Testing abrasive wheels is a mandatory safety requirement, not an operational choice. Regulatory bodies like OSHA enforce these safety checks to prevent catastrophic failures. The ANSI B7.1 standard details specific testing protocols, setting strict tolerances for wheel parallelism and cylindricity. To ensure safety and serviceability, operators must perform essential abrasive wheel tests.

These crucial checks include:

- The Ring Test

- Visual Inspection

- Speed Check

- The final Trial Run for every abrasive wheel

Key Takeaways

- Always perform safety checks on abrasive wheels before use. This prevents accidents and follows safety rules.

- The Ring Test checks vitrified wheels for hidden cracks. A clear ring means it is safe; a dull thud means it is broken.

- Visually inspect all wheels for damage like cracks or chips. Also, check that the wheel’s speed limit is higher than the machine’s speed.

- Super hard wheels like diamond or CBN wheels need different checks. Look for surface damage and ensure the abrasive part is secure.

- After mounting a new wheel, always do a trial run. Let it spin for at least one minute, or three minutes for best safety, before using it.

The Ring Test for Vitrified Wheels

The Ring Test is a simple yet effective procedure for checking the structural integrity of vitrified abrasive wheels. This specific quality test is not effective for other types, such as resin or metal bond wheels, which do not produce the same sound. Operators should perform these tests before mounting any vitrified wheel to prevent catastrophic failure.

Purpose of the Ring Test

The primary purpose of the Ring Test is to detect hidden structural damage. An abrasive wheel can develop internal cracks from shipping or handling that are not visible on the surface. These cracks pose a significant danger. They can cause the wheel to fracture violently at high speeds. This test acts as a critical first line of defense, ensuring the wheel is sound before it ever reaches the grinder spindle.

How to Perform the Test

An operator can perform the testing procedure correctly by following a few simple steps. This process ensures accurate results and operator safety.

- Ensure the wheel is dry and clean of any debris.

- Suspend the wheel freely. An operator can hang smaller wheels on a finger or a small pin through the bore.

- Use a light, non-metallic object. A plastic screwdriver handle or a small wooden mallet works well.

- Gently tap the wheel on its side, about 45 degrees from the vertical centerline on each side.

- Rotate the wheel 180 degrees and repeat the tap. Listen carefully to the sound it produces.

Interpreting the Results

The sound the wheel makes reveals its condition. A clear, high-pitched “ring” indicates the wheel is intact and safe to use. Conversely, a dull “thud” or a dead sound suggests the wheel is cracked.

Important Safety Note ⚠️

A wheel that produces a thud is compromised and must be removed from service immediately. The operator must destroy the wheel to prevent accidental use by another person.

Fundamental Safety Checks: Visual and Speed

Beyond the Ring Test, a series of visual and mechanical checks are essential for ensuring operator safety. These fundamental tests help identify obvious flaws and compatibility issues before an abrasive wheel is ever mounted. Proper grinding wheel inspection is a non-negotiable step in any professional setting.

Performing a Thorough Visual Inspection

An operator must conduct a careful visual examination of all abrasive wheels before use. This process involves looking for any signs of physical damage that could compromise the wheel’s integrity. An operator should check for the following defects:

- Visible cracks or fine hairline fractures on the surface.

- Chips or gouges, especially around the arbor hole or edges.

- Discoloration, such as blue or brown spots, which indicates heat damage.

- Wet spots, suggesting the wheel has absorbed moisture.

- Warped or uneven surfaces.

- A damaged or missing blotter (the paper washer on the side).

Checking for Improper Storage Signs

Damage often occurs long before a wheel reaches the grinder. Improper storage can expose an abrasive wheel to harmful conditions. Operators should look for signs of exposure to moisture, extreme temperatures, or solvents. A wheel stored in a damp area may show condensation or feel wet, which weakens its bonding material. Storing wheels in freezing temperatures can also cause hidden fractures. These conditions create a significant risk of failure during operation.

Verifying Speed and Dimensional Compatibility

The most critical safety check involves speed compatibility. An operator must compare the maximum RPM (Revolutions Per Minute) listed on the wheel’s blotter with the spindle speed of the grinding machine.

The Golden Rule of Grinder Safety ⚙️

The wheel’s maximum RPM must always be higher than the machine’s RPM. Operating a wheel above its rated speed can cause it to shatter from centrifugal force, sending fragments flying at high velocity.

