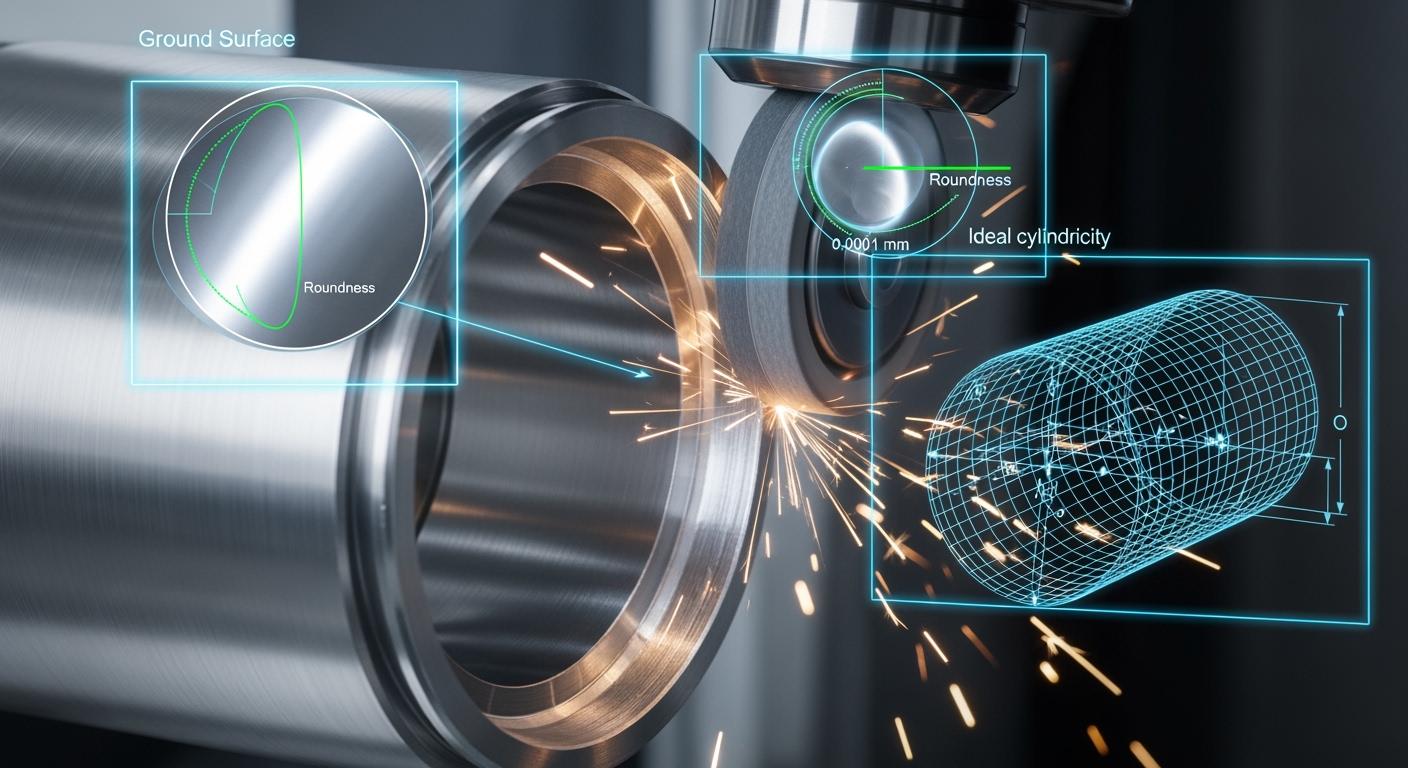

Achieving micro-inch precision for surface finish, roundness, and cylindricity results from a systematic control process. This control is vital in internal grinding applications. It manages key variables to improve surface quality and reduce surface roughness.

Key Control Pillars ⚙️

- Machine Stability

- Workpiece Fixturing

- Grinding Wheel Selection

- Operational Parameters

- Coolant Management

A successful grinding process can yield an achievable surface finish with low roughness. This quality finish on the part’s surface helps meet a tight tolerance, often within +/- 0.00005 inches. This guide breaks down each pillar, providing strategies to master this precision process. We draw on Aimgrind‘s expertise to help you obtain the desired surface finish, reduce roughness on the surface, and improve your process for a better final finish and tolerance.

Key Takeaways

- A stable machine and secure workpiece clamping are important for good surface finish and precision.

- Choose the right grinding wheel, abrasive, grit, and bond for the material you are grinding. CBN wheels are best for hard steels.

- Properly dress and true your grinding wheel to keep it sharp and balanced. This helps prevent surface problems.

- Adjust wheel speed, work speed, infeed rates, and spark-out to control the final surface finish and part shape.

- Use clean coolant and check for machine alignment and vibrations to fix common problems like chatter and out-of-roundness.

Foundational Control for Internal Grinding Applications

Excellent surface finish and tight tolerance begin with a stable foundation. The machine and workpiece must be completely rigid during the grinding process. Any unwanted movement introduces errors, increasing surface roughness and compromising precision. This foundational control is the first step toward a successful outcome in internal grinding applications.

The Role of Machine Rigidity and Damping

A grinding machine’s performance depends heavily on its rigidity. Vibrations are the enemy of a smooth finish. They can originate from several sources within the grinding process.

Common Causes of Machine Vibration Vibration 📉

- Uneven ground support can cause the machine to resonate.

- Poor quality grinding wheels with uneven particle size create unstable rotation.

- A non-standard inner hole on the wheel can cause bouncing during the grinding process.

Modern machines use advanced technology to fight this roughness. Hydrostatic guideways, for example, use a thin film of oil to separate moving parts. This oil layer dampens vibrations, which improves the machine’s dynamic stiffness and overall performance. The result is a superior surface finish, reduced surface roughness, and a more efficient process. This technology allows for a faster grinding process without sacrificing the final finish or precision.

Workpiece Clamping and Fixturing for Stability

A rigid machine is only half the battle. The workpiece itself must be held securely. Improper clamping is a direct cause of poor part quality and can ruin the entire process. It leads to issues that directly impact the final finish and tolerance.

Clamping is Critical! ⚠️

An improperly clamped workpiece can lead to misalignment, chatter, or distortion. This not only damages the part but also poses a safety risk. A secure setup is essential for achieving the required precision and dimensional accuracy.

Effective fixturing ensures the part remains perfectly still during the grinding operation. This stability is crucial for maintaining a consistent surface and preventing roughness. A well-managed clamping process provides the control needed to meet a tight tolerance and achieve a flawless surface finish. This attention to detail defines high-precision internal grinding applications.

The Grinding Wheel: Your Primary Tool for Control

The grinding wheel is where the magic happens. It is the direct point of contact with the workpiece. Your choice of wheel and its condition are the most significant factors in achieving the desired surface finish. Proper selection gives you direct control over the final part quality, from its surface texture to its geometric precision. A well-managed wheel is essential for a successful grinding process.

Selecting the Right Abrasive, Grit, and Bond

A grinding wheel has three main components: the abrasive grain, the grit size, and the bond that holds it all together. Each element plays a specific role in the wheel’s performance and its effect on the workpiece surface.

- Abrasive: This is the cutting material. Common abrasives include aluminum oxide and silicon carbide. For hardened steels, Cubic Boron Nitride (CBN) is the superior choice.

- Grit Size: This refers to the size of the abrasive particles. Grit size directly determines the final surface roughness. Finer grits create a smoother surface finish, while coarser grits remove material faster but leave a higher roughness. The goal is to balance material removal with the required finish.

- Bond: The bond holds the abrasive grains together. The type of bond (e.g., vitrified, resin, electroplated) affects the wheel’s hardness, durability, and cutting action.

Choosing the right combination is critical for controlling the process and achieving a specific tolerance.

| Grit Size Category | Primary Use | Resulting Surface Roughness |

|---|---|---|

| Coarse (60-120) | Rapid material removal | High roughness |

| Medium (140-240) | General purpose grinding | Moderate roughness |

| Fine (270+) | Finishing operations | Low roughness, smooth surface |

Why CBN Wheels Excel in Grinding Hardened Steels

When working with hardened steels and superalloys in internal grinding applications, CBN wheels offer unmatched performance. Their primary advantage lies in thermal management. CBN has nearly 50 times the thermal conductivity of conventional abrasives. This means heat generated during grinding is pulled into the wheel and away from the workpiece.

Cooler Grinding, Better Parts 🧊

This efficient heat removal prevents thermal damage to the part’s surface. It protects the material’s properties, which is crucial for component life and performance. The result is a superior surface finish with less risk of workpiece burn, even at high removal rates. This control over heat is key to maintaining tight tolerance and precision.

This is where Aimgrind’s two decades of expertise become your advantage. We specialize in providing customized CBN grinding wheels designed to match your specific equipment and process. Whether you need a porous vitrified bond for cool cutting, a durable resin bond for high-speed grinding, or an electroplated bond for complex forms, we engineer the perfect solution. Aimgrind’s wheels enhance your productivity and reduce costs by minimizing wheel changes and preventing thermal damage, ensuring a flawless finish and consistent precision.

Precision Dressing and Truing for Optimal Geometry

A new wheel does not stay perfect forever. Over time, it can become loaded with material or lose its sharp cutting edge. Dressing and truing are maintenance processes that restore the wheel’s geometry and cutting ability.

- Truing makes the wheel perfectly concentric to the spindle.

- Dressing cleans the wheel’s surface and exposes fresh, sharp abrasive grains.

A properly dressed wheel is essential for eliminating issues like chatter and achieving a uniform surface. The parameters used during dressing have a direct impact on the final surface roughness.

Key Dressing Parameters for Vitrified CBN Wheels:

- Velocity Ratio: A ratio of 0.8 between the diamond dresser and the grinding wheel ensures effective bond removal.

- Overlap Ratio: An ideal range of 2 to 4 ensures the dresser moves across the wheel face uniformly.

- Depth of Dress: A precise depth, often around 0.0002 inches per pass, optimizes the wheel’s cutting surface without excessive wear.

Proper dressing is a repeatable process that guarantees consistent performance from your grinding wheel. This level of control is fundamental to producing parts with extremely low surface roughness and meeting the tightest geometric tolerance requirements.

Mastering Operational Parameters

A perfect setup and the right wheel are just the beginning. The next step is to master the operational settings. These surface finish parameters give you direct control over the grinding process. Adjusting speeds, feeds, and coolant flow is essential for achieving high precision and the desired surface finish. This control over the process ensures excellent performance.

Adjusting Wheel and Work Speed Ratios

The relationship between the grinding wheel’s speed and the workpiece’s speed is a critical surface finish parameter. A higher wheel speed generally leads to a better surface finish. It reduces the chip thickness taken by each abrasive grain. This creates a smoother surface with less roughness. However, the work speed must be balanced. A slower work speed allows for more cutting passes over the same surface area. This refines the surface and reduces roughness. Finding the optimal ratio is one of the key surface finish techniques for consistent performance.

Using Infeed Rates and Spark-Out for Precision

Infeed rates and spark-out are two powerful surface finish parameters for managing the final finish.

- Infeed Rate: This is the speed at which the wheel moves into the workpiece. A faster infeed increases the material removal rate. This can significantly reduce cycle times and improve productivity. Optimizing this process parameter is vital for efficient grinding.

- Spark-Out: This is a period at the end of the grinding cycle where there is no infeed. The wheel continues to rotate against the surface. This phase allows the system’s elastic deformation to relax. It reduces surface roughness and improves the part’s roundness, delivering superior precision.

The Spark-Out Advantage ✨

The spark-out phase is one of the most effective surface finish techniques. It smooths out tiny imperfections on the part’s surface. This step is crucial for achieving a mirror-like finish and tight geometric precision.

The Impact of Coolant on Dimensional Stability

Coolant does more than just cool the part. It is a critical part of the process for maintaining dimensional stability and a clean surface. Contaminated coolant carries small particles back into the grinding zone. These particles can scratch the workpiece surface, increasing surface roughness and ruining a good finish. Proper coolant filtration is a key surface finish parameter. It ensures a stable process and maintains high machining accuracy. Clean coolant supports a better surface finish and consistent performance, which is essential for achieving high precision.

Troubleshooting Poor Surface Finish and Geometry

Even with a perfect setup, geometric errors and poor surface finish can occur. Troubleshooting is a systematic process of elimination. High-end internal grinding applications can achieve an incredible tolerance for roundness and cylindricity, often in the 5 to 10 micro-inch range. Reaching this level of precision requires identifying and correcting problems as they arise. This section provides a guide to diagnosing and fixing common issues to meet demanding surface finish standards.

Correcting Out-of-Roundness

Out-of-roundness means the part’s diameter is not constant, creating lobes or an oval shape. This error directly impacts the part’s function and fit. The cause is often related to instability somewhere in the grinding system. A key symptom of severe spindle bearing wear is out-of-roundness. When bearings are “totally shot,” they lose rigidity and allow unwanted movement. Spindle imbalance can also cause the spindle to move in an elliptical pattern instead of a perfect circle. This motion transfers directly to the workpiece surface, ruining its geometry and precision.

Diagnostic Checklist for Out-of-Roundness 📝 Use this checklist to find the source of the problem.

- Workpiece Clamping: Is the part held securely? Uneven clamping pressure can distort a thin-walled part.

- Spindle Bearings: Is there any play or noise from the workhead or wheelhead spindles? This indicates wear.

- Machine Drive Belts: Are the belts worn or loose? This can cause inconsistent rotation speed.

- Work Speed: Is the work speed too high? A very high speed can cause the part to vibrate.

Eliminating Taper and Bell-Mouth

Taper and bell-mouth are common cylindricity errors.

- Taper is when the diameter of the hole changes gradually from one end to the other.

- Bell-mouth is when the hole flares out at the very end, creating a “bell” shape.

These errors often stem from alignment issues in the process. Angular misalignment between the grinding wheel and the workpiece centerline is a primary cause of taper. The grinding wheel quill can also deflect under pressure, causing it to grind a slightly different path than intended. Bell-mouth often occurs when a tool is not perfectly aligned as it enters or exits the workpiece. Some machines have compensation features that can be adjusted to correct for this. Using a guide or bushing helps maintain alignment and prevent this defect.

Common Causes of Taper and Bell-Mouth

- Machine Alignment: The headstock or wheelhead may be misaligned. An incorrect adjustment angle of the grinder head frame is a frequent cause of taper.

- Wheel Wear: Serious wear on one side of the grinding wheel can create a taper.

- Stroke Length: If the grinding stroke does not extend far enough past the ends of the hole, it can cause bell-mouth or undersized ends.

- Tool Holding: For some operations, rigid tool holders can cause misalignment. Floating holders can help the tool self-align, preventing bell-mouthed holes.

Fixing these issues requires careful measurement and machine adjustment to ensure the wheel travels perfectly parallel to the workpiece axis. Achieving the desired surface finish depends on this geometric accuracy.

Improving Finish and Eliminating Chatter

Chatter appears as wavy, evenly spaced marks on the workpiece surface. It is a form of vibration that ruins surface quality and creates high surface roughness. A poor finish can also result from a dull or loaded grinding wheel. An improperly dressed wheel is a major source of problems. A dull wheel generates excessive heat. This heat can cause the material surface to swell and then cool unevenly, destroying the finish. This process increases roughness and fails to meet the required tolerance.

A good surface finish measurement will reveal this roughness. To get the desired surface finish, you must eliminate chatter and ensure a sharp wheel. This requires a systematic approach to diagnosis. The goal is to create a stable process that produces a smooth surface with low roughness. This ensures the final quality of the part.

Chatter and Poor Finish Checklist ✅

- Wheel Dressing: Is the diamond dresser sharp? A dull diamond will burnish or dull the wheel. Is the dressing speed correct? A faster dressing traverse often creates a sharper, more open wheel surface.

- Wheel Balance: Is the grinding wheel properly balanced? An out-of-balance wheel is a primary cause of vibration and roughness.

- System Rigidity: Check the stability of the workpiece, fixture, and machine components. Any looseness will cause chatter.

- Coolant: Is the coolant clean and flowing correctly? Contaminated coolant can carry grit back into the grinding zone, scratching the surface and increasing roughness.

- Speeds and Feeds: Are the wheel speed and work speed appropriate? An incorrect ratio can induce vibration and a poor finish.

By methodically checking these points, you can identify the root cause of poor surface quality and take corrective action. This attention to detail is essential for achieving superior precision and a flawless finish.

Achieving superior part quality is a holistic process. This process controls the machine, wheel, and parameters to manage surface roughness. A stable setup, a custom Aimgrind CBN wheel for a better surface finish, and an optimized process reduce surface roughness. This process improves the final finish and surface quality, reducing surface roughness. Lowering roughness is key to a good surface. This low roughness defines a quality surface.

Take Control of Your Finish ⚙️

Ready to improve your process? Apply these principles to lower surface roughness and enhance your surface finish. For expert help to reduce roughness, improve quality, and get a better finish, contact Aimgrind. Grind with Passion, Achieve with Aim.

FAQ

What is a good surface finish in internal grinding?

A high-quality surface finish often has a roughness below 10 micro-inches (µin). Achieving this requires tight control over the entire grinding process. This precision ensures parts function correctly and last longer.

Why do my parts have chatter marks?

Chatter marks usually come from vibration. The most common causes are an unbalanced grinding wheel or a dull dressing tool. You should also check the rigidity of your machine and workpiece fixture.

Quick Tip 💡

Always balance your grinding wheel before use. This simple step prevents many surface finish problems.

When should I use a CBN grinding wheel?

Use CBN wheels for grinding hard materials like hardened steels and superalloys. They cut cooler and last much longer than standard abrasives. This prevents heat damage and improves your part’s final quality and precision.

How can I fix a tapered hole?

A tapered hole often points to a machine alignment issue. Check that the wheelhead and workhead are perfectly aligned. The grinding wheel must travel parallel to the workpiece axis to create a straight hole.

Contact Us

For More Grinding Solution or Customized Abrasive Tools