Choosing the right grinding method is essential for your project’s success. Your decision depends on two main things: your workpiece’s shape and its material. This is a crucial skill in a growing industry. The precision grinding market is expected to expand from USD 4.9 Billion in 2024 to USD 6.9 Billion by 2030.

Quick Tip: For flat parts, you will use surface grinding. For round parts, the appropriate grinding method is cylindrical grinding. This guide will help you achieve precision and efficiency in every grinding task.

Key Takeaways

- Choose your grinding method based on the part’s shape first. Use surface grinding for flat parts and cylindrical grinding for round parts.

- Match the grinding method to the material. Hard metals need special wheels like CBN or diamond to prevent damage.

- Soft metals can clog grinding wheels. Use specific wheels and lubricants to keep them clean.

- Brittle materials like ceramics need diamond wheels. This helps avoid cracks and ensures a smooth finish.

- Using the right grinding wheel for each material is important. It helps you get good results and keeps you safe.

Choosing the Right Grinding Method by Part Shape

The shape of your workpiece is the first clue in choosing the right grinding method. Different shapes require different approaches to achieve a precise finish. This section explores the main types of grinding processes based on part geometry, helping you match your project to the perfect technique.

For Flat Surfaces: Surface Grinding

You should use surface grinding to produce smooth, flat surfaces. In this process, a rotating abrasive wheel moves over a flat workpiece. A surface grinding machine holds the part on a magnetic chuck. The wheel then removes tiny amounts of material to create a perfectly flat plane. This method is ideal for finishing mold bases, plates, and blocks with high accuracy.

Many industries rely on a surface grinding machine for critical components.

| Industry | Primary Applications |

|---|---|

| Automotive | Engine blocks, cylinder heads, brake rotors, and gear faces. |

| Aerospace | Turbine blades, structural brackets, and landing gear parts. |

| Medical | Surgical instruments, orthopedic implants, and diagnostic device housings. |

For External Cylindrical Surfaces: Cylindrical & Centerless Grinding

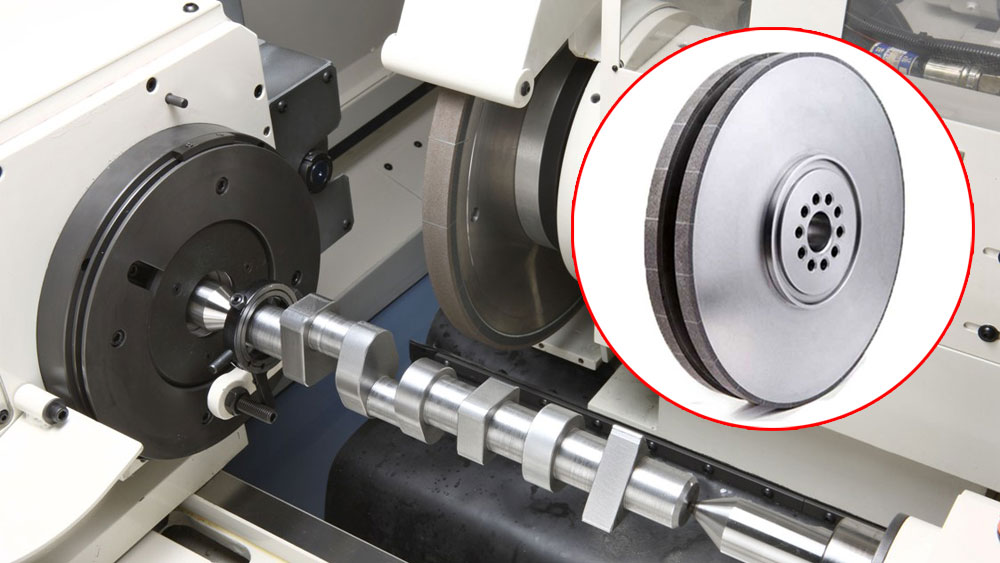

You will use cylindrical grinding for round or cylindrical parts. This process shapes the outside of a workpiece. There are two main techniques for external grinding: standard cylindrical grinding and centerless grinding.