This final step in pre-mount testing is a core requirement. The Occupational Safety and Health Administration (OSHA) standard 1910.215 also mandates that machines have proper safety guards in place, which provides a critical barrier if a wheel fails. These simple checks prevent catastrophic accidents.

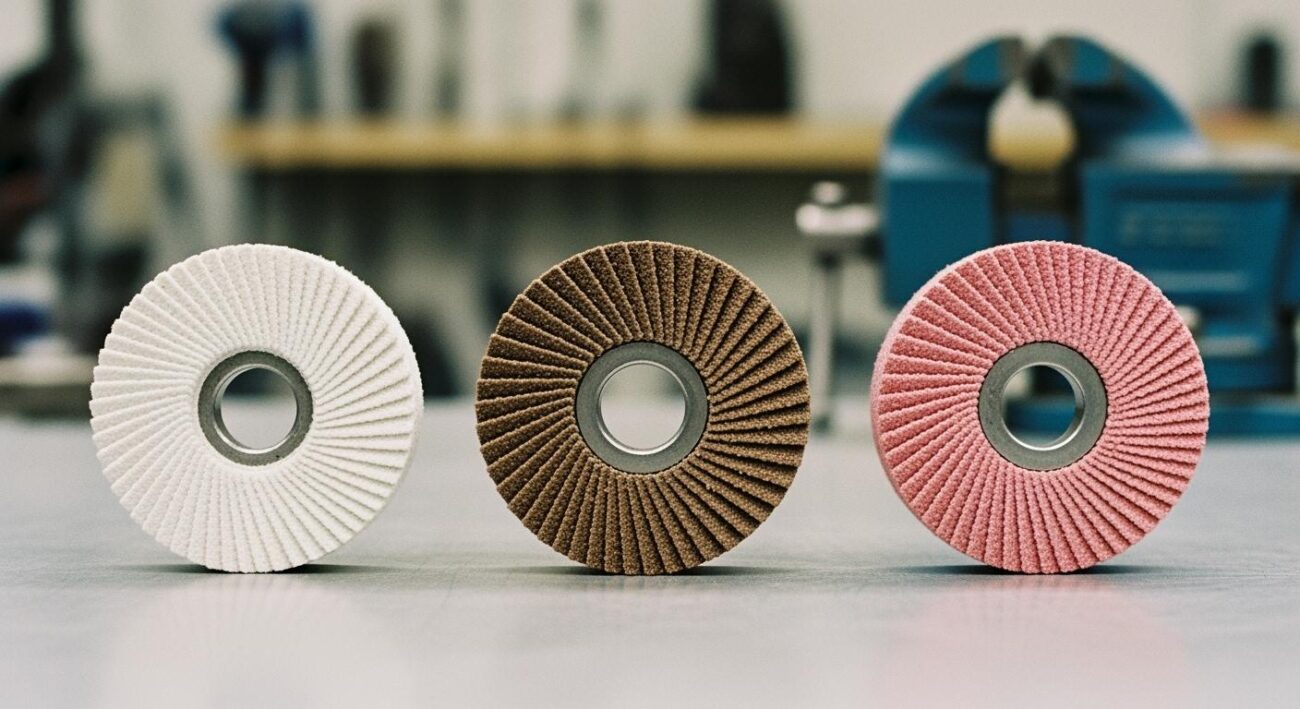

Tests for Super Hard Abrasive Wheels

Specialized tools like diamond and Cubic Boron Nitride (CBN) super hard abrasive wheels require different testing procedures than their conventional counterparts. Their unique composition and high-performance applications demand a modified approach to safety verification. These advanced tools are built for precision and longevity when grinding tough materials like ceramics, glass, or hardened tool steels.

Why Standard Tests Differ

The familiar Ring Test is a reliable quality test for vitrified wheels, but it is ineffective for most super hard abrasives. These wheels typically use resin or metal bonds, which have different material properties.

Important Note 📝

Organic-bonded wheels, including those with resin, are designed for toughness and do not produce a clear, high-pitched ring. Their composition absorbs the impact from a tap, resulting in a dull sound even when the wheel is perfectly safe. The same applies to dense metal bond wheels.

Therefore, an operator cannot rely on sound to verify the integrity of these specific abrasive wheels.

