For flawless High-Speed Steel grinding, the solution is a precise pairing: a friable aluminum oxide or advanced CBN grinding wheel with a high-pressure synthetic coolant system. This combination is the key to preventing thermal damage and achieving precision grinding. The HSS market is growing rapidly, with a projected value of USD 9.4 billion by 2030, making efficient grinding essential. This guide provides practical steps for mastering abrasive wheel selection and coolant strategy for superior precision grinding results.

Key Takeaways

- Choose the right grinding wheel for High-Speed Steel. Friable aluminum oxide works well for general use. CBN wheels are best for high-volume work and very smooth finishes.

- Balance how fast you remove material with the finish you want. Sometimes, removing material faster can make the wheel last longer and reduce heat.

- Use a soft grinding wheel with a vitrified bond for hard materials like HSS. This helps the wheel stay sharp and prevents the metal from burning.

- Use synthetic coolant with high pressure. This coolant type cools better and keeps the work area clean. High pressure helps the coolant reach the grinding spot.

- Keep your coolant clean with a good filter system. Clean coolant stops scratches and helps your grinding wheel work its best.

Part 1: Abrasive Wheel Selection for HSS

Proper abrasive wheel selection is the foundation of successful HSS grinding. The right wheel prevents thermal damage, extends tool life, and delivers the required accuracy. This choice involves more than just size; it requires a careful analysis of the abrasive grain, its bond, and the desired balance between speed and finish. Making the correct grinding wheel selection ensures efficiency and quality in every operation.

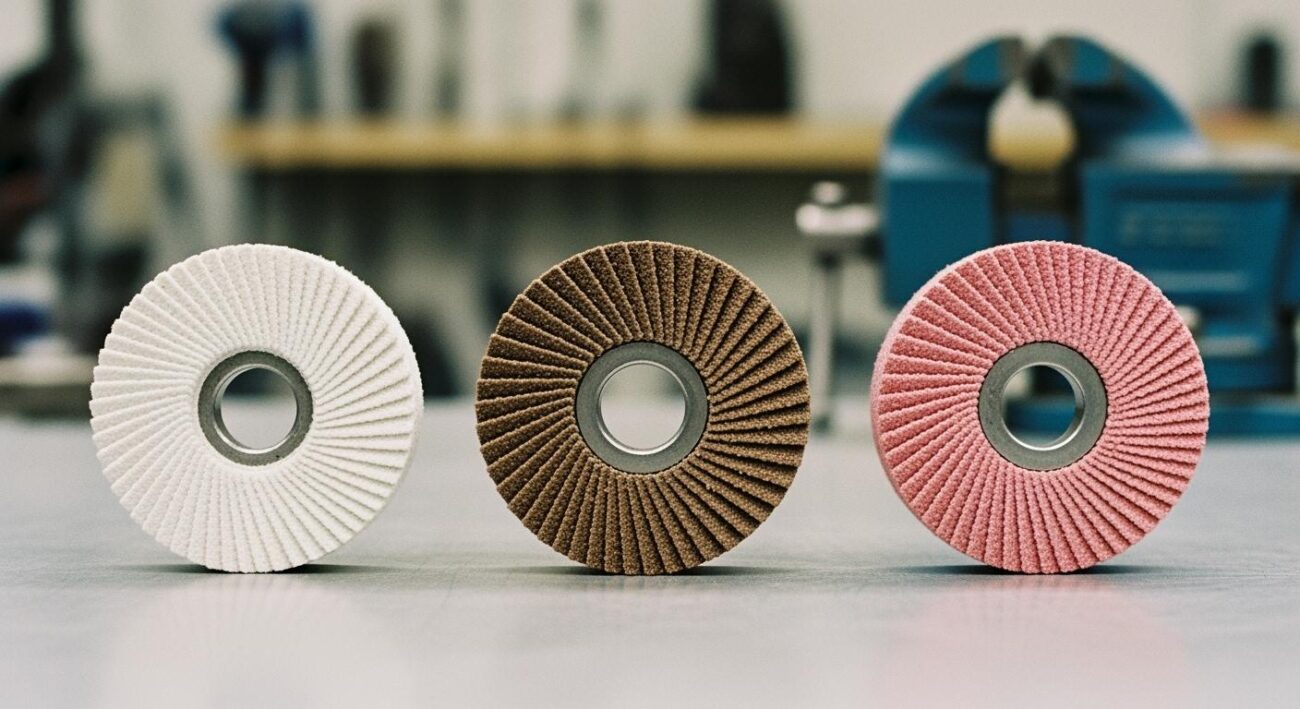

Choosing the Right Abrasive Grain

The abrasive grain does the actual cutting. Your choice of grain directly impacts the grinding temperature and final surface quality.

1. Friable Aluminum Oxide (AO): The Workhorse for HSS

Friable aluminum oxide is an excellent starting point for general-purpose HSS grinding. Its grains are designed to fracture under pressure. This self-sharpening action constantly exposes new, sharp cutting edges.

