Think of a grinding wheel bond as the essential “glue.” It holds the abrasive grains together and determines the wheel’s physical properties. The bond’s performance is just as crucial as the abrasive for achieving your desired results. Choosing the correct grinding wheel bond is key to improving efficiency and surface finish in various grinding applications. The industry’s growth underscores this importance:

- The global grinding wheel market is set to grow by USD 6.29 billion by 2029.

- This represents a compound annual growth rate (CAGR) of 5.2%.

Key Takeaways

- A grinding wheel bond holds abrasive grains together. It controls how the wheel works and affects grinding results.

- Different bond types suit different jobs. Vitrified bonds are for precision, resinoid for speed, and metal for tough materials.

- Choose the right bond for your task. Consider the material, desired finish, machine power, and type of grinding operation.

- Matching the bond to your goal is important. This helps you get the best results and makes your work more efficient.

The Role of a Grinding Wheel Bond

The bonding agent in a grinding wheel is more than just glue. You can think of it as the wheel’s manager. It controls how the abrasive grains work together to shape your workpiece. The primary job of the bonding agent is to hold these grains in place with a specific amount of strength.

This control directly impacts your grinding results. The bonding agent performs several key functions:

- It holds the abrasive grains together.

- It gives the wheel its shape and structural integrity.

- It determines when to release dull abrasive grains.

The hardness of the bonding agent, known as its “grade,” dictates how tightly it grips the abrasives. A hard-grade bonding agent holds grains longer, which reduces wheel wear. This leads to a better grinding (G) ratio, meaning you get more work done before the wheel wears down. A soft-grade bonding agent releases grains more easily. This action exposes new, sharp grains, which is useful when grinding very hard materials.

Your choice of bonding agent also influences how quickly you can remove material. For rapid stock removal, you need a tough bonding agent that can handle high pressure. The right selection ultimately defines the wheel’s overall grinding properties. The grinding wheel bond is the key to unlocking the wheel’s full potential.

Quick Tip: Match your bond type to your grinding goal for the best results.

| Grinding Objective | Recommended Bond Types |

|---|---|

| High Stock Removal | Resinoid, Porous Vitrified |

| Fine Surface Finish | Rubber, Shellac, fine grit Vitrified/Resinoid |

| Tight Tolerance/Form Holding | Vitrified, Metal |

Exploring Common Grinding Wheel Bonds

Now that you understand the role of a grinding wheel bond, let’s explore the most common types. Each bond offers unique characteristics, making it suitable for different materials, speeds, and finishes. Choosing the right one is crucial for your success.

Vitrified Bond (V): Precision and Rigidity

The vitrified bond is the most common and widely used bond in the industry. Think of it as a glass-like material that creates an extremely hard, rigid, and porous structure.

Manufacturers create vitrified grinding wheels by mixing abrasive grains with materials like clay, feldspar, and quartz. This mixture is then pressed into shape and fired at high temperatures in a kiln. The result is a strong, porous wheel with several key advantages:

- Engineered Porosity: The pores within the vitrified bond act as tiny channels. They deliver coolant effectively to the grinding zone, preventing heat damage. They also provide space for chips to clear away, which stops the wheel from clogging.

- Structural Rigidity: The hardness of the vitrified bond allows the wheel to hold its shape exceptionally well. This makes it perfect for precision grinding jobs that require tight tolerances.

- Aggressive Cutting: This bond holds abrasive grains securely, allowing for aggressive material removal on very hard materials.

At Aimgrind, we specialize in this technology. Our vitrified bond grinding wheels are engineered for exceptional hardness and thermal stability. This makes them ideal for the precision grinding of hard metals, ceramics, and composites. By holding their form and resisting wear, these wheels reduce downtime and boost your overall productivity. You can explore our solutions for your specific needs here: https://aimgrind.com/product-category/vitrified-bond-grinding-wheels/

Vitrified grinding wheels are versatile. You can use them on a wide range of materials:

- Vitrified Diamond Wheels: Perfect for PCD/PCBN, tungsten carbide, ceramics, and glass.

- Vitrified CBN Wheels: Ideal for hardened steels, aerospace alloys, and tool steels.

These wheels also operate at impressive speeds, though the maximum speed depends on the abrasive and application.

| Grinding Type | Abrasive Type | Maximum SFPM (Wet Grind) |

|---|---|---|

| OD Grinding | Diamond | 6,890 |

| OD Grinding | CBN | 31,496 |

| ID Grinding | N/A | 13,780 |

Resinoid and Resin Bond (B): Speed and Flexibility

When your job demands high-speed operation and a degree of flexibility, the resinoid bond is your go-to choice. A resinoid bond consists of synthetic resins, such as phenolic resin, mixed with plasticizers and fillers. This composition gives resinoid grinding wheels a key advantage: shock absorption.

