Form grinding solutions offer high-precision manufacturing for complex cutting tools. These advanced grinding solutions use a specialized grinding wheel and precise CNC programming. The CNC machine guides the grinding wheel with exceptional precision. This precision grinding process shapes a tool blank into a high-performance finished product. The demand for such advanced tools is a key driver in the cutting tool production market.

Note: The industry’s growth highlights the importance of effective grinding.

Metric Value Market Size (2025) USD 35.67 billion Projected Market Size (2034) USD 96.56 billion Compound Annual Growth Rate (CAGR) 11.70% (2025-2034)

This rapid expansion underscores the need for superior grinding and manufacturing capabilities to create the next generation of tools.

Key Takeaways

- Form grinding makes complex cutting tools with high precision.

- Advanced technologies like CNC control and simulation improve grinding accuracy and prevent mistakes.

- Super hard abrasives, such as diamond and CBN, are important for grinding tough materials effectively.

- Automation and robots help factories make more tools faster and with better quality.

- Modern grinding solutions create very precise tools and make production more efficient.

Core Form Grinding Solutions

Modern cutting tool production relies on several core form grinding solutions. Each method offers unique advantages for creating high-performance tools. These grinding solutions combine advanced machinery and smart processes. They deliver the precision and efficiency manufacturers need.

Creep-Feed Grinding for Deep Profiles

Creep-feed grinding is a powerful process for creating deep, complex shapes in a single pass. This technique uses a slow feed rate with a large depth of cut. It is ideal for producing tools with deep flutes or intricate “fir-tree” forms used in aerospace parts. The main benefit is a massive increase in material removal efficiency. This single-pass grinding approach reduces total machining time.

Note: The material removal rate of creep-feed grinding far exceeds conventional methods, making it highly productive for specific applications.

| Grinding Method | Specific Material Removal Rate Q’w [mm³/ (mm·s)] |

|---|---|

| Conventional Surface Grinding | 0.5 to 4 |

| Creep-Feed Grinding | 8 to 80 |

This high-efficiency grinding is possible because the grinding wheel remains in contact with the workpiece longer, completing the profile quickly.

