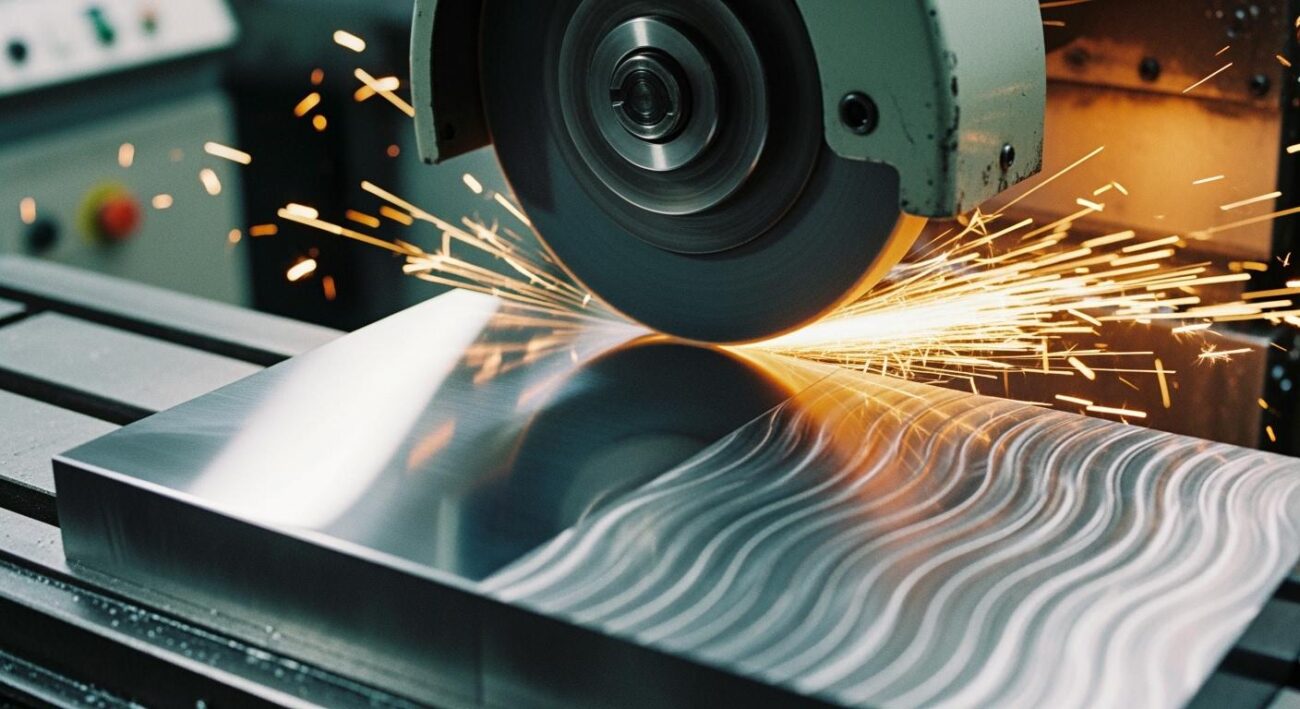

Achieving high-quality surface finishes is a critical goal in precision grinding. Industries have stringent standards for part quality.

For example, demanding sectors like aerospace require an exceptionally low roughness, often between 2-4 µin Ra for specific coatings.

The final surface roughness is a direct result of several key factors within the grinding process. These factors for the surface finish in grinding fall into three main groups, all vital to precision grinding: the grinding wheel, operational parameters, and system conditions.

Key Takeaways

- The grinding wheel’s grain size and type greatly affect how smooth a surface becomes.

- Adjusting grinding speed, workpiece speed, and depth of cut helps control the final surface smoothness.

- A stable machine without vibrations is important for a smooth surface.

- Grinding fluid cools the workpiece and lubricates the process, which helps make the surface smoother.

