Optimizing the coolant supply is the most effective way to reduce heat buildup in grinding. A “golden rule” guides this process: operators must match the coolant velocity to the wheel speed. This action breaks the wheel’s air barrier, ensuring the coolant reaches the grinding zone. An ineffective coolant supply and poor coolant flow can cause grinding burn.

Grinding burn from poor coolant flow can lead to:

- Surface cracks on the workpiece

- Weakened material structure

- Eventual part failure in the grinding operation

This guide provides practical steps for operators to achieve cooler, more efficient grinding. Proper coolant velocity and coolant flow are crucial for successful grinding. The coolant is key.

Key Takeaways

- Match the coolant’s speed to the grinding wheel‘s speed. This helps the coolant reach the grinding area and stops heat from building up.

- Choose the right nozzle for your coolant. A good nozzle helps the coolant hit the grinding wheel correctly.

- Adjust grinding settings like wheel speed and depth of cut. Making cuts shallower can greatly reduce heat.

- Pick the correct grinding wheel for your material. Some wheels, like Aimgrind CBN wheels, help keep the grinding process cooler.

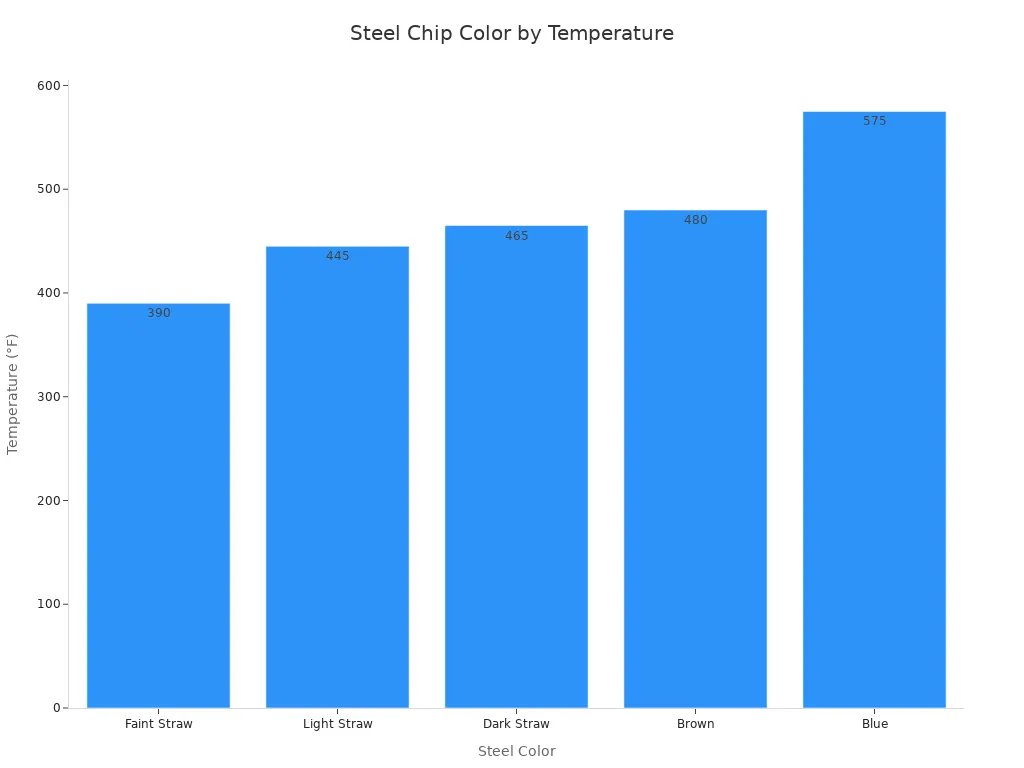

- Check the color of your grinding chips. Silver or straw-colored chips mean the grinding is cool, but brown or blue chips show too much heat.

Optimizing Coolant Velocity

Effective heat management in grinding starts with controlling the coolant velocity. A fast-spinning grinding wheel creates a powerful air barrier around its circumference. This barrier can deflect the coolant, preventing it from reaching the critical grinding zone. Optimizing the coolant outlet velocity ensures the coolant penetrates this barrier, delivering the necessary cooling and lubrication. A proper coolant supply is essential for any grinding process.

The “Golden Rule” of Velocity Matching

The “golden rule” of grinding is simple: match the coolant outlet velocity to the grinding wheel‘s surface speed. When the coolant velocity is correct, it travels with the wheel instead of bouncing off. This action ensures the coolant flow effectively reaches the point of contact between the wheel and the workpiece. This rule is the foundation for preventing thermal damage during a grinding operation.

