Your wheel’s bond directly controls wheel performance. This bond manages how grinding wheels hold and release abrasive grains. Your wheel selection involves a key trade-off. A softer bond allows for aggressive grinding, while a harder bond delivers a superior finish and longer performance.

Note: Understanding the wheel’s bond is crucial. This knowledge helps you optimize your grinding process for speed, a fine finish, or maximum wheel life. Choosing the right bond for your wheels ensures you get the results you need.

Key Takeaways

- The wheel’s bond holds abrasive grains. It controls how the wheel grinds.

- Softer bonds remove material faster. They wear out quicker.

- Harder bonds give a smoother finish. They last longer.

- Different bonds work best for different materials. Choose the right bond for your job.

Understanding Your Wheel’s Bond Type

The wheel’s bond is the “glue” holding the abrasive grains together. Different bond types offer unique performance characteristics. You must choose the right bond to match your material and grinding goals. This choice directly impacts your efficiency, finish quality, and overall costs.

Vitrified Bonds for High Efficiency

Vitrified bonds are very rigid and strong. They create a porous wheel structure. This porosity helps with coolant flow and chip clearance, making these wheels excellent for high-speed grinding and heavy stock removal. You will find this bond is perfect for precision tasks.

Common Applications for Vitrified Bonds:

- Precision grinding of hardened steels and tungsten carbide.

- Internal and external grinding in the automotive and aerospace industries.

- Manufacturing high-precision components like molds and dies.

Resin Bond Grinding Wheels for Versatility

Resin bond grinding wheels offer great flexibility. This resin bond allows the wheel to produce an excellent surface finish. The resin bond grinding wheels absorb shock, which reduces chatter during grinding. This makes resin bond grinding wheels ideal for applications needing a smooth finish. The resin bond grinding wheels are also very versatile. You can use resin bond grinding wheels for grinding superalloys, ceramics, and tool steels. The resin bond provides good edge stability for the superabrasive grains. The resin bond grinding wheels maintain a sharp edge. The superabrasive stays effective. The resin bond grinding wheels give a consistent edge.

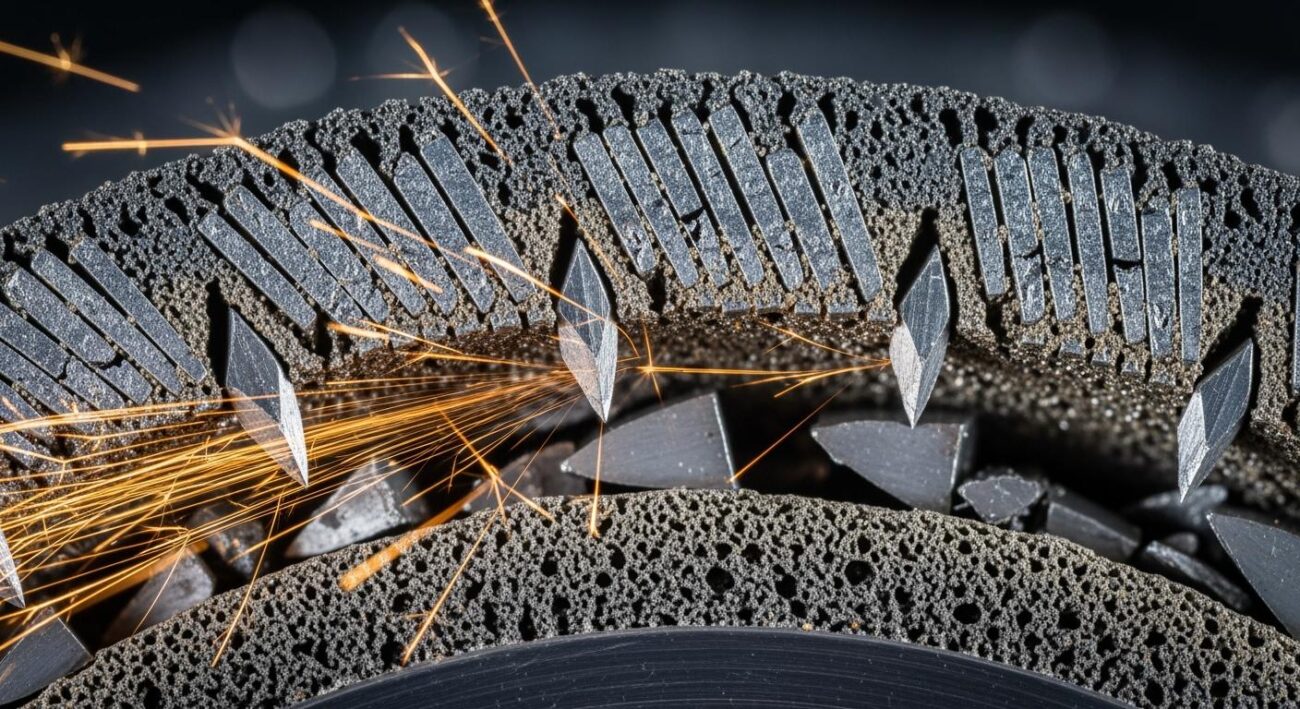

Metal Bonds for Extreme Durability

For the most demanding jobs, you need a metal bond. This bond provides the highest wear resistance and longest wheel life. It excels at holding its shape, ensuring superior edge stability and precision. When you work with tough materials like tungsten carbide, industrial ceramics, or superalloys, a metal bond is your best choice.

