Centerless grinding is a high-production machining process. This centerless method shapes parts held securely between three components. The centerless setup uses a grinding wheel, a regulating wheel, and a work-rest blade. This centerless grinding process delivers the high precision needed for automotive components. The centerless market is growing, showing the value of this centerless technique. The centerless advantage is efficiency. Centerless grinding is a key centerless technology for modern manufacturing. The centerless approach is superior for many centerless grinding applications.

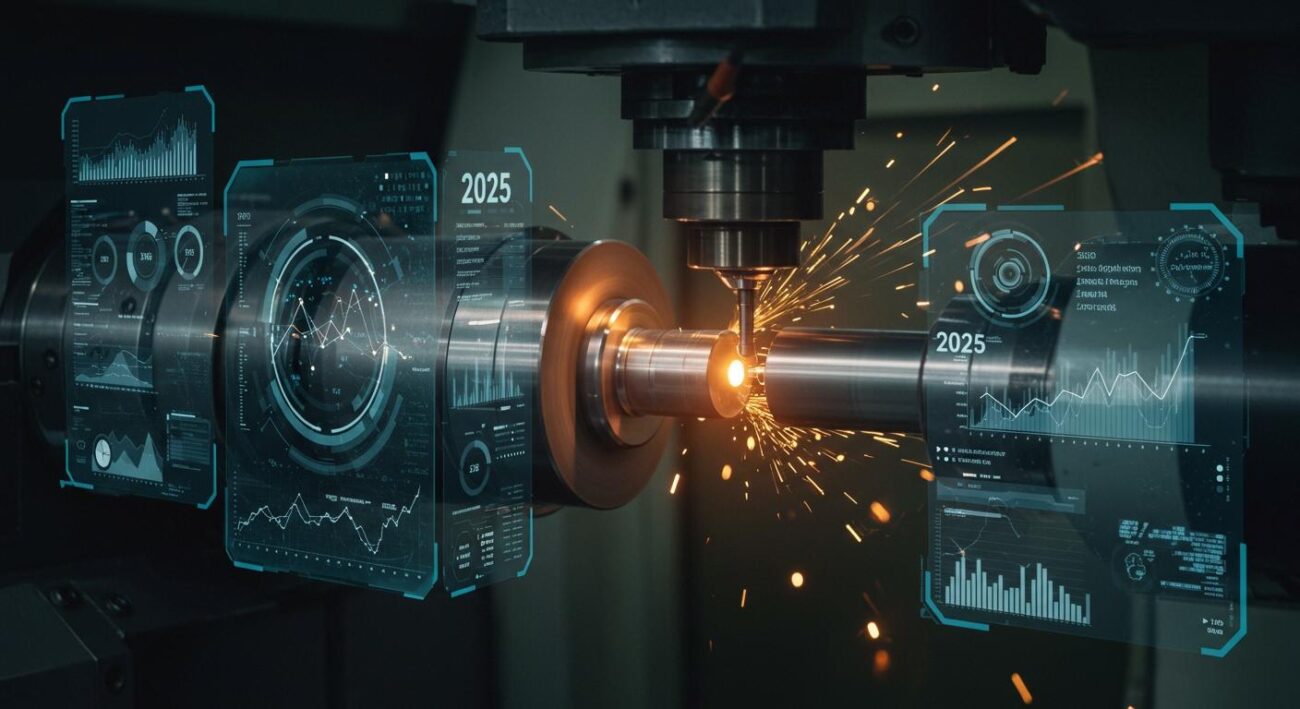

| Year | Projected Market Size (USD Billion) |

|---|---|

| 2024 | 2.5 |

| 2034 | 4.1 |

This growth reflects a projected Compound Annual Growth Rate (CAGR) of 5.2% as industries demand more efficient production methods.

Key Takeaways

- Centerless grinding shapes parts without holding them in the middle. It uses three main parts: a grinding wheel, a regulating wheel, and a work-rest blade.

- The grinding wheel cuts the material. The regulating wheel controls how fast the part spins and moves. The work-rest blade holds the part steady.

- This method makes parts very round and precise. It is good for making many parts quickly, like shafts or pins.

- There are two main types: through-feed for long, simple parts and in-feed for parts with different shapes.

- Special wheels, like CBN wheels, grind very hard materials better. They cut faster and stay cool.

Core Components of Centerless Grinding

The precision of centerless grinding comes from the interaction of three key components. Each part has a specific job. Together, they support and shape the workpiece without needing centers. Understanding these components is the first step to mastering the centerless process.

The Grinding Wheel

The grinding wheel is the primary cutting tool in any centerless setup. It rotates at high speed to remove material from the workpiece. The wheel’s material and bond type are critical for performance. The choice depends on the material being ground.

- Steels and Cast Irons: Conventional abrasives work well for soft to medium-hard steels and for rough grinding cast iron.

- Non-Ferrous Metals: Wheels for aluminum, brass, and copper are used for general-purpose grinding.

- Hard Materials: Superabrasives like diamond or CBN are needed for composites, ceramics, and hardened tool steels.