Cylindrical grinding is perfect for parts that need high concentricity, like shafts. The workpiece is fixed between two centers and rotates as the grinding wheel removes material. You can use this for parts such as:

Centerless grinding is a highly efficient method for high-volume production. The workpiece rests on a work blade between a grinding wheel and a smaller regulating wheel. This setup eliminates the need to mount the part, making the process very fast. Centerless grinding is best for producing long, straight parts like:

- Dowel pins and rods

- Stainless steel shafting

- Small, uniform round components

Quick Comparison: Cylindrical vs. Centerless Grinding

This table helps you see the key differences.

| Feature | Cylindrical Grinding | Centerless Grinding |

| :— | :— | :— |

| Workpiece Support | Fixed between two centers | Supported by a regulating wheel and work rest blade |

| Production Speed | Slower, offers greater control | Rapid, ideal for mass production |

| Ideal Use | Parts needing precise circular dimensions | High-volume production of uniform parts |

For Internal Cylindrical Surfaces: Internal Grinding

You need internal grinding to finish the inside diameter (ID) of a workpiece. This process uses a small grinding wheel to precisely shape bores, holes, and cylinders. It is essential in industries where internal dimensions are critical for performance. The aerospace industry uses internal grinding for hydraulic cylinders and turbine components. The automotive industry uses it for cylinder bores and connecting rod bearings.

Working inside a small bore presents unique challenges.

Note: Challenges in Small-Bore Grinding ⚠️

Grinding inside a small diameter can be difficult. The confined space makes it hard for heat to escape, which can cause thermal damage. Vibration is also a common issue, leading to a poor surface finish. Using the correct wheel and coolant is critical to overcome these problems and achieve dimensional accuracy.

For Complex Shapes & Profiles: Form, Creep-Feed, & Gear Grinding

Some parts have complex shapes that standard grinding cannot produce. Specialized methods are needed for these jobs.

Form Grinding: This technique uses a grinding wheel shaped to the reverse of the part’s desired profile. It transfers that specific shape directly onto the workpiece. You can use it to create intricate geometries like turbine blades, helical gear teeth, and drill flutes.

Creep-Feed Grinding: This is a high-efficiency grinding method for removing a large amount of material in a single pass. It uses a very deep cut at a slow feed rate. This process is excellent for producing complex parts like medical implants and aerospace components from tough materials. It combines rapid material removal with a precision finish.

Gear Grinding: This is a finishing process that corrects gear tooth profiles with extreme accuracy, often after heat treatment. The grinding wheel’s ability to hold its form is critical for achieving the correct gear geometry. This process ensures gears run smoothly and quietly.

For Threads: Thread Grinding

Thread grinding creates highly precise threads on screws and other fasteners. You use a specially dressed grinding wheel to form the thread profile. This process is more accurate than thread cutting or rolling. It is essential for applications demanding high precision and repeatability.

There are several ways to perform thread grinding, including using single-rib or multi-rib wheels. The method you choose depends on the thread geometry. This precision is why thread grinding is necessary for manufacturing:

- High-precision ball screws

- Precision lead screws for machine tools

- Electromechanical cylinders

The accuracy of a ground screw ensures smooth, reliable movement in high-performance machinery.

Matching the Grinding Method to Your Material

After you select a grinding process based on your part’s shape, you must consider its material. The material’s properties—hard, soft, or brittle—determine the right abrasive, speed, and technique. This step is vital for achieving a high-quality finish and preventing damage to your workpiece.

For Hard Metals: Tool Steel & Carbide

You face unique challenges when grinding hard metals like tool steel and tungsten carbide. These materials resist abrasion, which can generate intense heat.

Warning: Avoid Grinding Burn 🔥

Excessive heat during grinding can cause “grinding burn.” This thermal damage softens or re-hardens the metal’s surface. It leads to low hardness, surface cracks, and premature part failure.

To avoid these issues, you need the right abrasive.

- For Tool Steel: You should use Cubic Boron Nitride (CBN) wheels. CBN is very effective for grinding tough tool steels that are otherwise difficult to finish.