Grinding Wheel: The Foundation of Surface Roughness

The grinding wheel is the primary tool that contacts the workpiece. Its composition directly shapes the final surface. Proper grinding wheel selection is the first step toward controlling the surface finish in grinding. Three characteristics are especially important: abrasive grain size, abrasive type, and bond hardness.

Abrasive Grain Size and Its Impact

Abrasive grain size, or grit, has a direct effect on the final surface roughness. Finer grains create smaller scratches, resulting in a smoother surface. Coarser grains remove material faster but leave a higher roughness value. The goal of precision grinding is to balance material removal with the desired finish.

For example, a finer abrasive like diamond can achieve a significantly lower roughness compared to a coarser conventional abrasive.

| Abrasive Grain Type | Ra Value (µm) |

|---|---|

| Si-C 500 grain | 0.103 |

| Diamond 2-3 µm | 0.009 |

Choosing the right grit is a key part of grinding wheel selection for any precision grinding task.

Abrasive Type: From Conventional to Aimgrind’s Super Hard Abrasives

The type of abrasive material determines its cutting efficiency and suitability for different workpieces. Conventional abrasives like aluminum oxide and silicon carbide are common. Aluminum oxide often produces a more refined surface on metals. Super hard abrasives, such as diamond and cubic boron nitride (CBN), offer unmatched performance for demanding applications.

- Diamond excels at grinding extremely hard, non-ferrous materials like ceramics, glass, and tungsten carbide.

- Cubic Boron Nitride (CBN) is the best choice for grinding hardened steels and other ferrous alloys because it remains stable at high temperatures.

For challenging grinding operations on hard materials, a specialist can provide the right solution. Aimgrind is a specialized brand providing customized grinding wheels. Aimgrind’s super hard abrasives are the ideal choice for achieving a superior surface finish. Their durability and cutting efficiency ensure a longer tool life and consistent results, which is vital for controlling roughness in precision grinding.

Bond Type and Hardness

The bond holds the abrasive grains together. Its hardness dictates how quickly the wheel exposes new, sharp grains. A simple rule guides the selection:

- Use a softer bond for harder materials. The bond breaks down faster, exposing fresh abrasive grains to maintain cutting efficiency and prevent workpiece burn.

- Use a harder bond for softer materials. The bond retains the abrasive grains longer, maximizing the wheel’s life since the grains do not dull as quickly.

This relationship is fundamental to effective grinding. Matching the bond hardness to the workpiece material prevents premature wheel wear and ensures a consistent cutting action.

Key Factors Affecting Surface Finish: Operational Parameters

Beyond wheel selection, operational settings are key factors affecting surface finish. Operators control these grinding parameters and machine settings to achieve specific outcomes. Adjusting these cutting parameters allows for fine-tuning the final surface finish in grinding.

Grinding Wheel Speed

The linear speed of the grinding wheel directly influences the cutting action. Increasing the wheel speed reduces the undeformed chip thickness for each abrasive grain. This action weakens the plowing and scratching effects. The result is a more uniform surface texture and lower surface roughness. Proper wheel speed is essential for effective precision grinding.

Workpiece Speed and Feed Rate

Workpiece speed and feed rate are critical cutting parameters. A higher workpiece speed often creates thinner, more distinct grinding marks. This leads to a more uniform appearance and improved roughness. The feed rate, however, has a different effect.

A lower feed rate reduces the load on individual abrasive grains. Reducing the feed rate from 0.1 mm/rev to 0.02 mm/rev can improve roughness by as much as 20%.

Careful control of these variables is vital for high-quality grinding.

Depth of Cut: Roughing vs. Finishing

Grinding is a finishing process, not a roughing operation. It uses a very shallow depth of cut to maintain precision and control heat. A typical depth of cut in grinding ranges from 0.01 mm to 0.1 mm per pass. This small depth of cut is a hallmark of precision grinding. For a mirror-like surface finish in grinding, the final passes require an even smaller depth of cut.

- A radial depth of cut of just 1-2 µm is used for the final passes.