The grit size of the wheel also affects the outcome. Research shows that multi-granular wheels, which mix different grit sizes, can improve surface quality. The smaller grains fill gaps between larger ones. This creates a more uniform cutting surface, reduces wheel wear, and results in a smoother finish on the centerless part.

The Regulating Wheel

The regulating wheel is a vital control element in centerless grinding. It spins much slower than the grinding wheel. Its main purpose is to control the workpiece’s rotational speed. This wheel is almost always made with a rubber bond. The rubber provides a consistent grip and controlled friction. This ensures the workpiece rotates smoothly and accurately.

The speed of the regulating wheel is adjustable. The ideal speed depends on the part and the type of centerless operation.

- Small, Hard Parts: Speeds are often set between 15 and 40 meters per minute for through-feed jobs.

- Large, Soft Parts: Slower speeds from 8 to 20 meters per minute are common.

- In-Feed Grinding: These applications use the slowest speeds, typically 5 to 15 meters per minute.

In through-feed centerless grinding, the regulating wheel is set at a slight angle. This angle creates the axial feed force. It gently pushes the workpiece through the centerless machine, ensuring continuous movement.

The Work-Rest Blade

The work-rest blade is the foundation of the centerless system. It provides stable support for the workpiece. The workpiece rests on this blade, positioned between the grinding and regulating wheels. The top edge of the blade, where the part makes contact, is often made from very durable materials. These include precision-finished carbide or Polycrystalline Diamond (PCD) to resist wear.

The height of the work-rest blade is extremely important. Incorrect height is a common cause of out-of-roundness in finished parts.

“Setting the right height of the work rest is critical to ensuring the correct placement of the workpiece to achieve the necessary roundness and diameter tolerances.”

— Dan Geddes, President of GCH Tool Group

Positioning the blade slightly above the centerline can improve the surface finish on soft materials. Placing it slightly below the center may help with aggressive material removal. However, the standard position at the centerline offers the best stability for most centerless applications.

Advanced Abrasives like CBN

Standard grinding wheels work well for many materials. However, grinding hardened steels and superalloys requires a more advanced solution. These tough materials generate immense heat and wear down conventional wheels quickly. This is where superabrasives like Cubic Boron Nitride (CBN) become necessary for effective centerless grinding.

CBN offers superior performance compared to traditional abrasives like aluminum oxide.

| Feature | Cubic Boron Nitride (CBN) | Aluminum Oxide |

|---|---|---|

| Hardness | Second hardest material known | Durable but much softer |

| Heat Dissipation | Excellent (1300 W/m.K) | Poor (40 W/m.K) |

| Wear Resistance | Very low wear | Dulls and breaks down |

| Best For | Hardened steels, superalloys | General-purpose steel grinding |

The exceptional thermal stability of CBN allows for cooler, faster cutting. This reduces the risk of heat damage to the workpiece and extends the life of the wheel. For manufacturers working with difficult materials like HSS, Inconel, or hardened stainless steels, CBN is the ideal choice.

Achieving top performance in demanding centerless applications requires the right abrasive formula. Brands like Aimgrind specialize in this area. With nearly two decades of experience, they provide customized grinding solutions. Their high-performance CBN grinding wheels are engineered for cooler operation, faster cutting, and longer life, making them a perfect match for high-precision centerless tasks.

How the Centerless Process Works

The magic of centerless grinding lies in its unique method of holding and machining a workpiece. Unlike traditional grinding, the centerless method does not use centers or chucks. Instead, it relies on a clever geometric relationship between its core components. This setup provides constant support, enabling high throughput and exceptional precision.

The Three-Point Contact Principle

Every workpiece in a centerless machine is supported at three distinct points. This creates a very stable and self-correcting system. The three points of contact are the grinding wheel, the regulating wheel, and the work-rest blade. The geometry of this setup is the key to the entire centerless grinding process.

The position of the workpiece is critical. It usually rests on the blade slightly above the centerline of the two wheels. This height setting directly influences the contact points and the rounding action.

- The workpiece height determines the contact points on the grinding and regulating wheels.

- These contact points form angles relative to the centerline of the wheels.

- The work-rest blade itself has a support angle, often around 30 degrees, to guide the workpiece securely.

This three-point system has an amazing built-in benefit. It naturally corrects out-of-roundness. If a high spot on the workpiece touches the regulating wheel or blade, the part is pushed more firmly into the grinding wheel. The grinding wheel then removes the high spot. This action repeats with every rotation, making the workpiece rounder and rounder. This is how the centerless method achieves excellent roundness and precision. The centerless setup is designed for stability.

Controlling Rotation and Axial Feed

The centerless process controls two key movements: the workpiece’s rotation and its movement through the machine (axial feed). The regulating wheel is the master of this control.

Rotation Speed ⚙️ The regulating wheel spins much slower than the grinding wheel. It grips the workpiece with friction and dictates how fast it rotates. Slower rotation generally leads to a finer surface finish. Faster rotation allows for quicker material removal. The ability to adjust this speed gives operators precise control over the grinding process. This control is essential for the final quality of a centerless part.

Axial Feed ➡️ In through-feed centerless grinding, the workpiece moves continuously through the machine. This movement is created by tilting the regulating wheel at a slight angle.