This process offers several key benefits:

- Cooler Grinding: The sharp grains slice cleanly through the metal rather than rubbing against it. This action reduces friction and prevents heat buildup, minimizing the risk of burning the HSS.

- Reduced Loading: The fracturing nature of the grain prevents the wheel from “loading” up with metal chips, ensuring a consistent cutting action.

- Finer Finishes: It produces smooth bevels and can achieve a near-honing finish on high-carbon tools.

Different types of friable aluminum oxide offer unique characteristics. The table below compares common options.

| Abrasive Type | Description | Key Characteristic | Primary Application |

|---|---|---|---|

| 38A | White Aluminium Oxide | Highly Friable | Precision grinding, cool cutting |

| 32A | Monocrystalline AlO | Strong and Sharp | Heavy-duty precision grinding |

2. Cubic Boron Nitride (CBN): The Premium Solution

For high-volume production, hardened tool steels, and achieving a superior surface finish, Cubic Boron Nitride (CBN) is the ultimate choice. CBN is the second-hardest material known, surpassed only by diamond. This property makes it ideal for the demanding task of grinding HSS.

Pro Tip: CBN’s exceptional thermal stability allows it to maintain its sharp cutting edge even at the high temperatures generated during aggressive grinding. This prevents wheel breakdown and ensures dimensional accuracy over long production runs.

For operators seeking peak performance, Aimgrind’s CBN grinding wheels are a leading solution. Engineered for longevity and precision, these wheels deliver unmatched thermal stability and a long service life. Their ability to produce consistent, high-quality results makes them an indispensable asset for any serious manufacturing or tool-sharpening operation. Explore the range of options for your precision grinding needs at Aimgrind’s CBN grinding wheels.

Balancing Finish with Removal Rate

Achieving a balance between rapid material removal and a superior surface finish is a critical aspect of abrasive wheel selection. Many operators believe a slower process yields a better finish, but this is not always true for HSS grinding.

Increasing the material removal rate (MRR) by adjusting the workpiece or wheel speed can actually improve results. A higher MRR can:

- Extend the life of the grinding wheel.

- Reduce the heat penetrating the workpiece surface.

- Improve surface quality by engaging more abrasive grains.

For applications demanding a mirror finish, the focus shifts to fine-grit wheels.

- Grit sizes of 400 and finer are used for superfinishing.

- CBN wheels are preferred for their ability to achieve a fine finish without burning the HSS.

- The goal is to achieve a low Ra (Roughness Average), indicating a very smooth surface.

Achieving this level of precision grinding requires clean coolant and a rigid machine setup to prevent any scratches or chatter marks.

Matching Bond and Hardness to Your Grinding Wheel

The bond holds the abrasive grains together. The bond’s type and hardness must match the material you are grinding. For hard materials like HSS, a softer grinding wheel is required.

Rule of Thumb: Use a soft-grade wheel (rated G to K on the hardness scale) for grinding hard materials. A harder wheel will not release dull grains effectively, leading to rubbing, heat generation, and workpiece burn.

The most common bond for precision grinding HSS is the vitrified bond. Vitrified bonds are essentially a glass-like material fused at high temperatures. They are favored for their:

- Rigidity: They hold the wheel’s form under pressure, ensuring dimensional accuracy.

- Porosity: The porous structure allows coolant to penetrate the grinding zone effectively, flushing away chips and heat.

- Strength: They are strong enough to handle high wheel speed and demanding grinding operations.

A complete grinding wheel selection strategy considers the grain, the bond, and the operational goals to create a stable, efficient, and precise system.

Part 2: Effective Coolant Strategies for HSS Grinding

A superior grinding wheel is only half of the equation for HSS grinding. Effective coolant use is the other critical component. The right coolant, applied correctly, removes heat, flushes away abrasive swarf, and lubricates the grinding interface. This prevents thermal damage, extends wheel life, and is essential for achieving the tight tolerances required in precision grinding.

Selecting the Best Coolant Type

The choice of coolant impacts everything from cutting efficiency to operator safety. For HSS grinding, synthetic coolants are the premier choice. They contain no mineral oil and offer superior cooling properties, excellent microbial resistance, and a clean operating environment.

Proper coolant selection also involves considering service life and maintenance. Different coolants have varying lifespans, which affects operational costs.

| Coolant Type | Typical Service Life (if properly maintained) |

|---|---|

| Synthetic Coolant | Up to 12 months (for large tanks); every 60 days (for small tanks) |

| Oil Coolant | Long service life (if filtered properly) |

Note on Dilution: Maintaining the correct coolant concentration is vital. For synthetic coolants, an ideal dilution ratio is between 20:1 and 10:1 (5-10% coolant in water). Always start new tank fills at 20:1. When topping off to compensate for evaporation, use a leaner ratio like 40:1 to maintain the correct balance.

Beyond performance, responsible coolant use involves health and safety. In the 1990s, organizations like the United Auto Workers (UAW) petitioned OSHA to investigate the health impacts of metalworking fluids. This led to studies confirming that prolonged exposure could cause issues like dermatitis and asthma. This history underscores the importance of choosing modern, high-quality synthetic fluids and maintaining them properly to ensure a safe workplace.

Mastering Coolant Application

How you apply coolant is just as important as the coolant itself. A spinning grinding wheel creates a stiff air barrier around its periphery. This layer of air, generated by the wheel’s high-speed rotation, can block low-pressure fluid from ever reaching the critical grinding zone.

To overcome this, you must use a high-pressure, high-volume delivery system.

- Break the Barrier: High pressure, often 1,000 psi or more, gives the coolant stream enough force to penetrate the air layer. This ensures the fluid directly cools the workpiece and wheel interface, preventing the formation of super-heated steam that leads to tool failure.

- Ensure Sufficient Flow: A high volume of coolant is needed to carry away heat effectively. A good rule of thumb is to supply approximately 1 gallon per minute for each horsepower of the grinding spindle (or 3.8 L/min per hp).

- Use the Right Nozzle: The nozzle design is critical for effective delivery. Coherent-jet nozzles are highly effective because they create a concentrated, powerful stream. This design focuses kinetic energy to pierce the air barrier and fully wet the wheel, optimizing the cooling process for precision grinding. Matching the jet velocity to the wheel speed provides the best results.

Proper coolant application is fundamental to successful grinding. It directly enables higher material removal rates, improves surface finish, and extends the life of your tools and grinding wheel.

The Role of Coolant Filtration

Clean coolant is non-negotiable for high-quality precision grinding. Contaminated fluid, filled with metal fines and abrasive particles, can cause a host of problems. It can scratch the workpiece surface, reduce cooling efficiency, and accelerate wheel wear. This is especially true when using high-performance abrasives like Aimgrind‘s CBN wheels, where clean coolant is essential to protect your investment and maintain peak performance.

Choosing the right filtration system depends on your specific grinding application, the materials involved, and your budget.

| Filtration System | Pros (Efficiency) | Cons (Efficiency) |

|---|---|---|

| Magnetic Separators | Low maintenance, no filter media cost, ideal for ferrous grinding swarf | Useless for non-ferrous metals (e.g., aluminum) |

| Paper Bed Filters | Handles mixed ferrous and non-ferrous debris, good for high-load environments | Ongoing paper cost, requires waste handling |

| Centrifugal Systems | No consumables, compact footprint, can remove tramp oils and bacteria | Higher initial cost, less effective for particles below 5 microns |

Each system has its place. Magnetic separators are excellent for ferrous materials like HSS but are ineffective for non-ferrous metals. Paper bed filters are versatile but create ongoing consumable costs. Centrifuges offer excellent filtration without consumables but come with a higher upfront cost and more intensive maintenance. A well-managed coolant use and filtration strategy is the final step in mastering the HSS precision grinding process.

Mastering HSS grinding requires the right system. The optimal setup combines a soft, vitrified bond grinding wheel with a high-performance abrasive. A high-pressure synthetic coolant system is also critical for successful precision grinding. This combination ensures a cool, efficient grinding process.

Final Tip: Always perform test grinds to perfect your results. Documenting key grinding parameters like wheel speed and surface finish helps you fine-tune your grinding parameters. This detailed approach to adjusting grinding parameters is key for consistent precision grinding and optimizing your abrasive wheel selection and overall grinding parameters for precision grinding. For expert help, consult with the specialists at Aimgrind for customized solutions.

FAQ

Why use a soft wheel for hard HSS?

A soft wheel is crucial for grinding hard materials like HSS. It allows dull abrasive grains to break away, exposing fresh, sharp edges. This self-sharpening action prevents heat buildup and ensures a clean, efficient cut without damaging the workpiece.

What makes CBN wheels better for HSS grinding?

CBN wheels provide exceptional hardness and thermal stability. They cut faster and last longer than standard abrasives. This makes them the premium choice for high-volume production and precision grinding, delivering superior finishes on hardened tool steels without thermal damage.

Is high-pressure coolant really necessary?

Yes, it is essential. A spinning wheel creates an air barrier that blocks low-pressure fluid. High-pressure coolant penetrates this barrier, directly cooling the grinding zone. This action prevents heat damage and is critical for achieving tight tolerances and a fine surface finish.

Can I use one wheel for both roughing and finishing?

It is generally not advisable.

- Roughing requires a coarser grit for rapid material removal.

- Finishing needs a finer grit for a smooth surface.

Using two different wheels for each stage of the grinding process ensures optimal results for both speed and quality.

Contact Us

For More Grinding Solution or Customized Abrasive Tools