Understanding the Ideal Velocity Ratio

Experts measure the relationship between coolant speed and wheel speed using a velocity ratio. The ideal ratio of coolant velocity to wheel speed (v_cool / v_s) is between 0.8 and 1.0.

💡 Pro Tip: A ratio below 0.8 indicates an inefficient coolant supply. This low coolant velocity allows heat to build up, often turning grinding chips brown or blue. Silver or straw-colored chips signal a cooler, more effective grinding process with better coolant flow.

Achieving the optimal ratio maximizes the coolant flow into the contact zone. Any significant deviation, either faster or slower, reduces the volume of coolant that can dissipate heat, making the entire grinding process less efficient.

How to Calculate Your Target Coolant Velocity

Operators can calculate the target coolant outlet velocity with a straightforward formula. This calculation helps set up the machine for optimal performance.

- Step 1: Determine the wheel’s surface speed in meters per second (m/s).

- Step 2: Aim for a coolant outlet velocity that matches this speed.

Use this formula to find your target coolant velocity:

Target Coolant Velocity (m/s) = (Wheel Diameter (mm) × π × RPM) / 60,000

This formula provides a precise target for your coolant flow and coolant velocity adjustments.

Practical Methods for Adjusting Velocity

Once you know the target coolant velocity, you can make practical adjustments. The coolant outlet velocity depends on both pressure and nozzle design. Here are two common methods:

- Adjust Pump Pressure: Increasing the system’s pressure will increase the coolant flow and its exit speed.

- Change Nozzle Aperture: A smaller nozzle opening will increase the coolant outlet velocity, assuming the same flow rate.

Fine-tuning these elements helps you achieve the perfect coolant velocity for your grinding application.

Selecting the Right Coolant Nozzle

Choosing the right nozzle is just as important as managing coolant velocity. The nozzle’s design directly influences the shape, coherence, and effectiveness of the coolant stream. A well-chosen nozzle ensures the coolant flow penetrates the air barrier and reaches the grinding zone efficiently. This choice impacts the overall success of the grinding process.

Flat-Jet vs. Needle Nozzles

Flat-jet and needle nozzles are common choices in high-speed grinding. Both are considered “atomization” nozzles because their jets break up into tiny droplets over a short distance. While they perform similarly in removing material, their operational characteristics differ slightly.

| Feature | Flat Nozzle (Atomization) | Needle Nozzle (Atomization) |

|---|---|---|

| Jet Decay | Short length | Short length |

| Pressure (constant flow) | 5.7 to 13.8 bar | 13.8 bar |

| Impact Pressure | Low with minimal fluctuations | Relatively low |

| Droplet Distribution | Evenly distributed | Evenly distributed small droplets |

Both nozzle types deliver a good coolant supply for many grinding tasks. The choice often depends on the specific machine setup and pressure capabilities.

The Impact of Nozzle Geometry

Nozzle geometry significantly affects the integrity of the coolant stream. Coherent-jet nozzles are designed to create a solid, focused stream of coolant. This design improves the coolant supply and enhances the grinding operation.

- A coherent jet has more impact energy, which helps clean the wheel and remove the air barrier.

- It carries less entrained air, reducing foam in the filter system.

- The focused flow is more efficient, allowing operators to potentially reduce the overall coolant flow rate.

Designs with a converging angle of 13–15° and a throat length of 2–4 times the nozzle diameter create a stable, powerful flow. This ensures the coolant effectively wets the wheel during grinding.

Balancing Aperture Size, Velocity, and Volume

Operators must balance nozzle aperture size, coolant velocity, and flow volume. These three factors are directly related. The mass flow rate equation shows this relationship clearly.

The mass flow rate (

ṁ) is defined by the equation:ṁ = A * v * ρWhere:

ṁis the mass flow rateAis the cross-sectional area of the nozzlevis the velocity of the fluid (coolant velocity)ρis the density of the fluid

A smaller aperture (A) will increase the coolant velocity (v) if the pump pressure and flow rate remain constant. Adjusting the aperture is a key method for achieving the target coolant velocity without changing the entire coolant supply system.

Correct Nozzle Positioning and Aim

Proper nozzle positioning is critical for an effective coolant flow. Incorrect aim can render even a perfect coolant velocity useless. Operators should follow these best practices for every grinding setup:

- Position the nozzle above the grinding wheel’s centerline.