Critical Checks for Diamond and CBN Wheels

For diamond and CBN wheels, visual and dimensional checks become the most critical pre-mounting safety procedures. An operator must perform a rigorous inspection because the cost of failure is high, both in terms of safety and equipment. The essential checks include:

- Surface Condition: Carefully examine all surfaces for any signs of damage, such as cracks, chips, or distortions.

- Abrasive Uniformity: Verify that the diamond or CBN abrasive section is consistent and securely attached to the wheel core.

- Label Verification: Confirm the wheel’s label is intact and that its specifications (max RPM, diameter, grit size) match the job requirements.

Dimensional accuracy is equally important. An operator must check the bore size to ensure a precise fit on the machine spindle. An improper fit can cause dangerous vibrations and lead to catastrophic failure during high-speed operation.

Consulting Experts like Aimgrind

When grinding advanced materials like PCD, ceramics, or tungsten carbide, standard tests may not be sufficient. These applications require a perfectly matched abrasive wheel and a specialized testing protocol. For this level of precision, consulting an expert is the best course of action.

Professionals like the team at Aimgrind offer comprehensive services that go beyond a simple product sale. They provide problem diagnosis and parameter matching to ensure the grinding wheel is perfectly suited for the customer’s equipment and process. This expert guidance is invaluable for ensuring safety and achieving optimal performance when testing abrasive wheels for specialized, high-stakes jobs.

The Final Check: The Trial Run

After an abrasive wheel passes all pre-mounting inspections, one final, non-negotiable step remains: the trial run. This procedure is the last line of defense against catastrophic failure. It ensures the wheel is stable and sound at its full operational speed before it ever touches a workpiece. This part of the testing process is essential for overall workshop safety.

Purpose of the Trial Run

The trial run serves as the ultimate final safety check. Its main purpose is to confirm that no issues occurred during the mounting process. A wheel can pass a ring test and visual inspection but still have a hidden flaw. This flaw may only become apparent under the immense stress of centrifugal force. This run verifies several key points:

- The wheel is seated correctly on the spindle.

- The mounting hardware is secure.

- There are no invisible cracks that open up at high RPMs.

Successfully completing this test gives the operator confidence that the wheel is ready for use.

How to Conduct a Safe Trial Run

An operator must follow a strict procedure to conduct a safe trial run. The machine’s safety guard must be in place and properly adjusted before starting.

- Clear the Area: The operator must ensure all personnel are away from the grinder. Everyone should stand clear and outside the direct line of rotation.

- Start the Machine: The operator should turn on the machine and allow the new abrasive wheel to reach its full operating speed.

- Run the Test: The wheel must run for a designated period. While a minimum of one minute is standard for all abrasive wheels, best practices for a brand-new mount are more stringent.

OSHA & ANSI Best Practice 🛡️

A newly mounted wheel should run for at least three minutes before its first use. This extended duration provides a greater margin of safety.

- Listen and Observe: During the run, the operator should listen for any unusual noises, such as rumbling or rattling, and watch for excessive vibration. If any issues are detected, the operator must shut down the machine immediately and investigate the cause.

An operator’s best defense against failure is a commitment to consistent safety checks. Performing the essential tests—the Ring Test for vitrified wheels, a thorough visual inspection, speed checks, and a final trial run—is a mandatory part of handling any abrasive wheel. These routine inspections of all abrasive wheels build a strong culture of workplace safety. By prioritizing these procedures, operators ensure both personal protection and equipment integrity.

Grind with Passion, Achieve with Aim

FAQ

Why can’t an operator use the Ring Test on all wheels?

The Ring Test is effective only for vitrified wheels. Wheels with resin or metal bonds absorb sound and do not “ring.” An operator must rely on visual and dimensional checks for these super hard abrasive wheels.

What is the most important rule for wheel speed?

An operator must ensure the wheel’s maximum RPM is higher than the machine’s speed. Exceeding the wheel’s rated speed can cause it to break apart. This simple check is a critical step for preventing accidents.

What should an operator do with a cracked wheel?

A cracked or damaged wheel is unsafe. An operator must remove it from service immediately. The wheel should be destroyed to prevent anyone else from using it by mistake. This action protects everyone in the workshop.

How long is the trial run for a new wheel?

A newly mounted wheel must run for at least one minute before use. For best practice, safety standards recommend a three-minute trial run. This extended test provides an even greater margin of safety.

Contact Us

For More Grinding Solution or Customized Abrasive Tools