How Axial Feed Works: The regulating wheel is angled from 0.5 to 6 degrees. This tilt creates a gentle, consistent pushing force on the workpiece. This force guides the part from one side of the centerless machine to the other, making the process automated and highly efficient for producing many identical centerless parts.

This combination of controlled rotation and automated axial feed is what makes the centerless technique so productive. The centerless system is a model of manufacturing efficiency.

Main Types of Centerless Grinding

Centerless grinding is a versatile process. It is divided into two main methods. The choice of method depends on the workpiece’s shape. These two types are through-feed and in-feed grinding. Each centerless technique offers unique advantages for different production needs.

Through-Feed Grinding

Through-feed grinding is the most common type of centerless grinding. This method is ideal for grinding simple, straight cylindrical parts. The workpiece passes completely through the machine. It enters on one side and exits on the other. This continuous process makes it extremely efficient for high-volume production. This is a form of external centerless grinding. The centerless setup is perfect for parts like:

- Shafts

- Pins

- Rods

- Bushings

- Bearing components

Production rates can be very high. Some centerless systems with magazine-style bar feeders can process up to 1,500 parts per hour. This makes the centerless method a top choice for mass production.

In-Feed (Plunge) Grinding

In-feed grinding, also called plunge grinding, is used for more complex parts. This centerless method is necessary when a workpiece has features that prevent it from passing through the machine. The part is placed on the work-rest blade. The regulating wheel then pushes, or “plunges,” the workpiece into the grinding wheel. The part remains in place until it reaches the final size and is then ejected. This centerless technique is also used for internal centerless grinding applications.

This type of centerless grinding is perfect for parts with varied shapes.

- Parts with heads, like bolts

- Components with shoulders or tapers

- Workpieces with multiple diameters

- High pressure needle valve stems

The in-feed centerless process provides precision for parts that cannot be made with the through-feed centerless method.

Key Advantages and Limitations

Centerless grinding is a powerful machining process, but it is important to understand both its strengths and its weaknesses. The centerless method is ideal for certain applications, while other jobs may require a different approach.

Advantages of the Process

The centerless technique offers several major benefits, making it a top choice for high-volume production.

- High Throughput: The process is incredibly fast. Automated systems can process hundreds of parts per minute. This speed significantly reduces per-part cycle times and manufacturing costs for many centerless applications.

- Excellent Support: The workpiece is rigidly supported by the grinding wheel, regulating wheel, and work-rest blade. This robust support prevents the part from bending, which allows for heavier grinding passes compared to other methods.

- Superior Precision: The centerless method delivers outstanding accuracy. The self-correcting nature of the three-point contact produces excellent roundness and dimensional control.

| Factor | Achievable Precision |

|---|---|

| Dimensional Tolerance | 2–5 µm |

| Roundness | 1–3 µm |

- Fast Setup: Setting up a centerless grinder is often faster than a traditional cylindrical grinder. There are no centers or fixtures to align, which reduces downtime between jobs. This makes the centerless process efficient for a wide range of applications.

Common Limitations

Despite its advantages, centerless grinding has some limitations. The centerless design is not suitable for every part or every production scenario.

One primary limitation of centerless grinding is the ‘Complexity of part shapes‘. Parts with intricate geometries, which include non-cylindrical parts, ‘may not be successfully processed using this method’.

Other common challenges for centerless applications include:

- Part Size: The centerless machine’s physical size limits its use for very large or heavy workpieces.

- Material Type: The efficiency of the centerless process can change depending on the material being ground.

- Setup for Low Volume: The setup time, while fast for high-volume applications, may not be cost-effective for very small batches of parts.

Understanding these factors helps manufacturers choose the right process to achieve the desired precision and efficiency for their specific applications.

The precision of centerless grinding comes from its stable three-point contact. This centerless setup uses a grinding wheel, regulating wheel, and work-rest blade. This centerless method removes the need for centers. The centerless advantage enables high throughput and excellent roundness. Mastering this centerless process involves understanding these parts. Future centerless systems use AI and robotics for even greater precision. Selecting the right abrasive solution is key for any centerless application. Specialists like Aimgrind provide custom tools for optimal centerless grinding results. This ensures the best centerless performance.

FAQ

What is the main advantage of centerless grinding?

The main advantage of centerless grinding is speed. The process is very fast for making many identical parts. This high throughput lowers production costs and saves time. It is ideal for mass production.

How does centerless grinding make parts round?

The process uses a three-point contact system. This system supports the workpiece securely. If a high spot appears, the part is pushed into the grinding wheel. The wheel grinds the high spot away, making the part rounder with each rotation.

What materials are best for centerless grinding?

Centerless grinding works on many materials. It can shape metals like steel, aluminum, and brass. For very hard materials like hardened tool steels or superalloys, specialized wheels are necessary to achieve the best results.

Why are CBN wheels important for centerless grinding?

Note: CBN wheels are used for grinding very hard materials. They cut faster and stay cooler than normal wheels. This prevents heat damage to the part. CBN wheels also last much longer, making them a great choice for tough jobs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools