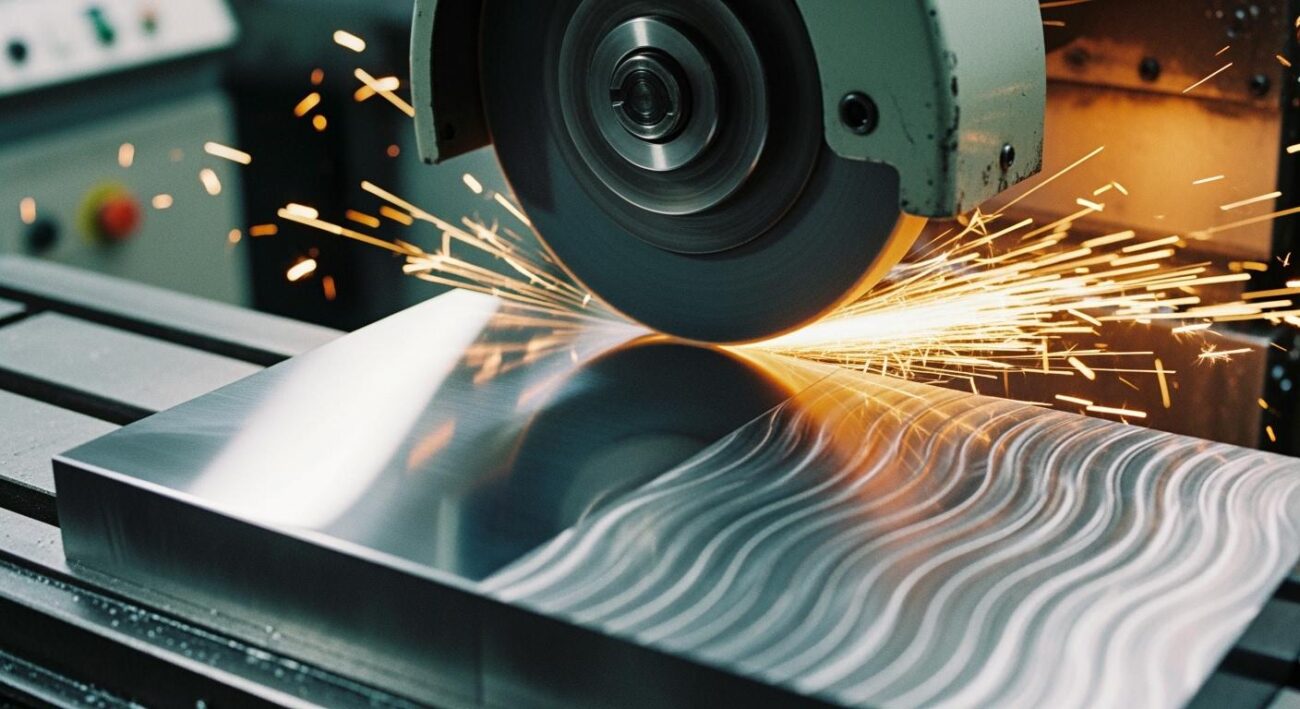

You often face a tough choice in surface grinding: high speed or great surface finishes. This trade-off becomes clear when adjusting grinding parameters.

Parameter Increased Effect on Speed (MRR) Effect on Surface Finish (Ra) Feed Rate Maximized Worsened (Higher Ra) Depth of Cut Maximized Minimal Effect

Achieving both speed and quality is possible. This optimization is not a secret. It is a systematic approach to balancing your grinding variables for boosting performance. Properly optimizing grinding process leads to excellent grinding performance.

Key Takeaways

- Balance grinding settings like wheel speed and depth of cut. This helps you get both fast material removal and a smooth surface.

- Choose the right grinding wheel for your material. Diamond wheels work for hard materials, and CBN wheels work for hard steels.

- Use a two-pass grinding method. First, remove a lot of material quickly. Then, make a slow, gentle pass for a perfect finish.

- Keep your machine and wheel in good shape. Dress your wheel often and ensure your machine is stable. This prevents mistakes and makes parts look good.

Fundamentals of Surface Grinding Parameters

Mastering surface grinding requires you to understand its core parameters. Each setting you adjust directly affects your final product. Proper grinding process optimization starts with these fundamentals. Let’s explore the key variables you can control.

The Role of Wheel Speed (SFPM)

Wheel speed, measured in Surface Feet Per Minute (SFPM), is a critical factor. It dictates how fast the abrasive grains cut into your workpiece. Finding the correct SFPM is essential for both efficiency and finish. The right grinding wheel speeds prevent thermal damage and ensure a clean cut.

SFPM Level Heat Generation Impact Surface Finish Impact Too High Overheating, part warping, chips sticking Rough, inconsistent, burned surface Too Low Heat buildup from rubbing, tool struggles Rough, uneven finish, chatter marks Just Right Manages heat, avoids thermal issues Clean, shiny, professional surface

Impact of Table Speed (Feed Rate)

Table speed, or feed rate, controls how quickly the workpiece moves past the grinding wheel. Slower speeds generally produce a better surface finish. This is because each abrasive grain takes a smaller bite. Faster speeds increase material removal but can leave a rougher surface. Your goal is to find the fastest speed that still meets your finish requirements.

Effect of Downfeed (Depth of Cut)

Downfeed is the depth of material you remove with each pass. A heavy downfeed removes material quickly but puts significant stress on the machine and wheel. An aggressive downfeed can stall the spindle, cause burning, and accelerate wheel wear. For finishing passes, you should use a very light downfeed to achieve precision. This careful approach is key to optimizing grinding process results.

Key Levers for Grinding Process Optimization

Successful grinding involves balancing many variables. This optimization makes the process feel like an art. You have several levers to pull for the best outcome.

- Cutting Parameters: Adjust wheel and workpiece speeds, depth of cut, and feed rate.

- Coolant and Lubrication: Use the correct type, flow rate, and application method.

- Machine Condition: Ensure your machine is rigid and the spindle runs true.

- Wheel Dressing: Regularly dress the wheel to maintain its sharpness and shape.

Controlling these elements transforms your grinding from a simple task into a precise science.

Selecting the Right Grinding Wheel

Your grinding parameters are only half of the equation. The grinding wheel itself is the heart of the operation. Choosing the wrong wheel can undermine even the most carefully planned process, leading to poor finishes, slow cycle times, and excessive wheel wear. The right wheel, however, works in harmony with your machine and parameters to deliver exceptional results.

Expert Tip: Finding the perfect wheel can be complex. A specialist like Aimgrind can simplify this for you. With deep experience in customized grinding wheels and abrasive tools, they provide personalized selection and formula design to match your exact material and application needs.

Choosing the Abrasive: Diamond, CBN, and Conventional

The abrasive is the material doing the cutting. Your choice depends entirely on the material you are grinding.

- Conventional Abrasives (Aluminum Oxide, Silicon Carbide): These are the workhorses for grinding softer steels, cast iron, and non-ferrous metals. They offer a great balance of cost and effectiveness for general-purpose tasks.

- Cubic Boron Nitride (CBN): As the second-hardest material, CBN excels at grinding hard ferrous materials like tool steels and superalloys. It is chemically stable with iron, which prevents rapid wear at high grinding speeds.

- Diamond: As the hardest known material, diamond is the ultimate choice for grinding extremely hard and brittle materials.

When you work with materials like ceramics, composites, or hard alloys, you need a wheel that can handle the challenge. Aimgrind’s high-performance diamond grinding wheels are engineered for this purpose. Their exceptional durability ensures efficient material removal and a superior finish, making them ideal for demanding precision grinding jobs.

The table below compares the two superabrasives, Diamond and CBN, to help you choose.

| Feature | Diamond | CBN (Cubic Boron Nitride) |

|---|---|---|

| Best For | Hard, brittle, non-ferrous materials (Carbide, Ceramics, Glass) | Hard ferrous materials (Hardened Steel, Tool Steel, Cast Iron) |

| Hardness | Hardest known material | Second-hardest material |

| Chemical Reactivity | Reacts with iron at high temperatures, causing wear | Chemically inert with iron, perfect for high-speed steel grinding |

| Primary Use | Precision grinding of non-ferrous parts | High-efficiency grinding of steel alloys |

Grit Size: Balancing Roughing and Finishing

Grit size refers to the size of the individual abrasive particles in the wheel. It is identified by a number—the higher the number, the smaller the grain and the finer the finish.

You should select grit size based on your goal for a specific pass:

- Roughing: Use a coarse grit (lower number, e.g., 46-80) for rapid material removal. The larger grains take bigger “bites,” clearing material quickly but leaving a rougher surface.

- Finishing: Use a fine grit (higher number, e.g., 150-320+) for a smooth surface. The smaller grains take tiny chips, creating a high-quality finish with low Ra values.

The chart below shows how a higher grit number generally leads to a better surface finish (lower Ra).

This table gives you a reference for the kind of finish you can expect from different grit sizes.

| Standard Grit | Expected Surface Finish (Ra µin) |

|---|---|

| 150 | 27 – 32 |

| 180 | 16 – 23 |

| 240 | 14 – 18 |

| 320 | 8 – 10 |

Bond Type and Hardness Explained

The bond is the glue that holds the abrasive grains together. The bond’s characteristics control how the wheel wears, its cutting action, and its suitability for different speeds and materials. The three primary bond types are resin, vitrified, and metal.

| Bond Type | Key Characteristics | Best For |

|---|---|---|

| Resin | Flexible and shock-absorbent. Creates excellent surface finishes. | Tool sharpening and precision grinding where finish is critical. Lower thermal resistance. |

| Vitrified | Rigid, strong, and porous. Allows for high stock removal and effective coolant flow. | High-production, precision grinding. Excellent for maintaining shape at high speeds. |

| Metal | Extremely durable and wear-resistant. Offers the longest wheel life. | Grinding highly abrasive materials like glass and ceramics. Aggressive cutting. |

Choosing the correct bond is crucial for top performance. A specialized provider like Aimgrind can analyze your grinding process and help you select the ideal bond—whether resin, metal, or vitrified—to optimize your results.

Finally, bond hardness determines how tightly the grains are held.

- Harder Bonds: Hold grains securely. Use them for grinding soft materials or when you need the wheel to maintain its form.

- Softer Bonds: Release dull grains more easily. Use them for grinding hard materials. This creates a self-sharpening effect that exposes fresh, sharp abrasives.

A Strategic Approach to Optimizing Grinding Process

You can achieve both speed and finish by separating your grinding operation into distinct stages. This strategic approach is key to optimizing grinding process results. Instead of trying to do everything in one pass, you can use a method that gets the best of both worlds. This involves a powerful roughing pass followed by a precise finishing pass.

The Two-Pass Strategy: Roughing vs. Finishing

The two-pass strategy is a highly effective method for balancing speed and quality in surface grinding.

- Roughing Pass: The goal here is maximum material removal efficiency. You use aggressive parameters like a deeper depth of cut (e.g., 0.05 mm) and a faster table speed. Dressing the wheel with a deeper pass (e.g., 0.002 inches) creates sharp grits that remove material quickly. This first step of the grinding process optimization gets the bulk of the work done fast.

- Finishing Pass: Here, your focus shifts entirely to quality. You use very gentle parameters, such as a shallow depth of cut (1-2 µm) and a fine-grit wheel. This is followed by “spark-out” passes, where you perform grinding with zero infeed to perfect the surface.

As Prof. Stephen Malkin noted, gentle parameters change the grinding action from “cutting” to “plowing.” This minimizes heat and prevents damage below the surface, giving you a flawless part.

Calculating Material Removal Rate (MRR)

Material Removal Rate (MRR) measures how much material you remove in a set amount of time. A higher MRR means a shorter cycle time and greater efficiency. Maximizing q-prime is essential for boosting your MRR. You can calculate it with a simple formula:

- Calculate the specific removal rate (Q’):

(surface speed/min * radial infeed amount per pass) - Calculate MRR:

(Q' * traverse rate)

A higher material removal rate directly boosts your productivity. Optimizing MRR can increase your output by 15-25%. However, pushing it too high during finishing can ruin surface finishes and increase rework, which lengthens the overall cycle. The key is maximizing q-prime during roughing and reducing it for finishing.

Measuring Surface Finish (Ra)

Surface finish (Ra) measures the average roughness of a surface. You use a tool called a profilometer, which drags a fine needle across the part to measure its microscopic peaks and valleys. A lower Ra value means a smoother surface. This measurement is critical in industries with strict quality standards. For example, maximizing q-prime is not the goal when high-precision surface finishes are required. The goal of optimizing grinding process is to hit the target Ra.

Industries like aerospace and medical demand extremely smooth surfaces. A hip implant, for instance, may require an Ra of 0.2 µm or less. Achieving these numbers requires careful control over the final grinding passes of your cycle.

Fine-Tuning for a Perfect Finish

After your aggressive roughing passes, the final stage of grinding is all about precision and quality. This is where you transform a roughly shaped part into a finished product with an impeccable surface. Small adjustments here make a huge difference in the final outcome.

How to Achieve Precision in Surface Grinding

To achieve precision in surface grinding, you must shift your focus from speed to control. Use an incremental down-feed for the final passes, removing only a tiny amount of material each time. This minimizes stress and heat. A key technique is the “spark-out pass.”

Spark-out is a finishing step where you make passes without any additional downfeed. As the wheel wears slightly, its finishing portion becomes smoother. This allows the wheel to “spark out,” removing the last microscopic imperfections and creating a superior finish. This is how you achieve precision in surface grinding.

Wheel Dressing and Truing for Consistency

A consistent finish requires a perfectly prepared wheel. You must understand the difference between truing and dressing for effective grinding.

- Truing: This process makes the wheel concentric to the spindle. It ensures the wheel is perfectly round and has the correct profile. You always perform truing first.

- Dressing: This process sharpens the wheel. It removes old bond material and exposes fresh, sharp abrasive grains. A trued wheel will not cut effectively until you dress it.

Regularly performing both actions keeps your grinding process stable and predictable.

Optimizing Coolant Flow and Concentration

Coolant is vital for managing heat and clearing chips during high-speed grinding. The right flow rate prevents thermal damage. A good rule of thumb is to supply 1.5 to 2 gallons per minute (gpm) for each horsepower of your spindle. Incorrect coolant concentration can cause problems like:

- Poor surface finish

- Increased wheel wear

- Foaming issues

- Risk of part burning

Check your coolant concentration regularly to ensure optimal grinding performance at all speeds.

The Importance of Machine Rigidity

Your machine’s stability is the foundation of a great finish. A machine that lacks rigidity will vibrate under cutting forces, causing chatter marks on your workpiece. Poor damping allows these vibrations to build up, making the problem worse. Common sources of vibration in surface grinding include:

- An unbalanced grinding wheel

- Worn spindle bearings

- A workpiece that is not held securely

- Running at incorrect grinding speeds

Ensuring your machine is rigid and well-maintained is essential for smooth, chatter-free grinding.

Optimizing your surface grinding process is a balancing act. You must manage grinding parameters, wheel selection, and machine setup. A two-pass strategy often works best for achieving both speed and a fine finish. This optimization can lead to significant improvements in your overall performance.

Don’t be afraid to experiment to find your unique sweet spot. A systematic approach to grinding will boost your efficiency. For expert guidance, partners like Aimgrind can help you accelerate these improvements and perfect your process.

FAQ

Can I really get both speed and a great finish?

Yes, you can achieve both. Use a two-pass strategy. A fast roughing pass removes material quickly. Then, a slow finishing pass creates the high-quality surface you need. This method balances efficiency and precision.

What causes burn marks on my workpiece? (fire emoji)

Burn marks result from too much heat. This can happen if your wheel speed is too high or your coolant flow is too low. A dull wheel or an overly aggressive cut also generates excess heat, leading to burns.

How often should I dress my grinding wheel?

You should dress your wheel when performance drops. Look for signs like a poor surface finish, increased grinding noise, or burn marks. Consistent dressing is key to maintaining wheel sharpness and achieving predictable results.

How do I choose the right wheel for a new material?

You must match the abrasive to the material’s hardness. For example, use diamond for ceramics. For a perfect match, a specialist can help. Aimgrind offers personalized selection to ensure you get the ideal wheel for your job.

Contact Us

For More Grinding Solution or Customized Abrasive Tools