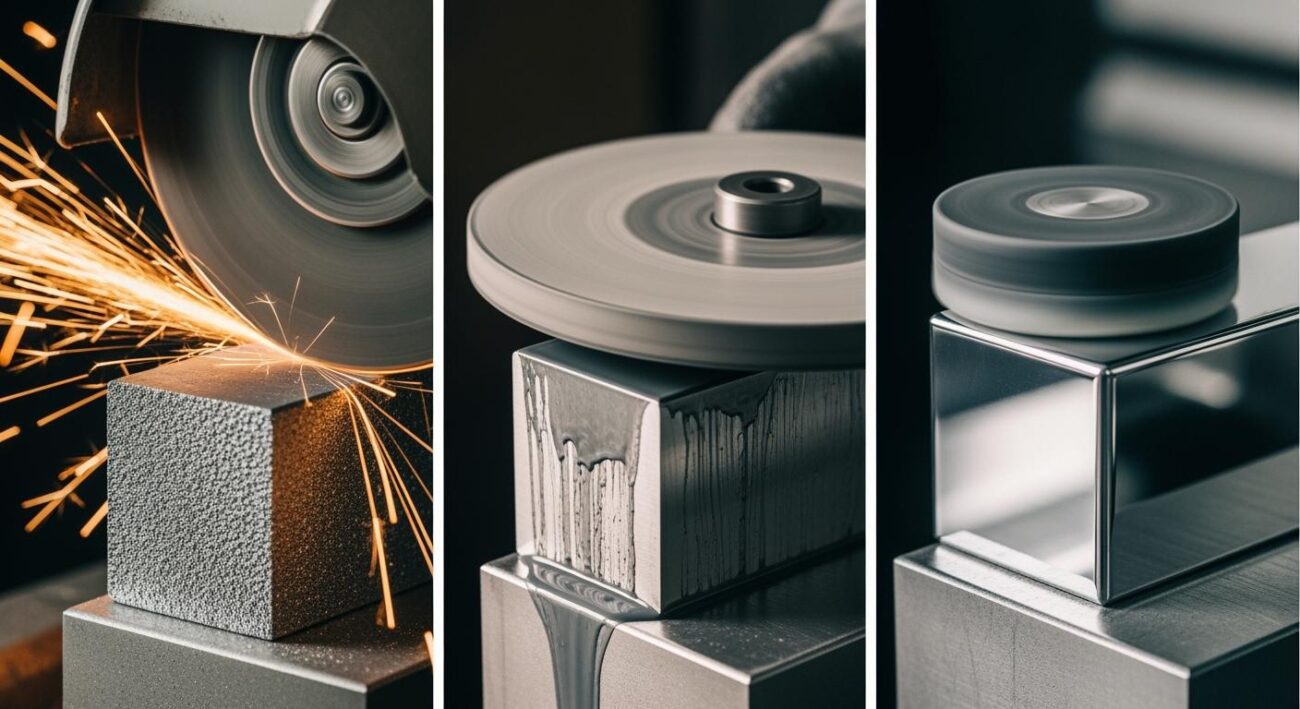

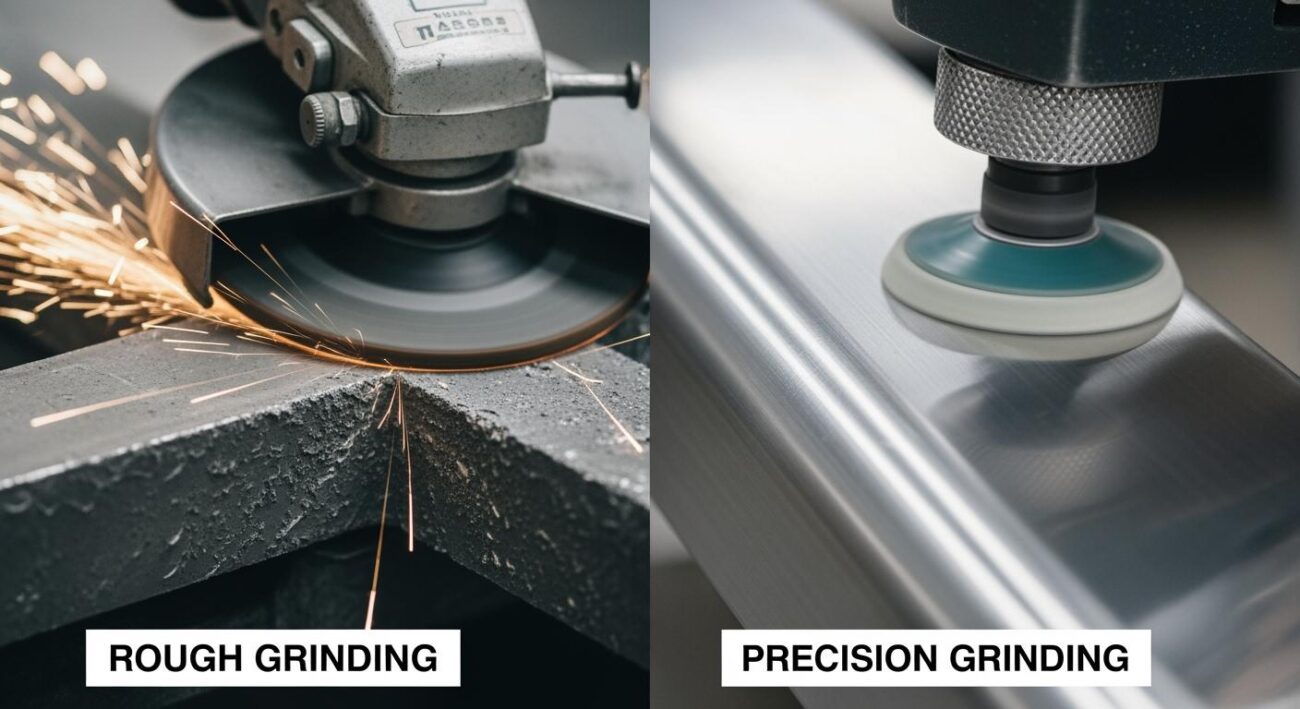

Achieving nanometer-level accuracy in ultra-precision grinding presents significant obstacles. The demand for high-precision parts is rising, with the market growing steadily.

- The ultra-precision machine market is projected to reach $0.75 billion by 2030.

- North America held the largest market share in 2023.

Engineers face key challenges in meeting these tight tolerances. The primary difficulties include thermal instability, machine vibration, and the challenges of grinding difficult materials. Fine process control and real-time measurement are also key challenges for successful grinding operations. This guide helps professionals navigate these technical hurdles.

Key Takeaways

- Thermal stability is important. Heat causes parts and machines to change shape. This makes grinding less accurate.

- Machine stiffness stops vibrations. Vibrations cause errors and bad surfaces. Strong machines help make perfect parts.

- Grinding hard materials is difficult. Special tools are needed for ceramics and strong metals. These tools prevent damage and wear.

- Precise control is key. You must prepare the grinding wheel carefully. You must also control how much material you remove.

- Measuring during grinding helps. Sensors check parts as they are made. This allows for quick fixes and better accuracy.

Thermal Stability and Deformation

Thermal stability is a critical factor in ultra-precision grinding. Uncontrolled heat creates thermal deformation. This distortion is a primary barrier to achieving nanometer-level tolerances. Both the workpiece and the machine itself are vulnerable to heat-related inaccuracies. Managing this thermal energy is essential for consistent and precise outcomes.

Managing Grinding Zone Heat

The grinding zone is a major source of intense heat. Most of this heat does not come from the cutting action alone. Instead, it results from the rubbing and plowing actions of abrasive grains against the workpiece. This friction generates significant thermal energy right at the point of contact.

Effective cooling is necessary to remove this heat. However, applying coolant is not simple. A rotating grinding wheel creates a surrounding air cushion. This barrier of turbulent air can block fluid from reaching the contact area. To overcome this, engineers use advanced strategies.

- Minimum Quantity Lubrication (MQL): Delivers a fine mist of oil in compressed air for targeted cooling.

- Cryogenic Cooling: Uses liquefied gases like nitrogen to drastically lower temperatures.

- Optimized Nozzles: Coolant nozzle speeds are matched to the wheel’s cutting speed for better penetration.

Countering Machine Thermal Expansion

Heat generated during the grinding process does not stay in one place. It travels from the workpiece into the machine’s structure. This causes components like the spindle and machine bed to expand. Even a microscopic expansion can throw off the final dimensions of a part.

Key Insight: Thermal expansion in the core materials of the grinding wheel itself can also cause dimensional changes. This reduces precision. Using materials with low thermal expansion coefficients for both the machine and the wheel is crucial for maintaining accuracy.

Certain grinding modes, such as creep-feed grinding, can help stabilize thermal expansion. However, the fundamental solution lies in a system designed for thermal stability. This includes internal cooling channels in the machine structure and selecting materials that resist heat-induced growth.

Machine Stiffness and Vibration

Machine stiffness is the foundation of ultra-precision grinding. Even the smallest amount of flex or vibration in the machine structure can ruin a workpiece. These unwanted movements introduce errors that are larger than the nanometer-level tolerances required. A rigid and stable machine is essential for achieving the highest levels of accuracy and surface quality.

Eliminating Micro-Vibrations

Micro-vibrations are tiny, high-frequency movements that occur during the grinding process. They are a major cause of chatter marks and poor surface finish. These vibrations can come from the machine’s motors, external sources, or the cutting action itself. Controlling them is a significant engineering challenge.

Engineers use advanced damping systems to combat these vibrations. These systems fall into two main categories:

- Passive Damping: These systems absorb energy without external power. They often use materials that dissipate vibration as heat.

- Active Damping: These systems use sensors and actuators to counteract vibrations in real time. For example, piezoelectric actuators can be controlled to actively cancel out chatter, significantly improving the machine’s dynamic behavior.

By integrating these damping technologies, manufacturers can create a more stable platform for precision grinding operations.

Ensuring Spindle and Wheel Rigidity

The spindle is the heart of a grinding machine. Its rigidity directly impacts the final part accuracy. A stiff spindle resists deflection under load, ensuring the grinding wheel maintains its precise position. High-rigidity spindles are critical for achieving tight tolerances.

Key Insight: Advanced spindles often use hydrostatic or air bearings instead of traditional roller bearings. Hydrostatic bearings provide exceptional damping—up to 100 times greater than roller bearings—and high stiffness, which prevents heat-related errors and allows for superior accuracy.

The required rigidity varies by application, with high-rigidity grinding spindles demanding exceptional stiffness to maintain precision.

The grinding wheel’s bond system also contributes to overall rigidity. A rigid bond, like a metal or vitrified bond, holds the abrasive grains securely. This helps the wheel maintain its shape, which is crucial for precision form grinding on hard materials. However, the bond must match the machine’s power. A powerful, rigid machine can effectively use a hard bond, while a less rigid machine may require a softer bond to prevent vibration and ensure a quality finish.

Key Challenges in Grinding Difficult Materials

The properties of the workpiece material introduce significant key challenges for ultra-precision grinding. Standard abrasives often fail when machining advanced materials. This failure leads to rapid tool wear, surface damage, and an inability to meet tight tolerances. Specialized abrasive solutions are therefore critical for success.

Grinding Brittle Materials

Brittle materials like ceramics, silicon, and zirconia are essential for many modern technologies. However, their hardness and brittleness make grinding them extremely difficult. Improper grinding techniques can cause severe surface and sub-surface damage.

These defects limit the component’s lifespan and can lead to catastrophic failure. Common failure modes include:

- Sub-surface cracks

- Microcracking

- Pulverization of material grains

- Median and lateral cracks

Achieving a smooth, damage-free surface requires a specialized approach called ductile-regime grinding. This process removes material without creating fractures. It depends on highly engineered tools. Brands like Aimgrind focus on creating customized grinding wheels for these applications. For example, Aimgrind’s diamond grinding wheels use specific bond and grit compositions to enable ductile-regime grinding, preventing micro-cracks and ensuring high surface integrity.

Machining High-Strength Alloys

High-strength alloys are another difficult category. These materials are designed to perform under extreme conditions. Examples include nickel-based superalloys like Inconel, cobalt-based alloys, and hardened bearing steels used in aerospace. Their inherent properties make them resistant to conventional grinding.

The low thermal conductivity of these alloys causes intense heat buildup in the grinding zone. This heat leads to rapid tool wear and can damage the workpiece surface. The material may also adhere to the grinding wheel, reducing its effectiveness. Overcoming these key challenges is essential for producing reliable high-performance components. The solution lies in using advanced abrasive tools. Aimgrind’s diamond grinding wheels are engineered to withstand high temperatures and minimize wear when processing tough alloys, directly addressing these difficult grinding issues.

Sub-Micron Process Control

Achieving sub-micron precision requires exceptional command over every process variable. The machine’s hardware provides the potential for accuracy. However, realizing tight tolerances depends entirely on how the grinding process is managed. This level of control separates standard machining from true ultra-precision work. Two areas are especially critical: preparing the grinding wheel and managing material removal.

Precise Wheel Dressing and Truing

The condition of the grinding wheel surface directly impacts the final workpiece finish. Precise wheel dressing and truing are not just maintenance tasks; they are fundamental process control steps. The goal is to create a specific wheel topography for finishing.

Dressing parameters are key to this process. A higher dress aspect ratio, for instance, creates duller abrasive grains. These grains are less aggressive but produce a much smoother surface finish. Similarly, using multiple shallow dressing passes instead of one deep one cleans the wheel and refreshes its surface without creating sharp grains.

Advanced techniques further enhance this control:

- ELID-assisted dressing can reduce wheel run-out errors.

- Electro-contact discharge (ECD) truncating uses thermochemical removal to improve wheel stability.

These methods ensure the wheel is perfectly prepared for the delicate task of nanometer-level finishing.

Controlling Nanometer Depth of Cut

Ultra-precision grinding involves removing material in incredibly small increments. The depth of cut can be 1 µm or even less. Controlling these nanometer-level adjustments is a significant technological challenge. It requires sophisticated control systems that operate in real time.

Modern machines achieve this using multi-axis motion controllers. These systems use feedback from high-resolution encoders and sensors to make microscopic adjustments.

- Voice Coil Drives provide smooth motion with no backlash.

- Direct Drive Stages offer rapid response for high-resolution positioning.

- Laser-Based Autofocus can track the workpiece surface for continuous adjustments.

This combination of robust hardware and intelligent software allows operators to control the grinding depth with nanometer precision, which is essential for creating components for the semiconductor and aerospace industries. This level of control in precision grinding is what makes sub-micron accuracy possible.

Accurate In-Process Metrology

Ultra-precision grinding demands more than just a stable machine; it requires the ability to see and react to microscopic changes in real time. You cannot control what you cannot measure. Accurate in-process metrology provides the critical data needed to close the feedback loop, turning a good process into a perfect one. This involves measuring both the workpiece surface and the condition of the grinding wheel itself.

On-Machine Surface Measurement

Removing a component for off-machine inspection introduces delays and potential re-alignment errors. On-machine surface measurement solves this problem. This method creates an iterative feedback loop for continuous correction.

The process often follows these steps:

- A grinding pass is completed.

- A profiler measures surface errors directly on the machine.

- CAM software analyzes the error data.

- The software generates new, corrected NC codes for the next grinding pass.

Advanced non-contact systems like White Light Interferometry (WLI) provide even greater detail. These optical profilers offer sub-nanometer vertical resolution. This allows them to measure the finest surface finishes with extreme precision, ensuring the part meets its final specifications without ever leaving the machine.

Real-Time Tool Wear Compensation

The grinding wheel wears down during operation. This wear directly affects the final dimensions and quality of the part. Real-time tool wear compensation uses sensors to monitor and correct for this degradation automatically. Instead of direct visual inspection, this method relies on indirect signals.

Sensors monitor machine data like spindle motor current, vibration, and even acoustic emissions. A change in the sound of the grinding process, for example, can indicate wheel wear. Adaptive control systems use this real-time data to make immediate adjustments. The system automatically calculates the necessary tool offset and sends feedback to the CNC control. This closed-loop process adjusts machining parameters on the fly, compensating for tool wear to maintain consistent quality and precision.

Successfully navigating the key challenges of ultra-precision grinding—thermal effects, vibration, material processability, control, and metrology—demands a unified strategy. This requires a systems-level approach that considers the machine, abrasive, and grinding parameters together.

Future progress in precision grinding hinges on continuous innovation. This includes advancements like AI-enhanced controls and the development of custom abrasive solutions. These innovations are essential for pushing the boundaries of what is possible in high-precision manufacturing.

FAQ

How do micro-vibrations affect surface finish?

Micro-vibrations introduce tiny movements during grinding. These unwanted motions create chatter marks and waviness on the workpiece surface. This directly prevents the achievement of a smooth, nanometer-level finish. Effective damping systems are essential to eliminate these microscopic errors and ensure high surface quality.

Why are special grinding wheels needed for ceramics?

Ceramics are hard and brittle. Standard abrasives can cause micro-cracks and sub-surface damage. Specialized tools are required for ductile-regime grinding. For instance, Aimgrind’s diamond grinding wheels are engineered with specific bonds and grits to remove material without causing fractures, ensuring surface integrity.

What is in-process metrology?

In-process metrology is the measurement of a part during the manufacturing process. It uses on-machine sensors to check dimensions and surface finish in real time. This data provides immediate feedback to the control system, allowing for automatic corrections to improve accuracy without stopping production.

How does thermal expansion impact grinding accuracy?

Heat from grinding causes both the machine and workpiece to expand. This thermal growth changes their dimensions, leading to significant inaccuracies. Even a microscopic expansion can ruin a part’s tolerance. Managing heat with advanced cooling and stable machine design is critical for precision.

Contact Us

For More Grinding Solution or Customized Abrasive Tools