- These passes are followed by “spark-out” passes with zero depth of cut to remove any remaining deflection.

The Role of Wheel Dressing

Wheel dressing restores the wheel’s cutting surface, ensuring consistent performance. The frequency of dressing is one of the most important cutting parameters for maintaining quality over a production run. Dressing the wheel before the final finishing passes in a multi-stage grinding process ensures each part receives a consistent action. Rotary diamond dressers often provide a more controlled dressing pattern than single-point dressers. This leads to superior finishes and better dimensional accuracy in precision grinding.

Improving Surface Finish in Grinding: Machine and Workpiece

The grinding system, including the workpiece and the machine itself, introduces another layer of variables that influence the final surface. Understanding these elements is crucial for achieving top-tier results in precision grinding.

Workpiece Material and Hardness

The workpiece’s material type and hardness directly affect the grinding process. Harder materials resist cutting, while softer materials can clog the wheel. Exotic alloys present unique challenges.

- Inconel has poor machinability, making finishing a slow process that requires high-performance tools.

- Titanium is delicate and prone to tool wear, demanding sharp abrasives and proper cooling during grinding.

Achieving a high-quality surface finish in grinding on these materials often requires post-machining operations like polishing or lapping to meet strict specifications.

Machine Rigidity and Vibration Roughness

A stable machine is the bedrock of precision grinding. Machine vibrations cause the grinding wheel and workpiece to oscillate, creating chatter marks and increasing surface roughness. Common sources of vibration include:

- Imbalance in the grinding wheel

- Worn or damaged machine components

- Improper wheel dressing

- Insufficient machine rigidity

Technicians can measure and analyze these vibrations using tools like accelerometers. This helps pinpoint issues such as worn bearings or tool misalignment, preventing poor surface quality before it occurs.

A rigid, well-maintained machine minimizes unwanted movement, which is essential for a smooth grinding operation and a flawless finish.

The Function of Grinding Fluid

Grinding fluid, or coolant, performs two critical functions: cooling and lubrication. Proper coolant selection and application are vital for managing heat and friction.

- Cooling: The fluid removes intense heat from the grinding zone. This prevents thermal damage to the workpiece and extends the life of the grinding wheel.

- Lubrication: The fluid forms a film between the wheel and workpiece. This film reduces friction, which improves the final surface roughness and prevents material from sticking to the wheel.

Effective coolant and lubrication enable higher material removal rates and reduce the need for frequent wheel dressing. Both water-based and synthetic coolants are used in precision grinding, each offering distinct benefits for friction reduction and thermal management.

Achieving the desired surface finish in grinding requires mastering three areas: wheel selection, operational parameters, and system stability. Attaining high-precision surface finishes is a balancing act between these interconnected key factors. Proper grinding optimization improves part quality and the economy of the grinding operation. Systematically analyzing your grinding process helps lower surface roughness and overall roughness. For a superior surface finish, expert partners like Aimgrind provide customized grinding solutions.

FAQ

How can operators best control surface roughness?

Operators control roughness by balancing three areas. They must select the correct grinding wheel. They also adjust operational parameters like speed and feed rate. Finally, they ensure machine stability to prevent vibration. This provides a comprehensive approach.

What tools provide an accurate measurement of surface roughness?

Technicians use a profilometer for an accurate measurement of surface roughness. This tool traces a stylus across the surface. The resulting measurement provides a precise roughness value. Optical profilers offer another non-contact measurement method for delicate surfaces.

What is the first step to fix a poor surface finish?

Operators should first inspect the grinding wheel. Dressing the wheel often restores its cutting ability and improves the finish. This simple action removes dull grains and loading. It is a critical step for consistent quality.

Why is coolant so important for surface finish?

Coolant serves two key roles. It removes heat to prevent thermal damage to the workpiece. It also lubricates the grinding zone, reducing friction. This dual action leads to a smoother surface. A final measurement confirms the improvement.

Contact Us

For More Grinding Solution or Customized Abrasive Tools