Thermal distortion is a critical challenge in form grinding. It directly compromises part accuracy and integrity. Effectively managing thermal energy is the key to success. Operators can minimize distortion by mastering a toolkit of thermal controls. This thermal approach reduces thermal stress on the workpiece.

A Three-Pillar Approach to Thermal Management This comprehensive thermal strategy gives you direct control over thermal generation and its effects. It focuses on three core methods for achieving thermal stability:

- Optimizing machine parameters.

- Implementing advanced thermal cooling.

- Strategic wheel selection.

This complete thermal system works together to protect your parts.

Key Takeaways

- Control machine settings to stop heat. Adjust wheel speed, depth of cut, and feed rates. This prevents parts from getting too hot.

- Use good cooling methods. High-pressure coolant and proper nozzle placement remove heat. Cryogenic cooling helps very sensitive materials.

- Pick the right grinding wheel. Wheels with special materials and porous designs create less heat. Keep the wheel sharp with regular dressing.

- Combine all three methods for best results. Using good settings, strong cooling, and the right wheel works best. This stops thermal distortion.

Optimize Parameters for Preventing Part Distortion

Your machine’s settings are the first line of defense in preventing part distortion. Fine-tuning grinding parameters gives you direct control over thermal energy. This control is essential to stop heat before it causes problems. A careful approach to these settings can significantly reduce thermal stress and minimize distortion.

Control Wheel Speed to Lower Heat

Wheel speed directly impacts how much thermal energy enters the workpiece. A faster wheel often generates more friction and heat. This excess thermal energy can lead to thermal softening of the material’s surface. For heat-sensitive alloys, a lower wheel speed is better.

Pro Tip for Sensitive Materials

Industry studies recommend a wheel speed between 15 to 20 m/sec for materials like Inconel or titanium. This slower speed reduces thermal buildup and helps prevent thermal softening.

Adjust Depth of Cut for Less Thermal Load

The depth of cut determines how much material is removed in one pass. An aggressive, deep cut creates a large thermal load. This can cause rapid thermal expansion and damage the part. Using smaller, incremental cuts is a safer strategy. This approach manages the thermal input, preventing the workpiece from overheating and avoiding thermal softening. A lower thermal load protects the part’s final shape and integrity.

Manage Feed Rates to Avoid Localized Heat

Feed rate is the speed at which the workpiece moves past the grinding wheel. A feed rate that is too fast can concentrate thermal energy in one area. This localized heat leads to thermal softening and can cause warping.

- Slower Feed Rates: Allow more time for heat to dissipate. This prevents dangerous thermal spikes.

- Creep-Feed Grinding: This technique uses a very slow feed rate with a high depth of cut. It is effective for some materials because it produces thicker chips that carry away more thermal energy.

Properly managing these parameters is a proven method to fight thermal distortion. Optimization techniques have shown great success in achieving accuracy by controlling the thermal effects of the grinding process and preventing thermal softening.

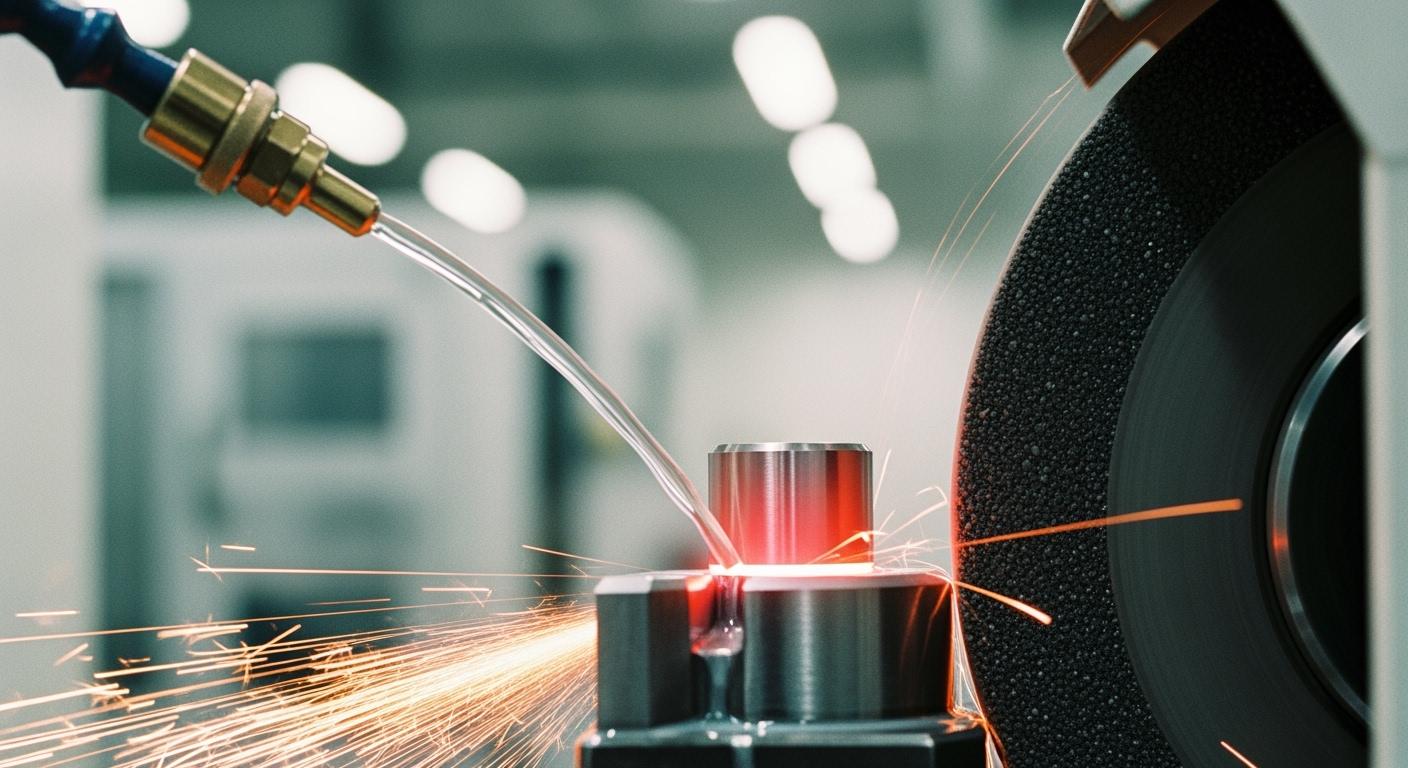

Use Advanced Cooling to Manage Thermal Distortion

Proper cooling is your second pillar for thermal control. While optimizing parameters reduces heat generation, advanced cooling actively removes the thermal energy that is created. An effective cooling strategy is essential to prevent thermal softening and minimize distortion. This involves more than just flooding the part with fluid; it requires a precise and powerful approach.

Apply High-Pressure Coolant

High-pressure coolant systems are a game-changer for thermal management. These systems deliver fluid at pressures often between 600 to 800 psi. This high pressure is strong enough to break through the vapor barrier that forms around the grinding wheel.

The Power of Pressure

The vapor barrier acts like a thermal shield, preventing standard flood coolant from reaching the cutting zone. High-pressure jets penetrate this barrier. This ensures the fluid directly cools the wheel and workpiece, dramatically reducing thermal buildup and the risk of thermal softening.

This method significantly improves part quality and can increase tool life by over 300%. It is a powerful tool against thermal softening.

Optimize Coolant Nozzle Placement

Where you aim the coolant is just as important as how much you use. Poor nozzle placement can waste fluid and fail to cool the most critical areas. The goal is to create a hydraulic wedge that flushes away hot chips and provides constant thermal regulation. Engineers often use Computational Fluid Dynamics (CFD) models to find the perfect nozzle angle and distance. This scientific approach ensures the coolant provides even heating and cooling, preventing thermal shocks that cause thermal softening.

Use Cryogenic Cooling for Sensitive Materials

For extremely heat-sensitive materials like superalloys, cryogenic cooling offers a superior solution. This advanced technique uses liquid nitrogen or CO2 to super-chill the grinding zone.

- Benefits: It provides excellent thermal control, leading to better surface quality and preventing thermal softening.

- Drawbacks: Cryogenic systems require special equipment, including safety monitors for oxygen levels and protective gear for operators.

While more complex, it is an unmatched method for protecting delicate parts from thermal damage and avoiding thermal softening.

