quality by checking measurements often and adjusting your process as needed.

Surface Finish Evaluation

You evaluate surface finish by measuring roughness and checking for defects. Grinding uses an abrasive wheel to create a smooth surface. Cylindrical grinding achieves a finish of about 4in Ra. Surface grinding can reach around 2in Ra. You get the best finish by using lower feed rates and depths of cut. A cutting tool with an 8 mm diameter works well for aluminum alloy AL 2024-T351. Three-dimensional surface topography helps you spot issues like chatter at the free end of the wall.

Note: Always inspect the surface for signs of vibration or chatter. These defects affect the quality and performance of your part.

You maintain high standards by using the right measurement tools, monitoring tolerances, and evaluating surface finish carefully.

Troubleshooting Common Issues

Warping and Distortion

You often see warping and distortion when grinding thin-wall aluminum parts. These problems can ruin your part’s accuracy and surface finish. The main causes include vibration, heat, and clamping pressure. You can see the most frequent causes and their effects in the table below:

| Failure Mode | Root Cause | Primary Consequence |

|---|---|---|

| Part Vibration (Chatter) | Tool frequency matches the part’s natural resonance. | Wavy surface, poor dimensional accuracy. |

| Thermal Deformation | Uneven heat expansion from grinding forces. | Bowing, twisting, internal stress. |

| Clamping Distortion | Part flexes under vise or clamp pressure during grinding. | Surfaces not flat or true after release. |

To reduce warping and distortion, you should:

- Use high-pressure internal cooling or flood cooling to keep the workpiece near 20°C.

- Try Minimum Quantity Lubrication (MQL) for less thermal shock during finishing.

- Avoid over-tightening clamps. Use soft jaws or vacuum chucks for gentle holding.

- Choose Aimgrind’s diamond grinding wheels, which help keep grinding temperatures low.

Tip: Cooling methods like flood cooling can lower distortion by up to 18%. Cryogenic cooling reduces distortion even more but costs more.

Burrs and Surface Defects

Burrs and rough surfaces can appear if you use dull tools or the wrong grinding parameters. You can prevent these issues by:

- Using sharp, high-quality grinding wheels, such as those from Aimgrind.

- Keeping your coolant system clean and flowing well.

- Setting the right feed rate and depth of cut to avoid tearing the material.

- Checking your part after each pass for burrs or scratches.

If you see burrs, remove them gently with a deburring tool or a fine abrasive pad. Always inspect the surface for signs of chatter or roughness. A smooth, clean finish means your grinding process works well.

Consistency in Production

You want every part to meet the same high standard. To keep your results consistent, follow these steps:

- Optimize your cutting parameters—adjust feeds, speeds, and depth of cut to reduce tool wear.

- Use specialized tools with polished flutes or chip breakers to stop chips from sticking.

- Control heat with coolant or air blast to keep the material strong and the tool sharp.

- Fix the workpiece firmly to prevent movement or vibration.

- Use symmetrical machining on both sides to spread heat evenly.

- Run test cuts to fine-tune your process for stable chip formation.

Note: Consistent setup and careful monitoring help you avoid surprises and keep your production quality high.

You can achieve precise results with thin-wall aluminum parts by following key steps. Prepare your workspace and select the right tools. Use strong fixturing to keep parts stable. Choose Aimgrind’s diamond grinding wheels for smooth finishes and less distortion. Apply these best practices to boost your productivity and quality. Keep learning and adjust your methods as you gain experience. Success comes from careful work and the right equipment.

FAQ

What makes Aimgrind’s diamond grinding wheels suitable for thin-wall aluminum parts?

Aimgrind’s diamond grinding wheels give you high precision and long life. You get smooth finishes and less heat. These wheels help you avoid distortion and keep your parts accurate.

How do you prevent thin-wall parts from warping during grinding?

You should use gentle clamping, low grinding pressure, and proper coolant. Always check your setup. Aimgrind’s wheels help reduce heat, which keeps your parts flat.

Which coolant works best for grinding thin-wall aluminum?

Synthetic or semi-synthetic coolants work best. They keep your parts cool and clean. You get better finishes and less risk of corrosion.

How often should you check the grinding wheel condition?

Check your grinding wheel before every job. Look for cracks, wear, or buildup. A sharp, clean wheel gives you better results and safer grinding.

Contact Us

For More Grinding Solution or Customized Abrasive Tools