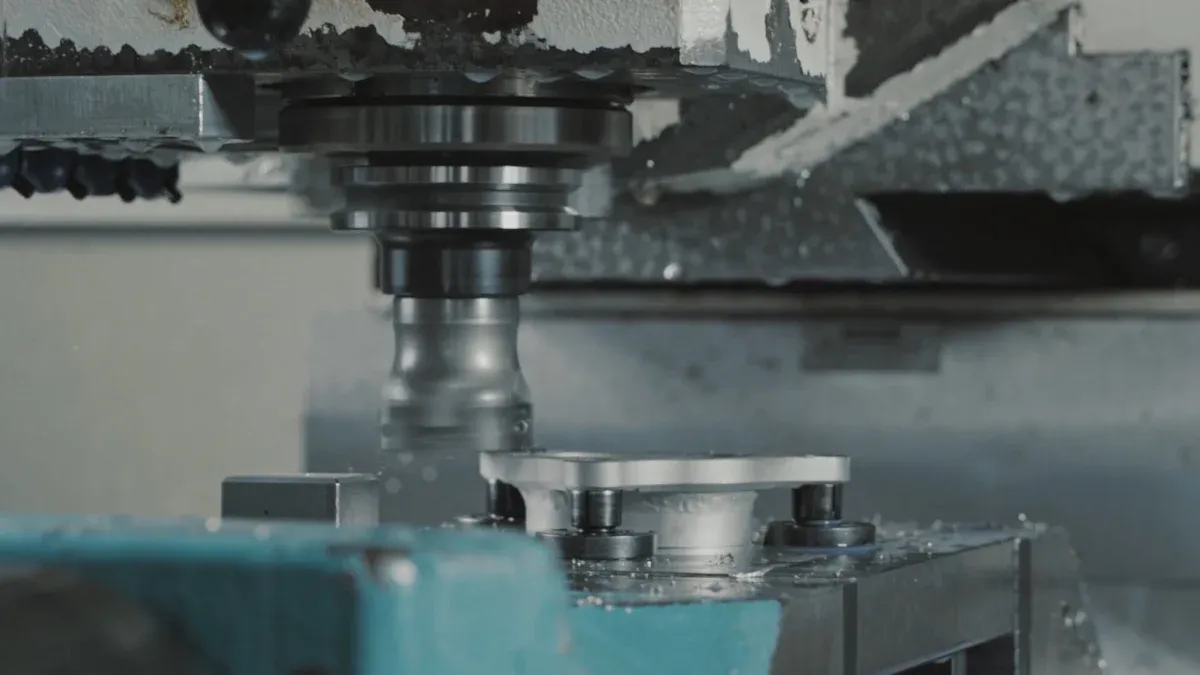

CNC Profile Grinding for High Versatility

CNC profile grinding provides exceptional versatility for manufacturing custom tools. CNC grinding machines use computer programming to guide the grinding wheel with incredible precision. This allows for the creation of complex geometries, such as variable-helix end mills designed for specific materials like aluminum. The CNC system can produce a wide variety of custom tools, from tapered end mills to multi-diameter step tools. The precision of CNC grinding ensures every tool meets exact specifications. The CNC process is essential for modern tool making.

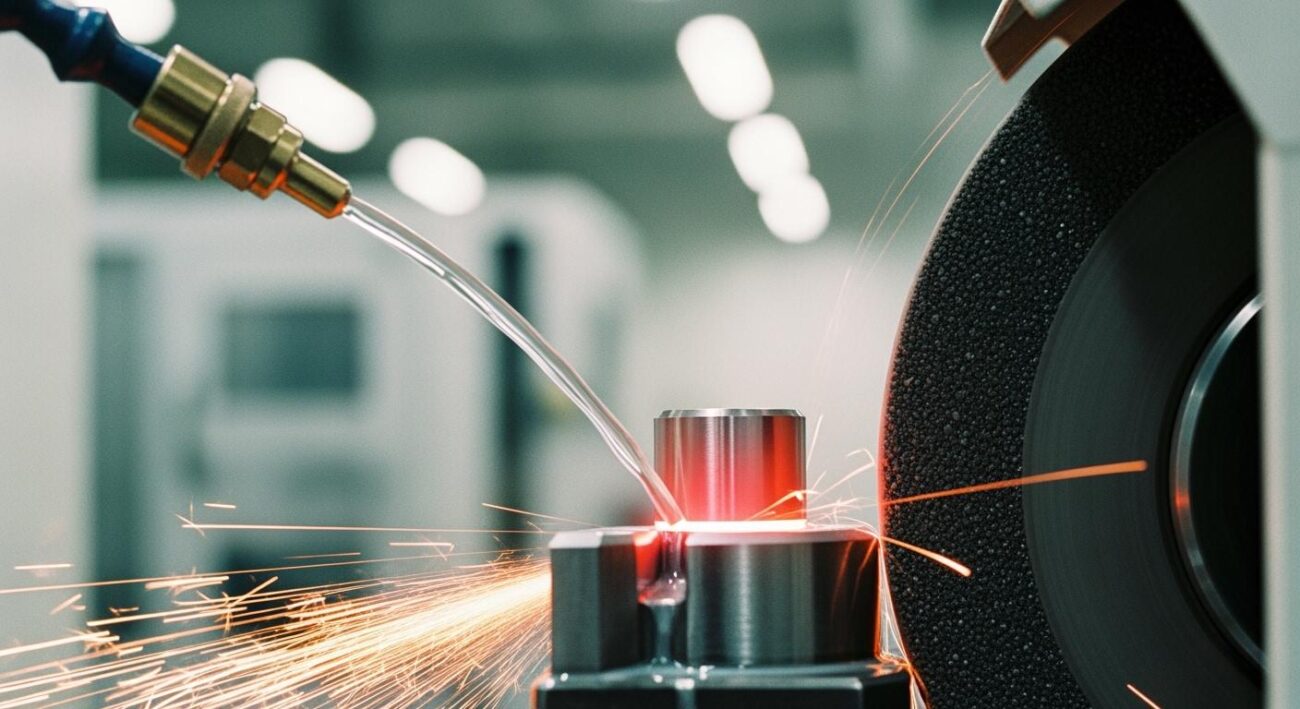

In-Process Dressing for Continuous Accuracy

In-process dressing keeps the grinding wheel in optimal condition during the grinding operation. A sharp and clean grinding wheel is crucial for maintaining precision. Dressing removes worn grains and reshapes the grinding wheel. This ensures consistent performance from the first tool to the last.

Several advanced dressing systems are used:

- Rotary Diamond Dressers: These rotating tools reshape the grinding wheel with high accuracy. They can create complex profiles and extend the life of the grinding wheel by over 50%.

- CNC Dressing Systems: These automated systems use CNC controls for dressing the grinding wheel. They offer high repeatability and can make real-time adjustments for superior precision grinding.

- Laser Dressing: A newer method that uses a laser to soften the grinding wheel material, making it easier for a diamond dresser to work. This improves dressing quality and efficiency.

These CNC-controlled dressing techniques are vital for continuous, high-quality production of cutting tools.

Key Technologies in Modern Grinding

The evolution of form grinding solutions is driven by several key technologies. These advancements in machinery, software, and materials work together. They enable the manufacturing of cutting tools with unprecedented precision and efficiency. Understanding these technologies is essential for any modern manufacturing operation.

Advanced CNC Control and Simulation

Modern CNC systems are the command center for high-precision grinding. These controls translate a digital design into precise machine movements. This allows for the creation of incredibly complex tool geometries. However, the complexity of CNC programming also introduces risks. A small error in the code can damage the workpiece, the grinding wheel, or the machine itself.

This is where CNC simulation software becomes invaluable. It creates a virtual environment to test the entire grinding process before it begins. This digital twin approach helps prevent costly mistakes and optimizes the grinding operation. Key features include:

- 3D Collision Detection: This feature simulates all moving parts, including the grinding wheel, workpiece, and machine components. It identifies potential collisions in real-time, allowing programmers to correct the CNC code and prevent tool breakage.

- Virtual Material Removal: This function shows a 3D visualization of how the grinding wheel will shape the tool blank. It verifies that the final tool geometry is correct and ensures the material removal process is efficient and accurate.

Using CNC simulation, manufacturers can perfect the grinding process digitally. This reduces setup times, minimizes waste, and guarantees the quality of the final tools.

Aimgrind’s Super Hard Abrasives

The grinding wheel is the heart of any grinding operation. Its performance directly impacts the quality and efficiency of the entire process. For hard materials like tungsten carbide and High-Speed Steel (HSS), standard abrasives are not enough. This is where Aimgrind‘s super hard abrasives provide a critical advantage. These advanced grinding solutions use diamond and Cubic Boron Nitride (CBN), two of the hardest materials known.

The choice between diamond and CBN depends on the material being ground. Using the correct abrasive is crucial for achieving optimal grinding performance.

| Abrasive Type | Best for Grinding | Why It’s the Best Choice |

|---|---|---|

| Diamond Wheels | Tungsten Carbide, Ceramics, Glass | Diamond is the hardest substance. It cuts through carbide efficiently with minimal heat and wear, ensuring superior precision. |

| CBN Wheels | High-Speed Steel (HSS), Hardened Steels | CBN is chemically neutral to iron at high temperatures. It avoids the rapid wear that diamond experiences when grinding steel-based materials. |

Beyond the abrasive material, the bond holding the grains together is equally important. Aimgrind offers different bond types for its grinding wheel products, each designed for specific applications:

- Vitrified Bond: This rigid bond provides excellent heat resistance and shape retention. It is perfect for high-precision grinding of carbide tools.

- Resin Bond: This bond offers more flexibility, resulting in smoother grinding and better surface finishes. It is ideal for grinding tough materials like stainless steel.

- Metal Bond: This is the strongest bond, offering exceptional durability and the longest tool life. It is used for the most demanding grinding of hard and brittle materials, including carbide.

Leading CNC tool grinding machines from brands like WALTER, ANCA, and UNITED GRINDING rely on high-performance abrasives to reach their full potential. A superior grinding wheel from Aimgrind ensures these advanced machines can produce the highest quality carbide tools and other precision components.

Automation and Robotic Integration

Automation is transforming the cutting tool manufacturing landscape. Integrating robots and automated systems into grinding cells boosts productivity, improves consistency, and enhances worker safety. One of the most significant applications is automated tool loading and unloading.

Robots can work 24/7 without breaks, significantly increasing machine uptime. For example, aerospace manufacturer Kemco Aerospace integrated a FANUC robot to tend three CNC machines, leading to a major increase in efficiency and new business. This “lights-out” manufacturing capability allows production to continue around the clock.

