Achieving nanometric tolerances is not about a single magic bullet. It is about the rigorous, synergistic control of several core factors. The demand for this technology in precision manufacturing is undeniable. Over 70% of semiconductor components rely on precision grinding for quality. Successful precision grinding requires exceptional accuracy. This advanced technology ensures high accuracy in all grinding operations. The foundation of excellent precision grinding is a systems approach. Mastering this precision grinding for ultimate accuracy is critical. This level of precision grinding is achievable. For successful ultra-precision grinding, you must control:

- Machine Stability

- Advanced Abrasives

- Fluid Management

- Process Optimization

- Environmental Control

Key Takeaways

- A stable machine is the base for good grinding. It needs strong parts and good spindles.

- Special diamond wheels cut hard materials well. Pick the right size and bond for the best results.

- Adjust grinding speed and depth carefully. This helps you get a smooth surface and work fast.

- Keep the grinding fluid clean. Control the temperature and stop vibrations. This makes sure the grinding is very exact.

Machine Stability for Ultra-Precision Grinding

The foundation of any successful ultra-precision grinding process is the machine itself. A machine’s stability directly impacts its ability to perform precision grinding. This stability is not a single feature but a combination of high stiffness, advanced spindle technology, and overall system design. Without this core stability, achieving nanometric accuracy is impossible. This technology is essential for modern precision manufacturing.

High Static and Dynamic Stiffness

Stiffness is a machine’s resistance to deformation under load. For precision grinding, both static and dynamic stiffness are critical. Ultra-precision machines require extreme stiffness, often greater than 1 kilonewton per micrometer (kN/µm). This high stiffness prevents the machine frame from flexing during grinding operations. Dynamic stiffness is the system’s ability to absorb vibration. Insufficient stiffness leads to chatter, which ruins surface quality.

Chatter is a harmful vibration that degrades the workpiece surface. A system with high dynamic stiffness can effectively dampen these vibrations, ensuring superior accuracy and a smooth finish in precision grinding.

Aerostatic and Hydrostatic Spindles

The spindle holds and rotates the grinding wheel. Its rotational accuracy is paramount. Advanced spindles use air (aerostatic) or fluid (hydrostatic) bearings to achieve near-perfect rotation. This technology eliminates the contact and friction found in traditional bearings. Aerostatic spindles can achieve rotational accuracy with subnanometer repeatability. Hydrostatic spindles, using high-pressure oil, offer a key advantage. They provide a much higher load capacity than aerostatic spindles. This makes them ideal for demanding precision grinding tasks. This advanced technology ensures the highest level of accuracy.

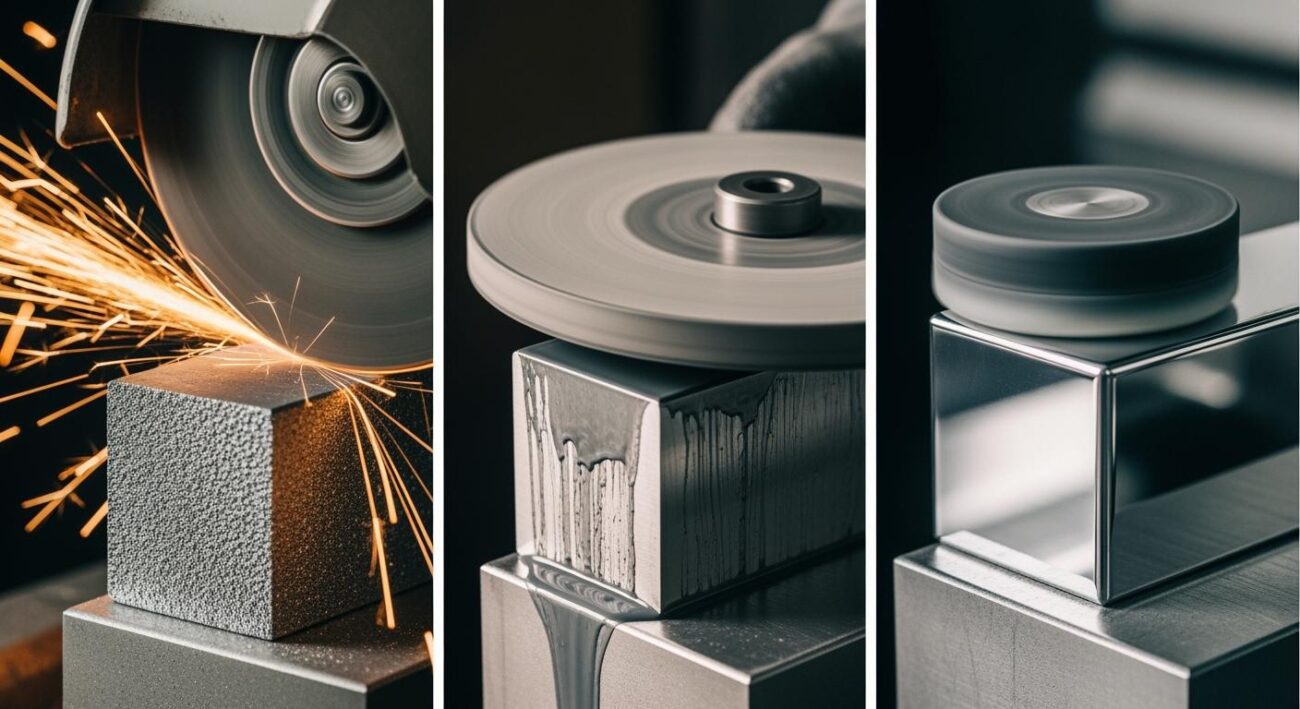

From Precision Grinding to Ultra-Precision

The journey from standard precision grinding to ultra-precision grinding is a leap in engineering. It requires a machine system where every component contributes to ultimate accuracy. This includes:

- A machine frame with exceptional stiffness.

- Spindle technology that offers nanometer-level rotational precision.

- Control systems capable of minute adjustments.

Mastering this level of precision grinding transforms what is possible. It allows for the production of components with flawless surfaces and tolerances. This commitment to stability is what separates good precision grinding from world-class precision grinding. It is the bedrock of consistent, high-level accuracy in every operation.

Advanced Abrasives: The Diamond Grinding Wheel

A stable machine is only half the equation. The cutting tool itself is equally vital. For hard and brittle materials like ceramics, sapphire, or silicon carbide, diamond grinding wheels are a necessity. They are not just an option for ultra-precision grinding. Diamond holds over 50% of the superabrasive market for a reason. Its superior hardness and wear resistance are essential for achieving nanometric finishes. This advanced technology delivers exceptional performance in demanding grinding operations.

Abrasive Type and Grit Size

The selection of abrasive grit size directly influences the final surface quality. A simple rule applies: finer grits produce smoother surfaces. For example, grinding with a fine #3000 grit diamond wheel can produce a mirror-like surface with a roughness (Ra) under 1 nanometer. Using a coarser grit creates more prominent peaks and valleys on the workpiece. This choice is fundamental to the success of precision grinding. The right grit size minimizes defects and ensures the required level of accuracy.

The Role of Bond Material

The bond material holds the diamond abrasives in place. Its properties are critical for wheel performance and longevity. The main types are resin, metal, and vitrified bonds. A stronger bond provides superior support for the abrasive grains. This allows them to remove material more effectively before breaking away.

Expert Tip: Matching the bond to the workpiece material is a key step in process optimization. A specialized provider like Aimgrind offers customized diamond grinding wheels, using deep expertise to formulate the ideal bond for your specific application. This ensures optimal performance in your precision grinding tasks.

In-Process Wheel Truing and Dressing

Even the best diamond wheel requires maintenance to sustain peak performance. Two processes are essential: truing and dressing.

- Truing restores the wheel’s geometric shape for consistent contact and accuracy.

- Dressing removes clogged material and dull grains, exposing a fresh, sharp cutting surface.

Properly dressing a wheel enhances material removal rates and improves part quality. This maintenance is crucial for all precision grinding. Modern technology offers advanced methods like laser dressing to maintain the wheel’s condition. Effective wheel care ensures reliable and efficient precision grinding.

Grinding Process Optimization

A stable machine and a superior diamond wheel are the tools. Grinding process optimization is the skill. This step involves fine-tuning every parameter to balance productivity with surface integrity. Successful grinding process optimization ensures that the theoretical capabilities of the machine and wheel are realized on the workpiece. It is the bridge between having great equipment and achieving great results in precision grinding.

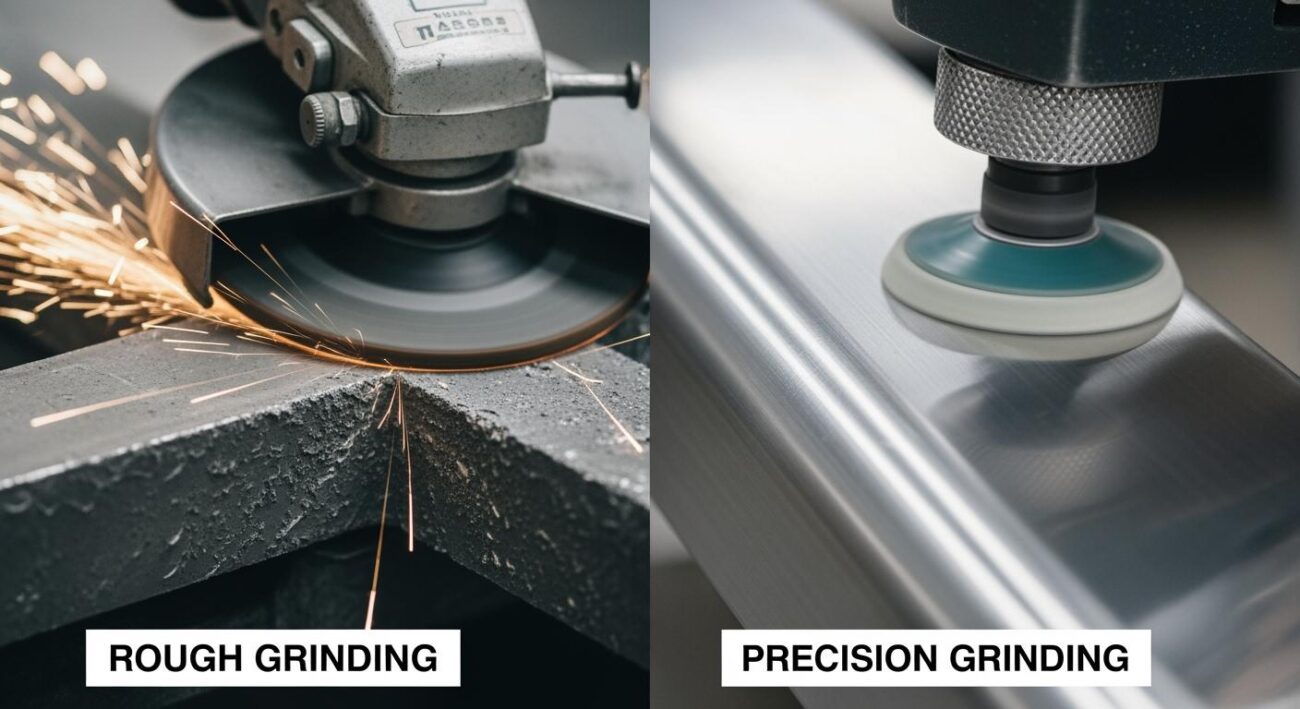

Wheel Speed and Feed Rate Control

The most fundamental parameters in any grinding operation are wheel speed and feed rate. These settings directly control the interaction between the abrasive and the workpiece. For grinding hard and brittle materials, the grinding wheel speed is typically set around 30 m/s. The depth of cut must also be carefully managed. For instance, with a fine 220-grit diamond wheel, the depth of cut might be limited to just 15 microns. This level of control is essential for successful precision grinding.

Understanding Q-Prime and G-Ratio

To truly master precision grinding, operators must understand two key performance indicators: q-prime and the g ratio. The specific material removal rate, or q-prime, measures how quickly material is removed. Its formula is Q' = ae × vw, where ae is the depth of cut and vw is the feed rate. A high q-prime value means higher productivity. Therefore, maximizing q-prime is often a goal. However, an excessive q-prime can degrade surface quality. The challenge of precision grinding is finding the optimal q-prime.

The g ratio is a crucial index of efficiency. It is the ratio of material volume removed from the workpiece to the volume of wheel wear. A higher g ratio indicates better performance and less wheel wear. Monitoring the g ratio is vital for maintaining consistent accuracy and quality. The ideal g ratio depends on many factors.

The bond material, abrasive type, and wheel hardness all influence the g ratio. A harder bond, for example, generally reduces wheel wear, which can affect the g ratio. A coarse abrasive might increase the g ratio but at the expense of surface finish. The goal is to find a balance that optimizes the g ratio for your specific application. Maximizing q-prime while maintaining a high g ratio is a core objective. A stable g ratio ensures process reliability, while a controlled q-prime delivers the desired material removal rate. This balance between q-prime and the g ratio is central to precision grinding.