Unlike the rigid vitrified bond, a resinoid bond has higher elasticity. This allows it to better withstand sudden impacts and vibrations, making it suitable for heavy-duty work like snagging in foundries or high-speed cutting. The flexibility of the resinoid bond also helps it conform slightly to the workpiece, which is beneficial for grinding complex shapes.

You will find resinoid grinding wheels in a vast number of applications due to their versatility and performance at high operating speeds.

Did You Know? Resinoid grinding wheels are excellent for applications requiring rapid stock removal and can be used for both wet and dry grinding.

Common uses for resinoid wheels include:

- Tool Manufacturing: Sharpening and grinding high-speed steel, carbide tools, and saw blades.

- Fabrication: Cutting-off operations, deburring, and general-purpose metal grinding.

- Aerospace & Automotive: Grinding tough alloys, cast iron components, and finishing composite materials.

The resinoid bond is a workhorse for many industries, providing a balance of speed, flexibility, and efficiency. The performance of a resinoid wheel makes it a popular choice.

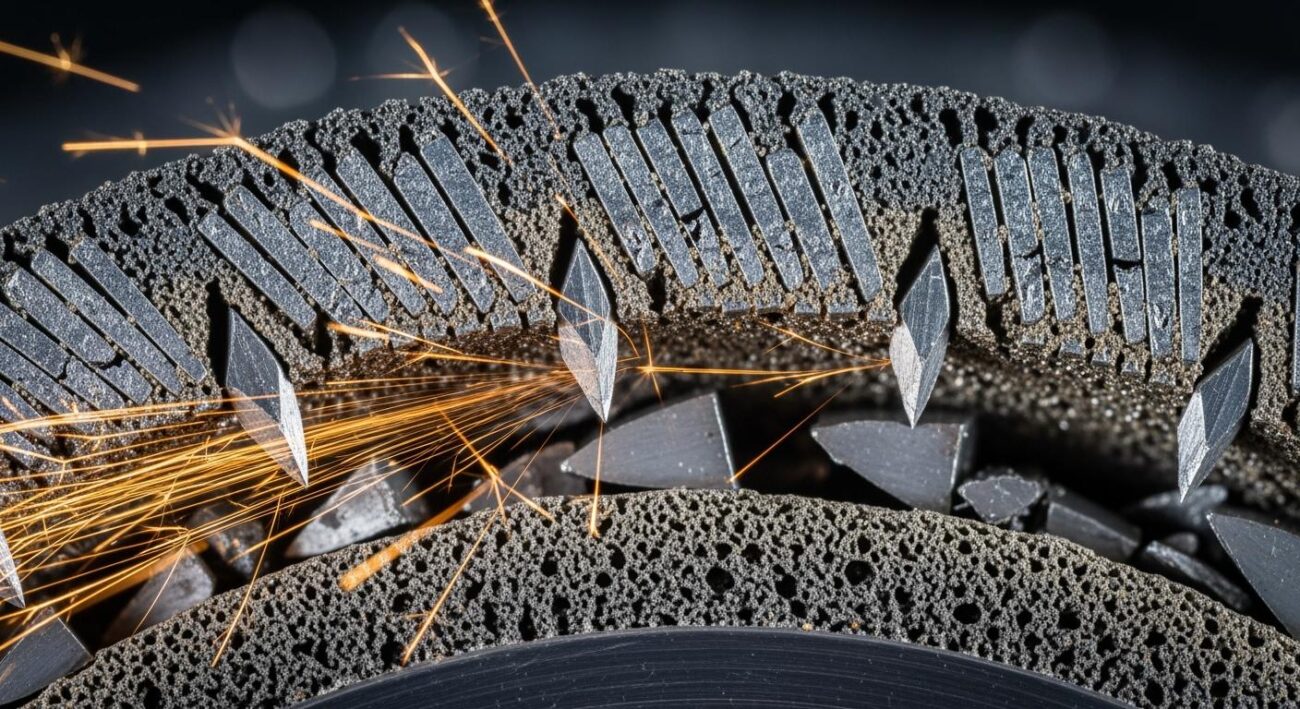

Metal Bond (M): Extreme Durability

For the toughest grinding jobs on the hardest materials, you need the extreme durability of a metal bond. A metal bond wheel is made by sintering powdered metals—like cobalt, copper, or silver—with superabrasive grains. This process creates an incredibly strong and wear-resistant bond.

The primary strength of the metal bond is its ability to hold onto abrasive grains longer than any other bond type. This results in an exceptionally long wheel life, making it a cost-effective choice for high-volume production. A metal bond provides the robust support needed to prevent superabrasives from pulling out under intense grinding pressure.

A metal bond is almost always paired with superabrasives:

- Diamond: Use a metal bond diamond wheel for non-ferrous materials like tungsten carbide, ceramics, glass, and composites.

- CBN (Cubic Boron Nitride): Choose a metal bond CBN wheel for grinding hardened ferrous metals, such as tool steels and superalloys.