- Aim the coolant jet to strike the wheel tangentially at a 20-degree angle.

- Ensure the coolant jet adheres firmly to the wheel surface once the wheel is at operating speed.

Correctly aiming the nozzle ensures the coolant flow follows the wheel directly into the grinding zone, providing maximum cooling and lubrication.

Core Grinding Parameters to Reduce Heat Buildup

Beyond the coolant flow, operators can adjust core grinding variables to manage thermal energy. The wheel speed, feed rate, and depth of cut are critical grinding variables that directly impact how much heat enters the workpiece. Fine-tuning these grinding variables is essential to reduce heat buildup and prevent damage. A good coolant flow can only do so much if the primary grinding variables are incorrect.

Adjusting Wheel Speed and Feed Rates

Adjusting wheel speed and feed rates has a complex effect on grinding temperature. These grinding variables must be balanced carefully. An excessive feed rate increases friction and contact area, causing a rapid heat rise. However, a faster feed rate can also shorten heat transfer time, sometimes leading to a lower temperature.

- Increasing grinding speed generally raises the temperature because the wheel makes more cuts per second.

- In some cases, a higher wheel speed can lower the temperature by reducing friction effects.

- Optimizing these grinding variables is key. Reducing the feed rate is a reliable way to lower heat. The coolant flow must support these adjustments.

The Effect of Grinding Depth on Temperature

Research shows that the grinding depth has the most significant influence on temperature. It surpasses the effects of wheel speed and feed rate. A deeper cut removes more material, which generates substantially more heat. This makes depth one of the most important grinding variables to control.

💡 Key Insight: To effectively reduce heat buildup, operators should first consider making shallower cuts. This single adjustment can have a greater impact than changing any other parameter. A proper coolant flow is still needed to manage the remaining heat.

Controlling Vibration to Minimize Friction

Vibration is an unwanted source of friction and heat in any grinding process. Controlling it is crucial for a cooler operation. Vibration can stem from several sources, and a good coolant flow cannot fix these mechanical issues.

Common causes of vibration include:

- Internal: An unbalanced grinding wheel, worn bearings, or a bent shaft.

- External: An improperly secured workpiece or a dull grinding wheel.

Regular machine maintenance, proper wheel balancing, and secure workholding are essential practices. Minimizing vibration leads to a more stable grinding process and less unwanted heat. The coolant flow can then work more efficiently.

Using Narrower Wheel Widths

Using a narrower grinding wheel is another effective strategy. A smaller contact area between the wheel and the workpiece reduces the total thermal load. This simple change means less heat is generated, making it easier for the coolant flow to keep the grinding zone cool. This adjustment to the grinding variables helps ensure the coolant flow can manage the temperature effectively.

Choosing the Right Grinding Wheel

The grinding wheel itself plays a huge role in heat generation. While a good coolant flow is essential, the wheel’s composition can either create more heat or help manage it. Selecting the right wheel is a key step to reduce heat buildup and achieve high-performance grinding.

How Abrasive Type Affects Heat Generation

Different abrasives generate different amounts of heat. Cubic Boron Nitride (CBN) has excellent heat resistance and thermal conductivity. This makes it ideal for the grinding of hard steels because it pulls heat away from the workpiece. In contrast, white aluminum oxide produces less heat, making it a good choice for materials like wood. The abrasive type directly impacts the temperature of any grinding job, so a good coolant flow is always needed.

The Role of Bond Type in Cooler Grinding

The bond holds the abrasive grains together and affects how coolant reaches the grinding zone.

💡 Pro Tip: Vitrified bonds contain many small pores. These pores allow for better coolant flow, which helps cool the grinding process. This improved coolant flow is especially useful when grinding materials that do not handle heat well.

Other bonds, like resin, have lower thermal resistance and can soften under high heat. A porous bond structure supports the coolant flow for cooler high-performance grinding.

Why Aimgrind CBN Wheels Excel in High-Speed Applications

For demanding jobs, specialized wheels are necessary. Aimgrind CBN grinding wheels are an excellent solution for the high-performance grinding of hard materials like tool steels and superalloys.

- Cooler Operation: Aimgrind wheels have exceptional thermal stability. They act as conductors, drawing heat away from the workpiece and into the wheel. This prevents thermal damage.

- Exceptional Hardness: The hardness of CBN ensures the wheel stays sharp, leading to efficient grinding with less friction.