- For Tungsten Carbide: You must use diamond grinding wheels. Diamond is the hardest material known, so it cuts carbide efficiently. CBN wheels are not hard enough and will wear out quickly, providing poor results.

For these demanding materials, methods like cylindrical grinding or creep-feed grinding deliver excellent precision. However, the grinding wheel itself is the most critical factor. With nearly two decades of experience, Aimgrind specializes in creating solutions for tough materials. Our custom diamond grinding wheels are the perfect choice for achieving precision on hard alloys and composites. They offer superior performance because they:

- Cut Efficiently: The exceptional hardness of diamond ensures clean, fast material removal.

- Reduce Heat: They are designed for low heat generation, protecting your parts from thermal damage.

- Last Longer: The durable diamond abrasive resists wear, giving you more grinding time and consistent results.

For Soft Metals: Aluminum & Copper

Grinding soft metals like aluminum presents a different problem: clogging. The heat from friction can melt the metal, causing it to stick to the wheel. This is called “loading.”

A loaded wheel creates several issues:

- It stops cutting effectively.

- It ruins the surface finish.

- It generates even more heat, creating a safety hazard.

To prevent this, you must use the right wheel and technique. You should use wheels made specifically for non-ferrous metals, such as silicon carbide wheels. Applying a lubricant like wax or a specialized coolant also helps prevent material from sticking. For flat parts, surface grinding provides an excellent finish. For high-volume production of small cylindrical parts, centerless grinding is a highly efficient method. Using the correct wheel for centerless grinding ensures you can produce thousands of parts quickly without stopping to clean a clogged wheel.

For Brittle Materials: Ceramics & Glass

Brittle materials like ceramics and glass can easily crack or chip during grinding. The hardness of these materials causes micro-cracks beneath the surface, which can lead to sudden part failure later. This makes achieving a defect-free finish a major challenge. The primary goal is to remove material without causing fractures.

You can use cylindrical grinding to successfully finish ceramic rods and tubes with high precision. The key is using an abrasive that can cut these ultra-hard materials cleanly. This is where diamond wheels are essential.

Synthetic diamond is much harder than ceramic materials like silicon carbide. Aimgrind’s diamond grinding wheels are engineered to solve the challenges of grinding brittle materials. They use high-quality diamond abrasives to:

- Minimize micro-cracking by cutting with low grinding force.

- Improve chip removal to prevent wheel clogging.

- Create smooth, precise surfaces on the hardest ceramics.

This advanced grinding method makes it possible to manufacture reliable, high-performance ceramic components. When grinding glass, you must also follow strict safety rules to prevent the wheel from fracturing. Always inspect wheels for damage and operate the machine within its specified speed limits.

You can master any grinding project with a simple, two-step approach.

- Start with Shape: First, match the grinding method to your part’s geometry—whether it is flat, cylindrical, or internal.

- Consider Material: Next, refine your choice based on the material to select the right abrasive for the job.

This process, when paired with high-quality tools from Aimgrind, is your most reliable path to a smoother surface finish. It ensures a high quality of finishing and boosts efficiency, turning complex grinding tasks into successful outcomes.

FAQ

How do I choose between cylindrical and centerless grinding?

You should choose cylindrical grinding for precise control on individual parts like crankshafts. Use centerless grinding for high-volume production of simple, uniform parts like dowel pins. Centerless grinding is much faster for mass production.

What is the biggest risk when grinding hard metals?

The biggest risk is grinding burn. 🔥 This happens when too much heat damages the metal’s surface. It can cause cracks and make the part fail. You can prevent this by using the correct wheel and technique.

Why are diamond wheels necessary for ceramics?

Ceramics are extremely hard and brittle. You need diamond wheels because diamond is harder than ceramic materials. This allows the wheel to cut cleanly without causing cracks, ensuring a high-quality finish and preventing part failure.

Can I use one grinding wheel for all materials?

No, you should not use one wheel for all jobs. Soft metals require wheels that resist clogging. Hard metals need durable abrasives like diamond or CBN. Using the right wheel for each material is essential for safety and performance.

Contact Us

For More Grinding Solution or Customized Abrasive Tools