Nanometer-Scale Depth of Cut

The ultimate goal of ultra-precision grinding is to achieve ductile-regime grinding. Scientific models show that even hard, brittle materials can deform plastically like soft metals if the machining depth is kept below a critical value. This advanced technology prevents the formation of micro-cracks, resulting in a flawless, mirror-like surface.

Achieving this requires controlling the depth of cut on a nanometer scale. For a material like silicon, the critical depth to ensure ductile mode is approximately 20 units. By keeping the grinding depth below this threshold, manufacturers can produce components with superior surface integrity. This level of control is a defining feature of modern precision manufacturing and the key to unlocking the highest levels of accuracy.

Grinding Fluid and Environmental Control

The machine, abrasive, and process are only part of the system. The surrounding environment plays an equally critical role. Controlling grinding fluid, temperature, and vibration is essential for achieving the highest levels of accuracy. These factors create the stable conditions necessary for successful ultra-precision grinding.

Sub-Micron Fluid Filtration

Grinding fluid is vital for cooling, lubrication, and chip removal. Inadequate fluid management leads to serious defects.

- Burning (Thermal damage): Insufficient cooling causes discoloration and surface distortion.

- Poor surface finish: Inconsistent fluid application degrades workpiece quality.

Optimizing fluid use is key. Studies show that efforts to optimize coolant delivery can reduce surface roughness by over 34%. For ultra-precision grinding, filtration must go beyond standard methods. Sub-micron filtration is required. This technology removes tiny metal chips and sludge from the fluid. Absolute filtration cartridges are often used to capture particles smaller than 10 microns. This prevents contaminants from recirculating and scratching the workpiece surface, ensuring superior quality and accuracy.

Strict Thermal Stability

Temperature fluctuations are a major threat to precision grinding. Heat causes materials to expand. Even a small expansion can push a component out of its required tolerance. This thermal effect is a significant challenge for dimensional accuracy. To combat this, the machine environment and coolant must be strictly controlled. The ideal room temperature is around 20°C, with fluctuations of less than ±1°C. Maintaining this thermal stability prevents dimensional changes in the machine and workpiece during the precision grinding process.

Foundational Vibration Isolation

Vibrations can destroy the delicate process of precision grinding. External disturbances can travel through the floor and disrupt the machine. Common sources of vibration include:

- Other machines on the shop floor, like power presses or forging hammers

- General ground excitations

Isolating the machine from these vibrations is non-negotiable. Active vibration isolation systems are superior to passive ones for this task. Active systems use sensors and actuators to cancel vibrations across a broad frequency range, even at very low frequencies. They automatically adapt to changing loads and maintain a perfectly stable platform. This advanced isolation is fundamental for any serious precision grinding operation.

Successful ultra-precision grinding is a systems-based achievement. It demands the harmonious integration of machine, tool, and process for superior precision grinding. This approach ensures the tightest tolerances and highest quality in precision manufacturing. This advanced technology delivers exceptional accuracy for every precision grinding task. Mastering these factors is the key to excellent precision grinding. It embodies the spirit of our mission:

Grind with Passion, Achieve with Aim. This is the path to world-class precision grinding and ultimate accuracy.

FAQ

What is q-prime and why is it important?

The specific material removal rate is called q-prime. A high q-prime means faster production. A low q-prime improves surface finish. The ideal q-prime balances speed and quality. Your target q-prime depends on the job. This makes q-prime a critical process parameter.

How do you optimize the q-prime value?

You optimize q-prime by adjusting feed rate and cut depth. A higher q-prime is aggressive. A lower q-prime is gentle. Testing helps find the best q-prime for your material. This optimal q-prime prevents surface damage while maximizing efficiency. The right q-prime is essential.

What does the g ratio measure?

The g ratio measures grinding efficiency. It compares the volume of material removed to the volume of wheel wear. A high g ratio indicates less wheel wear and better performance. This metric is vital for process stability and cost control.

Why are custom diamond wheels necessary for ultra-precision?

Standard wheels cannot meet ultra-precision demands. Hard materials require specific diamond grits and bonds. A custom wheel from a specialist like Aimgrind ensures the tool is perfectly matched to your material and process, delivering superior accuracy and performance.

Contact Us

For More Grinding Solution or Customized Abrasive Tools