When paired with a proper coolant flow, these wheels deliver superior results in high-performance grinding. The coolant flow helps carry away the heat that the wheel absorbs.

Matching the Wheel to Your Material

Finally, operators must match the wheel to the workpiece material. Using the wrong wheel can cause serious problems, even with perfect coolant flow. For example, CBN wheels are highly effective for grinding hardened superalloys due to their durability. Choosing the correct wheel ensures a successful high-performance grinding operation. The right combination of wheel, coolant, and parameters makes all the difference in modern grinding.

Managing Coolant Flow and Pressure

Many operators believe that a high volume of coolant equals better cooling. This is a common mistake. An effective coolant supply depends on the correct coolant velocity, not just a high coolant flow rate. If the coolant velocity is too low, the coolant will not penetrate the wheel’s air barrier. This makes the coolant flow useless, no matter how high the coolant flow rate is. Proper management of the coolant flow and pressure is essential for any grinding process.

The Link Between Flow Rate, Pressure, and Velocity

The coolant flow rate, system pressure, and coolant velocity are all connected. Increasing the pump pressure raises both the coolant flow rate and the coolant velocity. This relationship allows operators to adjust the coolant flow to match the needs of the grinding job. A balanced flow ensures the coolant reaches the grinding zone effectively. The right coolant flow rate is key.

Finding the Optimal Flow Rate

Finding the best coolant flow rate is critical for an efficient coolant supply. Operators can use several methods to determine the ideal coolant flow for their specific grinding operation.

- Integrate pressure and flow rate sensors into the coolant system.

- Directly measure the coolant velocity with a calibrated anemometer.

- Calculate the coolant velocity using nozzle size and pressure data.

- Use a special collecting box to measure the coolant flow rate in the contact zone.

Achieving the optimal coolant flow rate maximizes the coolant flow through the grinding area, which helps control the process temperature. A good coolant supply is vital for quality grinding.

Validating Adjustments with Chip Color Analysis

Operators can check the effectiveness of their coolant flow by looking at the grinding chips. The color of the chips provides a quick visual indicator of heat.

💡 Chip Color Guide:

- Silver or Straw-Colored Chips: Indicate a cooler, optimal grinding process. The coolant is working well.

- Brown or Blue Chips: Signal excessive heat. The coolant flow is not effective enough.

The color of steel changes at specific temperatures. This scientific fact allows operators to estimate the grinding temperature.

| Steel Color | Degrees Celsius | Degrees Fahrenheit |

|---|---|---|

| Pale Straw Yellow | 232 | 450 |

| Brown Yellow | 260 | 500 |

| Full Blue | 293 | 560 |

| Dark Blue | 299 | 570 |

Monitoring chip color helps validate that the coolant flow rate and coolant velocity adjustments are creating a cooler grinding environment.

Intelligent adjustments to coolant delivery and grinding parameters are more effective than simply increasing coolant volume. Operators can reduce heat buildup in any grinding process. The most critical actions include matching coolant velocity to wheel speed, selecting the right nozzle for coolant flow, and choosing a suitable grinding wheel like Aimgrind’s CBN wheels for demanding grinding. These practices improve workpiece surface quality and can increase productivity by over 30%. Proper coolant flow and grinding techniques extend tool life, boosting overall efficiency in every grinding operation. A good coolant flow improves surface quality and the entire grinding process.

FAQ

Why is matching coolant velocity to wheel speed important?

Matching coolant velocity to wheel speed breaks the air barrier around the grinding wheel. This action ensures the coolant reaches the grinding zone. Effective coolant delivery is crucial for preventing heat buildup during any grinding process. This is a fundamental part of good grinding.

What do different grinding chip colors mean?

Chip color indicates the temperature of the grinding process.

Silver or straw colors show cool, efficient grinding. Brown or blue chips signal excessive heat. This means the coolant is not working effectively. This visual check is key for any grinding job.

Can I just use more coolant to reduce heat in grinding?

No, simply increasing the coolant volume is not effective. The coolant velocity must be correct to penetrate the air barrier. Proper velocity is more important than high volume for successful grinding and heat management. The grinding setup needs the right coolant speed.

How does the grinding wheel choice affect heat?

The grinding wheel’s material affects heat generation. Aimgrind CBN wheels have high thermal stability, pulling heat from the workpiece into the wheel. This feature makes them ideal for cooler grinding of hard materials. The coolant then carries the heat away from the grinding area.

Contact Us

For More Grinding Solution or Customized Abrasive Tools