Automation in grinding extends beyond just robotics. Advanced systems are used for other critical tasks:

- Automated Quality Control: Systems like the Zeman™ ENSPECTOR™ can automatically identify, inspect, and sort finished parts, ensuring every tool meets strict quality standards.

- In-Process Measurement: High-precision measurement systems can be integrated directly into the grinding cell. They provide real-time feedback to the CNC, allowing for automatic adjustments to maintain tight tolerances.

The benefits of automation are clear and measurable. Companies implementing these technologies report faster cycle times, reduced downtime, and maximized spindle utilization. By automating repetitive tasks, manufacturers can free up skilled operators to focus on higher-value activities, driving further innovation and efficiency in their grinding operations.

Benefits of Advanced Grinding Solutions

Advanced grinding solutions provide major benefits for cutting tool manufacturing. They improve the quality of tools and make the entire process more effective. Manufacturers who adopt these technologies gain a significant competitive edge. The right grinding solution is essential for modern production.

Achieving Superior Precision and Finish

Modern grinding delivers exceptional precision and surface quality. This precision is vital for creating high-performance tools that meet tight tolerances. Form grinding solutions produce a finish that other methods cannot easily match. For example, grinding can achieve a much smoother surface on carbide than processes like EDM or sandblasting.

The quality of tools depends heavily on the grinding process, as industry standards like ISO do not define minimum requirements for precision or finish. A superior grinding wheel and process are therefore critical.

| Method | Roughness Outcome (Ra) |

|---|---|

| Grinding | 0.2 – 0.8 μm |

| Lapping | 0.05 – 0.2 μm |

| Polishing | 0.05 – 0.3 μm |

| EDM | 1.0 – 3.2 μm |

This level of precision grinding ensures every tool performs reliably.

Enhancing Production Efficiency

High-efficiency grinding solutions directly boost manufacturing productivity. Techniques like creep-feed grinding dramatically reduce cycle times. This improved grinding efficiency helps lower costs and increase output. Key benefits include:

- Cycle times reduced by up to 50 percent.

- Scrap rates lowered by as much as 90 percent.

- Grinding wheel life extended by 50 percent.

These improvements help manufacturers optimize production processes. Better efficiency means more tools can be made in less time, increasing profitability. The overall grinding performance is a major factor in a company’s success.

Versatility for Complex Cutting Tools

Modern grinding solutions offer incredible versatility. A single CNC grinding machine can produce both standard and custom tools. This flexibility is possible due to multi-axis control and advanced software. The machine can create simple flat surfaces or complex curved profiles without changing fixtures. This allows manufacturers to serve a wider range of customer needs. For example, C&S Machine Products Inc. used advanced grinding technology to expand into making high-precision parts for the aerospace and medical industries. This versatility is key to growing a business and adapting to new market demands.

Modern form grinding solutions are essential for high-performance cutting tools. The best grinding solutions combine machinery, software, and quality abrasives from Aimgrind. This synergy boosts manufacturing efficiency and the quality of grinding. Adopting these grinding solutions is key for manufacturing. It helps create precision tools for new industries, improving production efficiency.

Advanced grinding software improves overall efficiency. This smart grinding approach optimizes the manufacturing of every tool. The grinding process ensures all tools meet high standards for grinding performance. The grinding of these tools requires careful grinding, and the future of grinding is smart grinding.

FAQ

What is form grinding?

Form grinding is a manufacturing process. It uses a specialized grinding wheel to create precise, complex shapes on cutting tools. This method is essential for making high-performance tools like:

- End mills

- Drills

- Custom inserts

Why are CNC machines important for form grinding?

CNC (Computer Numerical Control) machines provide the extreme precision needed for form grinding. They follow digital instructions to guide the grinding wheel. This automation guarantees that every tool is made to exact specifications with high repeatability.

Why use super hard abrasives like diamond or CBN?

Super hard abrasives are perfect for grinding tough materials.

- 💎 Diamond wheels cut hard materials like tungsten carbide.

- ⚙️ CBN wheels are best for grinding steels like HSS.

These abrasives from brands like Aimgrind last longer and create a superior finish.

What is the purpose of in-process dressing?

In-process dressing keeps the grinding wheel sharp and clean during operation. It removes worn abrasive grains and reshapes the wheel. This action ensures continuous accuracy and consistent quality from the first tool to the last.

Contact Us

For More Grinding Solution or Customized Abrasive Tools