Aimgrind specializes in these high-performance solutions. Our metal bond grinding wheels deliver unmatched durability and form-holding. They provide a precise edge for critical applications. This superabrasive grinding wheel maintains its edge integrity, giving you a perfect finish and exceptional performance. The superabrasive particles are held securely, offering a reliable edge for every pass. The superabrasive ensures a clean edge.

How Bond Hardness Impacts Stock Removal

The hardness of your wheel’s bond directly controls how quickly you can remove material. A harder bond holds abrasive grains longer, while a softer bond releases them more easily. Your choice between the two depends entirely on whether your priority is speed or control in your grinding operation.

Softer Bonds for Faster Material Removal

You should choose softer bond wheels for fast stock removal. These wheels have a unique “self-sharpening” ability. This process is especially effective in resin bond wheels. The resin bond allows for consistent performance.

- Abrasive grains become dull as they cut material.

- Grinding chips erode the surrounding resin bond.

- This erosion releases the old, dull grains.

- Fresh, sharp grains are exposed to continue cutting.

This cycle ensures your grinding process remains efficient. Softer resin bond wheels are excellent for hard materials because they constantly supply fresh cutting edges. The resin bond provides good self-sharpening, and the resin bond helps maintain a consistent cutting edge. The resin bond is key to this process. The resin bond allows the resin bond wheels to work well.

Harder Bonds for Controlled Grinding

You need a harder bond for controlled grinding and precision tasks. A strong bond holds abrasive grains securely. This improves grain retention and boosts material removal efficiency, especially at higher removal rates. This strong bond helps the wheels resist wear during tough grinding jobs.

A harder bond often requires more energy. The material’s hardness is directly related to the power needed for grinding. However, this trade-off gives you incredible control, which is essential for specific applications.

- Metal Bonds: You can use these for highly abrasive materials like ceramics and carbide.

- Vitrified Bonds: These are ideal for tasks that demand high form accuracy.

A harder bond gives you the durability needed for a precise and consistent grinding result.

The Bond’s Role in Surface Finish Quality

The bond in your grinding wheels plays a huge role in the final surface finish of your workpiece. A harder bond holds superabrasive grains securely, creating a smooth, consistent surface. A softer bond, which wears away faster, generally results in a rougher surface finish. Your choice of bond directly impacts the quality and precision of your grinding work.

Achieving Finer Finishes with a Harder Bond

You should choose a harder bond for a superior surface finish. A rigid bond minimizes wheel deflection and vibration during grinding. This stability transfers directly to your workpiece, improving dimensional accuracy and creating a finer finish. Vitrified and metal bonds excel in this area.

For applications where tight tolerances are critical, the precision and durability of metal bond grinding wheels are unmatched. Products like Aimgrind’s metal bond grinding wheels are ideal for achieving an excellent surface finish. The strong bond holds the superabrasive particles firmly, ensuring the wheel maintains its exact shape for precise grinding. This makes them perfect for creating a flawless finish on hard materials.