While a metal bond offers unmatched durability, it typically has a slower material removal rate compared to a resinoid or vitrified bond because it does not expose new abrasive grains as quickly. This makes the metal bond ideal for applications where form holding and longevity are more important than cutting speed. You can find this type of superabrasive grinding wheel in industries that process ultra-hard materials. The metal bond is the ultimate choice for wear resistance.

Other Specialized Bonds: Rubber and Shellac

Beyond the main three, you will find specialized bonds designed for unique finishing tasks.

Rubber Bond (R) A rubber bond is made from natural or synthetic rubber mixed with abrasive grains. These wheels are known for their flexibility and ability to produce exceptionally smooth surface finishes. You can use them to achieve a mirror-like finish on parts like roller bearing races and in precision applications in the medical and aerospace industries.

Shellac Bond (E) Shellac is a natural resin that creates a bond known for its cool-cutting action. This makes it perfect for applications where you must avoid generating heat. Shellac bond wheels are not for heavy grinding. Instead, you use them for precision finishing on delicate parts like surgical blades, hypodermic needles, and cutlery.

Advanced Bonds Technology continues to evolve, leading to more advanced options.

- An electroplated bond holds a single layer of superabrasives on the wheel’s surface, ideal for creating intricate forms and profiles. The electroplated bond offers aggressive cutting but has a shorter life. You will see an electroplated bond used in tool and die making.

- A hybrid bond combines the properties of different bond types, such as the durability of a metal bond with the cutting speed of a resinoid. These advanced bonds, including custom hybrid bonds, are engineered to deliver specific performance characteristics for highly specialized applications. A hybrid bond can offer the best of both worlds. The hybrid bond is a testament to innovation in abrasive technology.

How to Select the Right Bond for Your Task

Choosing the right bond can feel complex, but you can simplify the process by focusing on a few key factors. Your success depends on matching the wheel to your specific job. Consider these points to make the best choice.

1. The Material You Are Grinding ⚙️ Your workpiece material is the most important factor. Different materials require different bonds and grit sizes. For example, you should use wheels free of iron to grind stainless steel. This prevents contamination. Soft metals like aluminum need softer grade wheels with a coarser grit to avoid loading, which is when chips clog the wheel.

2. Your Desired Surface Finish ✨ What kind of finish do you need? The bond you select directly impacts the final surface quality. For a very smooth, mirror-like finish, you need a bond designed for precision. For jobs where the finish is less critical, a more flexible bond will work well.

Quick Tip: A fine grit (100–120) paired with a vitrified bond is excellent for precision grinding.

| Bond Type | Impact on Surface Finish |

|---|---|

| Vitrified | Offers high precision and is ideal for fine finishes. |

| Resinoid | More flexible and great for general-purpose finishes. |

3. Your Grinding Machine’s Power 💪 The power of your grinding machine plays a big role. A high-horsepower machine has enough force to use a harder grade wheel. The wheel holds its shape and the machine can fracture the durable grains to keep them sharp. A low-horsepower machine needs a softer wheel. A hard wheel on a low-power machine will become dull, causing heat and damaging your workpiece.

4. The Grinding Operation Finally, think about the type of job. Are you removing a lot of material quickly (heavy stock removal)? Or are you performing a delicate, precise task (finishing)?

- Heavy Stock Removal: Resinoid bonds are often best.

- Precision Grinding: Vitrified or metal bonds provide the rigidity needed for tight tolerances.

By evaluating these four areas, you can confidently select the perfect bond for your task.

The grinding wheel bond is a critical component that defines your wheel’s performance. You can choose vitrified for precision, resinoid for high-speed operations, or metal for ultimate durability. Experts know that customized solutions deliver the most precise and repeatable results. For a grinding tool tailored to your exact needs, it is best to consult with specialists.

Grind with Passion, Achieve with Aim. Let the experts at Aimgrind help you find the perfect grinding solution.

FAQ

What is the difference between bond grade and bond type?

Bond type is the “glue” material, like vitrified (V) or resinoid (B). Bond grade tells you the hardness of that glue. A hard grade holds abrasive grains tightly. A soft grade releases them more easily to expose fresh, sharp grains.

Which bond should I choose for the smoothest finish? ✨

You should select a rubber or shellac bond for the smoothest, mirror-like finishes. These bonds are flexible and create very little heat. For precise finishes on hard materials, a fine-grit vitrified wheel is also an excellent choice.

Why is my grinding wheel getting clogged?

Your wheel may be “loading” if the bond is too hard for your material. Soft metals like aluminum require a softer grade wheel. This helps the wheel shed old grains and clears chips, preventing them from packing into the wheel’s surface.

Can I use a vitrified wheel for high-speed cutting?

No, you should use a resinoid bond for high-speed cutting. Vitrified bonds provide rigidity for precision grinding. Resinoid bonds offer the flexibility and shock absorption needed for demanding cut-off jobs, making them the safer and more effective choice.

Contact Us

For More Grinding Solution or Customized Abrasive Tools