Prevent Thermal Softening with Proper Cooling

Thermal softening occurs when the grinding process heats a workpiece surface beyond its tempering temperature. This excessive thermal energy causes the material to lose its hardness and strength. This is a major cause of part failure. Effective cooling is the direct countermeasure to thermal softening. By efficiently removing thermal energy, a good cooling system keeps the workpiece temperature stable. This prevents the material from ever reaching the point of thermal softening. A robust thermal management plan is key to avoiding thermal softening and achieving the desired part integrity. This is crucial for preventing thermal distortion.

Select and Condition Wheels to Reduce Heat

The final pillar of thermal control is the grinding wheel itself. Your choice of wheel and how you maintain it directly impacts thermal generation. A well-chosen and conditioned wheel cuts efficiently, creating less friction and less thermal energy. This is fundamental to preventing thermal softening.

Choose the Right Abrasive and Bond

The materials that make up your wheel are critical for thermal management. Superabrasives like Cubic Boron Nitride (CBN) have much higher thermal stability than conventional abrasives. This property allows them to cut hardened steels with less thermal input, reducing the risk of thermal softening. For top-tier thermal performance, brands like Aimgrind specialize in these solutions. They offer high-performance CBN grinding wheels known for their cool cutting action and thermal stability, which directly helps overcome thermal distortion.

The bond material also plays a role.

- Vitrified Bonds: Offer excellent heat resistance and have a porous structure that promotes cooler cutting. This helps prevent thermal softening.

- Resin Bonds: Have lower thermal resistance, making them less suitable for applications with high thermal loads where thermal softening is a concern.

Utilize Porous Wheel Structures

Modern wheels can be engineered with porous structures. These wheels contain a network of internal channels. This design helps solve a common problem: the air barrier. A fast-spinning wheel creates a barrier of air that blocks coolant. Porous structures allow coolant to flow through the wheel, delivering it directly to the cutting zone. This active thermal cooling removes heat efficiently. It also provides space for hot chips to be flushed away, preventing thermal buildup and thermal softening. The thermal benefits are significant, leading to less thermal softening.

Implement Effective Dressing Routines

A wheel becomes dull and clogged with use. This increases friction and generates dangerous levels of thermal energy, causing thermal softening. Dressing is the process of cleaning and sharpening the wheel’s surface. An effective dressing routine removes clogged material and exposes fresh, sharp abrasive grains. A sharp wheel cuts freely with less force. This action produces less thermal energy, which is key to preventing thermal softening. Regular dressing is not just maintenance; it is an active strategy for thermal control to avoid thermal softening.

Controlling thermal effects in grinding involves three core methods: optimizing parameters, using advanced thermal cooling, and selecting the right wheel. These methods are most effective when used together. A combined thermal strategy delivers the best thermal results. For example, a combined thermal approach in aerospace showed significant thermal improvement:

| Industry | Approach | Outcome |

|---|---|---|

| Aerospace | Combined approach (Digital Twin & topology optimization) | Up to 40% reduction in thermal distortion-related defects |

A systematic thermal plan is the key to preventing thermal distortion and achieving precision. This total thermal control ensures success.

Grind with Passion, Achieve with Aim.

FAQ

What is the main cause of thermal distortion?

The primary cause is excessive thermal energy. This thermal buildup makes the material expand unevenly. This uneven thermal expansion leads to warping. Proper thermal management is key. This thermal issue is a common challenge. The goal is to control this thermal effect.

How does coolant pressure help with thermal control?

High pressure breaks the vapor barrier around the wheel. This allows coolant to remove thermal energy directly from the grinding zone. Better thermal regulation prevents thermal damage. This thermal strategy is very effective. It is a key part of any thermal management plan.

Why is wheel selection important for thermal management?

The right wheel generates less thermal friction. Superabrasives have high thermal stability. They cut cooler, reducing the thermal load on the part. This choice directly impacts thermal control. A good wheel is a great thermal tool. This reduces the overall thermal stress.

Can changing machine settings really prevent thermal issues?

Yes. Optimizing parameters is your first defense against thermal problems. Slower speeds and smaller cuts reduce thermal generation. This proactive thermal control stops heat before it builds up. It is a fundamental thermal principle. This is a core thermal strategy.

Contact Us

For More Grinding Solution or Customized Abrasive Tools