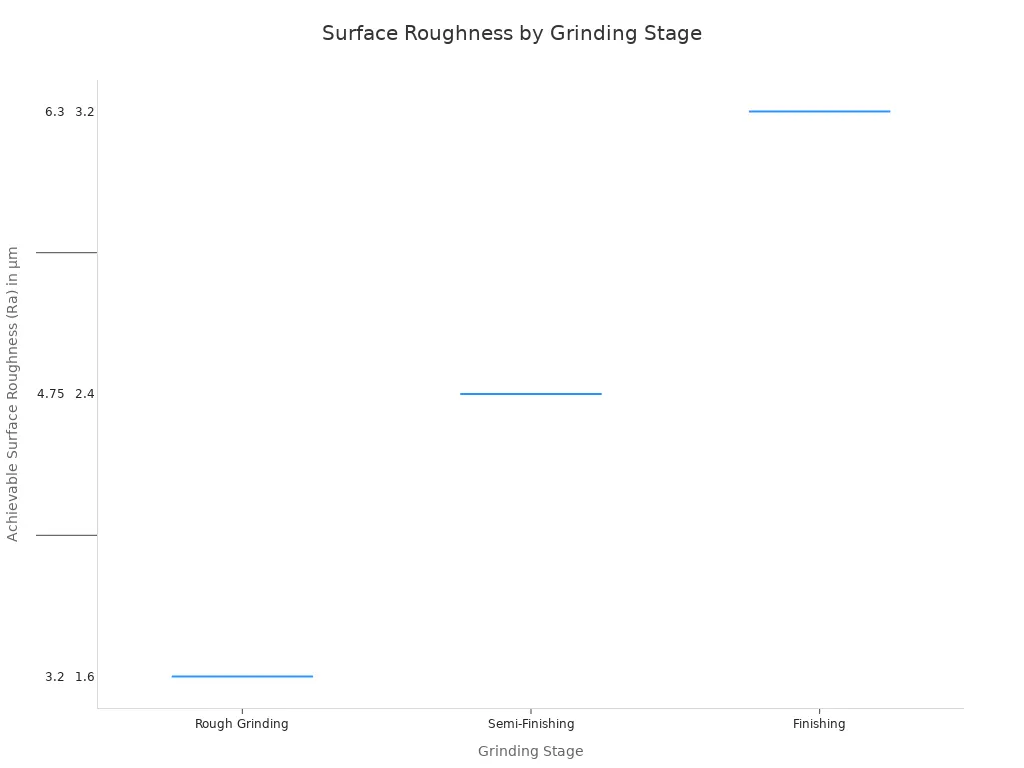

As you move from rough grinding to ultra-finishing, the required surface finish becomes much finer. Harder bond wheels with superabrasive grains help you achieve these precise results.

How Softer Bonds Affect Surface Roughness

Softer bond wheels typically create a rougher surface finish. The bond breaks down more quickly, which is great for rapid stock removal but less ideal for precision. The resin bond is a key component in these wheels. While a resin bond is known for producing a good surface finish, especially with fine superabrasive grits, its softness can lead to a less perfect result compared to a hard metal bond. The resin bond allows for flexibility. This resin bond is versatile. The resin bond works well in many situations. The resin bond is a popular choice. The resin bond is effective. The resin bond helps the superabrasive cut well. The resin bond is reliable.

However, you can still achieve an acceptable surface finish with softer wheels under certain conditions. A general rule is to use a softer grade of wheel for grinding harder materials. The resin bond allows the wheel to adapt, preventing glazing and ensuring effective cutting.

Bond Strength and Your Grinding Wheel’s Life

The strength of your grinding wheel’s bond directly determines its lifespan. A stronger bond provides greater durability, while a softer bond is designed for controlled wear. Your choice affects how often you replace wheels and the overall economy of your grinding operation. Understanding this relationship helps you select the right wheel for maximum longevity or planned efficiency.

Harder Bond for Maximum Longevity

You should choose a harder bond for the greatest wheel longevity. A strong bond holds abrasive grains tightly, so the wheel wears down much slower. This means you get more use from a single wheel, reducing downtime and replacement costs. The integrity of the bond also allows wheels to operate safely at higher speeds, boosting productivity. Metal bonds, for example, offer superior longevity for demanding jobs.

Tip: The maximum safe operating speed, measured in Surface Feet Per Minute (SFPM), is directly related to the bond type. Stronger bonds can handle higher speeds.

Bond Type (Wet Grind) SFPM (Wet Grind) Bond Type (Dry Grind) SFPM (Dry Grind) Resin Bond 3937-9843 Resin Bond 3937-7874 Metal bond 3937-15748 Metal bond 3937-9843 Vitrified bond 4921-31496 Vitrified bond N/A

Softer Bonds and Planned Wheel Wear

Softer bond wheels are designed for planned wear. This might sound counterintuitive, but it is a key feature for certain applications. The concept is linked to friability, which is the ability of abrasive grains to fracture and expose new, sharp cutting edges. A softer resin bond allows this to happen efficiently.

The resin bond erodes as you work, releasing dull grains. This self-sharpening action is why a resin bond is perfect for grinding hard materials without glazing. The resin bond ensures a consistent cut. This feature of the resin bond makes the wheel’s performance predictable. The resin bond keeps the grinding process effective. The resin bond is a key part of this design. The resin bond makes these wheels a smart choice. The resin bond is very useful. The resin bond is great.

Your choice of bond creates a clear trade-off. A softer bond, like a resin bond, improves grinding speed but shortens the life of your wheels. A harder bond delivers a superior finish and longer performance.

Selecting the right bond for your grinding wheels is a strategic decision. You must analyze your grinding goals for speed, finish, or economy.

For the best grinding results, consider Aimgrind’s customized grinding wheels. Our experts help you find the perfect bond for your specific needs.

FAQ

How do I choose the right bond for my material?

You should match the bond to your material’s hardness. A general rule is to use a softer bond for hard materials and a harder bond for soft materials. This ensures the wheel wears correctly and cuts efficiently.

Can a soft bond wheel still produce a good finish?

Yes, you can achieve a decent finish with a soft bond wheel, especially with fine abrasive grits. However, a harder bond provides more stability. You should choose a harder bond for a superior, high-quality finish.

Are harder bond wheels more cost-effective?

Harder bond wheels often have a higher initial cost. They last much longer, which reduces replacement frequency and downtime. This extended life can make them more cost-effective for many operations over time.

When should I use a metal bond grinding wheel?

You should use a metal bond for the toughest jobs. These are ideal for grinding very hard materials like ceramics or carbide. They offer extreme durability and help you achieve a precise, fine finish where tolerances are critical.

Contact Us

For More Grinding Solution or Customized Abrasive Tools